The recycling of fiber reinforced composite materials will therefore play an important role in the future, in particular for the wind energy, but also for aerospace, automotive, construction and marine sectors to reduce environmental impacts and to meet the demand.

- composites

- recycling

- composite materials

1. The History, Development and State-of-the-Art of the Composite Industry

Composite materials are the materials made from two or more constituent materials with significantly different physical and/or chemical properties that, when combined, produce a material with characteristics different from the individual components. Historically, the use of composite materials is dated back to about 3000 years ago in ancient Egypt, where natural fiber straws were used as reinforcements to build walls. Over the years, more durable materials were developed and today we have fiber reinforced composites that can also be produced in large scales [1]. Since 1932, the Fiber Reinforced Plastics (FRPs) have become materials widely used in an automobile, aerospace, marine, offshore, structural and transportation industries, public transport vehicles, buildings, sports equipment, pleasure boats, wind energy and wave energy converters [1][2]. This is due to FRPs having an excellent mechanical performance, light weight and durability—FRPs have great advantages due to their corrosion resistance and high strength-to-weight ratio [1][3]. The history of wind turbines, however, dates back to 1887, when a first known wind turbine was built in Scotland to produce electricity, whereas implementation of composite blades was first mentioned almost a century later, starting from 1975 [4]. Since then, the composite and wind energy industries have been inseparable. According to Hartman [5], the timeline of the composite industry can be divided into five periods of its development:

- 1932–1946, Start-of-the-Industry Phase. Applications: FiberglasTM by Owens Corning, commercial boat hulls, FRP car body by Stout Scarab. Processes: Chopped Strand Mat (CSM)/Continuous Filament Mat (CFM) process, resin systems developed, hand layup process.

- 1947–1960, Niche Applications Phase. Applications: Commercial FRP car body, composite panels (Trucks), helicopter blades for Alouette II. Processes: chopped strands process, carbon fibers developed, direct roving process, spray-up process, pultrusion process.

- 1961–1978, Industrial Applications Phase. Applications: Glass Reinforced Thermoplastics, Sheet Molding Compound (SMC) air deflector, glass mat reinforced shingles, commercial wind turbine blades. Processes: filament winding process, Sheet Molding Compound (SMC) process, high-strength S-glass process, Kevlar (aramid) fibers developed.

- 1979–1996, Corrosion Resistance Phase. Applications: Composite storage tanks, fiberglass windows, hybrid front-end modules. Processes: continuous fiber thermoplastic laminates, long-fiber thermoplastics, resin infusion process.

- 1997–2014, Hybrid Technology Integration Phase. Applications: Commercial Wind turbine (major 1990s wave of wind power), commercial aircraft, structural automotive parts, consumer electronics. Processes: hybrid molding technologies.

- 2000–2020s, State-of-the-Art Phase, also Composite Recycling Phase. The highly detailed timeline by Hartman was presented in 2014 and needs a few updates (and a sixth period in the timeline). During the recent years, ageing and corrosion studies have reached a new wave of interest, due to novel concepts and technologies being available [6][7][8][9]. Furthermore, composite materials recycling, started during the Hybrid Technology Integration Phase, is now one of the fastest growing niches of the composite research. Health monitoring also deserves a mention in the modern day [10]. The trend during the last two decades was an attempt to save weight, reduce the cost of composite materials, and to develop the composites recycling technologies [1][11][12]. Judging on the appearing number of publications in the recent two decades, the scientific interest in this composite recycling topic has grown significantly (about three-to-four-fold), and the scientific interest in composite recycling is accelerating with every passing year in the last decade alone [1].

