The genus Acacia belongs to the subfamily Mimosoideae of the family Fabaceae. It comprises a large group of more than 1350 species, widely distributed throughout tropical and warm temperate areas of the world. Most of the species are native to Australia but are spread all over the world because of their wide variety of uses and economic importance such as for ornamental purposes, for sand and dune stabilization, as a fuel through the production of woodfuel and charcoal, as an important source of fodder, tannins for the leather industry, gums, and essences for perfumes.

- Acacia spp.

- invasive species

- nanomaterials

- adsorbents

1. Introduction

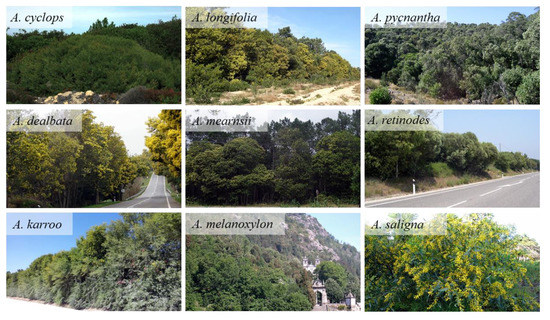

Acacia spp. are considered invasive in many territories around the world [1]. Amongst invasive Acacia spp., A. cyclops A. Cunn. ex G. Don fil., A. dealbata Link, A. longifolia (Andrews) Willd., A. melanoxylon R. Br., A. saligna (Labill.) H. L. Wendl., A. retinodes Schlecht., A. karroo Hayne, A. mearnsii De Wild. and A. pycnantha Bentham are the most representative. Figure 1 shows examples of invaded areas by Acacia spp. in the Portuguese territory.

Figure 1. Examples of invaded areas by Acacia spp. in the Portuguese territory (elaborated from images taken from Plantas Invasoras em Portugal (http://invasoras.pt), accessed on 1 November 2020).

The threat to protected areas, and the negative impacts on the ecosystems and on the productivity of the forest sector have motivated expensive removal initiatives by local authorities in order to minimize its proliferation [2], generating high amounts of biomass which is usually burned for energy production or landfilled. The valorization of some Acacia spp. for energy may have a positive contribution to the economic sustainability of the involved operations [3], but this option is often limited due to collection and transportation costs. However, finding high-value applications for these species can contribute to overcome these costs and make the process economically sustainable. Furthermore, given the magnitude of the invasion, the radicular system of these species, the dispersion of seeds in the natural environments, and the years necessary before soil nutrients and processes return to similar pre-invasion levels, their elimination by removal has been considered unfeasible from practical and economical perspectives [4], and has the potential of by itself to cause significant environmental impacts, namely the destabilization of large volumes of soil.

Acacia spp. fractions, namely bark, wood, leaves, flowers, pods, seeds or roots, are rich sources of bioactive secondary metabolites (e.g., amines and alkaloids, cyanogenic glycosides, cyclitols, fatty acids and seed oils, gums, non-protein amino acids, terpenes, tannins and other flavonoids and simple phenolics) [5][6][7] that have been used in traditional medicine for a wide range of ailments, such as diabetes, worm infection, dysmenorrhea, eczema, malaria, gout, jaundice, abdominal pain, kidney problems, constipation, leprosy, piles, pneumonia, rheumatism, fever and cancer [8]. These secondary metabolites can play an important role in reducing oxidative stress, by acting as antioxidants, and possess antimicrobial properties, which are important in the development of alternatives to antibiotics due to the increasing resistance to the conventional antimicrobial agents [8]. Besides, other important biological activities, such as anti-inflammatory, antiviral, anticancer, antidiabetic, immunomodulatory, hepatoprotective, cardioprotective and anthelmintic, were already reported for extracts obtained from Acacia spp. [8] In this way, the production of bioactive preparations of Acacia spp., either from well-established areas or from the biomass generated in the control operations, can be an option to bring an important economic return, overcoming expenses with collection and transport, while simultaneously contributing to motivating forest cleaning and management actions, reducing the risk of fires and improving the social-economic development of rural areas. Moreover, the valorization of its flowers, as an example, will have a positive contribution to the control of the proliferation by preventing the formation of seeds, thus minimizing the spread through the seed dispersal route [9]. Other well-studied applications of Acacia spp. biomass fractions with the potential to contribute to the industrial exploitation of these species, and therefore to the control of their unregulated widespread, include its incorporation in polymers and composites, micro and nanomaterials or as adsorbents.

