Recently, a dynamic increase in the number of polymer elements ending their life cycle has been observed. There are three main ways of dealing with polymer waste: reuse in an unchanged form, recycling (both material and energy), and disposal (mainly in the form of landfilling or incineration). The legislation of European countries promotes in particular two forms of waste management: reuse and recycling. Recycling processes are used to recover materials and energy especially from contaminated waste, which are structurally changed by other materials, friction, temperature, machine, process, etc. The recycling of polymers, especially of multi-plastic struc-tural elements, requires the use of special technological installations and a series of preparatory operations, including crushing and separating.

- shredding

- mechanical recycling

- contaminated polymeric materials

Note: The following contents are extract from your paper. The entry will be online only after author check and submit it.

1. Introduction

In the last decade, there has been a growing interest in the issues of optimal choice of materials processing parameters and technologies providing high efficiency and low environmental impact [1–5]. The carried out research and analyses as well as technological development have resulted in a dynamic growth of plastics consumption in almost every field: packaging, the aviation and automotive industries, and power engineering [6,7]. The problem is the post-use management of plastics. The amount of plastic waste has been increasing year by year, while the methods of its segregation, processing, and recovery are limited. The limitations in processing are mainly caused by the variability of properties of materials forming the waste stream and technological possibilities of processing equipment [6,8–11].

The actions implemented to protect the climate and increase energy efficiency have led to a rapid development and increase in the number of functioning photovoltaic and wind installations in which polymeric materials are the main building material [8,12–14]. Due to a relatively short period of development of these installations, no effective method of management and processing of polymeric materials into end-of-life (EoL) stages has been developed so far [8,15–18]. The post-use materials and components of wind power plants and PV modules are most often stored or burned with energy recovery in specially designed installations for the processing of polymeric waste [8,15–18]. While various forms of mechanical, chemical, and thermal recycling are used in recycling, they are still at the initial stage of development, and it is necessary to develop machines, devices, and technologies based on innovative solutions that are highly effective and consistent with the idea of eco-design [8,19,20].

Environmental assessment at the EoL stage should also be an inseparable element of the analyses, especially considering that the main raw materials for the production of polymeric materials are oil and gas, the extraction of which exhausts the available resources and causes negative environmental impacts [8,10]. The recycling of plastics makes it possible to significantly reduce the environmental burden during the life cycle and to recover some of the natural resources and energy [21,22]. Previous studies [14,18,22–28] have shown that for multi-plastic components from which it is difficult to separate individual materials (e.g., wind turbine blades, automobile tires), the use of recycling as a form of post-consumer management significantly contributes to the reduction of environmental impacts during the life cycle of these components.

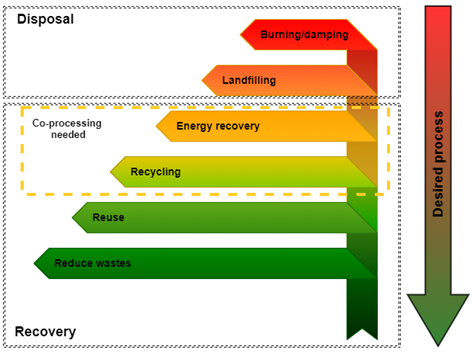

The EU Waste Framework Directive explicitly indicates the guidelines for the treatment of waste, including polymeric waste, emphasizing waste treatment during which it is possible to recover as much raw material and energy as possible (Figure 1) [29,30].

Figure 1. Polymers waste end-of-life (EoL) options based on the EU Waste Framework Directive.

The reprocessing of materials in recycling requires their initial preparation [6]. The most frequently used operations are segregation, cleaning, or washing and shredding, which is particularly important in the case of processing large-size polymeric materials [6,9,18,31]. Shredding processes are in principle an integral part of recycling; therefore, their efficiency should be as high as possible, and their energy consumption should be as low as possible, in order to have an adequate balance between the energy and environmental inputs for the processing of recycled materials, and the benefits of raw material and energy recovery [32–34]. In this case, it is necessary to recognize the relations between the shredding parameters, design features of shredders, and the properties of polymeric materials. The mentioned relations will influence the process efficiency and the obtained product quality as well as the energy consumption during the shredding process. Issues regarding relationships in material–machine–process areas in the case of polymeric materials shredding have not yet been sufficiently addressed [35–44]. In this paper, an attempt has been made to describe the indicated issues in the aspect of polymeric materials recycling.