2. Recycling Techniques

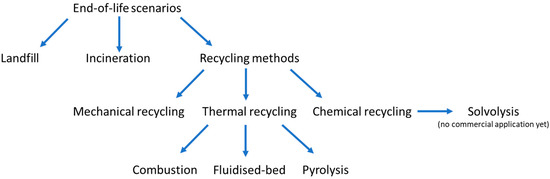

There has been considerable concern for the environment due to the continued use of finite resources and the need to address waste management, which has led to improved recycling of materials. Landfilling has in many cases been a comparatively economical method of disposing of waste based on polymer composites, since polymers are generally more difficult to recycle and the recycling process is also expensive. Typically, the production of carbon composites produces up to 40% scrap material, which can end up in landfills or waste incineration [13]. To protect the environment, therefore, in addition to the use of economic means such as taxes, rules have been introduced to encourage recycling [14]. Waste management had gained enormously in importance in the European Union and to reduce it, waste prevention should start at the production stage by reusing a product, the recycled material, the incineration of waste and the reduction of landfill. Compared to fast melting thermoplastics, thermoset composites have a cross-linked structure with the inability to be formed. Several thermoset polymers, such as polyurethane, can be easily converted into their starting monomer. Conversely, commercially available thermosetting resins, such as polyester and epoxy resin, are difficult to depolymerize into their starting monomers [15]. At present, it can be assumed that full recovery of fibers, known as a direct structural recycling approach, will benefit the composites sector. The recycled fibers from this approach have an additional market value due to the low consumption of natural resources, energy and labor, together with a near virgin fiber quality [16]. As far as the breakdown of recycling technologies of research and industry is concerned, solvolysis (24%), pyrolysis (31%) and mechanical grinding (18%) are characterized by the highest acceptance. 20% make up so-called “other” technologies [15]. Numerous methods have been investigated and established. These include mechanical, thermal and chemical-based recycling approaches, as the choice of methods depends on the type of material to be recycled and the application in which it is reused [11]. Furthermore, it is difficult to determine a standard recycling method among the various methods [17]. Different recycling processes have been reported and promoted for thermoset composites, as it is depicted in Figure 1. Basically, three classification processes have been reported so far: mechanical, chemical and thermal recycling. Mechanical recycling consists of mechanical shredding processes to reduce the waste into recyclates. Thermal recycling involves thermal processes to break down the waste material for material and energy and the chemical recycling involves dissolving the matrix from the fibers in a reactive medium.

Figure 1. Representation of End-of-Life (EoL) scenarios of carbon fiber/glass fiber–reinforced composites.

Technology Readiness Level (TRL) is a framework used in many variations across industries to provide a measure of technology maturity from ideation (basic principles) to commercialization [18]. Incineration and landfilling are considered to be at TRL 9, which means it is present as a currently operating system. Pyrolysis for carbon fibers and mechanical milling for glass fiber applications achieved average values of 8.3 and 8.2 and a median of 8, which places them at TRL 8. As far as conventional pyrolysis of recycled carbon fibers is concerned, the process is commercially available on an industrial scale (e.g., ELG Carbon Fibre Ltd., Bilston, UK and CFK Valley Stade Recycling GmbH & Co. KG, Wischhafen, Germany) [19]. Pyrolysis for glass fibers and mechanical grinding for carbon fibers had a mean of 6.25 and 6.3 respectively with a median of 7. Fluidized bed pyrolysis and solvolysis had a mean value of 4.2 and 2.24 (median of 4). Microwave heating had a mean value of 3.2 (median of 3) [15].

3. Effect of Recycling on Composite Properties, Regeneration and Future Applications

Lightweight constructions enable to reduce fuel consumption and the associated emissions of air and car traffic [20]. It has been shown that a 10% reduction in the structural weight of a vehicle can lead to a 6–8% reduction in fuel consumption [21].

Recyclability is particularly important for the automotive industry, which is confronted with the ELV Directive (2000/53/EC) stipulating at least 95% of a new vehicle must be recycled by average weight at the end of its life (EoL) by January 2015 [22]. Therefore, it is expected that material recycling will attract more attention for research projects and government investments as a promising approach to improve the circular economy and sustainability. Most products made of carbon fiber reinforced plastic (CFRP) are durable and still at the beginning of the product life cycle. An appropriate selection of a recycling strategy depends on the fiber reinforcement and matrix of a composite structure. If certain products should become established on the market, it will be important how the recycling of the production residues can be implemented and what happens at the end of the product life cycle. Furthermore, established design protocols and reliable end-to-end predictive modelling techniques for composites and components are lacking. The recycling rules that need to be included in the whole design process are still under formalization. Decisions which are made today influence the use of the product later as described by Perry et al. [23].

