Sustainability is the prime focus nowadays; hence researchers are keen on developing sustainable materials. Green composites are the type of the materials that are derived from natural sources that do not have any impact on the environment since its inception to the end of its life. The main objective of this paper is to given a comprehensive review of polylactic acid compoistes reinforced with natural fibers focusing on jute and flax. This article has reported the recent progress that has happend in the area of polylactic acid focuing on the improvement of interfacial adhesion between fibers and matrix which leads to the improvement of mechanical properties.

- Polylactic Acid

- Jute

- Flax

- Natural Fibers

- Biopolymers

1. Introduction

Composite materials have received much attention due to their versatile properties, which allow many applications in a huge number of fields. Composite materials are made up of two or more materials with considerably different physical and chemical properties. When combined, they make a material with properties that are different from the individual components. They are composed of a rigid phase, so-called matrix and the reinforcement, which is a strong load-carrying material. The strength and stiffness to support the structural load are provided by the reinforcement. The major benefits of the composite materials, when compared with conventional bulk materials, are their stiffness and strength relative to their typically low weight. These materials find applications in various industries like aerospace, automotive, sports, furniture, medical and packaging industries [1]. Various types of composite materials are developed with polymer matrix composites due to the flexibility, cost and ease of fabrication. Synthetic polymers are used in the production of these composites and are obtained from petroleum resources. The main limitation of these polymers is their non-biodegradability, which increases the amount of material that ends up in the landfills causing pollution [2]. The strict regulations from the government authorities also limit the use of traditional composite materials. These are usually made of glass, carbon or aramid fibers reinforced with epoxy, unsaturated polyester resins and polyurethanes. During recent decades, the scientific community has been looking towards sustainable materials to reduce its impact on the environment [3]. Therefore, there has been a constant interest in the development of green composites.

2. PLA

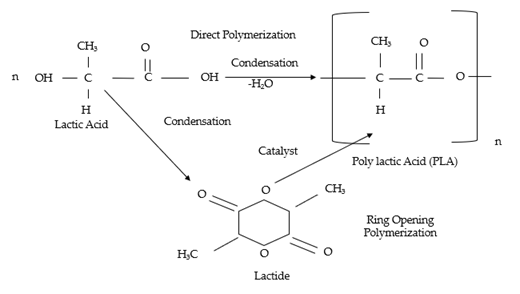

PLA is an aliphatic polyester with lactic acid as its basic constitutional unit. It was recognized since 1845 but was not available commercially till the early 1990s [4]. PLA can be synthesized by the polymerization of Lactic Acid (LA) or the Ring-Opening Polymerization (ROP) of Lactide [5][6]. Due to inherent disadvantages and environmental concerns, other new methods such as biosynthesis of PLA by enzymatic action and new solutions were developed that is, incorporation of non-toxic catalysts such as Magnesium (Mg), Calcium (Ca), Zinc (Zn) and so forth [7]. Figure 1 shows the PLA synthesis.

It is a renewable, recyclable, biodegradable and compostable polymer that shows outstanding processing ability. Due to its good properties Table 1, its applications comprise several industries, such as packaging, textile, biomedical, structural and automotive [4][8][9]. It is the only commercially available polymer with glass transition temperature (55–60 °C) above ambient and melting point (130–180 °C) [10] below the degradation temperature of lignocellulosic fibers (200 °C) [11].

Figure 1. Polylactic Acid (PLA) Polymerization [14].

3. PLA/Flax Composites

Melt compounding and solution dipping process were employed to produce PLA/Flax composites. The effects of different surface modifications techniques such as alkaline, silane, polymer coating + alkaline and polymer coating + silane on the mechanical performance were studied. Polymer coating on the surface of the flax fibers combined with silane treatments showed an improvement in the performance. The maximum tensile strength of 74.3 MPa and impact strength of 12.7 kJ/m2 were observed in the salinized and polymer-coated flax fiber composites [12]. Polymer coating also showed a decrease in the hydrophilicity nature of the flax fibers. Similar composites were produced by using a twin-screw extruder, reporting higher values of tensile modulus (3.8 GPa), impact strength (15 kJ/m2), elongation at break (6.2%) for PLA/Flax composites when compared to the neat PLA. The toughness of the PLA/treated fiber composites has been increased when compared to the PLA/untreated fiber composites [13].

