Additive Manufacturing (AM), also called 3D printing, has been expanding into several industrial sectors due to the technology providing opportunities in terms of improved functionality, productivity, and competitiveness.

- metal additive manufacturing

- 3D printing

- advanced manufacturing systems

- Industrial application

1. Introduction

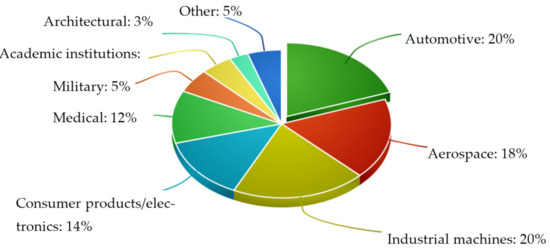

Additive manufacturing (AM) or three-dimensional (3D) printing is a manufacturing process that enables fabrication of objects by successively printing layer upon layer guided by a digital 3D model [1,2]. This unique feature allows the manufacture of complex geometries that are almost impossible to fabricate using conventional systems. Therefore, AM is a tool resource that enables designers to create custom or intricate models in one-step without conventional manufacturing limitations such as high material waste, difficulty to manufacture complex shapes, and the need for specialised tooling. Accordingly, through the use of AM, engineers have increased ‘design freedom’ [3]. Furthermore, part counts can be reduced and consequently, assembly time and cost are reduced or eliminated [4]. In addition, parts can be manufactured on demand, which improves response time, shortens supply chain(s), reduces storage needs, eliminates delivery costs, and decreases lead-time for critical replacement parts [3]. Wohlers et al. [5] concluded that it is expected that the AM industry growth continues over the next few years, and the sale of AM is predicted to exceed AU$22.9 (US$15.8) billion worldwide by industry sectors. According to the data published by Wohlers et al. [5], Figure 1 represents the distribution of AM revenues for the end-market in 2018, and represents the diverse industrial adoption of AM.

Figure 1. Industrial Adoption of additive manufacturing (AM).

AM technologies can use various materials including polymers, ceramics, and metals. Among these materials, metallic materials are gaining an increased interest from researchers and industries. In addition to the above mentioned benefits, metal AM may provide some environmental advantages such as less wastage, quality improvement, less pollutant emissions, and making parts on demand [6,7]. While metal AM provides these benefits, the extent of utilisation of metal AM technologies in industry is currently limited to a few industry sectors such as dental [8], construction [9], and aerospace [10]. In addition, researchers have generally focused on the investigation of a narrow set of metal AM processes. For instance, Ahn [11] reviewed different direct metal AM processes and addressed constraints related to applications of them. Pan et al. [12] introduced arc welding AM processes and reviewed mechanical properties of metallic materials such as Titanium alloy. Ziaee and Crane [13] presented a review of binder jetting processes, materials, and current technologies. Some researchers focused only on the material properties of metal AM products. For instance, DebRoy et al. [14] introduced microstructures, defects, and mechanical properties of metallic printed materials. Yakout et al. [15] reviewed the effects of key printing parameters on the mechanical properties and microstructure of several metallic materials such as Titanium, Aluminium, and Nickel-based alloys. Additionally, DebRoy et al. [16] reviewed metal AM materials, particularly refractory alloys, precious metals, and compositionally graded alloys.

2. Industrial Applications

Metal AM opens up new opportunities to improve manufacturing capability. Short lead times, access to new materials, material waste reduction, and fabrication of novel complex geometries and difficult to machine materials are key factors to encourage industry sectors to adopt metal AM technologies [67]. This section presents a range of recent applications in different industries along with several case studies where AM technologies have been successfully applied.

2.1. Automotive

2.2. Aerospace

One of the earliest adopters of AM technologies is the aerospace industry. All sectors of this industry such as commercial aircraft, military applications, and missile systems are applying AM technologies [10]. The capability of metal AM to perform rapid tooling and repairing, fabricate freeform and complex geometries, and consolidate parts, makes it ideal for the aerospace applications [76]. Moreover, the aerospace components are commonly made of difficult to machine materials such as high resistant super-alloys [77].

