Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Ocean

In order to implement a new type of escort towing, specially designed to be employed in very adverse weather conditions, considerable changes in the hull form of escort tugs had to be made to improve their stability and performance. Since traditional winch and ropes technologies were only effective in calm waters, tugs had to be fitted with new devices. These improvements allowed the remodeled tugs to counterbalance the strong forces generated by the maneuvers in open waters. This entry presents a review of the new high-performance automatic dynamic winches.

- Ship Handling in Unprotected Waters

1. Introduction

Ship handling operations, traditionally focused around protected waters, had led to little attention being paid to open or unprotected water conditions formerly [1]. However, especially as a result of the catastrophic oil spill from the grounding of the Exxon Valdez in 1989 and, more recently, the opening of new Liquefied Natural Gas (LNG) terminals in exposed ocean conditions, escort towing development has triggered an ongoing demand of authorities and offshore terminal operators to increase the performance of pure escort and offshore terminal tugs [2,3].

The tug industry has responded by developing a new generation of high-tech escort tugs [4,5,6]. As at high speeds these tugs are capable of producing steering and braking forces greater than the bollard pull (BP) of their propulsion systems alone (known as indirect mode) [7], designers initially centered their efforts on:

-

Achieving the necessary high stability to withstand the overturning forces produced at yaw or drift angles (angle between the centerline of the tug and the centerline of the assisted ship) [8];

-

Achieving an efficient underwater hull form and skeg capable of generating very high forces with different attack angles against the incoming waterflow. In those situations, the propulsion system is used to maintain this relative position by resisting the hydrodynamic force tendency over the tug to put the towline in line with their centerline [2].

However, the significant relative motions between tug and ship induced by the large waves encountered at many sites have triggered ongoing research to face critical risks that can occur in this condition in order to improve the safety of those maneuvers [1,5].

In these dynamic environments, two recent developments to cope with them deserve special mention: the winch and rope cutting-edge technologies [4,9].

After a brief consideration of the escort towing methods carried out by an Azimuthal Stern Drive (ASD) escort tug, the objective of this paper is to analyze these two new technological advances and to highlight how they can make escort towing maneuvers safer.

2. Escort Towing Methods of an ASD Tug

Basically, there are four escort tug types (the tractor Voith, the Azimuth Tractor Drive (ATD) or tractor Z, the ASD and the Rotor Tug) that carry out their specific escort towing methods [3] (pp. 235–263). As in Baniela and Díaz [2], the methods used by a tractor Voith were analyzed, here, we will show those used by an ASD with the help of figures, adding comments where a specific method needs a particular explanation for this tug.

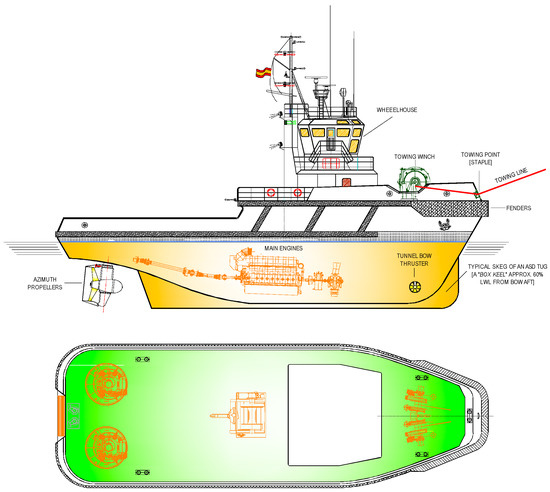

Figure 1 shows an ASD escort tug. Even though it is common that this type of tug has a winch aft in order to increase its versatility, it is used in ocean towing maneuvers, not in escort or harbor ones where they work “bow first”, with the towline leading to the ship from the forward winch through the staple.

Figure 1. A typical Azimuthal Stern Drive (ASD) escort tug. Drawing: Authors.

