Energy is essential for the nature of life and the development of countries. The main demand for the 21st century is to fulfill growing energy needs. Pakistan, through the use of fossil fuels, meets energy demands. There is pressure on the economy of the country due to the massive reliance on fossil fuels, and this tendency is influenced by various environmental impacts. To overcome the burden on fossil fuels, more attention has been drawn to provide fossil fuel substitution. Tire pyrolysis is among the effective substitutes of the fuel technology that generates useful products of liquid oil, char, and pyro gas.

- sustainable environment

- renewable

- waste to energy

- alternative fuel

- tire pyrolysis oil and climate change

- renewable energy

1. Introduction

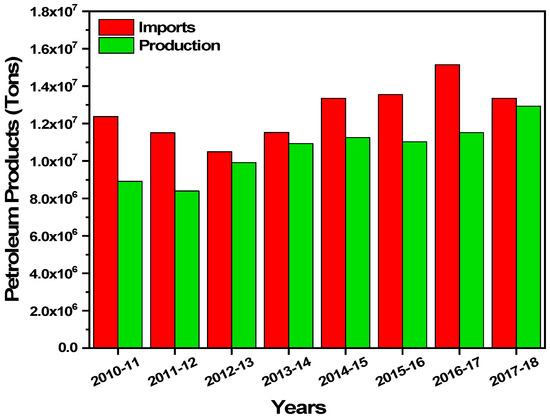

Economic development requires valuable input from all areas to expand. The key demand of the 21st century is to cope with the rising energy demands [1,2,3]. Pakistan is the world’s fifth most populated country, its energy demand and population are rising every day, too. Pakistan’s 2010 population was 179,424,641, which rose to 220,892,340 in 2020 and is expected to cross 24.22 million in 2025 [4]. Due to the growing population, Pakistan needs a massive supply of energy to maintain normal things, but this country is unable to meet its energy demand [5]. Conventional fuels, i.e., oil, natural gas, and coal, are currently 63% of Pakistan’s total energy supply, followed by hydroelectric power (26%), nuclear power (3%), and renewable energy (8%). The transport sector is the largest user of oil/petroleum products, hitting 76% in 2018–2019 [6]. Total petroleum products production in 2010–2011 was 8,911,000 tons, increasing to 12,929,000 tons in 2017–2018, and the total petroleum products imports in 2010–2011 were 12,371,000 tons, increasing to 13,344,000 tons in 2017–2018 as shown in Figure 1. The shortage of petroleum products is covered by the import of petroleum products [6].

Figure 1. Total production and imports of petroleum products in Pakistan from 2010 to 2018 [6].

Similarly, in 2010–2011, oil/petroleum consumption for transport was 8,892,268 tons, which increased to 16,047,392 tons in 2017–2018 but the use of gas (compressed natural gas, CNG) for transport in 2010–2011 was 113,055 mm cft, which decreased to 70,455 mm cft in 2017–2018 [6]. Problems with energy crises not only disturb the livings of people but also disrupt Pakistan’s economic development. The recent part of renewable energy to the overall contribution of the country’s energy is insufficient [7]. Pakistan is meeting energy demands through the use of fossil fuels [8]. With the high dependency on fossil fuels, there is pressure on the economy of the country, and this pattern is also affected by many environmental impacts [9,10]. Pakistan has faced energy shortages that have forced the closure of many factories. The amount of CO2 emissions from the industry has also decreased, however, due to the growing trend of cars, there is an increasing trend in the amount of CO2 emissions [11,12,13]. The CO2 emissions in Pakistan were 132,805 ktons in 2005, which rose to 174,843 ktons in 2015 [14].

To overcome these problems, sustainable, secure, and pollution-free energy sources must be used at the same time which could combine social and economic development with environmental protection [15,16,17]. Tire pyrolysis oil (TPO) is among the effective substitute fuel technologies, and it is used to produced useful products of tire pyrolysis oil, char, and pyro gas [18]. Tire pyrolysis oil, derived from waste automotive tires, was tested and compared with petroleum products and it could also be used in the compression-ignition engine [19]. Converting tire waste into fuel would not only minimize the issues of waste disposal, but it could also lower the burden on fossil fuels and could be an ideal substitute for renewable fuel [20]. The annual production of tires worldwide is 1.5 billion, which become end-of-life tires after a particular period of time [21]. It is currently estimated that approximately 4 billion waste tires are in stock and landfills, worldwide [22]. One billion waste tires can generate 5.26 million tons of tire pyrolysis oil [18].

2. Tire Pyrolysis Oil

The worldwide yearly production of tires is 1.5 billion which will become end-of-life tires after the specific time [21]. Around 3.3 million tons of used tires were treated in an environmentally sound way in 2010. This reflects a 2% rise relative to 2009. After setting out the data of the tires that are going to be reused, approximately 2.7 million tons of end-of-life tires (ELTs) were remaining for treating [21]. About 0.1 million tons of tires are used in power plants and co-incineration each year. The material recovery used 0.1 million tons of tires which include the rubberized flooring for sports, blocks for paving, as a roofing material, and to make a playground. A significant quantity of end-of-life tires is used in many civil engineering applications such as 0.24 million tons for embankments, roads, and rail foundations [21].