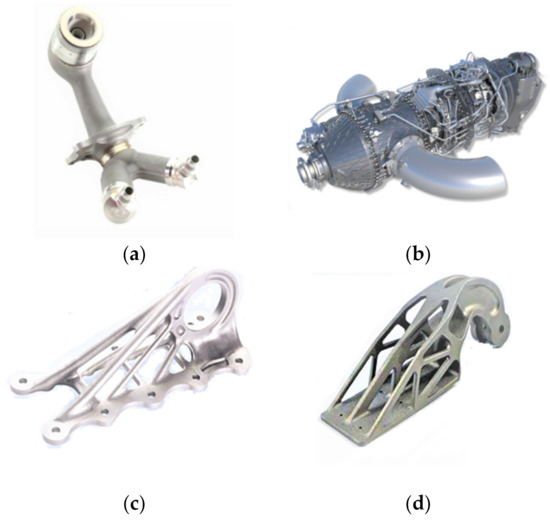

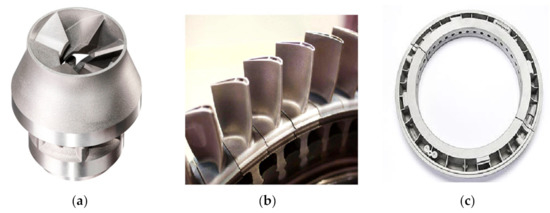

General Electric (GE) Aviation uses Concept Laser and Arcam metal printers to manufacture fuel nozzles for its new LEAP engine [10,78]. Figure 5a shows the LEAP fuel nozzle, which is 25% lighter and stronger than the original nozzle. More importantly, this component boosts the fuel efficiency of the engine up to 15% higher than the previous best CFM56 engines [77]. Figure 5b shows another additive manufactured product, the GE Turboprop engine, which features subassemblies with just 12 parts, in stark comparison to the original engine that had 855 parts. Chapin reported that the novel AM Turboprop also boosts the fuel burn efficiency by up to 20%.

Furthermore, Airbus is using EOS and Concept Laser machines to manufacture metal brackets and bleed pipes for its aircrafts. Moreover, this company is producing large-scale AM airframe components in collaboration with Arconic [10]. Figure 5c shows an AM wing bracket that is printed with a Concept Laser machine, for the next generation Airbus A350 XWB jets [77]. Figure 5d shows an AM lightweight Titanium Ti64 turbine cover door hinge, used on an Airbus A380, printed with an EOS laser sintering machine. Another step of this company toward use of metal AM is the development of optimised A320 components and redesigning Titanium parts of the A350 [5].

In addition to the above, DED technologies have received considerable attention from the aerospace industry in recent years. For instance, LMD technology was used for fabricating the impeller blades of turbomachinery as well as repairing damaged areas [79]. This metal AM process provides ‘Near-Net-Shape’ geometry [80]. DED technologies are also used for the repair of turbine airfoils, engine combustion chambers, and blisks [10]. In another research study, Wilson et al. [81] applied LENS technology to repair defective voids in turbine airfoils. The results showed that the repaired airfoil matched the geometry of the original geometry with the 0.03 mm mean accuracy, improved the carbon footprint by 45% and increased the total energy saving by up to 36%.

From the above, it can be seen that the aerospace industry has already started to receive benefits from adoption of AM technologies. According to a report published by Raja et al. [82], the aerospace industry benefits from AM technologies in different ways as follow: Lead time is shortened by up to 70%; Non-recurring costs is reduced by up to 45%; and mass is decreased by 35% or more.

