Isoflavones are compounds of plant origin that can be ingested and metabolized by cattle and, subsequently, secreted into bovine milk. They are substances beneficial to human health. An especially healthful substance called equol is ranked among isoflavone metabolites, commonly produced in the digestive tract of cattle. Equol content in milk can be modified by using feedstuffs with different contents of isoflavones or by milk processing and storage.

- cows

- dairy

- carry-over

- isoflavone

- metabolism

- health

1. Introduction

Functional food includes natural or processed foods that contain unknown or known biologically active compounds [1]. These compounds have a documented health benefit for treatment or prevention of chronic diseases [2]. Milk and dairy products contain a number of essential substances (vitamins, bioactive peptides, highly absorbable calcium, and probiotic bacteria) and other biologically active components [3]. Furthermore, the composition of numerous of these substances can be modified. These properties, together with their prevalence, offer opportunities to use milk and dairy products as functional foods [4]. Isoflavones, which are studied especially in soya products, are among biologically active substances whose content in milk and dairy products can be increased. Nowadays, studies have focused on modifying cows’ feed to produce dairy products enhanced in isoflavones [5].

2. Changes in Isoflavone Contents during Technological Processing of Milk and Dairy Products

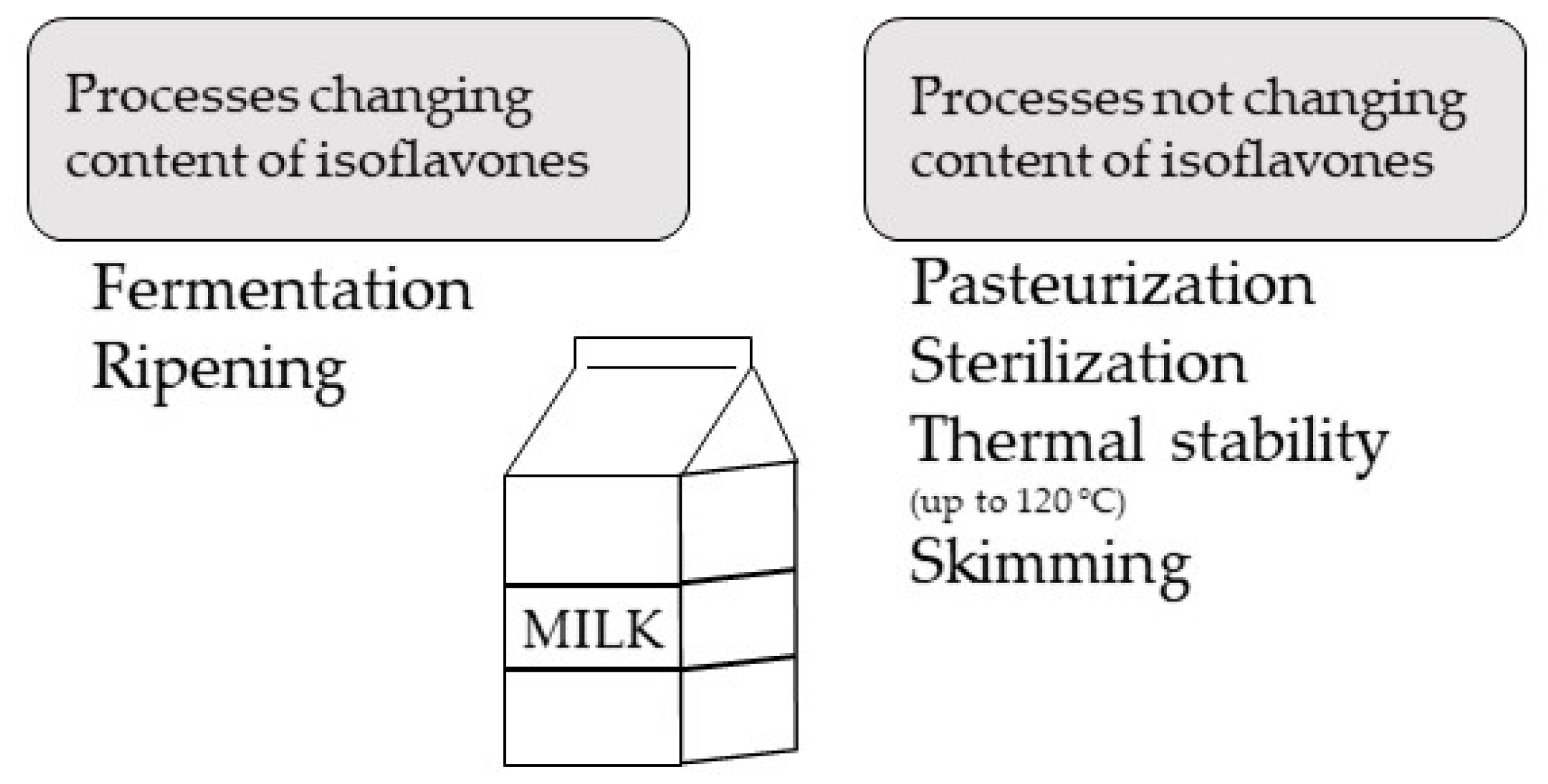

Recent data have suggested that the concentration of isoflavones in milk and dairy products can be changed by a number of processes during the course of technological processing (Figure 4) [6].

