Extensive use of multi-walled carbon nanotube (MWCNT) has been done for the fabrication and implementation of flexible sensors due to their enhanced electrical, mechanical, and thermal properties. These nanotubes have been deployed both in pure and composite forms for obtaining highly efficient sensors in terms of sensitivity, robustness, and longevity.

- multi-walled

- carbon nanotubes

- flexible

- sensors

- strain

1. Introduction

The intervention of sensors in the microelectronics world has increased the pace of life to a great extent. In earlier times, when most of the data signal collection and processing was done manually, a considerable amount of time and money was required. The initial days of sensorial prototypes saw the popularization of semiconducting sensors [1,2]. These devices were mainly developed using the microelectrochemical (MEMS) technique [3,4]. These sensors used silicon to form the substrates due to their dynamic nature in terms of tolerating harsh conditions, robustness, small size, and wide range of temperature and humidity [5]. Although these sensors served a great purpose, there were certain limitations that deterred their widespread consideration for multifunctional applications. Some of the disadvantages related to the use of MEMS-based silicon sensors can be attributed to their instability in their responses when operated over a long time period of time, high signal-to-noise ratio (SNR) at low frequencies, inability to handle high power and irregular behavior at higher frequencies [6]. Other than characteristically, these sensors have also found challenges in terms of fabrication process due to the requirement of clean-room facilities and expertise to handle the complexities in the steps of fabrication. For these reasons, sensors have been developed using materials that altered the electrical and mechanical characteristics.

Flexible sensors have been made from different kinds of polymers and nanomaterials based on their electrical, mechanical, and thermal characteristics [7,8]. The wearable nature of the flexible sensors [9,10] has also increased their value due to their ubiquitous sensing capabilities. While considering the type of polymer to fabricate a flexible sensor, some of the primary attributes that are considered are Young’s modulus, high permeability toward heat and temperature, and ability to integrate with nanomaterials to form composites. A few of the polymers used to fabricate the flexible sensors are polydimethylsiloxane (PDMS) [11,12,13], polyethylene terephthalate (PET) [14,15,16], polyethylene naphthalate (PEN) [17,18,19], polyimide (PI) [20,21,22], polyvinyl chloride (PVC) [23,24,25], and poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT: PSS) [26,27,28]. Each of these materials has individualistic advantages and disadvantages associated with them. For example, PDMS is low cost, highly optically transparent, and biocompatible in nature, thus is favored over a wide variety of applications. However, there are certain drawbacks, like the deposition of metals and high hydrophobic nature, which has led to the use of other polymers. Although certain processes like plasma treatment can change the hydrophilicity of the PDMS surface, they will eventually revert back when in contact with air. In comparison, PET is much stronger and lighter than PDMS, which makes them perfect for barring moistures and gases. PET and PEN also exhibit high insulating properties similar to PDMS, but their higher tensile strength and stiffness makes them ideal for forming commercial sensors. The advantages of PI have been largely attributed to their high heat resistance, high wear resistance, and excellent dimensional stability. These factors make this polymer ideal for use in critical applications like aerospace aviation and forming laminating resins and high-temperature structural adhesives. PVC might not be as strong as PI in terms of mechanical tear or heat stability, but its easy welding nature has led the researchers to ingrate it with different kinds of nanomaterials for forming flexible sensors [29]. This material has been used to form sensors that are not subjected to fire as a result of the emission of toxic fumes. Polymers like PEDOT: PSS have recently been popularized due to their conductive nature, which has revolutionized the nature of composites and multi-layered structured prototypes to a great extent. However, there are still some disadvantages associated with PEDOT: PSS including its acidic nature and high stocking of insulating PSS. Similarly, different kinds of nanomaterials [30,31] have been considered to develop the electrodes of the flexible sensors. The characteristics of nanomaterials that are analyzed before choosing them for synthesis purposes are high electrical conductivity, mechanical flexibility, optical transparency, and the ability to form high interfacial bonding with the polymers. The conductive nanomaterials for flexible sensors can be broadly classified into two forms, namely carbon-based allotropes and metallic nanomaterials. These nanomaterials consist of various shapes like nanosheets [32,33], nanorods [34,35], nanoribbons [36,37], nanowires [38,39], and nanoparticles [40,41]. While the first category includes carbon nanotubes (CNTs) [42,43,44], graphene [45,46,47], and graphite [48,49,50], the second category primarily includes gold [51,52,53], silver [54,55], aluminum [56,57], and copper [58,59]. Among these conductive materials, CNTs have been used a lot due to their advantages like lightweight, small size, high specific area, high aspect ratio, and high thermal and chemical stability. Other than these attributes, their biocompatible nature has increased their usage for biomedical applications [60,61,62,63,64] to a large extent. CNTs are categorized into two classes including single-walled carbon nanotubes (SWCNTs) [65,66,67] and multi-walled carbon nanotubes (MWCNTs) [68,69,70] based on their size, structural, and electromechanical characteristics. Comparing these two types of CNTs, MWCNTs are advantageous over SWCNTs for certain reasons like low cost, ease of mass production, easy functionalization, and enhanced stabilities. As a result of this, these MWCNTs have been used for different kinds of electrochemical [71,72,73] and strain-sensing [74,75,76] applications. Out of these two genres, the use of MWCNTs to determine a spectrum of strain values has been widely done to exploit their mechanical characteristics. These nanotubes were conjugated with different kinds of nano and polymeric materials to form prototypes that were able to successfully detect the micro- and macro-natured strain values. Strain sensors have been operated for biomedical [77,78] and industrial [79,80] applications, where a certain degree of strain caused by tactile and contact forces has led to the change in the responses of the prototypes. These types of sensors have been able to perform well in research environments with controlled temperature and humidity conditions due to a couple of reasons. First, the real-time operations of the prototypes introduce interruptions in terms of unwanted vibrational motions and connection with the conditioning circuits. This disturbs the stability of the responses. Second, the deployment of the sensors is done with chosen people, specifically researchers, and for a limited amount of time whereas real-time operations of these sensors are done for a longer period of time with a larger group of people. This is why, although these sensors have functioned successfully in research laboratories, they have still not been commercialized for the market. Based on their enhanced performances, there is a need for commercialization, which would not only lead to the use of these sensors for chosen applications, but will also form a podium for future researchers to fabricate and operate novel sensors.