Comparing the properties of two types of unidirectional flax composites using PLA as matrix: one made with layers of aligned flax rovings alone and the other containing an additional paper layer fabricates using paper making techniques, it was observed that the PLA/Flax composites have better performance in terms of impact strength (800 ± 15 J/m), tensile strength (339.0 ± 22 MPa) and flexural strength (363 ± 26 MPa) than PLA/Flax-Paper composites. The specific tensile properties of both the composites can be compared with the composites made of woven glass fabrics impregnated with epoxy. It also observed that PLA/Flax-Paper composites have achieved good impact strength (600 J/m) [14].

When flax was grafted, composites produced by hot press molding and gel dip coating technique exhibited a significant improved adhesion bonding of the modified fibers to the matrix. This led to an increase in the impact resistance of the PLA when reinforced with fiber by three times and observed to be 15.4 kJ/m2. The hydrophilic nature of the fiber was reduced by 18% in the modified grafted fiber composite [15]. In order to evaluate the effect of fiber treatment, three different approaches were used to produce PLA/Flax composites by film stacking. The fibers were treated with Maleic Anhydride (MA), Silane (ST) and Tributyl Citrate (TBC). In any case, the addition of fibers increased the mechanical properties. The tensile strength, Young´s modulus and flexural strength were improved by 80%, 300% and 27% respectively when compared to the neat matrix. The highest values of tensile strength (102.5 ± 5.2 MPa), Young’s modulus (25 ± 1.4 GPa) and flexural strength (140 ± 6.9 MPa) was obtained for the composites treated with silane, maleic anhydride and untreated respectively. The other surface treatments also improved tensile and flexural properties [16]. Later, the flexural properties and morphology of the surface of the composites were examined and found that 2% w/w silane content improved the flexural strength of the composite material by 18% [17].

Nano-Coated Flax was reinforced with PLA to produce composites by hot pressing. The values of ultimate tensile strength, tensile modulus and interlaminar strength were found to be (187 ± 10.6 MPa), (12.2 ± 0.33 GPa) and (24.84 ± 0.650 MPa) respectively. Ultimate tensile strength, tensile modulus and interlaminar strength was increased by 6%, 13% and 20% respectively when compared to the raw composites. Coating the fibers also allowed the decrease in water absorption by more than 10% in comparison with raw composites and their protection during conditioning, preserving their mechanical properties [18]. With the aim of improving flame retardancy, a thin coating of polydopamine adhesive was used to protect hot compression molded composites. Limiting Oxygen Index (LOI) values were highest for the Fiber-Modified with Iron Phosphonate (Fep-Flax) composites and increased by 26.1% compared to pure PLA. The self-extinguished ability of PLA/Fep-Flax composites improved remarkably and decreased the combustion time. PLA/Fep-Flax showed reduction of tensile strength (55.4 ± 0.9 MPa) by 6% when compared to neat PLA, however there was an improvement of Young´s modulus (2908 ± 104 MPa) by 35% [19]. Table 1 the values of the mechanical properties obtained by various researchers.

The influences of the fiber alignment were assessed by comparing the performance of Random (NM) and Unidirectional (UD) fiber composites produced by compression molding. Air laying was used to produce random flax reinforcements. UD flax composites showed improved properties when compared to NM flax composites. The tensile(151 ± 7 MPa) and flexural strength (215 ± 17 MPa) of PLA/UD Flax composite was increased 82 and 65% respectively and the tensile (19 ± 2 GPa)and flexural modulus (19 ± 1 GPa)was improved 99 and 90% respectively compared to NM PLA/Flax composite. The PLA/UD Flax and NM PLA/Flax lost 19 and 27% mass respectively after 120 days as per soil burial test [20].

Table 1. Mechanical properties of PLA composites reinforced with flax fibers.