There are many publications devoted to specific, single aspects of polymeric materials shredding [6,9,45–52], but there is a lack of study summing up and connecting different aspects of shredding in the recycling process, dealing with relation between shredded material, machine features, process indicators, and the environment. These relations will be fundamental for shredding process development.

The aim of this study is to organize and systematize knowledge about shredding in the recycling process of end-of-life polymeric materials, which could help properly design these processes in the context of sustainable development and circular economy. It examines the latest literature data on different shredding technologies in the recycling of polymeric material as well as recommendations for the eco-design of energy–material systems. In this study, we provide fundamentals for the mathematical description of shredding in the recycling engineering including energy–material potential, energy relations, and efficiency indicators. The issues of efficiency, control, optimization, and modeling of the end-of-life polymeric materials shredding process were presented. These were considered for the special construction of a multi-hole shredding unit, taking into account the following variables: machine design features, movement indicators, changes in the volume of material, and cutting surface during shredding.

2. Recycling Engineering and Shredding

Recycling engineering describes the areas of activity connected with the designing of the EoL and processing of the EoL materials. It includes issues of design for recycling as well as process and materials engineering on the complete life cycle stages of objects.

In recycling engineering, there are four basics principles of the development and potential of recycling processes control. The first basic principle is high quality and development of polymeric construction materials that are easy to recycle. The second is efficiency (energy and material) of the processing and use of these materials. The third one is the harmlessness of products and processes throughout their life cycle. Finally, the fourth principle is constant development of knowledge about polymer engineering and recycling pathways [9,53,54].

2.1. End-of-Life Options for Contaminated Polymeric Materials

With the development of technology, many methods of recovery, processing, and management of end-of-life contaminated, structurally changed polymeric materials have appeared over the years [55]. The universality of a given management technology is influenced by, among others, the current legislation, the cost of its implementation, and the environmental impact. Currently, the most important legal acts covering the issues of handling polymer waste include the following:

- Waste Framework Directive (Directive 2008/98/EC on waste) [29],

- Council Directive 1999/31/EC of 26 April 1999 on the landfill of waste [56],

- Directive (EU) 2018/852 Of The European Parliament and of The Council of 30 May 2018 amending Directive 94/62/EC on packaging and packaging waste (Text with EEA relevance) [57],

- Directive 2000/53/EC of the European Parliament and of the Council of 18 September 2000 on end-of-life vehicles [58],

- Directive 2012/19/EU of the European Parliament and of the Council of 4 July 2012 on waste electrical and electronic equipment (WEEE) [59].

These documents define, inter alia, the method of collection, segregation, processing, or EoL management, along with an indication of preferred methods ensuring the possibly highest share of material and energy recovery and the possibly lowest generation of environmental burdens, e.g., in the form of dust, harmful substances, noise, etc.

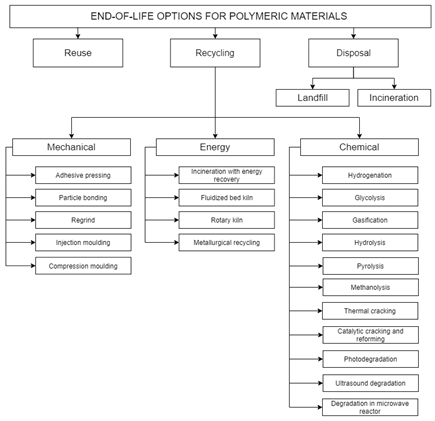

According to the EU Waste Framework Directive (Figure 1), the amount of generated waste should be reduced first (e.g., through a conscious design of products consisting of minimizing the consumption of raw materials, facilitating reuse and recycling) [29,54,60,61]. With regard to plastic waste, four main methods of EoL management (Figure 2) are used: reuse, recycling, landfilling, and incineration (without energy recovery).

Figure 2. End-of-life options for contaminated, structurally changed plastic waste. Own work based on data from [62–69].