2.3. Medical and Dental

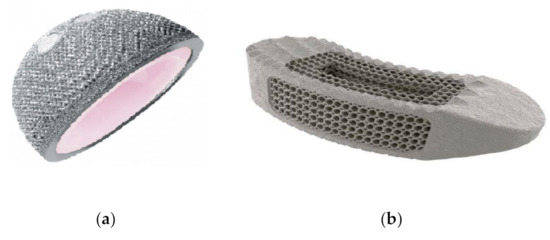

The medical and dental industries are well-suited to the application of metal AM technologies for making end-use products. Metal AM technologies enable these industries to fabricate custom models tailored to patient needs and access to new materials. For instance, LimaCorporate company based in Italy has been developing Titanium-alloy orthopedic devices with Metal PBF and Arcam’s EBM technologies [5]. Figure 6a shows a commercially available metal AM orthopedic device. Another example is the Titanium AM spinal cage produced by Nexxt Spine based in USA (Figure 6b). According to this company, spinal surgery is becoming more commonplace due to aging, spinal tumors, or trauma [83]. Therefore, Nexxt Spine is developing additively manufactured porous Titanium spinal implants. Another example is custom orthopedic implants based on the accurate capture of bony structures. Harrysson et al. [84] developed integrated implants based on a CT scan and fabricated the custom implants, which were made of Ti6Al4V, via the EBM or DMLS technologies. Some companies that have used AM technologies to manufacture dental/medical devices are Osseus Fusion Systems, OMX Solutions, Egan Dental Laboratory, Johnson & Johnson Medical Devices, and Endocon GmbH.

In addition to the above applications, researchers investigated the applications of metal AM in the medical industry. For instance, Vilardell et al. [85] developed topology optimised human using lattice structures. The novel geometries were made of Ti6Al4V and printed by a SLM EOS M28 printer. The results showed that the new designs can reduce the stress shielding effect on implant applications. In another study, a PBF printer made by Aurora Labs was applied to fabricate a dental strut-like geometry [86]. The results showed that material properties of the new product provide a low hardness near the gums. Revilla-León et al. [87] reviewed several recent medical and dental AM applications for interested readers.

2.4. Building and Construction

The scale of use of metal AM technologies for construction applications is currently low due to long printing times, small print volumes, high initial cost, and environmental issues; however, the number of applications in this field is increasing. For instance, Arup Group, an international engineering consultancy, developed a topology optimised node (Figure 7a,b). This component is made of stainless steel and it is 75% lighter than the original node, which is manufactured by traditional methods [88]. Figure 7c shows the printed Nematox facade node, which is developed at the University of Applied Sciences in Detmould. This part is made of Aluminum and it is printed with the Concept Laser system [89]. Another example of metal AM application is the MX3D bridge (Figure 7d). The Joris Laarman Lab and Arup use a WAAM system, which is attached to a robotic arm to print stainless steel components of the Amsterdam’s bridge [9].

The above literature shows that metal AM is enabling the construction industry to create complex structural shapes with minimised weight and a reduced production lead time. Currently, metal AM is used for production of customized components on demand. Furthermore, metal AM is beneficial for the circumstances where construction components are lost or damaged, and on-site production using AM can be of significant benefit as waiting for replacements may cause construction delays and costs [88].

2.5. Electronics and Communication

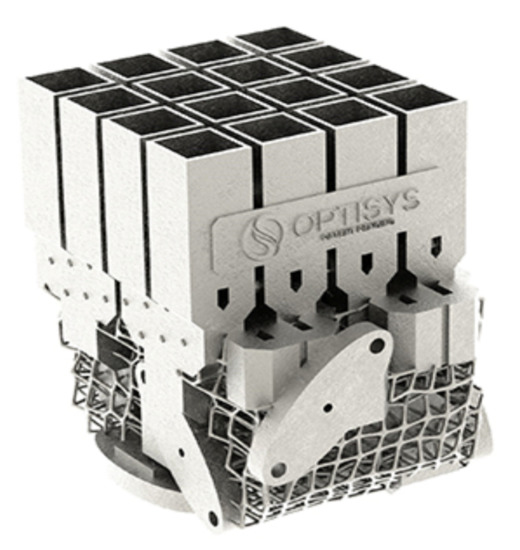

The cartridge includes 1.5 mL of ink with silver nanowires. The Robert Hofmann company developed a lightweight RF filter for communication satellites [5]. Figure 8 shows an AM RF antenna manufactured by Optisys LLC. This company manufactured a metallic micro-antenna with Concept Laser’s PBF technology, and this AM product is employed in aerospace and defence applications. Compared to an equivalent conventionally manufactured antenna, the AM antenna provides benefits such as 95% weight saving, 20% production cost reduction, and lead time reduction from eleven months to two months [96]. Another example of the metal AM application is developing high-efficiency metal waveguides. Verploegh et al. [97] developed a W-band component, which includes a 10 cm straight waveguide piece and a 20 dB coupler. This component was manufactured with DMLS technologies in Maraging Steel (MS), which provides structural integrity and reasonable conductivity.