|

Fiber Content wt (%) |

Process |

Tensile Strength (MPa) |

Flexural Strength (MPa) |

Impact Strength (kJ/m2) |

Young’s modulus (GPa) |

Additional Information |

Ref |

|

|

IM |

74.3 |

- |

12.7 |

- |

ST and PC |

[12] |

|

22 |

FS |

99.0 |

140 |

- |

16.0 |

UT |

[16] |

|

22 |

FS |

102.5 |

117 |

- |

12.5 |

ST |

[16] |

|

22 |

FS |

63.0 |

83 |

- |

12.7 |

TBCT |

[16] |

|

22 |

FS |

35.0 |

63 |

- |

25.0 |

MAHT |

[16] |

|

30 |

HP |

177 |

- |

- |

10.8 |

Before conditioning |

[18] |

|

30 |

HP |

187 |

|

-- |

12.2 |

Nano silica coated and before conditioning |

[18] |

|

30 |

HP |

89 |

- |

- |

4.68 |

After conditioning |

[18] |

|

30 |

HP |

114 |

- |

- |

6.2 |

Nano Silica coated and after conditioning |

[18] |

|

30 |

CM |

55.4 |

|

- |

2.90 |

Coated with PDA film |

[19] |

|

30 |

CM |

60.1 |

- |

- |

3.40 |

- |

[19] |

|

48 |

CM |

83.0 |

130.0 |

|

9.3 |

Random |

[20] |

|

48 |

CM |

151.0 |

215.0 |

|

18.5 |

Aligned |

[20] |

CM—Compression Molding; FS—Film Stacking; HP—Hot Pressing; IM—Injection Molding; MAHT—Maleic Anhydride Treated; PC—Polymer Coated; ST—Silane Treated; TBCT—Tributyl Citrate Treated; UT—Untreated.

Although PLA/Flax composites already exhibit excellent properties, it is possible to improve this material with the inclusion of other types of fibers. This process that combines more than one type of fiber is known as hybridization. In this sense, a first attempt was made to compare the properties of PLA/Flax composites and PLA/rayon produced by injection molding. Some of the mechanical properties of PLA/rayon samples were better than PLA/Flax composites at a fiber mass proportion by mass of 30%. The highest impact strength and tensile strength of 72 kJ/m2 and 58 MPa, respectively, were observed for rayon reinforced with PLA. However, the highest Young’s modulus (6.31 GPa) was found for the composite made up of flax reinforced with PLA. Poor matrix fiber interfacial bonding is found in both cases [21]. From this study was concluded that a potential benefit could be obtained by the hybridization of PLA using both types of fibers. The hybridization prospective of PLA-based composites were assessed by producing compression-molded samples reinforced with Cotton Gin Waste (CGW) and flax fibers where overall fiber fraction is 30%. The flexural modulus increased by 42% by the addition of 30 wt % of CGW compared to neat PLA and there was a reduction of flexural strength by 85% in comparison with neat PLA. Nevertheless, in the hybrid composites the addition of 10–20 wt % of flax fiber reduced the flexural properties. The modulus of elasticity for the composites containing 30 wt % of CGW and composites containing 30 wt % of flax fibers were comparable [22]. In this regard, hybridization produced insignificant advances given the similar nature of the two types of reinforcement.

4. PLA/Jute Composites

After the initial studies, long jute fibers (6 mm) were incorporated up to 50% by mass into PLA, which resulted in the enhancement of flexural strength and modulus of injection molded composites, although impact strength of the composite did not increase [23]. The effect of long (618 mm) and short (387 mm) jute fibers on the performance of PLA injection-molded composites was studied, the samples made of short fiber fillers showed optimal performance, exhibiting a significant 182% increase in strength (90.7 ± 1.3 MPa) compared to that of pure PLA%. The effective dispersion of the fibers and the high intensity mixing of the fibers have led to the improvement in the interfacial strength which leads to the improvement of the properties of short fiber fillers. The suppression of hydrolysis was necessary for the improvement of overall performance for both long and short fibers [24].

Another possibility of producing PLA/Jute composites is the combination of both PLA and jute filaments to produce composite spun yarns to be aligned in the same direction. this type of composites were produced by pressing the spun yarn at different temperatures [25]. From the results the optimum compression molding temperature was found to be 185–195 °C for fabrication the jute spun yarn/PLA unidirectional composite. It was clear that the impregnation quality and dispersion of fiber bundle increased with higher molding temperatures, since the elastic modulus increased. While increasing the molding temperature, the achievement ratio of tensile strength was decreased because of deterioration of jute fiber [25]. Jute also leads to an improvement of the PLA mechanical performance when its strands are added. In this regard, when strands of jute act as reinforcing elements, lignin content plays a key role. Hence, PLA composites were produced by injection molding where treated jute strands are used as reinforcements and the amount of lignin present in the jute are varied. The obtained results showed that mechanical properties of PLA can be interestingly improved with the incorporation of 30 wt % of jute but in different magnitude depending on the chemical composition thereof. A lignin mass fraction of 4% was found to be most suitable as PLA reinforcement because of the improved mechanical properties. There was an enhancement of tensile strength up to 46% as the amount of lignin was decreased, as the interface between fiber and matrix was improved [26].