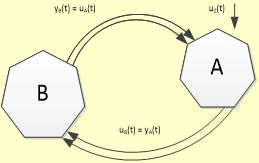

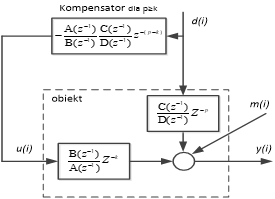

Most often, after the use phase, polymer materials have disturbances (contamination, changes) (system A) of the internal and external structure (shape), filling with other materials, substances, pollutants, etc. [62]. Waste processing technologies can be implemented under the condition of appropriate control, appropriate regulation, and disturbance compensation. Waste treatment system control requires defining the input function in a way that ensures the achievement of the set goal (Figure 3). Processing system A is affected by disturbances and is controlled with feedback by system B, the inputs of which depend on the disturbance state of the polymer material by waste.

Controlling a waste processing system requires determining an output function yA(t) (control) that depends on process, material, and machine factors (input variables uA(t)) (Figure 3). The output function can be a set of specified parameters of the processing product, assumed performance, or energy consumption level. Maintaining the parameters at the assumed level is realized on the basis of the feedback principle of the connected two systems: processing system A and control system B (Figure 3). If the processing system A is affected by interference uz(t) (e.g., in the form of impurities of the processed materials), which results in deterioration of the set of output parameters yA(t), then system A is controlled with feedback by system B, in which the values of the output function are analyzed. For system B, the values of the output function of system A yA(t) constitute the input signal uB(t) (input values), based on which the control system B will generate the output signal yB(t) which is also the input signal uA(t) for system A. In this way, the interference is compensated, and it is possible to maintain the output values of system A at the assumed level.

Negative feedback is used for the following purposes:

- Reduce the impact of disturbances in polymer materials from operation, affecting the initial size of the object.

- Reduce the impact of changes in object parameters on its output size.

- Modify the static and dynamic properties of the object

|

|

System A is feedback controlled by system B, the inputs of which depend on the state of system A, and system A is affected by interference: uA(t)—input control variables uz(t)—disturbing input variables |

|

In order to remove the influence of post-consumer disturbances in the polymer materials d(i) on the output y(i), an algorithm was introduced to cognitively compensate system A for the variable u(i): (u(i)) = f‖required ∗ −y (i)‖ For the technical implementation, the variant where p ≥ k is sufficient.

|

Figure 3. Control, regulation, and compensation of interference of polymer materials resulting from operation. Own work based on data from [70–72].

2.1.1. Reuse

The concept of material/product reuse assumes that after the completion of the first life cycle, the product is not discarded (e.g., in the case of bottles after they have been emptied) but begins another life cycle with the same function (e.g., beverage bottles collected by manufacturers are filled again) or a completely different function without any processing operations, e.g., using yogurt containers as flower pots. [29,61]. Most often, in the case of a contaminated (disturbed) polymer waste (system A, Figure 3), certain preparatory operations (e.g., system B, Figure 3) are necessary, such as sorting, washing, drying, or repair. Reuse operations can take place in a closed loop within a single enterprise or company [61]. A system B example would be the refilling of beverage bottles.

2.1.2. Recycling

Recycling is the next way to manage contaminated EoL polymer materials. There are mechanical, energy, and chemical recycling methods (Figure 2), with priority being operations resulting in the highest recovery of materials and energy and the lowest energy demand in processing.

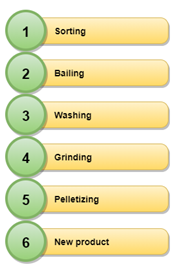

Mechanical recycling includes operations of the mechanical processing of polymer waste without interfering with their chemical structure [9,73]. As a result of mechanical recycling, pellets are obtained, which are then used as input material in the creation of new products [9]. Mechanical recycling takes into account the elimination of disturbances, e.g., (Figure 4): sorting, bailing, washing, shredding, pelleting, and the production of a new product [64,73]. The ASTM D7209 standard [74] introduced the notions of primary and secondary recycling, which basically cover activities in mechanical recycling. Primary recycling most often refers to closed-loop recycling in the pre-use phase, when waste directly from production goes back to the extrusion process, e.g., in the case of obtaining incorrectly shaped bottles that do not meet the requirements [64,65]. In turn, secondary recycling concerns post-consumer waste, which is processed in accordance with the diagram in Figure 4, as a result of which new materials are created, often with worse properties [64,65].