The typical skeg of a modern ASD escort tug, necessary to generate hydrodynamic forces, does not have the high aspect ratio of a tractor tug, for hull geometric reasons, but a box keel located approximately 60% of the waterline length along from the bow aft. This appendix is used to:

-

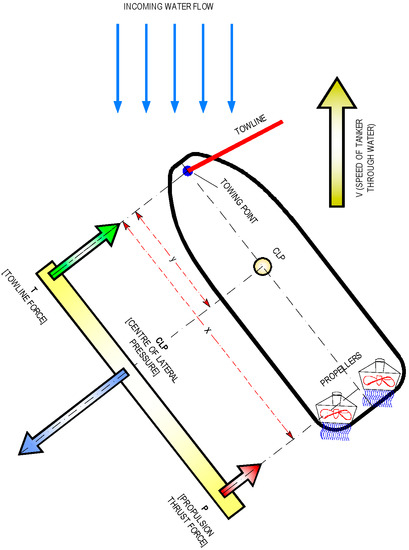

Shift the center of lateral pressure (CLP) towards the end opposite the thrusters (i.e., towards forward) in the direction of the attack point of towline force. This is to increase leverage between the CLP and the thrusters so that the thrust necessary for the equilibrium of forces is minimized (Figure 2) [2] (pp. 155–156), and the towline force is maximized with this design option (Figure 1 and Figure 3). However, the CLP should be kept aft of the towing point (the staple) to ensure a “fail-safe” operation so that the towline force will not be prone to overturn the tug in case the propulsion system on the tug fails [10].

-

Increase directional stability.

-

Increase the underwater hull lateral area in the most effective way to improve the hydrodynamic effect at high speeds so that it generates high towline forces in the indirect mode.

Figure 2. The athwartships force balance of an ASD escort tug using the pure indirect method. Drawing: Authors.

Figure 3. (a,b) The ASD escort tug “Costante Neri” delivered in September 2009 by Gondán Shipyard, S.A. (Spain), to the owner Fratelli Neri S.p.A. (Italy). Photo: Authors.

In short, there are two methods whose use and forces generated in the towline depend on the speed of the assisted ship a lot:

-

The direct mode, when forces in the towline are generated almost entirely by the thrusters alone and the towline works aligned with the tug’s centerline. This mode is effective at speeds lower than six knots, where the propulsion thrust dominates (around 90% of the towline force).

-

The indirect mode, when thrusters are used to adopt an angle of attack against the incoming waterflow and the hydrodynamics of the tug underwater hull and skeg are used to create large braking and steering forces. This mode is effective at speeds higher than eight knots, when hydrodynamic forces from the hull begin to dominate (around 70% of the towline force).

The ASD escort tug will use either method depending on the assistance required—braking or steering and braking—by the escorted ship and their speed.

From an operational point of view, turning the tanker in the most suitable direction is the quickest way to control it, provided that there is sufficient sea room, because its speed is reduced very quickly in this case [11]. This is the reason why the capability of an escort tug to generate maximum steering force is essential. However, the escort tug’s capability to apply maximum braking force becomes necessary in restricted waters when there is not enough room to turn the tanker; therefore, its performance in applying this force in this condition is also important. As a typical escort towing speed is about ten knots, when an emergency occurs, an indirect mode is used first, and as speed is reduced, the escort tug will change to direct mode.

3. Evolution of Escort Tug Winches

To cope with the challenging requirements of escort towing authorities to improve the safety of assistance maneuvers by new winch technologies in dynamic rough water operation environments, the starting point was the conventional winch with tow in the brake, the constant tensioning winch with tow in the drive and, later, the more sophisticated render-recovery winch [12,13].

4. New High-Performance Dynamic Winches

This term applies to those escort tug winches specially designed to work in rough weather conditions in unprotected waters. The state of the art allows their operating system to be fully automated so that it follows what the waves do to the tug in dynamic environments, without the need for the tug’s skipper to be directly involved. It constitutes the last stage in the improvement of render–recovery winches’ performance, which first appeared in the escort towing world in the mid-1990s and to which we have referred in Section 3.2.

In conditions where wave and wind action often generates extreme relative motions between a tug and tow, the need to design a dynamic winch capable of regulating line tension by automatically anticipating rather than reacting to tension changes in the towline is a must.

To achieve this goal, the so-called “symmetrical” render and recover capability had to be overcome, because the significant power required in dynamic braking or load attenuation is much higher than the inherent haul-in power limits of a typical render–recovery winch drive [15]. As the braking power was not enough to cope with the high peak loads that can be generated in these conditions, other sophisticated means had to be provided.

This provided an opportunity to winch manufacturers and designers to work hard to fill this gap for some time, claimed by authorities and terminal operators in order to give the tug the capability to handle the highly dynamic environmental forces it operates in, making these maneuvers safer. Ongoing research on these demands also contributes to this largely demanded development, with the SAFETUG Joint Industry Project II (JIP II) being the most significant individual instance of research carried out on this item [18,19].