Although many review articles have been published in this area [81,82,83,84,85], there are a couple of aspects that make this paper favorable and interesting for the readers. First, none of the papers as of yet have been particularly focused on the use of MWCNTs for strain-sensing applications. Although both SWCNT- and MWCNT-based strain sensors have been capable of displaying excellent performances, the morphological advantages of MWCNTs over SWCNTs have always demanded further analysis. Due to a high interfacial bonding of MWCNTs with the polymer matrix, the sensors tend to revert back to their original position, even with the presence of micro-cracks formed under the influence of applied strain. Additionally, lower cost and higher purity are the advantages of MWCNTs over SWCNTs, which has led to a shift in focus in using MWCNTs to develop flexible strain and pressure sensors. From a fabrication point of view, the bulk formation of MWCNTs is easier, along with enhanced electrical, thermal, and chemical stabilities. Even though SWCNTs provide a structural simplicity, a higher degree of functionalization and comparatively minimized tendency to form agglomerates has recently popularized the use of MWCNTs as a favorable carbon-based nanomaterial. Over a broader aspect, research on SWCNT-based sensors is still continuing equally, but mostly to develop electrochemical sensors due to their high chiral nature [86]. Second, a categorical view of the exploitation of MWCNTs for forming strain sensors is necessary to deduce the impact of processing materials on the performance of the prototypes. Most of the review articles have generalized on the employment of CNTs for strain and pressure-sensing applications, thus making it a requirement to particularly focus on MWCNT-based strain sensors. Table 1 highlights a comparative study on some of the significant works done on MWCNT-based strain sensors based on certain parameters. It can be seen that with the change in processing materials, the corresponding quality of the prototypes varied.