Figure 4. The typical route of contaminated plastics waste processing in mechanical recycling according to [64,65].

Chemical recycling is defined as “a process which converts contaminated polymeric waste by changing its chemical structure to produce substances that are used as raw materials for the manufacturing of new products, which excludes [the] production of fuels or means of energy generation” [75]. There are many technologies for chemical recycling (see Figure 2), and some of them need a high temperature to break the polymer bonds, for example pyrolysis, gasification, and thermal cracking [65,66]. In this case, the waste also requires appropriate preparation. Chemical recycling is also called tertiary recycling [64,65].

Energy recycling or energy recovery (and also quaternary recycling according to ASTM D7209 [74]) covers operations aimed at recovering the energy contained in disturbed polymer materials [64,65]. Energy recovery is most often carried out during waste incineration in waste incineration plants, fluidized bed furnaces, and the metallurgical industry (Figure 2). Then, the amount of polymer waste, which cannot be reprocessed in mechanical recycling and would be deposited in landfills, is reduced. The recovered energy is mainly used to produce heat and electricity [64–66,76]. Energy recovery is a controversial method of recycling due to the emissions resulting from the combustion of contaminated polymers, although in recent years, a number of solutions have been introduced to prevent the release of harmful substances during combustion or reduce their amount [66–69].

2.1.3. Disposal

Disposal is the last option of EoL management of contaminated polymer materials according to the EU Waste Framework Directive [29], and at the same time, it is the least appropriate method of ending the life cycle of products from the point of view of the circular economy. Disposal is defined as [62] “any operation which is not recovery even where the operation has as a secondary consequence of the reclamation of substances or energy”. The two most common disposal methods are landfilling and incineration without energy recovery. In both cases, the material and energy potential is lost because they will not be used (they will not replace the natural, original raw materials) [62,63].

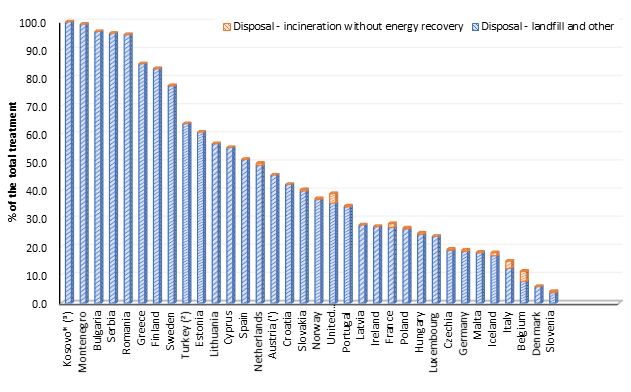

Landfilling is considered to be the simplest and cheapest method of managing EoL disturbed polymer materials, although it requires large land areas for this purpose. Landfilling may cause soil and groundwater pollution with toxic substances derived from the decomposition of polymer waste. Currently, it is popular to build biogas plants that extract methane from the decomposition of organic polymer waste [63,68,76]. In many EU countries, according to Eurostat data, landfilling is the dominant form of waste management (Figure 5) [77].

The number of contaminated polymeric materials, which was increasing from year to year, and the lack of areas for their storage resulted in the spread of waste incineration. Incineration is primarily aimed at reducing the amount of waste deposited in landfills [67–69]. Incineration was a very popular method of waste management, right after landfilling, until 1980, when it was found that incineration plants emit significant amounts of emissions in the form of dioxins and volatile heavy metal compounds, and then air pollution control (APC) technologies were introduced [67]. With the development of technology and the introduction of climate protection directives and waste management strategies, incineration is carried out with energy recovery (energy recycling), and in some countries, the incineration of waste (without energy recovery) has been completely prohibited [68]. In 2018, Belgium (3.6%) had the largest share of incineration without energy recovery in all forms of waste management, which was followed by Great Britain (3.4%) (Figure 5) [77].

Figure 5. The share of different types of disposal in total treatment options of waste in EU countries in 2018. Own work based on Eurostat data [77].