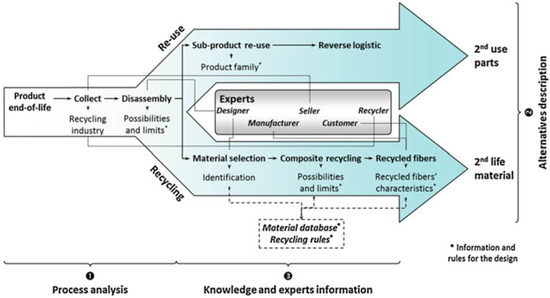

Figure 2 shows the core elements that make up the skeleton of the end-of-life of a product [23]. Each phase has its own limits and constraints that must be integrated. Different stakeholders in the cycle need to be considered to identify the information which is available or needed, and who obtains or requires it [24]. The expected data and decision rules which are used to move from one phase to another should be considered. It is important to consider that the different time frame between the real recycling process and the design phase of the parts increases the difficulties of integration. For existing and robust end-of-life pathways, constraints and reuse of materials are well known. For new recycling processes, robust validation may take time, yet designers need to make decisions. Research and development are counting on technological breakthrough to guide developments in recycling. Innovations are not only needed in the recycling phase, but for all important phases. It is important to improve disassembly techniques (see Design for Assembly/Disassembly approaches) or selection efficiency [25][26]. At the end of the process, it is important to develop innovative and valuable uses to compete with new raw materials having similar properties. As far as composites are concerned, new processes allow the recovery of fibers with very low deformation and breakage compared to the original reinforcement in the original composite part. In this regard, supercritical fluids may hold out the prospect of such possibilities [27][28]. However, the problem of de-alignment and re-alignment of recycled fibers remains. The competences and skills to spin and weave the fibers have been integrated by recycling. Other alternatives consist of reprocessing medium sized flat rectangular pieces of 1D pseudo-unidirectional or 2D woven recovered carbon fabrics. The innovation is to propose an approach for the construction of parts. Specific studies need to identify the mechanical properties and an efficient material characterization strategy from recycled fibers to the final product according to the product design development phase, [29] including design material constraints and a life cycle analysis (LCA) with different environmental and financial impact categories of rCF in CFRP [30]. This pyramidal testing problem, at all stages of the product life and at all scales (i.e., from fiber to structure) must integrate this uncertainty, but in real case tests [31][32].

Figure 2. Analysis of the recycling process, in the perspective of the product’s design specifications and recycling process information [23].

This entry is adapted from the peer-reviewed paper 10.3390/jcs5010028

References

- Amaechi, C.V.; Agbomerie, C.O.; Orok, E.O.; Ye, J. Economic Aspects of Fiber Reinforced Polymer Composite Recycling. In Encyclopedia of Renewable and Sustainable Materials; Elsevier BV: Oxford, UK, 2020; pp. 377–397.

- Suschem Materials Working Group. Polymer Composites Circularity. White Paper, Suschem. 2018. Available online: http://www.suschem.org/publications (accessed on 15 January 2021).

- Gharde, S.; Kandasubramanian, B. Mechanothermal and chemical recycling methodologies for the Fibre Reinforced Plastic (FRP). Environ. Technol. Innov. 2019, 14, 100311.

- Shahan, Z. History of Wind Turbines. Renewable Energy World. 2014. Available online: https://www.renewableenergyworld.com/2014/11/21/history-of-wind-turbines/ (accessed on 12 December 2020).

- Hartman, D. Advances in reinforcement materials (glass fiber materials). In Proceedings of the Composites and Advanced Materials Expo (CAMX), Orlando, FL, USA, 13–16 October 2014; pp. 1–25.

- Echtermeyer, A.T.; Gagani, A.I.; Krauklis, A.E.; Mazan, T. Multiscale Modelling of Environmental Degradation—First Steps. In Continuum Mechanics with Eulerian Formulations of Constitutive Equations; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2017; Volume 244, pp. 135–149.

- Keprate, A.; Moslemian, R. Multiscale Damage Modelling of Composite Materials Using Bayesian Network. In Proceedings of the Lecture Notes in Civil Engineering; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2021; Volume 110, pp. 135–150.

- Rocha, I.; Van Der Meer, F.; Raijmaekers, S.; Lahuerta, F.; Nijssen, R.; Mikkelsen, L.P.; Sluys, L. A combined experimental/numerical investigation on hygrothermal aging of fiber-reinforced composites. Eur. J. Mech. A Solids 2019, 73, 407–419.

- Krauklis, A.E.; Echtermeyer, A.T. Long-Term Dissolution of Glass Fibers in Water Described by Dissolving Cylinder Zero-Order Kinetic Model: Mass Loss and Radius Reduction. Open Chem. 2018, 16, 1189–1199.

- Krauklis, A.E.; Gagani, A.I.; Echtermeyer, A.T. Near-Infrared Spectroscopic Method for Monitoring Water Content in Epoxy Resins and Fiber-Reinforced Composites. Materials 2018, 11, 586.