Table 1. Comparative study of some of the significant works done on the use of multi-walled carbon nanotubes (MWCNTs) for strain-sensing applications.

|

Processed Materials |

Limit of Detection |

Stretchability |

Gauge Factor |

Ref. |

|---|---|---|---|---|

|

MWCNTs, PDMS |

5% |

10% |

513 |

[87] |

|

MWCNTs, PDMS |

10% |

120% |

4.5 |

[88] |

|

MWCNTs, Eraser |

30% |

30% |

2.4 |

[89] |

|

MWCNTs, PDMS |

146% |

12.15 |

[90] |

|

|

MWCNTs, Thermoplastic Polyurethane (TPU) |

5% |

100% |

2800 |

[91] |

|

MWCNTs, Graphite films |

5% |

100–620% |

43.4 |

[92] |

|

MWCNTs, Silicone rubber |

10% |

10–40% |

34.38 |

[93] |

|

MWCNTs, Graphene platelets |

1% |

237.5% |

181.36 |

[94] |

|

MWCNTs, Silicone polymer |

1% |

300% |

1–1.5 |

[95] |

|

MWCNTs, Thermoplastic Polyurethane (TPU) |

0.3% |

35–185% |

22 |

[96] |

2. Multi-Walled Carbon Nanotube (MWCNT)-Based Strain Sensors

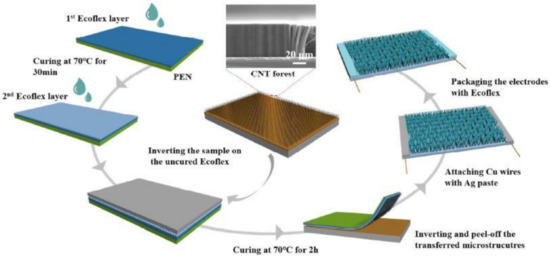

The utilization of MWCNTs for strain-sensing applications is highly effective due to the enhanced electrical, mechanical, and thermal qualities of the nanotubes compared to the other types of carbon allotropes. While using these MWCNTs in pure form, they primarily operate on the basis of the nature in which they are presented on the electrodes. For example, the presence of MWCNTs in different forms assists in increasing the sensitivity of the prototypes. Figure 1 [97] shows the fabrication process of flexible sensors developed from EcoFlex and vertically-aligned CNTs. These vertically aligned CNTs help in the precise measurement of the applied strain by preserving and accentuating the unique anisotropic properties of the individual nanotubes. The alignment also helps the sensors in possessing a morphology that can be easily customized and controlled to tune the sensitivity of the prototypes. The free-standing films used in the pure sensors also impart superb mechanical strength, low bulk density, and outstanding thermal conductivities. In the composite forms, the polymers provide additional attributes like biocompatibility, robustness, and overall sensitivity to the prototype. In addition to the distinctive mechanical flexibility and electrical properties exerted by the nanocomposites as a result of the tunneling effect caused by the internal conductive network, they also impart superior mechanical properties in terms of modulus and strength, noise damping, and corrosion resistance. The structural integrity of the MWCNT-based composite sensors is also much stronger, which helps in achieving long-term stability in terms of mechanical and thermal properties [98]. Furthermore, nowadays, with the presence of conductive polymers like PEDOT: PSS, the compromise in the electrical conductivity is also reduced to a great extent. Although the quality of the MWCNT composite-based strain sensors is better than the pure ones due to their higher selectivity, the pure ones have other advantages like simpler design, avoidance of any kind of distribution of the nano-fillers in the polymer matrix, and chances of agglomeration [99].

Figure 1. Fabrication of flexible strain sensors using carbon nanotubes (CNTs) and EcoFlex nanofin structures [97]. Reproduced from Zhang, S.; Wen, L.; Wang, H.; Zhu, K.; Zhang, M. Vertical CNT–EcoFlex nanofins for highly linear broad-range-detection wearable strain sensors. J. Mater. Chem. C 2018, 6, 5132–5139.