This new winch technology requirement was achieved by leading manufacturers at the end of the 2000s, and it is probably the one that changed more in the escort towing field over the past 15 years [9].

The main purpose of a high-performance winch in dynamic seas is to match the relative motion between a tug and a tanker. In order to do so, the winch must accelerate quickly enough to keep up with the changing directions of inhaul and payout, as well as being capable of maintaining the maximum speed in either direction [20].

In short, this new technology consists of preventing overload and slack towline events induced in escort towing by paying out and retrieving, respectively, with as short of a time delay as possible. Thus, these winches are capable of preventing towline breaking due to overloads by relieving the tension in the towline (render) when a snap load occurs and then recovering the towline to prevent snap loads when tension is generated again after a slack towline event, thus keeping the relative position of tug and tow.

5. The Towline

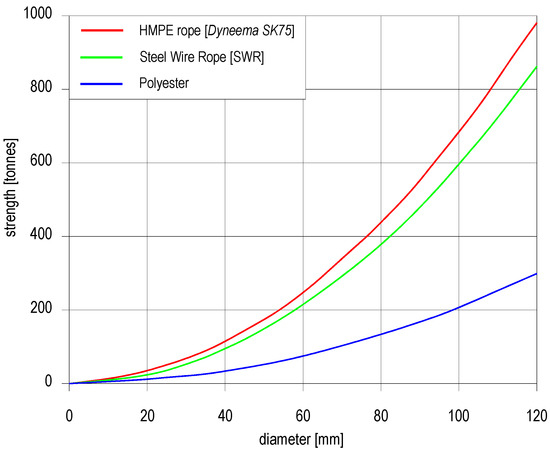

The towline, being the connection between the ship and escort tug, is of primary importance to operational safety. Therefore, it cannot be considered separately, and a holistic approach becomes necessary nowadays. In recent years, the winch power, as Griffin [22] depicts, has been multiplied sixfold on average over the past 20 years as compared to a doubling of propulsive power in the same time, and towline break strength should be designed accordingly due to the ever-increasing size of assisted ships as the requirements for escort towing forces are higher. Thus, advances in towline technology needed to go hand in hand with new winch technology in order to improve the safety performance of the whole system. This is the main reason why the industry has seen a nearly universal acceptance of high modulus polyethylene (HMPE) synthetic ropes, also known as ultra-high molecular-weight polyethylene (UHMWPE) or high performance polyethylene (HPPE), used successfully in escort towing since the mid-1990s [9,19,22,24].

HMPE lines have very little elongation or stretch under load, and if the winch performance can achieve a dampening effect to control the high tensions generated in dynamic environments, this low-inertia characteristic will give a better load control, which helps to work more safely in these conditions. However, regarding this lack of elongation property, some challenges should be overcome, as their use can lead to snap load effects in the towline of an escort tug working in these harsh conditions greater than in a higher elongation rope as polyester (Figure 12) and they can fail without warning. It is the reason why this type of rope should have the highest possible strength and working load factor [25]. Thus, to cope with those characteristics, two different strategies can be applied in escort towing:

Figure 12. Rope properties, strength versus diameter of different lines as per Samson Rope manufacturer. Drawing: Authors.

-

As new high performance winches can achieve a dampening effect to control the high tensions generated in dynamic environments, the low-inertia characteristics of HMPE synthetic ropes that have very little elongation or stretch under load give them a better load control, which helps to work more safely. In this case, the best option is the use of an HMPE rope as the total tow rope (monolithic).

-

In compliance with the Class Rules, the use of a less sophisticated winch (in case the tug owner does not embrace the new high performance winch concept) to limit slack line events and snap loads by increasing the elasticity of the towline with a higher elongation one such as polyester can, in comparison, attenuate the higher frequency energy better. Alternatively, an HMPE line connected with a stretcher (a short line of around 20 m in length with higher elasticity—typically polyester) to accommodate the tug motions with relatively little variation in the towline tension can be used. As it was traditionally made, these two options offer additional elasticity at the expense of having a higher risk of towline failure than with the previous strategy.

Obviously, if an escort tug is equipped with a high dynamic winch, to use an HMPE rope without a stretcher is the best option (though some tug operators use it). The reason is that as a stretcher stores much more energy when peak loads are generated, it is released again when the tug moves toward the tanker afterwards in such a way that if elasticity is too high, the tension cannot be controlled and the tug can be catapulted [18].