When woven jute fabric is introduced to reinforce PLA, it is possible to increase the impact strength of the plain polymer as well as the tensile strength with only a minor reduction of the flexural modulus [27]. To assess the low-velocity impact behavior of PLA/Jute laminates with alternated fabric layers 0°/90°, symmetrically arranged were developed with respect to the middle plane of the laminate in between PLA and pressed them. The obtained composites were tested by a falling dart machine operating at impact energies equal to 5 J, 10 J and 20 J. The results revealed that the composites were able to resist the first two energy levels with a barely visible damage. Minor fiber-breakage and delamination phenomena were registered by photographic images taken on the back side of impacted samples. Only impact tests at 20 J, gave rise to severe impact damage of bio composite samples with penetration of the impactor and delamination phenomena apparently confined to the material-impactor contact area [27]. Compared to other fibers with high cellulose content like cotton fibers, the tensile modulus of the PLA/Jute composites is approximately 25% higher than that of the PLA/cotton composites. [28]. Also, the compressive modulus of the PLA/Jute composite was 38% higher than that of the cotton composite. However, the compressive and tensile strength of the cotton/PLA composite was better than that of the PLA/Jute composite [28].

As previously described, despite all the gains of using jute to reinforce PLA composites, these fibers may undergo hygrothermal aging from the combined effects of humidity and heat. In a study it was observed that in composites produced by injection molding three degradation stages of hygrothermal aging of PLA/Jute composites take place and it can be related to the changes in mechanical properties [29]. In stage I, plasticization due to water absorption increases the ductility with a reduction in strength and tensile elastic modulus. In stage II, a detachment between the fiber and the matrix due to differential swelling leads to the weakening of the interface with a significant, detrimental effect on the mechanical properties. In stage III, the hydrolysis of the matrix causes microcracking with a further significant decrease in ductility. The durability of short jute fiber reinforced PLA composites in distilled water at different temperatures was studied. From the results of the water absorption test, it was noted that the composites maintained at 23 °C, 37.8 °C and 60 °C followed the Fickian behavior in the first stage. Once the rate of weight gain (Mt) was reached, the saturation point after Mt of PLA/Jute composites is like that of pure PLA [30]. However, the composites at 60 °C deviated from the Fickian law. PLA has shown slower water absorption rate compared to the PLA/Jute composites [30]. The mechanical properties have shown a significant decrease at the beginning of aging, then stabilized for a time period and decreased at last stage. These 2 researches [29][30] regarding aging mechanisms of PLA/Jute composites reported several undesired effects such as plasticization of the matrix, swelling of materials, structural damage of the PLA/Jute composites, change of the PLA crystallinity and hydrolysis of jute fiber and PLA matrix. Therefore, a fiber treatment is convenient to sort these drawbacks out. Table 2 shows the values of mechanical properties determined by various researchers through their experiments.

The most reported treatment in the literature about natural fibers in polymeric composites is alkali treatment. The effects of the treatment on both the single jute fiber and the PLA/Jute composites are examined and results revealed that the structure and shear strength of jute fibers and their composites were strongly affected by the surface treatment [31].

Moreover, the interfacial shear strength of the composite generally increased with an increase in the treating time and the concentration of NaOH solution and the maximum value was obtained at 8 h treatment with 12% NaOH solution. Meanwhile, alkali treatment of jute fibers significantly improved the tensile properties of both single fibers and composites. The optimum tensile properties of PLA/Jute composites were obtained at a 15 wt % fiber content and a processing temperature of 210 °C. Both the maximum flexural modulus and strength of composites were obtained at 220 °C and 15 wt % fiber content [31]. The influence of the alkali treatment with NaOH at various concentrations (5%, 10% and 15%) and with H2O2 was evaluated [32]. Fibers were added in different weight concentrations (5%, 10%, 15%, 20% and 25%) of untreated and treated jute fibers in PLA matrix. In composites produced by injection molding, it was observed from the experimental results that the surface modification of jute fibers with NaOH improved the flexural properties (tensile strength, Young’s Modulus and density) [32] but decreased the impact resistance [33]. It was found that the water absorption got leveled off after 24 h and was increased with the fiber content. Alkali treatment have reduced the water absorption rate and make fibers as hydrophobic.