2.2. End-of-Life Contaminated Polymer Material Potential and Scale

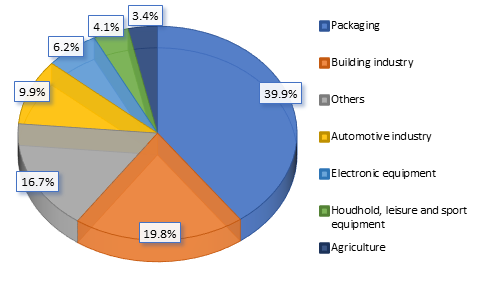

Polymer materials are a group of materials with various properties, which allowed them to be widely used in many industries, including construction, food, electronics, automotive, chemical, and gardening industries, of which the largest share is packaging (39.9% in 2018) and building (19.8% in 2018) (Figure 6) [78]. According to the PlasticsEurope report, the total demand for plastics in Europe was 51.2 million tonnes [78].

Figure 6. The contribution of different industries in plastics demand in Europe in 2018. Own work based on data published in [78].

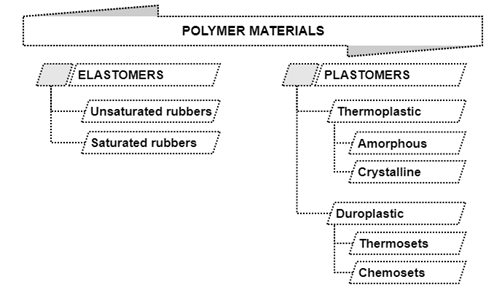

Polymer materials currently available on the market can be classified into elastomers, which are characterized by the reversibility of deformations resulting from the application of loads, and plastomers, which, when deformed, keep their shape, and their deformability is related to the temperature [79,80]. Plastomers are divided into thermoplastics, which soften under the influence of temperature and can be shaped many times, which is an obvious advantage in recycling processes, and duroplasts, which change their chemical structure under the influence of temperature. Special systems of bonds are formed, hardening the structure of the material, which means that they cannot be remelted or reshaped and make reprocessing difficult [79,80]. The full classification of polymers is shown in Figure 7.

The commonly used thermoplastics include the following: Polyethylene (PE), Polyamides (PA), Polypropylene (PP), Polycarbonate (PC), Acrylonitrile butadiene styrene (ABS), Ethylene-vinyl alcohol (EVOH), Styrene acrylonitrile (SAN), Polyether ether ketone (PEEK), Polyoxymethylene (POM), Expanded polystyrene (foamed) EPS, Polysulfone (PSU), Polystyrene (PS), Thermoplastic elastomers (TPE), Polyethylene terephthalate (PET), Polymethyl methacrylate (PMMA), Polyvinyl chloride (PVC), Fluoropolymers [78]. The commonly known thermosets are the following: Phenol–formaldehyde resins, Polysiloxanes (Silicones), Vinyl–ester resins, Polyesters, Urea–formaldehyde resins, Polyurethanes (PUR), Polyimides, Melamine resins, epoxy resins, acrylic resins [78]. The largest percentage of the mentioned plastics used in 2018 was Polypropylene and Polyethylene [78].

Figure 7. Classification of polymeric materials according to [79,80].

Due to their properties, polymers were divided into seven groups according to types of recyclable waste, which were specially marked for easier identification during sorting and waste collection (Figure 8) [81].

According to PlasticsEurope data, 29.1 million tonnes of contaminated polymer materials were collected, and a further upward trend is observed [78]. The dominant way of waste management was energy recovery (42.6%), followed by recycling (32.5%) and landfilling (24.9%) [82]. Both energy recovery and recycling show an upward trend every year, while a decrease in the number of waste subjected to landfilling is observed [78]. Nevertheless, it is evident how a huge challenge is the management of contamination during the use of polymers materials, which is expressed, among others, by the still significant share of waste storage as well as a large share of energy recovery in the total balance of polymer materials EoL management methods.

Figure 8. Designations for different groups of plastics in recycling according to [81].

To measure the level of recyclability of different materials, the recyclability indicators were proposed by some researchers. Recyclability describes the ability of materials to be recycled with the use of available technologies. In an ideal situation, 100% of a material can be reused, recycled, or regenerated without generating losses in material and energy as well as producing wastes. In fact, bearing in mind actual technological possibilities, the ideal state is not reached. As was presented in a Plastics Europe report, in 2018, 35.5% of polymer waste was recycled, and 42.6% was subjected to energy recovery processes [82]. In total, about 75.1% of all plastics waste was subjected to recycling and energy recovery processes.