2. Material Applications of Acacia spp. Biomass

In addition to bioactive extracts and aromatic oil, with potential uses in the nutraceutical, pharmaceutical, cosmetic, perfume, food or feed industries, a diversity of other interesting materials can be obtained from Acacia spp. Some of these materials are already available on a commercial scale and will not be further discussed. These include the use of A. mearnsii for the production of tannins for the leather industry and for the manufacture of adhesives, which has been implemented since the sixties, as well the manufacture of coagulants used in the wastewater treatment, which were also commercialized about forty years ago [10][11][12]. Besides these known applications, recent studies have shown that the potential of the Acacia spp. biomass or extracts obtained from it can have new applications with high added value, as in the polymer and composite industries, in the production of nanomaterials, in the manufacture of new adsorbents for the removal of pollutants as alternatives to conventional activated carbon, or wood and steel protection (Table 1).

Table 1. Material applications from Acacia spp. components.

| Acacia spp. | Component Used | Product/Application |

|---|---|---|

| A. dealbata | Bark and wood | Wood protection |

| A. karroo | Charcoal (activated) | Adsorbent (heavy metals) |

| A. mearnsii | Tannin extract from bark | Stabilizer for low-density polyethylene films |

| Superparamagnetic nanoparticles | ||

| Nanocellulose films | ||

| Nanofiber membranes | ||

| Encapsulated nanoparticles | ||

| Lactic-co-glycolic acid microparticles drug carriers | ||

| Spent bark from tannin production | Filler in polypropylene composites | |

| Cellulose nanocrystals | ||

| Adsorbent (dyes) | ||

| Biochar from woodchips (activated) | Adsorbent (ammonium) | |

| A. melanoxylon | Water extract from leaves | Colloidal silver nanoparticles |

| A. saligna | Silver nanoparticles from water leaves extract | Adsorbent (dyes) |

| Water leaves extract | Corrosion inhibitor |

2.1. Polymers and Composites from Bark

The growing awareness of sustainability in the polymer industry has led to the development not only of biopolymers but also of bio-based additives, such as stabilisers, that are often required to extend the service life of the material. Bridson et al. [13] investigated the use of a commercial tannin extract of A. mearnsii as a stabilizer of linear low density polyethylene films. The authors successfully increased the thermo-oxidative and UV stability of the films when using tannin extract compounded with co-polymers (ethylene vinyl alcohol, maleic anhydride modified polyethylene or ethylene acrylic ester maleic anhydride terpolymer) as additives. The tannin extract improved the strength and elongation retention of the polymer after the accelerated weathering, performed with UV light, elevated temperature and humidity to simulate in-service environmental conditions, probably due to radical scavenging reactions that reduces oxidation and limits the damage to the polymer [13]. The A. mearnsii extract is already produced at a commercial scale, so it can represent a cost-competitive additive for this purpose for industrial applications.

After the extraction of tannins from the bark of A. mearnsii, hundreds of tons of bark residue are produced, which represents an environmental problem if a proper strategy is not adopted. This residue is usually burned, but the alternative use of exhausted bark as a filler in polypropylene composites was investigated by Taflick et al. [14] The authors studied the impact of the addition of bark in the mechanical and thermal properties of the produced materials, using maleic anhydride as a compatibilizer to improve the adhesion between the matrix and the bark particles. The incorporation of 10% of bark particles with sizes ranging from 106 to 425 nm produced composites with higher impact properties, higher crystallization and degradation temperatures and comparable tensile strength, compared with the polymer matrix without the addition of bark [14]. These composites were considered suitable for use in non-structural applications, such as in decoration, sound isolation and household goods, bringing the advantages of reducing the environmental impact of using synthetic polymers and adding value to an abundant waste formed after tannin production from A. mearnsii bark.