Table 2. Mechanical properties of PLA composites reinforced with jute fibers.

|

Fiber Content wt (%) |

Process |

Tensile Strength (MPa) |

Flexural Strength (MPa) |

Impact Strength (kJ/m2) |

Young’s modulus (GPa) |

Additional Information |

Ref |

|

50 |

IM |

62.2 |

98.8 |

2.21 |

- |

- |

[23] |

|

- |

IM |

90.7 |

- |

4.22 (kJ/m) |

12.3 |

Short Fiber Pellet mix |

[24] |

|

- |

CM |

32.3 |

41.8 |

3.5 J |

2.11 |

Woven Jute Fabric |

[34] |

|

30 |

IM |

71.7 |

- |

- |

9.15 |

Lignin 4% |

[26] |

|

- |

RFM |

53.16 |

128.3 |

- |

8.11 |

- |

[28] |

|

20 |

IM |

55 |

110 |

1.6 |

1.7 |

10% NaOH + H2O2 |

|

|

25 |

IM |

54 |

80 |

2.5 |

2.7 |

05% NaOH + H2O2 |

|

|

30 |

IM |

70 |

- |

26 (J/m) |

- |

Alkali Treated |

[35] |

|

30 |

IM |

80 |

- |

28(J/m) |

- |

Alkali + Silane Treated |

[35] |

|

15 |

IM |

50 |

78 |

4.8 |

4.8 |

Treated with DOPO-ICN |

[36] |

|

10 |

- |

61.71 |

93.68 |

19.26 |

4.2 |

Graphene Modified |

[37] |

|

5 |

SC |

70.30 |

- |

- |

3.30 |

PLA Composite Films with Jute Nano Fibers |

[38] |

|

3 |

SC |

69.80 |

- |

- |

3.20 |

NaOH Treated Jute |

[39] |

|

40 |

HP |

77.5 |

115.3 |

|

3.67 |

Core Shell Nanoparticles (SiO2–PBA–NH2) |

[40] |

CM—Compression Molding; DOPO—9,10-dihydro-9-oxa-phosphaphenanthrene-10-Oxide; DOPO—ICN-Phosphorus Based Compound; HP—Hot Pressing; IM—Injection Molding; RFM—Resign Film Method; SC—Solvent Casting.

In addition to alkali treatment, it is possible to apply a subsequent silane treatment to further improve the properties of PLA/Jute composites. The effects of 2 different treatments on the fiber properties were compared using (i) alkali (NaOH) and (ii) alkali followed by silane (NaOH + silane) separately [41]. It was found that the surface treatments led to the improvement of thermal stability and crystallinity index of jute fibers. Jute fibers treated with (NaOH + silane) showed lower crystallinity index compared to NaOH treated fibers due to the conversion of crystalline cellulose into the amorphous cellulose as a result of silane of the jute fibers. Matrix-fiber adhesion between PLA and jute fibers, which was examined in terms of Interfacial Shear Strength (IFSS), was found to be highest for (NaOH + silane) treated jute fibers [41]. When these treatments were applied in jute reinforced PLA composites with 30 wt % of reinforcement [35], It was reported that the tensile strength of the reinforced composites was increased by 5% compared to neat PLA. PLA reinforced with jute fibers treated with NaOH aqueous solution showed an improvement of 10% in comparison to neat PLA. Furthermore, an improvement of 32% was seen in the composites reinforced with NaOH + Silane treated jute fibers (PLA/JFNASI) [35]. Impact strength of PLA/JFU, PLA/JFNA and PLA/JFNASI was shown improvement of 34%, 49% and 56% when compared to neat PLA respectively [35]. The addition of jute fiber has increased the storage modulus and it was further improved with the surface treatments. It is also possible to apply physical treatments, as electron beam, to improve the thermal properties of the PLA/Jute composites. It was reported that PLA/Jute compression-molded composites presented an increased thermal stability, storage modulus and heat deflection temperature with an electron beam irradiation of jute at 10kGy [42].

In order to improve the flame retardancy of PLA/Jute composites, phosphorous-based compounds exhibit excellent fire resistance for polymers and their composites. A compound was synthesized by the reaction between 9,10-Dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and maleic acid (MA) and was used in the composite formulation, ensuring a good interface by providing active sites linked between DOPO and PLA or jute [43]. Moreover, the addition of DOPO-MA improved the tensile, flexural and impact strength when compared to that of incorporation of DOPO. Flame retardancy was also improved and achieved due to the formation of char layer to protect the inner composite from further burning [43].