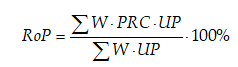

One of the indicators proposed by the Organisation for Economic Co-operation and Development (OECD) in the OECD Sustainable Manufacturing Toolkit to measure the level of recyclability is recyclability of products (RoP), which allows estimating the average recyclability of all products manufactured in a company in the reference year [83]. The RoP can be calculated according to the equation:

|

(1) |

where W—Weight of a product unit, PRC—Proportion of recyclable content, UP—Units produced. This indicator can take values from 1% to 100%. It does not give information about number of products actually recycled [83].

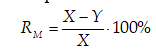

In report [84], a different understanding of recyclability was proposed. The measure of recyclability was connected with the mass of the products and described by the equation:

|

(2) |

where RM—recyclability by mass (%), X—mass of the recycled product (tonne), Y—material losses during recycling process (tonne). The advantage of this indicator is its ease of interpretation and implementation. It gives real information about the value of the product recycled; however, it does not take into account the differences between reused and recycled materials [84].

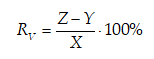

Other methods describe recyclability by monetary (cost) value. The WRAP report [84] presents two approaches for estimating the recyclability based on value. The first approach defines the difference in cost for processing products from recycling and from primary sources, referring to the cost of the product from primary sources [84]:

|

(3) |

where Z—cost of product B made from primary raw materials ($Z/tonne), Y—cost of product B reprocessed from product A ($Y/tonne), X—cost of production of product A ($X/tonne).

The second approach describes recyclability as a ratio of product A into product B reprocessing cost ($Y/tonne) and product A production cost ($X/tonne), according to the following equation [84]:

|

(4) |

The biggest drawbacks of assessing recyclability by value are difficulties in the estimation of real/detailed cost of products/material reprocessing, especially if only some percentage of material is reprocessed. The mentioned two approaches do not differentiate the quantities of different savings of material reprocessing [84].

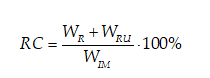

Currently, polymeric materials produced on the basis of recycled materials are determined by the recycled content index, which describes the content of recycled materials in the total weight of the product [85]:

|

(5) |

where WR—total weight of recycled material, WRU—total weight of reused material, WIM—total weight of material input.

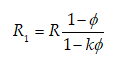

When considering the possibility of recycling the contaminated polymer materials, it should not be forgotten that the recycling processes change the properties of the processed materials. As a rule, deterioration of the functional and mechanical properties of polymers is observed. Some materials are more susceptible to reprocessing (they can be reused and processed several times), and unfortunately, some of them can only be processed once. Bearing in mind the assumptions of the circular economy, it is necessary to determine how many times a given material can be recycled without a significant loss of properties. The following indicator was proposed to assess the recirculation of plastics [86]:

|

(6) |

where R1—initial material property, —the degree of material reprocessing, which determines the mass fraction, which is constantly returned for processing (Φ < 1), k—coefficient of deterioration of the material properties, i.e., the number by which one should multiply e.g., the strength R1 of the material introduced into processing in order to calculate its strength R2, which it will show after leaving the processing (k < 1). This index describes the dependence of the selected property of input material R1 on this property of material after processing R2 after a known number of cycles n.

2.3. Importance of the Shredding Process in Recycling Engineering

To begin with, we consider the scale of contaminated polymer materials shredding. So far, no quantitative analysis of the materials that are subjected to shredding has been performed. This is a complex issue, because the contaminated part of plastics may require prior separation from multi-plastic elements, which is also very often done in comminution and separation processes. The study [48] shows the estimated percentage share of wastes (not only polymer wastes), which are subjected to shredding. Assuming a similar scale, it is possible to estimate the amount of disturbed polymer wastes subjected to shredding depending on the EoL management method. Table 1 shows the estimated scale of polymers shredding in 2018 in the EU countries based on the share of shredded plastics assumed according to [48].