2.2. Micro and Nanomaterials from Leaves and Bark

Shashanka and Kumara Swamy [15] successfully synthesized colloidal silver nanoparticles using a water extract of leaves of A. melanoxylon, and studied their application as a dopamine and hydrogen peroxide sensor. Dopamine and hydrogen peroxide are important intermediates in environmental and biological systems, whose determination has become important and has been given tremendous attention by neuroscientists and chemists in biomedical and bioanalytical research. The colloidal silver nanoparticles were prepared by treating the water A. melanoxylon extract with silver nitrate and were then used in the preparation of a carbon paste electrode, by mixing it with graphite powder and silicon oil [15]. The addition of silver nanoparticles prepared this way enhanced the sensitivity of the fabricated electrode towards the oxidation of both dopamine and hydrogen peroxide, which occurred at a physiological pH, by a diffusion-controlled process, and with a linear increase in peak current with different concentrations of both products [15].

Superparamagnetic nanoparticles based on a core consisting of iron oxides can have relevant applications, such as biomedical uses as drug delivery systems or as adsorbents to remove pollutants from wastewaters [16]. Research for the preparation of these materials in an eco-friendly way is important for the sustainability of the process, and the use of green processes and biobased nanoparticles were investigated by Khan et al. [17], using a tannin extract of A. mearnsii. The authors prepared superparamagnetic nanoparticles containing Fe3O4 cores in biochar, by carbonizing the precipitate formed at pH 10 from the mixture of tannin and ferric chloride and ferrous chloride solutions. The tannin molecules contain a large number of phenolic-OH groups capable of taking part in redox reactions that result in the reduction of the iron salt and formation of stabilized iron oxide nanoparticles at pH 10 [17]. The authors produced superparamagnetic nanoparticles with average sizes in the range 18–35 nm, with surface areas suitable for use in the adsorption of heavy metals from wastewater [17].

The concept of “active packaging” for food or pharmaceutical products arose a few years ago, with the intention of creating a packaging material to extend the shelf-life or the expiration date of products, which can be achieved by exerting antioxidant effects to protect against oxidation, UV radiation or moisture [18]. The current trend is moving towards the use of green and sustainable resources, where nanocellulose and bio-based additives with antioxidant properties can play an important role. Missio et al. [18] prepared a nanocellulose film containing 190 mg/g of proanthocyanidin-rich tannin extract of A. mearnsii, which was incorporated into the matrix by mechanical fibrillation of cellulose pulp and tannin mixture. The addition of the tannin extract improved the surface hydrophobicity, which resulted in a 6-fold enhancement in their air-barrier properties, while the mechanic features of the cellulose matrix were not significantly affected [18]. Moreover, good resistance to several organic solvents was verified, as well as a slow release of antioxidant components upon soaking (55% of the original tannins in one weak), thus showing the potential use of tannin-enhanced biofilms as a valid green and non-toxic material for food, pharmaceutical or cosmetic products [18].

Nanofiber membranes are used for diverse objectives, from the removal of pollutants from wastewater to biomedical, tissue engineering and regenerative medicine applications [19]. Poly (e-caprolactone) is one of the most important synthetic polymers used for developing nanofiber scaffolds, for repairing soft and hard tissues, due to its cytocompatibility, biodegradability and mechanical resistance, but it has also some limitations, such as high hydrophobicity and low water absorptivity [20]. To overcome these shortcomings, Martins et al. [20] produced a novel poly (ε-caprolactone) electrospun membrane, by blending poly (ε-caprolactone) with a commercial amino-functionalized tannin extracted from A. mearnsii, to be used as a scaffold for wound healing and tissue repair. The authors used different percentages of tannin incorporation (from 0% to 22%), which could be tuned to impart anchorage, adhesion and proliferation of human adipose-derived stem cells. Moreover, the incorporation of the tannin extract conferred bactericidal properties to the produced membrane against Pseudomonas aeruginosa, particularly with 22% of incorporation [20].