Given its chemical composition, jute can be used to obtain Crystalline Cellulose (CC) to reinforce PLA composites and it was reported that the thermal stability and the crystallinity of the composites have increased when composite was prepared from CC and PLA [44]. It was observed the existence of hydrogen bonding between CC and PLA when the composite was fabricated by extrusion or hot press. Moreover, PLA/CC composites showed increased hardness and tensile strength as well as better antimicrobial properties [44]. In a similar experiment, Nano Fibers (NF) from waste jute fibers were used to reinforce PLA films by solvent casting. For samples with 5 wt % of NF, the initial modulus (3.30 ± 0.05 GPa) and tensile strength (70.30 ± 6.32 MPa) were increased by 217% and 171% respectively compared to neat PLA films. The composites with a 10 wt % of NF showed a decline in the mechanical properties, however they have showed a 16% and 62% improvement in crystallization temperature and crystallinity respectively. Mechanical properties were improved until 5 wt % fiber content and declined thereon. Huge improvements of storage modulus by 475% was observed at 60 °C [103]. The addition of different nanoparticles, such as nano-silica, enable the formation of rigid-soft core–shell structures to improve the mechanical properties of woven jute fiber-reinforced PLA composites. Press-molded composites with rigid core and soft-shell nanoparticles reinforced with jute fibers were produced and results indicated an increase in tensile strength (from 43.1 to 52.4 MPa) compared to composites without nanoparticles [40]. The addition of SiO2–NH2 and SiO2–PBA–NH2 modifiers further improved tensile values to 71.9 MPa and 77.5 MPa respectively, while flexural strength and modulus were increased by 38% and 101% when compared to Natural Fiber-Reinforced Polylactide Composite(NFPC)respectively [40].

5. Conclusions

The properties of flax reinforced PLA composites have been displayed and different solutions to improve the drawback of this type of composites were described. The conditions used to produce the composites and the different treatments applied reveal that PLA-Flax multilayered composites may achieve tensile strength and Young’s modulus values over 100 MPa and 10 GPa respectively. Also, the modification of the initial properties of both PLA and flax fibers may also lead to increased values of impact strength, energy absorption and thermal performance of the composites.

Related to PLA composites reinforced with jute, lower mechanical performance was found compared to PLA-Flax materials. However, the functionalization of jute fibers creates a possibility for the functionalization of the overall composites. Thus, apart from the improvement of durability and matrix-fiber interface, other properties may be incorporated into the composites, such as fire retardancy barrier.

This entry is adapted from the peer-reviewed paper 10.3390/polym12102373

References

- Chauhan, V.; Kärki, T.; Varis, J. Review of natural fiber-reinforced engineering plastic composites, their applications in the transportation sector and processing techniques. J. Thermoplast. Compos. Mater. 2019.

- Sarapure, S. Nano Green Composites—An Overview. Int. J. Appl. Eng. Res. 2018, 13, 115–116.

- Jagadeesh, D.; Kanny, K.; Prashantha, K. A review on research and development of green composites from plant protein-based polymers. Polym. Compos. 2017, 38, 1504–1518.

- Babu, R.P.; O’Connor, K.E.; Seeram, R. Current progress on bio-based polymers and their future trends. Prog. Biomater. 2013, 2, 8.

- Rincon Lasprilla, A.J.; Rueda Martinez, G.A.; Lunelli, B.H.; Jaimes Figueroa, J.E.; Jardini, A.L.; Filho, R.M. Synthesis and Characterization of Poly (Lactic Acid) for Use in Biomedical Field. Chem. Eng. Trans. 2011, 24, 985–990.

- Murariu, M.; Dubois, P. PLA composites: From production to properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46.

- Auras, R.; Lim, L.-T.; Selke, S.E.M.; Tsuji, H. Poly Lactic Acid: Synthesis, Strucutes, Properties, Processing and Applications; Wiley: Hoboken, NJ, USA, 2011.

- Siakeng, R.; Jawaid, M.; Ariffin, H.; Sapuan, S.M.; Asim, M.; Saba, N. Natural fiber reinforced polylactic acid composites: A review. Polym. Compos. 2018, 40, 446–463.

- Lasprilla, A.J.; Martinez, G.A.; Lunelli, B.H.; Jardini, A.L.; Filho, R.M. Poly-lactic acid synthesis for application in biomedical devices—A review. Biotechnol. Adv. 2012, 30, 321–328.