Energy is an important aspect of any society and is crucial to enhancing society’s social and economic quality of living [23,24,25]. Over time, human beings, via wood to nuclear energy, have used diverse kinds of energy sources [26]. The energy sector has been the major contributor to the emissions of greenhouse gases (GHG). The most vulnerable of these GHG emissions is the release of CO2 into the environment from the consumption of non-renewable energy (fossil fuels) [27,28,29]. Their replacement is required to tackle the challenges of energy demand and greenhouse gases. The end-of-life tires can be used for fuel production to meet the fuel demand [30]. An alternative liquid fuel obtained from tires named tire pyrolysis oil has similar physicochemical properties to diesel fuel. The large-scale production of TPOs will become sustainable because there is a huge amount of feedstock (waste tires) available in the world, which increases by ~2% per annum [31]. Tire pyrolysis oil derived from waste automotive tires was tested and compared with petroleum products and found that it can also be used as a compression-ignition engine [19].

Williams et al. [32] investigate that car tires were pyrolyzed into a pyrolysis unit of the one-ton batch to generate oil, char, and gas. Properties such as calorific value, elemental analysis, nitrogen, and sulfur were analyzed in the derived fuel. To burn the oil, an 18.3 kW ceramic-lined, oil-fired, spray burner furnace having an internal diameter of 0.5 m and 1.6 m in length was used. The oil contained sulfur and nitrogen by wt% of 1.4 and 0.45 respectively, and fuel properties close to diesel fuel. It is also reported that due to the higher sulfur and nitrogen content in the tire oil, the NOx and SO2 emissions were higher for tire pyrolysis oil while comparing to diesel fuel. According to M.F. Laresgoiti et al. [33], 2 to 3 cm wide cross-sections of complete car tires were pyrolyzed underneath nitrogen in a 3.5 dm3 autoclave at a temperature of 300, 400, 500, 600, and 700 °C approximately 38% liquid and 17% gases yield was obtained. It was also seen that there was no effect on liquids and gas yields at a temperature of over 500 °C.

Mustafa Karagöz et al. [34] performed a study in which various percentages (0, 10, 30, and 50%) of waste tire oil combine with clean diesel. Tests were performed on various engine loads of 3, 6, 9, and 12 Nm in a single-cylinder diesel engine at a constant engine speed of 2000 rpm. It was noted that the heating value of tire pyrolysis oil (TPO) is less as compared to diesel fuel (DF) and due to the lower cetane number of TPO higher ignition delay in TPO-DF blend. The oxygen and carbon wt.% of tire pyrolysis liquid is relatively close to the diesel fuel. On the behalf of general measurements, tire pyrolysis oil with diesel blends can be used as an alternative fuel in compression ignition engines. Moreover, for the future, the authors proposed that ternary blends of TPO-DF with other fuels will produce more feasible results. They also proposed that adding biodiesel and some nanoparticles in the TPO-DF blend would enhance oxygen wt.% in blends and could improve the combustion quality and reduce the emissions.

Murugan et al. [19] revealed that crude TPO has a higher sulfur and viscosity content. After the desulfurization and distillation of crude TPO, its properties become similar to petroleum fuels and can be used in compression-ignition engines as fuel. According to Ali Alsaleh and Melanie L. Sattler [35], the heating value of tire pyrolysis oil is about 40 MJ/kg and can be easily used in diesel engines and furnaces. Valuable chemicals such as aromatic and olefins for petrochemical industries can be obtained from pyrolysis oil. Moreover, gases produced from the pyrolysis of waste tires, such as hydrogen, can be used for the pyrolysis process as fuel. Currently, due to the rising populations and industries, energy decline and environmental catastrophes are the main issues [36]. The discovery of feasible alternative fuels is required to address fossil fuel depletion [37]. Waste tire disposal is a major problem around the world, with landfills and stockpiles posing a serious environmental risk [38].

With the large quantities of used tires produced annually and without a proper disposal strategy, converting the used tires into TPO is an attractive way of approaching the waste tire problem [39]. The reuse of waste tires by pyrolysis is a good option for eliminating waste from the atmosphere and securing high-energy items such as pyrolysis fuel, gas, and coal [40,41]. It is noted that tire pyrolysis is an effective and sustainable method, provides neat production that is economically feasible, and a possible solution regarding waste tire handling [42]. A combination of several compounds is used in the design of the tires which includes rubber 60–65 wt.%, carbon black 25–35 wt.%, filler 3 wt.%, and also accelerators [35]. A rise in the gross domestic product (GDP) of the country also stimulates the supply and demand of vehicle and tire substitutes for safety concerns. The end-of-life tire extension is not majorly considering this trend [43].