The most common processes, namely sterilization and pasteurization, do not change the isoflavone level, as thermal stability of isoflavones is up to 120 °C [7][6][8]; similarly, skimming does not seem to alter isoflavone concentration [6]. However, raw milk contains a lower concentration of equol than skimmed milk, which implicates a higher affinity of equol for an aqueous fraction [7]. The processes that are involved in the preparation of yogurts do not affect the quantity of isoflavones [7], although maturation, which is the process that follows the preparation of yogurt, has a minor effect on isoflavone content. The glycitein concentration decreases, whereas the concentrations of daidzein, genistein, and equol remain unaffected [9]. Yogurts obtained from isoflavone-enriched milk contain higher concentrations of daidzein and equol, but the levels of genistein and glycitein remain unchanged [9].

In addition, fermentation causes substantial changes in isoflavone content, primarily in the concentrations of daidzein and glycitein. In contrast to fermentation of soymilk, which leads to increased concentrations of isoflavone aglycones, fermentation and ripening of cows’ milk causes high losses of isoflavones [9][8][10]. Similarly, storage decreases the amounts of isoflavones [8]. A study by Otieno et al. [11] showed a smaller degradation of aglycones than glucosides of isoflavones, but only for soymilk. Accordingly, cheese can contain isoflavones, but the concentrations decrease during the ripening process [8]. Low amounts of isoflavones were found in cream and kefir and, surprisingly, isoflavones were detected in whey [7][6].

3. Conclusions

Isoflavones in human nutrition are particularly important due to their wide range of pharmacological and antioxidant properties. However, the clinical effectiveness of isoflavones depends on the ability to metabolize daidzein to equol, which is true only for approximately 30–40% of humans. Thus, alternative dietary sources of equol in human nutrition are desirable. From the dietary sources, equol-enriched bovine milk seems to be the most suitable product for individuals lacking the ability to produce equol from its dietary precursors.

This entry is adapted from the peer-reviewed paper 10.3390/ani11030735

References

- Granato, D.; Barba, F.J.; Kovačević, D.B.; Lorenzo, J.M.; Cruz, A.G.; Putnik, P. Functional Foods: Product Development, Technological Trends, Efficacy Testing, and Safety. Annu. Rev. Food Sci. Technol. 2020, 11, 93–118.

- Martirosyan, D.M.; Singh, J. A New Definition of Functional Food by FFC: What Makes a New Definition Unique? Funct. Foods Health Dis. 2015, 5, 209–223.

- Tunick, M.H.; Van Hekken, D.L. Dairy Products and Health: Recent Insights. J. Agric. Food Chem. 2015, 63, 9381–9388.

- Bhat, Z.F.; Bhat, H. Milk and Dairy Products as Functional Foods: A Review. Int. J. Dairy Sci. 2011, 6, 1–12.

- Křížová, L.; Dadáková, K.; Kašparovská, J.; Kašparovský, T. Isoflavones. Molecules 2019, 24, 1076.

- Křížová, L.; Třináctý, J.; Hajšlová, J.; Havlíková, Š. The Effect of Technological Processing on the Content of Isoflavones in Bovine Milk and Dairy Products. In Soybean-Applications and Technology; Ng, T.-B., Ed.; InTech: Rijeka, Croatia, 2011; ISBN 978-953-307-207-4.

- Lefevre, A.; Daems, F.; Focant, M.; Peeters, J.; Ninane, V.; Larondelle, Y.; Froidmont, E. The Effect of Commonly Used Dairy Processing Techniques and Unit Operations on the Equol Content of Dairy Products. Int. Dairy J. 2019, 93, 30–34.

- Křížová, L.; Veselý, A.; Třináctý, J.; Schulzová, V.; Hurajová, A.; Hajšlová, J.; Kvasničková, E.; Havlíková, Š. Changes in Isoflavones Concentrations in Cheese during Processing and Ripening. Acta Univ. Agric. Silvic. Mendel. Brun. 2011, 59, 153–162.

- Kašparovská, J.; Dadáková, K.; Lochman, J.; Hadrová, S.; Křížová, L.; Kašparovský, T. Changes in Equol and Major Soybean Isoflavone Contents during Processing and Storage of Yogurts Made from Control or Isoflavone-Enriched Bovine Milk Determined Using LC-MS (TOF) Analysis. Food Chem. 2017, 222, 67–73.

- Marazza, J.A.; Nazareno, M.A.; de Giori, G.S.; Garro, M.S. Enhancement of the Antioxidant Capacity of Soymilk by Fermentation with Lactobacillus Rhamnosus. J. Funct. Foods 2012, 4, 594–601.

- Otieno, D.O.; Ashton, J.F.; Shah, N.P. Stability of Isoflavone Phytoestrogens in Fermented Soymilk with Bifidobacterium Animalis Bb12 during Storage at Different Temperatures. Int. J. Food Sci. Technol. 2006, 41, 1182–1191.