Although there are small differences among various ropes manufactured depending on their fibers—mainly Spectra® (Honeywell, New York, NY, USA) or Dyneema® (DSM Dyneema B.V., Geleen, The Netherlands)—and how rope manufacturers feature these fibers in their ropes, they have a similar strength to wire rope at the same sizes, but only around 1/6th of the weight, which simplifies their handling. It also floats (enabling tug operations to be much simpler and safer). However, it should be taken into account that if jacketed, they can have a higher density and may sink, depending on the rope’s diameter and the material the jacket is made of [26] (p. 9).

Abrasion is the ability to withstand wear and rupture due to motion against other fibers or rope components within the structure of the towline itself—internal—or by contact with external surfaces—external. As detailed lab simulations and field observations confirmed, it is the dominating factor and most serious threat to the integrity of HMPE ropes used in escort towing, affecting their service life [9,24]. Mitigating it in such a potentially abrasive and demanding environment and protection of the primary working parts of the lines is vital to extend their service life. This is mainly achieved by:

-

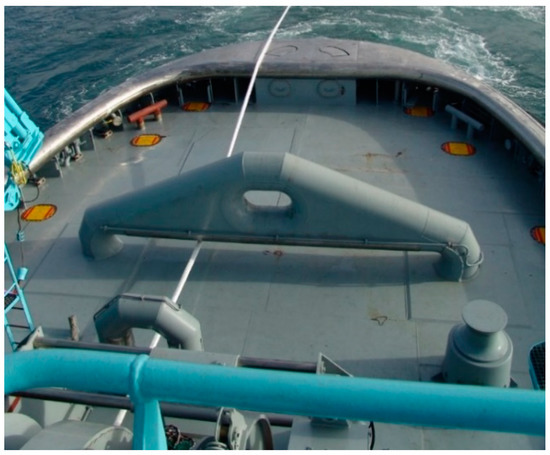

Proper deck hardware: To minimize unnecessary abrasion damage, all surfaces in contact with the towline should be smooth (it is recommended to be kept at a maximum roughness of 250 microinches, μ”). Typically, on board the tug, this is achieved by well-designed stainless steel staple and bitts being highly polished (Figure 11) and with a generous bend radius—ideally, the cap rail should be made of stainless steel as well [24]. As the towline leads from the winch drum to the staple and then directly to the tanker, a point of fatigue is generated at the staple, which is exacerbated by the back-and-forth tug motions, which is the reason why water spray cooling is recommendable to dissipate heat due to the friction there [4] (Figure 13).

Figure 13. Wide staple of Escort Voith Water Tractor Tug “Tenax” with water spray cooling for escort towing with a high modulus polyethylene (HMPE) towline. The contact surfaces of both the staple and all around the cap rail are made of a highly polished stainless steel. Photo: Authors.

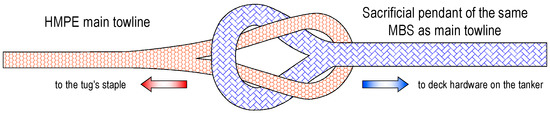

However, the main source of abrasion leading to failure in the towline, an Achilles’ heel as Arie [27] metaphorically describes, is when it comes into contact with poor fittings (chocks and bitts) on the tanker [9] (p. 5). A good example to follow in order to tackle this drawback is the tanker–escort tug system implemented in Prince William Sound, where tanker fittings should be designed according to the towline force capability of escort tugs deployed there [9,24]. To minimize this potential damage and extend the life of the main towline, a sacrificial pennant—sometimes referred to as pendant or forerunner (a short length of HMPE rope with an eye spliced at both ends)—of the same minimum breaking strength (MBS) is used to endure it [25,28]. The connection between the main towline and the pendant bights is usually made by a “cow hitch” (Figure 14) or by a “spectacle splice” (eye-to-eye connection) [29] (pp. 14–15).

Figure 14. Cow hitch connecting HMPE towline to a sacrificial pendant. Drawing: Authors.

-

Proper chafe protection: The localized abrasion points on the line should be protected by strategic positioning of chafe gear at the appropriate locations (to protect from both internal and external abrasion).

-

Coating technologies developed by manufacturers: Manufacturers are developing coatings at yarn level to reduce internal abrasion enhancing rope wear and snag resistance.