2.1. Pure Multi-Walled Carbon Nanotube (MWCNT)-Based Sensors

Among the earlier research work related to the use of pure MWCNTs for strain sensing, Vemuru et al. [100] explained the analysis related to the real-time response of the prototypes. MWCNT films were developed using a surfactant Nanosperse AQ, where the MWCNTs were sonicated, filtered, and peeled off from the filter to obtain free-standing nanotube films. The films had a density of 50% and a thickness of around 30–50 microns. These sensors were tested for their macroscale responses under tensile load. The responses of the prototypes were also detected in terms of voltage as a function of temperature. A brass specimen was used to attach the MWCNT films to determine the voltage through four-point probe measurements. A linear response of voltage was obtained when the MWCNT films were subjected to tensile strain. The linearity in the responses was maintained until 100 micro-strains, after which the response became non-linear. The films completely recovered in their unstretched state during the unloaded condition. The MWCNT films, when attached, the brass specimen had a Young’s modulus of 166 GPa and a gauge factor (G.F.) of 0.3482. The increase in temperature also led to an increase in the electrical conductivity of the MWCNT films. The resistance values changed by 0.0217 Ω with a temperature difference of 13.9 °C. Another work on the use of standing MWCNT-based films for strain sensing was presented by Zhang et al. [88]. These sensors were operated as resistive devices, where the MWCNT networks were reinforced by PDMS films. The sensors displayed high sensitivity toward both low and high strains. The advantage of these sensors was the customization of the performance of the sensors by adjusting the length and density of the MWCNTs. A gauge factor (GF) of 4.5 was obtained with the highest stretchability of 120%. The sensors were also used for human motions, where the movements of the fingers were monitored to analyze their capabilities for real-time applications. PECVD was used to develop vertical MWCNTs on a thin-film layer of silicon dioxide substrates. Fe was used as a catalyst along with high vacuum conditions. Other experimental conditions included a high temperature of 850 °C, and the presence of H2 and N2 gases with flow rates of 30 sccm and 10 sccm, respectively. After the MWCNTs were produced, they were transferred on PEN films that had a thin-film layer of PDMS with a thickness of 100 microns. The entire samples were then cured at 70 °C for 15 min, after which the second layer of PDMS was coated with a thickness of 15 microns. Then, the samples containing the MWCNTs and uncured PDMS were covered and cured at 70 °C for an hour. Finally, the silicon substrates on which the PEN films were positioned were peeled off to use the sensors for experimental purposes.

2.2. Composite MWCNT-Based Sensors

The research work on the formation of MWCNT composites has been done extensively for strain sensing applications. The advantages of using MWCNTs instead of pure ones lie in the additional advantages of the processed materials added to the composites. Scientists have tried different mixed kinds of polymers and nanoparticles to enhance the quality of MWCNT nanocomposite-based sensors [102,103,104]. These sensors have proven to have higher sensitivities in terms of G.F., lower response time, and lower hysteresis.

3. Future Scope of MWCNT-Based Strain Sensors

Even though a lot of work has been done related to the use of MWCNTs for strain-sensing applications, there are still some bottlenecks that need to be addressed to improve the quality of the prototypes. The above-mentioned research work related to the use of MWCNTs to combine with different kinds of polymers and conductive nanomaterials formed highly efficient strain sensors that showed enhanced performance in terms of G.F., stretchability, and detection range.

The use of different materials to compose the above-mentioned pure and composite strain sensors was based on the individualistic pros and cons associated with them. The inclusion of each of these materials has helped in enhancing the performance of the strain sensors. Certain processing materials like PDMS have been used to form both the substrates and composites of the sensors and has assisted in building robust sensors through the proper attachment of the electrodes. In addition to being biocompatible and hydrophobic in nature, it has allowed research groups to customize its mechanical flexibility and thickness to form the substrates of the sensors by optimizing the ratio between the pre-polymer and curing agent. Other advantages of PDMS include low cost and optical transparency, which not only decreases the overall fabrication cost but also increases the dynamicity in terms of applications of the prototypes. Another major advantage of PDMS for strain sensors is the hydrophobic nature it provides during wearable sensing applications. This property ensures the minimal disturbance of the body fluids on the responses during the experimental process. Other materials processed to form the substrates of the pure MWCNTs strain sensors include silicon and PEN, where the former one provides numerous advantages like small size, low hysteresis, the capability to operate in extreme conditions, and high repeatability in terms of large-scale production. The silicon-based sensors, as shown above, also give insights to researchers to integrate carbon-based and metallic nanomaterials with semiconducting elements. One of the issues with the use of silicon is the high cost related to its processing from single-crystal silicon with a thin oxidized layer above it. Certain techniques like 3D printing that contain PTFE molds to form the MWCNT-based strain sensors also had pros and cons associated with them. The advantages of PTFE molds include excellent release, reduced abrasion, and reduced build-up, while the disadvantages are high matrix impurity rate and high cost.