Dos Santos et al. [21] produced nanoparticles containing A. mearnsii tannin extract, encapsulated using sol-gel methods, and evaluated its application as antimicrobial agents. Amongst the sol-gel methods used, the acidic and alkaline routes affected the structure of the tannins during the synthesis and decreased the antibacterial activity of the material, while a non-hydrolytic route affected the final texture of the encapsulated materials, hindering the release of the extract. Only the silicate sol-gel option, performed by mixing a sodium silicate solution with dissolved extract in acidic medium, at 50 °C during 48–72 h, produced a material with a very small particle size (<1 nm), promoting a gradual release of tannins in aqueous medium and an improved interaction with microorganisms (moderate activity against Staphylococcus aureus, Aspergillus niger and Candida sp.).

Grasel et al. [22] successfully incorporated A. mearnsii tannin extract on lactic-co-glycolic acid microparticles, having obtained 73% of encapsulation efficiency and a particle size distribution between 0.6 and 2.4 μm. The authors demonstrated in vitro the biocompatibility of the produced material with normal cell lines (Vero), with no effects on cell proliferation being observed after 24 h, using microparticle concentrations up to 200 μg/mL.

These findings for the utilization of A. mearnsii bark extract deserve further attention and research for the implementation at larger scales, not only due to the improved properties given by the tannin extract to silver nanoparticles, superparamagnetic nanoparticles, nanocellulose films and nanofiber membranes, but mainly because this extract can be delivered from well-established procedures at a commercial scale, and can be provided at a relatively low cost.

Another way to valorize the exhausted A. mearnsii bark produced after the extraction of tannins, avoiding an environmental problem, is its use in the production of cellulose nanocrystals, which are used usually for polymer reinforcement, as well as in transparent films for several applications [23]. The common procedure for isolating cellulose involves costly and time-consuming extraction steps to remove extractives, but Taflick et al. [23] demonstrated, with exhausted A. mearnsii bark, that this step can be avoided if the purpose is producing cellulose nanocrystals. Only the common steps of delignification, bleaching and hydrolysis were applied, but without using chlorinated chemicals in the bleaching step. It was found that differences in the isolated cellulose, with the process without solvent extraction showing a higher crystallinity index (86% versus 82%), larger and more agglomerated particles, and higher residual mass after thermal degradation; however, no significant difference was observed in the morphology and thermal stability of obtained nanocrystals. Such a result represents lower costs with solvents and a more eco-friendly process to produce cellulose nanocrystals, using a bark residue.

2.3. Alternative Adsorbents from Bark, Wood and Leaves

The interest in the development of low-cost adsorbents for the removal of pollutants from wastewaters, such as dyes, heavy metals or organic compounds, has increased with the increased awareness to finding environmentally friendly and sustainable processes for that purpose, and preferentially at an affordable cost to make them usable in developing countries [24][25]. Conventional activated carbon is still the most-used adsorbent, but its widespread use is frequently restricted due to its high cost, besides other issues related to its efficiency and the cost of its regeneration, and its disposal at the end of its life cycle [25]. In this context, biomass from invasive species, such as Acacia spp., are good candidates due to their high abundance and availability, either in nature or as an industrial by-product from wood industries, charcoal production or tannin industries.

Silva et al. [26] prepared an alternative adsorbent using A. mearnsii bark waste from a tannin industry. The bark was pretreated by steam explosion, the adsorbent was prepared by an acetosolv method (boiling for 24 h a mixture of steam-exploded bark, acetone and a small percentage of sulfuric acid) and is then used for crystal violet dye removal. Besides the small surface area determined for the adsorbent (near 5 m2/g), this procedure promotes a chemical modification of lignin and polysaccharides by the solvent and the acid, generating new functional groups like ketones, ethers, open aromatic rings and carbonyl groups, that can act as new sites for adsorption [26]. The authors observed removal percentages of 95% from an initial solution containing a 50 mg/L dye concentration, after two hours of contact, using an adsorbent dosage of 750 mg/L, at pH of 10. The maximum adsorption capacity was estimated at 280 mg of dye per gram of adsorbent [26]. These results illustrate a way to aggregate value to bark waste, by producing an effective dye adsorbent, and using a simple and low-cost method, without further activation steps.