As the coefficient of friction (COF) (or μ) of HMPE ropes is low, to prevent them from slipping on the drum winch, a backer polyester rope of a smaller diameter with a higher COF and that is long enough to cover the core first layer of the drum (sometimes referred to as the “safety layer”) is helpful to mitigate this risk. It should be of sufficient diameter to fit into the bitter end of the winch drum and be spooled under as much tension as possible (to minimize the burying of these working ends of the rope). As the load is largely dissipated in friction while it migrates towards the drum core from the first external wraps, it is not necessary for the backer rope to have the same MBS as the HMPE working line [9,25].

To compensate for the loss of grip due to its low COF, a HMPE towline requires around twice as many wraps in the drum winch than a polyester one to achieve the same holding power. However, on an equal strength by strength basis, its diameter is approximately half, so the drum width can remain the same [30].

Even in relatively moderate sea states, Maritime Research Institute Netherlands (MARIN) found out that, excluding slack line events, towline force can be triple the tug’s bollard pull (BP). To prevent an HMPE towline from breaking in dynamic conditions (according to Allan [9], in extreme sea states, the dynamic loads can exceed ten times the BP), an MBS up to six times the BP is commonplace as a working load factor in order to provide greater safety and to extend the ropes’ service life [5].

6. Towing Winch Design Requirements

Regarding escort towing system design requirements, Classification Societies have had to redefine the design load of towing equipment and associated supporting structures and the design requirements of tow winches, towlines and their guiding fittings in their rules to take into account the dangers of operating in dynamic environments [5 ,24,31,32].

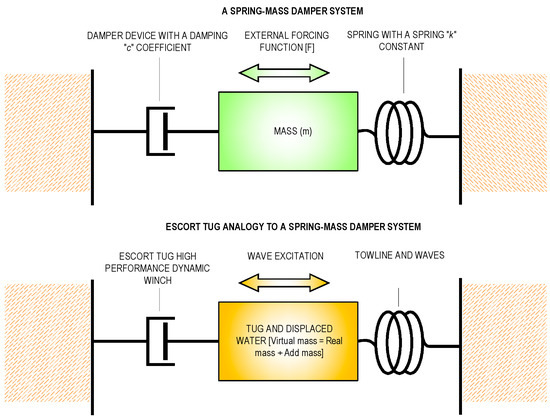

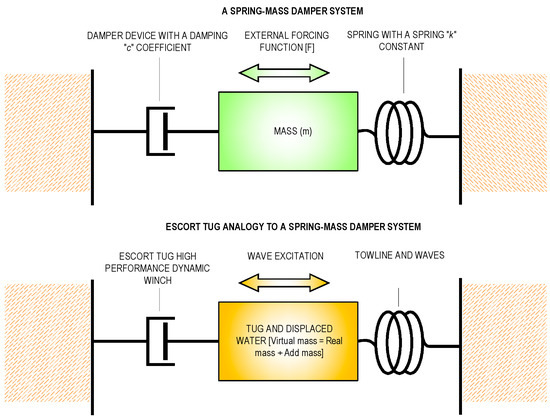

Figure 15. Analogy of an escort tug in a dynamic environment to a mechanical spring-mass damper system. Drawing: Authors.

To accurately define the maximum winch capacity of an escort tug, it is necessary to know its escort towing capability, and then, the final requirements of winch performance can be established accordingly [9,16]. This subject goes beyond the content of this paper; suffice it to say that empirical formulas based on model tests are used where the tug is seen as a spring–mass damper system (Figure 15). The mass is the virtual mass of the tug and the spring is the towline and waves, although the dampening constants of the model to match the wave size and speed are difficult to scale as the behavior of the wave differs with its size, so a margin of error becomes inevitable. Additionally, to achieve specific tailored design requirements to see how much power is needed in the winch, numerical modeling after model or full-scale testing permits to carry out multiple analyses, leading to a more detailed design by considering the behavior of the tug in dynamic environments. This can lead to a more accurate prediction of their performance in these conditions [1,33].

The use of simulation programs [34] to determine the design load, as far as the winch and towline are concerned, is valuable due to the cost and time savings. Its development and reliability is dependent on the accuracy of data collection obtained from previous full-scale tests as well as model tests [5]. It is a complicated task due to the physical complexity of the escort tug phenomenon, where the dynamic variables involved change a lot and very quickly. Based on the design load thus obtained, winch manufacturers are capable of producing a specific winch adapted to the demands of a harbor.

This entry is adapted from the peer-reviewed paper 10.3390/applmech2010004

This entry is offline, you can click here to edit this entry!