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99.

- Overcash, M.; Twomey, J.; Asmatulu, E.; Vozzola, E.; Griffing, E. Thermoset composite recycling—Driving forces, development, and evolution of new opportunities. J. Compos. Mater. 2017, 52, 1033–1043.

- Recycled Carbon Fibre Ltd. Converting Composite Waste into High Quality Reusable Carbon Fibre. Available online: http://www.recycledcarbonfibre.com (accessed on 23 December 2020).

- Bos, G. EU waste legislation and the composites industry. In Proceedings of the Seminar on Recycling of Composite Materials, IFP SICOMP, Molndal, Sweden, 14–15 May 2002.

- Rybicka, J.; Tiwari, A.; Leeke, G.A. Technology readiness level assessment of composites recycling technologies. J. Clean. Prod. 2016, 112, 1001–1012.

- Asmatulu, E.; Twomey, J.; Overcash, M. Recycling of fiber-reinforced composites and direct structural composite recycling concept. J. Compos. Mater. 2013, 48, 593–608.

- Gopalraj, S.K.; Kärki, T. A review on the recycling of waste carbon fibre/glass fibre-reinforced composites: Fibre recovery, properties and life-cycle analysis. SN Appl. Sci. 2020, 2, 1–21.

- Nakamura, H.; Kajikawa, Y.; Suzuki, S. Multi-level perspectives with technology readiness measures for aviation innovation. Sustain. Sci. 2012, 8, 87–101.

- Van Oudheusden, A. Recycling of Composite Materials. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2019. Available online: http://resolver.tudelft.nl/uuid:0749ed5c-7aeb-4275-abee-0f904a08ea4d (accessed on 21 December 2020).

- Bachmann, J.; Hidalgo, C.; Bricout, S. Environmental analysis of innovative sustainable composites with potential use in aviation sector—A life cycle assessment review. Sci. China Ser. E Technol. Sci. 2017, 60, 1301–1317.

- Chu, S.; Majumdar, A. Opportunities and challenges for a sustainable energy future. Nat. Cell Biol. 2012, 488, 294–303.

- Ec.europa.eu. End of Life Vehicles—Waste—Environment—European Commission. 2020. Available online: https://ec.europa.eu/environment/waste/elv/index.htm (accessed on 21 April 2020).

- Perry, N.; Pompidou, S.; Mantaux, O.; Gillet, A. Composite Fiber Recovery: Integration into a Design for Recycling Approach; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2014; pp. 281–296.

- Bernard, A.; Ammar-Khodja, S.; Perry, N.; Laroche, F. Virtual engineering based on knowledge integration. Virtual Phys. Prototyp. 2007, 2, 137–154.

- Boothroyd, G.; Alting, L. Design for Assembly and Disassembly. CIRP Ann. 1992, 41, 625–636.

- Aymonier, C.; Loppinet-Serani, A.; Reveron, H.; Garrabos, Y.; Cansell, F. Review of supercritical fluids in inorganic materials science. J. Supercrit. Fluids 2006, 38, 242–251.

- Loppinet-Serani, A.; Aymonier, C.; Cansell, F. Supercritical water for environmental technologies. J. Chem. Technol. Biotechnol. 2010, 85, 583–589.

- Kromm, F.; Lorriot, T.; Coutand, B.; Harry, R.; Quenisset, J. Tensile and creep properties of ultra high molecular weight PE fibres. Polym. Test. 2003, 22, 463–470.

- Laurin, F. Approche Multiéchelle des Mécanismes de Ruine Progressive des Matériaux Stratifiés et Analyse de la Tenue de Structures Composites. Ph.D. Thesis, Univ de Franche-Comté, Vesoul, France, 2005.

- Meng, F. Environmental and Cost Analysis of Carbon Fibre Composites Recycling. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2017.

- Puleston, D.J.; Forster, I.J. (Avery Dennison RFID Division) The Test Pyramid: A Framework for Consistent Evaluation of RFID Tags from Design and Manufacture to End Use. Paper. 2010. Available online: https://www.rfidjournal.com/wp-content/uploads/2019/07/76.pdf (accessed on 23 December 2020).

- Ladevèze, P.; Puel, G.; Romeuf, T. Lack of knowledge in structural model validation. Comput. Methods Appl. Mech. Eng. 2006, 195, 4697–4710.