- Iannace, S.; Sorrentino, L.; Di Maio, E. Biodegradable biomedical foam scaffolds. In Biomedical Foams for Tissue Engineering Applications; Woodhead Publishing Ltd.: Cambridge, UK, 2014.

- Hart, A.; Summerscales, J. Effect of time at temperature for natural fibers. Procedia Eng. 2017, 200, 269–275.

- Kodal, M.; Topuk, Z.D.; Ozkoc, G. Dual Effect of Chemical Modification and Polymer Precoating of Flax Fibers on the Properties of Short Flax Fiber/Poly(Lactic Acid) Composites. J. Appl. Polym. Sci. 2015, 132, 42564.

- Xia, X.; Liu, W.; Zhou, L.; Hua, Z.; Liu, H.; He, S. Modification of flax fiber surface and its compatibilization in polylactic acid/flax composites. Iran. Polym. J. 2016, 25, 25–35.

- Couture, A.; Lebrun, G.; Laperrière, L. Mechanical properties of polylactic acid (PLA) composites reinforced with unidirectional flax and flax-paper layers. Compos. Struct. 2016, 154, 286–295.

- Foruzanmehr, M.; Vuillaume, P.Y.; Elkoun, S.; Robert, M. Physical and mechanical properties of PLA composites reinforced by TiO 2 grafted flax fibers. Mater. Des. 2016, 106, 295–304.

- Georgiopoulos, P.; Christopoulos, A.; Koutsoumpis, S.; Kontou, E. The effect of surface treatment on the performance of flax/biodegradable composites. Compos. Part B Eng. 2016, 106, 88–98.

- Georgiopoulos, P.; Kontou, E.; Georgousis, G. Effect of silane treatment loading on the flexural properties of PLA/flax unidirectional composites. Compos. Commun. 2018, 10, 6–10.

- Bayart, M.; Gauvin, F.; Foruzanmehr, M.R.; Elkoun, S.; Robert, M. Mechanical and moisture absorption characterization of PLA composites reinforced with nano-coated flax fibers. Fibers Polym. 2017, 18, 1288–1295.

- Zhang, L.; Li, Z.; Pan, Y.-T.; Yáñez, A.P.; Hu, S.; Zhang, X.-Q.; Wang, R.; Wang, D.-Y. Polydopamine induced natural fiber surface functionalization: A way towards flame retardancy of flax/poly(lactic acid) biocomposites. Compos. Part B Eng. 2018, 154, 56–63.

- Akonda, M.; Alimuzzaman, S.; Shah, D.U.; Rahman, A.M. Physico-Mechanical, Thermal and Biodegradation Performance of Random Flax/Polylactic Acid and Unidirectional Flax/Polylactic Acid Biocomposites. Fibers 2018, 6, 98.

- Bax, B.; Müssig, J. Impact and tensile properties of PLA/Cordenka and PLA/flax composites. Compos. Sci. Technol. 2008, 68, 1601–1607.

- Bajracharya, R.M.; Bajwa, D.S.; Bajwa, S.G. Mechanical properties of polylactic acid composites reinforced with cotton gin waste and flax fibers. Procedia Eng. 2017, 200, 370–376.

- Fujiura, T.; Sakamoto, K.; Tanaka, T.; Imaida, Y. A Study on Preparation and Mechanical Properties of Long Jute Fiber Reinforced Polylactic Acid by the Injection Molding Process. WIT Trans. Built Environ. 2008, 97, 231–240.

- Arao, Y.; Fujiura, T.; Itani, S.; Tanaka, T. Strength improvement in injection-molded jute-fiber-reinforced polylactide green-composites. Compos. Part B Eng. 2015, 68, 200–206.

- Memon, A.; Nakai, A. Fabrication and Mechanical Properties of Jute Spun Yarn/PLA Unidirection Composite by Compression Molding. Energy Procedia 2013, 34, 830–838.

- Delgado-Aguilar, M.; Oliver-Ortega, H.; Alberto Méndez, J.; Camps, J.; Espinach, F.X.; Mutjé, P. The role of lignin on the mechanical performance of polylactic acid and jute composites. Int. J. Biol. Macromol. 2018, 116, 299–304.

- Russo, P.; Simeoli, G.; Papa, I.; Acierno, D.; Lopresto, V.; Langella, A. Low-Velocity Impact Behavior of Woven Jute/Poly(Lactic Acid) Composites. AIP Conf. Proc. 2016, 1736, 020025.