Referring to the estimated data presented in the Table 1, about 25% of plastic waste is shredded annually, which gives over 7 million tons. Globally, this number will increase due to a greater amount of disturbed polymeric materials generated. Only the scale of the process shows the great importance of shredding. It should be emphasized that, for some elements, shredding is a necessary stage in EoL management processes, e.g., in mechanical recycling of car tires [25,87–89], recycling of photovoltaic modules [17,18], recycling of wind power blades [16,90,91], or car recycling [92–94], where shredding is used to reduce the size and separate the individual materials that make up the elements, so the estimated amount of shredded waste can be much higher. According to the data published in [81], up to 100% of polymer materials are shredded for recycling, which significantly increases the share (up to 41.7%) of end-of-life materials that need to be shredded.

Table 1. Estimated scale of shredding EoL polymer materials in EU countries in 2018.

|

End-of-Life Option |

Total Amount of Waste 1, mln t |

Percentage of Waste Shredded 2, % |

Mass of Waste Shredded, mln t |

|

Landfill |

7.2 |

2 |

0.144 |

|

Energy Recovery |

12.4 |

20 |

2.480 |

|

Recycling |

9.5 |

50 (100 3) |

4.750 (9.500) |

|

Sum |

29.1 |

- |

7.374 (12.124) |

1 data based on Eurostat [78], 2 data based on [48], 3 data based on [81].

In order to determine the need and importance of comminution processes in recycling, or in the management of contaminated polymeric materials ending their life cycle, it is necessary to ask and answer the basic question: what is the purpose of the treatment of reducing the dimensions of polymer materials that ended their life cycle?

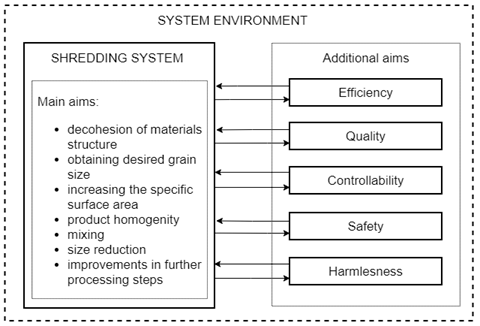

The purposes of shredding in the context of EoL management are closely related to further use, the chosen path of development, and further processing [45,95–97]. J. Flizikowski in [45] distinguishes between the main and additional goals (Figure 9).

The most important goal is to reduce the dimensions to facilitate the following, among others: separation of materials, transport by conveyors, pneumatic transport, mixing of ingredients, as well as reducing transport costs and the storage area due to the reduction of waste volume [45,48,95–97].

With regard to landfill processes, shredding can be done to reduce the volume of waste, to clean up and stabilize the landfill, and to protect the bottom seals of the landfill. Usually, self-propelled machines are used to crush and break polymer materials into fairly large particles [48].

In energy recovery processes in the context of incineration, shredding is carried out in order to reduce the content of flammable substances in the residues, to improve transport and dose to and from the combustion chamber, and to facilitate mixing processes. The material sizes are reduced to dimensions in the range of 300–500 mm by means of various types of mills, e.g., rotary shears, hook shredders. Depending on the needs of the incineration plants, from 10 up to 100% of the prepared charge is reduced in size [48].

Figure 9. Objectives of the polymer materials shredding process in recycling. Own study based on [45,95–97].

In the combustion of Refuse-Derived Fuel (RDF), the materials are shredded for the needs of fluidized beds and materials transport. Wastes are crushed into particles with dimensions from approximately 50 to 100 mm, although steelworks require fragmentation of the charge at a level of 15 mm, and cement kilns require one below 10 mm. Shredding usually takes place in two stages: the first stage is pre-shredding with e.g., rotary shears and hook shredders, and the second stage is secondary shredding to smaller particles with hammer mills, rotary shears, or impact mills [48].

In the case of shredding for recycling, the aim is in itself to reduce the form and dimensions and to facilitate the separation of different materials. The size of the particles after grinding depends on the way the material is used in recycling, e.g., whether the material will be used as a filler or the regranulate will be made of it, etc. In general, recycling uses a full range of grinding devices; very often, these are devices dedicated to the grinding of a given material [48].

This entry is adapted from the peer-reviewed paper 10.3390/polym13050713