In order to form the composites of MWCNT-based strain sensors, PU and silver nanoparticles are additional materials that are used other than PDMS. PU is one of the popular materials used to form strain sensors due to its high tear resistance and high tensile properties. They also show strong bonding properties while used in nanocomposites, along with enhanced performance in mild and harsh environmental conditions [115]. One of the major disadvantages of PU includes its low life expectancy, which would require the prototypes to be changed at frequent intervals. This would increase the overall cost of the sensing systems. Another disadvantage of PU is the water absorption characteristics, which might affect the output of the PU-based prototypes when used as wearable sensors. The inclusion of silver nanoparticles in the nanocomposites provided certain advantages like enhanced electrical properties as a result of increased conduction paths, increased stability, and lower detection limits. Toxicity is one of the issues with silver nanoparticles, but this is mostly related to the prototypes that are used for biosensing applications.

There are still some steps that can be taken to ensure further quality control of the MWCNT-based prototypes. Since the mixing of MWCNTs with aqueous solutions without the presence of any surfactants is still an issue, further functionalization should be done on these carbon allotropes, which will assist in their dissolution. Different kinds of functional groups should be added using nucleophilic addition reactions to add groups that would be multivariate in nature. The impurities present during the fabrication of MWCNTs using different techniques like chemical vapor deposition [116,117], arc-discharge [118,119] and liquid electrolysis [120,121] should also be reduced on the group level. This would not only help to improve the grade value of the MWCNTs, but also overall improve the quality of the resultant prototypes. The removal of the generated impurities can be addressed by focusing on the experimental parameters like the temperature of the chamber, catalyst, and gases. The conjugation of MWCNTs with other efficient materials like graphene should be further researched and worked on [122,123]. Due to the excellent characteristics of graphene, they should be intertwined with MWCNTs to introduce additive features to the electrodes. These conjugates would also help in improving the quality of nanocomposites that would have other polymers present in them. While the MWCNTs will assist with the interfacial bonding inside the polymer matrix, graphene would help in the electromechanical properties of the conductive fillers. Another improvement can be made on the alteration of the testing scenario of the fabricated MWCNT-based strain sensors. Although these sensors show excellent performances in laboratories with controlled ambiance conditions, their ubiquitous operation in real-time application is something that will have long-lasting influences on the industrial sectors. These strain sensors should be embedded with other signal-conditioning circuits to perform wireless operation. Once these above-mentioned issues are addressed, the dynamic range of the utilization of MWCNTs for strain and other similar applications would increase to a great extent. While using CNTs and other carbon-based allotropes to fabricate strain sensors, a reduced amount of toxicity of these nanomaterials is one of the parameters that need to be taken into account. This is primarily to ensure that safe operational procedures are being followed during the fabrication process. CNTs are said to have carcinogenic effects that can cause disastrous effects like tumors, pulmonary inflammation, fibrosis, and granuloma in the lungs [124]. However, the intensity of these effects varies depending on the diversified properties of CNTs such as length, aspect ratio, surface area, degree of aggregation, purity, and concentration [125]. Thus, a thorough study using simulations should be performed before using the CNTs and related-allotropes in order to optimize the critical parameters related to them. Additionally, the fabrication process should be carried out in closed chambers in specialized clean rooms to minimize exposure. Each of the fabrication steps carried out to design and develop the sensors followed standardized protocols that have been previously tested and verified. The laboratories containing these nanomaterials should also be equipped with paramedics who can be immediately consulted in the case of an emergency.

The market scope related to the use of CNTs for strain-sensing and other applications is said to increase exponentially in the near future [126]. There is an estimated rise in the use of CNTs from 4.55 billion USD in 2018 to 9.84 by 2023, with a compound annual growth rate of 16.70% [127]. This considers the fabrication of both SWCNTs and MWCNTs, along with their applications in the electronics, chemistry, energy, and medical fields. The increase is said to be worldwide, especially in countries like India, China, Brazil, and the Middle East due to their emerging economies [128]. The use of MWCNTs in the past few years is said to be more than that of SWCNTs due to their higher tensile strength, a result of which there has been a higher number of applications that try to employ MWCNTs for detection purposes.

This entry is adapted from the peer-reviewed paper 10.3390/s21041261