- Chen, J.-C.; Lin, J.-C. Manufacturing and properties of cotton and jute fabrics reinforced epoxy and PLA composites. Int. J. Mod. Phys. B 2018, 32, 1840084.

- Jiang, N.; Yu, T.; Li, Y.; Pirzada, T.J.; Marrow, T.J. Hygrothermal aging and structural damage of a jute/poly (lactic acid) (PLA) composite observed by X-ray tomography. Compos. Sci. Technol. 2019, 173, 15–23.

- Jiang, N.; Yu, T.; Li, Y. Effect of Hydrothermal Aging on Injection Molded Short Jute Fiber Reinforced Poly(Lactic Acid) (PLA) Composites. J. Polym. Environ. 2018, 26, 3176–3186.

- Ma, H.; Joo, C.W. Structure and mechanical properties of jute—Polylactic acid biodegradable composites. J. Compos. Mater. 2011, 45, 1451–1460.

- Rajesh, G.; Prasad, A.V.R. Tensile Properties of Successive Alkali Treated Short Jute Fiber Reinforced PLA Composites. Procedia Mater. Sci. 2014, 5, 2188–2196.

- Gunti, R.; Ratna Prasad, A.V.; Gupta, A.V.S.S.K.S. Preparation and properties of successive alkali treated completely biodegradable short jute fiber reinforced PLA composites. Polym. Compos. 2015, 37, 2160–2170.

- Singh, J.I.P.; Singh, S.; Dhawan, V. Effect of Curing Temperature on Mechanical Properties of Natural Fiber Reinforced Polymer Composites. J. Nat. Fibers 2018, 15, 687–696.

- Zafar, M.T.; Maiti, S.N.; Ghosh, A.K. Effect of surface treatments of jute fibers on the microstructural and mechanical responses of poly(lactic acid)/jute fiber biocomposites. RSC Adv. 2016, 6, 73373–73382.

- Yu, T.; Ding, D.; Sheng, C.; Tuerhongjiang, T.; Li, Y. Enhanced mechanical properties and flame retardancy of short jute fiber/poly(lactic acid) composites with phosphorus-based compound. Sci. China Technol. Sci. 2017, 60, 1716–1723.

- Yu, T.; Hu, C.; Li, Y. Functionalization of Graphene and Its Influence on Mechanical Properties and Flame Retardancy of Jute/Poly(lactic acid) Composite. J. Nanosci. Nanotechnol. 2019, 19, 7074–7082.

- Baheti, V.; Militky, J.; Marsalkova, M. Mechanical Properties of Poly Lactic Acid Composite Films Reinforced with Wet Milled Jute Nanofibers. Polym. Compos. 2015, 38, 96–104.

- Baheti, V.; Mishra, R.; Militky, J.; Behera, B.K. Influence of noncellulosic contents on nano scale refinement of waste jute fibers for reinforcement in polylactic acid films. Fibers Polym. 2014, 15, 1500–1506.

- He, H.; Tay, T.E.; Wang, Z.; Duan, Z. The strengthening of woven jute fiber/polylactide biocomposite without loss of ductility using rigid core–Soft shell nanoparticles. J. Mater. Sci. 2018, 54, 4984–4996.

- Zafar, M.T.; Maiti, S.N.; Ghosh, A.K. Effect of surface treatment of jute fibers on the interfacial adhesion in poly(lactic acid)/jute fiber biocomposites. Fibers Polym. 2016, 17, 266–274.

- Ji, S.G.; Hwang, J.H.; Cho, D.; Kim, H.-J. Influence of electron beam treatment of jute on the thermal properties of random and two-directional jute/poly(lactic acid) green composites. J. Adhes. Sci. Technol. 2013, 27, 1359–1373.

- Yu, T.; Tuerhongjiang, T.; Sheng, C.; Li, Y. Phosphorus-containing diacid and its application in jute/poly(lactic acid) composites: Mechanical, thermal and flammability properties. Compos. Part A Appl. Sci. Manuf. 2017, 97, 60–66.

- Rahman, M.M.; Afrin, S.; Haque, P.; Islam, M.M.; Islam, M.S.; Gafur, M.A. Preparation and Characterization of Jute Cellulose Crystals-Reinforced Poly(L-lactic acid) Biocomposite for Biomedical Applications. Int. J. Chem. Eng. 2014, 2014, 1–7.