2.6. Oil and Gas

Siemens is producing a number of metal AM products for the oil and gas industry such as nickel alloy gas turbine blades, fuel nozzles, gas turbine burners, heat shields impellers, and swirlers. One of the successful examples of metal AM application at Siemens is the production of an advanced burner swirl for the SGT-750 gas turbine. For this component, metal AM enabled the manufacturing of a swirl shape. Another effective application of metal AM technology is manufacturing a water pump impeller of the fire protection system at Slovenia power station [98]. Siemens also designed metal additively manufactured sealing rings of SST-300 steam turbines, which were used in India in 2018. Figure 9 shows some of these examples [103].

It can be seen that the oil and gas industry continues to drive the industrialisation of metal AM products. Barnes and Camisa [102] believed that AM also has the potential to manufacture lightweight offshore facilities such as separators, pumps, and deck structures through topology optimisation and the use of lattice/cellular structures. It should be highlighted that the application of metal AM in the oil and gas industry requires feasibility analysis, strategic planning, and careful examination to avoid excess costs and enjoy AM benefits such as lead-time reduction, enhanced design complexity, improved functionality, and increased supply chain efficiency.

2.7. Mining

Mining projects are often operated in remote and high-risk locations. Thus, when equipment components fail, supply chains are compromised due to access limitation, downtime, and delays in production due to lead-times in obtaining replacement parts. In such circumstances, metal AM may be very suitable, particularly for the manufacturing of on-demand spare parts [104].

2.8. Tools and Moulds

Metal AM is gradually being adopted by mould and tool makers. In this industry, metal AM is used to make tooling such as mould inserts, jigs, fixtures, and gauges [109,110]. Figure 10 shows an AM-manufactured tool with conformal-cooling channels, which would be difficult to manufacture by conventional manufacturing techniques. This optimised component offers minimal warpage and reduced cycle time, and hence, improves the part quality and cooling process [111]. Another example is a 3D printed mould, which has a skeletal form including lattice-shell and rib reinforced structures. This AM mould provides fast and uniform cooling processes. Results showed that the new AM mould is 30% more efficient than the original mould and has less deformation, residual stress, and casting defects [109].

2.9. Railway

The railway industry has started adopting AM technologies to carry out production and maintenance work. Alstom, a French multinational company, is adopting AM technologies for the production of lightweight components [112]. Elsewhere, the MODTRAIN project has been financed by the European Commission to explore the standardisation/modularisation of rail components to reduce production, maintenance, and reliability costs. This has been further continued in a project entitled ‘Run2Rail’ in Europe where they are investigating the applications of AM technologies and composite material applications within the railway industry [112]. Another example is the initiatives undertaken by Dubai’s Road Transport Authority’s maintenance team to apply AM technologies with respect to various metro rail assets such as manufacturing AM parts for ticketing. Additionally, railway companies face problems in finding spare parts that have been discontinued or where the manufacturers are no longer in business, and which would be expensive to reproduce using conventional manufacturing [113]. To overcome this problem, the railway sector is now turning to metal AM. For example, Webtec, a global rail and transit manufacturer, is developing metal spare parts with GE’s H2 Binder Jet technology. This company aims to use the H2 printer to produce up to 250 rail parts for its production lines by 2025 [114]. Similarly, Deutsche Bahn AG, a German railway company, in collaboration with Siemens produces spare parts for their older fleets [112,113].

This entry is adapted from the peer-reviewed paper 10.3390/app11031213