A tire pyrolysis plant is a profitable project and it depends on various factors, including product quality, production efficiency, and the overall cost of production, capital investment, and tipping fees. The decision for a waste management company to provide energy and materials for a tire depolymerization plant would depend on whether the cost of the pyrolysis process is less than that of incineration [44]. The 1.5 billion tires are generated globally and can be used to producing useful products of oil, char, and gas. Fixed-bed (batch), rotary kiln, vacuum, screw kiln, and fluidized bed are the most famous reactors that are used. The composition of gas and oil of TPO is mainly depending on which type of reactor is used, for which the heating rate and temperature are determined, as well as operating temperatures and residence time of feedstock in the reactor also affect the properties and composition of TPO. Tire pyrolysis oil is very complex chemically (aliphatic, aromatic, hetero-atomic, and polar fractions). Examples of commercial and semi-commercial tire pyrolysis systems demonstrate that small-batch reactors and continuous rotating kiln reactors have been commercially produced [45]. The advantages and disadvantages of the tire pyrolysis process are given in Table 1.

Table 1. Advantages and disadvantages of the tire pyrolysis process.

| Advantages | Disadvantages |

|---|---|

| Pyrolysis is a method that can help to resolve the waste management practices from insufficient places [46]. | Because of the absence of an established oil market and, in particular, for pyrolytic carbon black products, scrap pyrolysis has been uneconomic [47]. |

| Tire pyrolysis is an effective and sustainable method, provides neat production that is economically feasible and the finest solution regarding waste tire handling [42]. | CO, HC, SO2, and smoke emissions were considerably higher in the blends with TPO 50 wt.% and 75 wt.% [48]. |

| The fuel properties of the TPO-diesel blend indicate its potential viability and the finest replacement of fossil fuels [46]. | Incompetent waste pyrolysis plants may fail to meet environmental emission requirements, resulting in contamination of the air and soil [49]. |

| After desulfurization and distillation, its properties become similar to diesel fuel which can be used in passenger cars and vans [50]. | |

| Since pyrolysis plants do not emit poisonous or greenhouse gases, they would not contribute to the spread of respiratory diseases or climate shifts in the region’s cities [42]. | |

| As the plant produces energy, can help to meet the energy demand of the nearby cities [42] |

Recent statistical data on the production of tires in Europe reveals the difficulty of the market is recovering from the results of the financial crisis. More specifically, despite the sharp increase in tire production in 2010 (26% growth compared to 2009), the maximum production of all time has not been overcome (more than 5.1 million tons of tires were produced in 2007) [51]. Moreover, according to the report of European tire and rubber industry (ETRMA) statistics edition 2019, the production of tires in Europe from 2010 to 2018 was about 4.5 to 5.1 million metric tons [52]. Approximately 60% of worldwide production in Asia and Oceania [53]. Conversely, each year, Japan disposes of one million tons of tires, while in 2010, China produced 5.2 million tons of tires, making it one of the largest countries with used tires production [54,55]. With the rapid growth of the automotive sector and higher living standards in China, the number of automobiles is growing rapidly and China faces the environmental issue related to waste tire disposal.

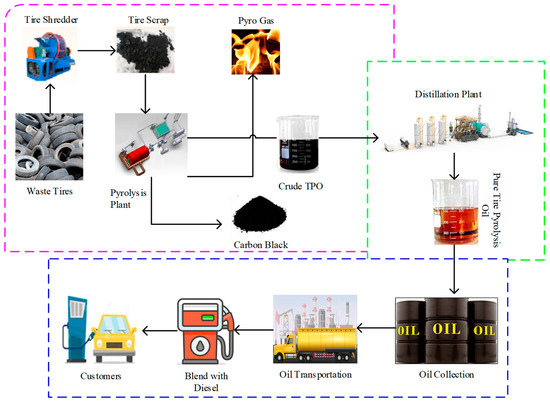

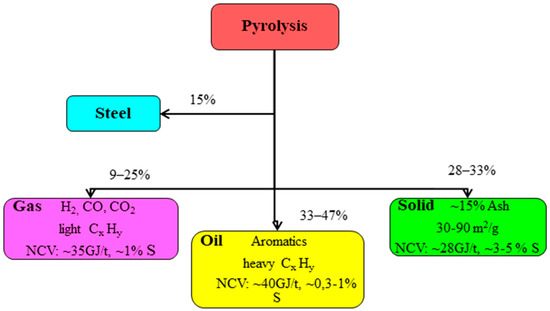

As per the World Health Organization (WHO) statistics, globally the amount of waste tires storage has reached 3 billion which is growing annually [56]. Countries like China, Japan, India, the European Union countries, and the United States of America accounted for a total of 88% of the production of waste tires [57]. This work compiles and summarizes the pneumatic recycling strategies widely accessible, paying particular attention to pyrolysis as a promising alternative to the need to accomplish a more sustainable energy scenario as fuel [58]. The step-wise diagram of waste tires to the final product is shown in Figure 2. Furthermore, the mass and energy balance of pyrolysis is illustrated in Figure 3 [59].

Figure 2. Step-wise diagram of waste tires to the final product.

Figure 3. Flow chart of mass and energy balance of pyrolysis [59].

This entry is adapted from the peer-reviewed paper 10.3390/su13063214