Singh et al. [27] tried the removal of heavy metals Ni(II) and Zn(II) from aqueous solutions using an industrially produced A. karroo charcoal. The authors performed a single activation process by boiling the charcoal in acidic medium (hydrochloric acid solution, 1 M) for 5 h and found removal percentages of Ni(II) and Zn(II) metals 90 and 83% at a dose of 15 g/L. The maximum adsorption capacities for Ni(II) and Zn(II) metals were estimated in 9 and 8 mg of metal per gram of adsorbent, at an optimum pH of 6 and 4, respectively. These findings show that this material holds good potential for removing heavy metals from aqueous solutions and could be used for desalinating metal ions from industrial wastewater [27]. Moreover, its production can be made using a discarded fraction from the charcoal production, which can be obtained at a regular rate and at a low cost.

Beckinghausen et al. [28] tried the removal of ammonium from artificial wastewater (1000 mg/L of ammonium solution) in a fixed-bed column, using activated biochar made from A. mearnsii woodchips. The woodchips were carbonized at 400 °C for two hours and then two activation processes were compared-steam activation at 850 °C and hydrogen peroxide activation by shaking the biochar in a 10% hydrogen peroxide solution. The steam activation proved to be the most suitable activation method, producing a material with a surface area of 340 m2/g, with an adsorption capacity of 1651 μg of ammonium per gram of adsorbent. Moreover, the steam activation decreased the desorption capacity of the ammonium-loaded adsorbent, making it suitable to use as a solid fertilizer, improving soil nitrogen content and plant growth [28]. The process needs to be improved to increase the adsorption capacity for ammonium, but this approach has the advantage of producing a material that can remove ammonium from wastewater, and then be used as a soil fertilizer, returning a considerable amount of carbon into the earth [28].

Another alternative approach was performed by Taşkıran et al. [29], through the use of silver nanoparticles produced with A. saligna leaves extract in a dye adsorption. The silver nanoparticles were produced by mixing the liquid water extract with silver nitrate, with the extract promoting the reduction of silver cations to its metallic form, and then used in the adsorption of the Basic Red 46 dye. The optimal conditions were found as pH 7, a temperature of 35 °C and an adsorbent dosage of 1 g/L, being estimated to have a maximum adsorption capacity of 126 mg of dye per gram of adsorbent. Moreover, the authors demonstrated that the reduction of dye concentration to a level below that required by legislation can be attained using four adsorption stages (i.e., four batches of adsorption), with the effluent of the first batch entering into the second batch, and so on [29].

2.4. Wood and Steel Protection Using Bark and Leaf Extracts

The use of natural extracts to protect materials from degradation or corrosion, instead of using synthetic formulations, is of great importance when a change to more sustainable and environmentally friendly industrial practices is required.

Taking advantage of the antioxidant and antimicrobial properties of extracts of A. dealbata, Yildiz et al. [30] tried to use methanol extracts from this species as wood (Scots pine) protecting agents. The decay resistance of Scots pine wood against the brown-rot fungus (Coniophora puteana) was accessed comparing the impregnation of wood samples with water or methanol extracts from A. dealbata sapwood, heartwood and bark, using concentrations of 3% and 5% by weight. The weight loss caused by the fungus varied in the range of 7% to 24% for treated samples, against almost 40% of weight loss verified with untreated samples. Bark extracts were overall more effective than wood extracts, and methanol was the most appropriate solvent, being the highest protection observed when using a concentration of 5% of methanol bark extract [30]. Although these experiments did not yet provide adequate protection to meet the requirements of European standards, these are encouraging results and deserve a further investigation to try higher concentrations or the mixing with other non-toxic antifungal materials [30].

The efficiency of A. saligna leaf extract as an environmentally friendly inhibitor for mild steel was investigated by Avci and Keleş [31], using a sulphuric acid solution (1 M) as the corrosive agent. The authors concluded that water leaves extract adsorbs onto the mild steel surface and form a protective film against metal corrosion. The corrosion inhibition efficiencies determined by potentiodynamic polarization measurements and by electrochemical impedance spectroscopy techniques were in agreement, with the highest values observed when using an extract concentration of 20 g/L (93 and 95% for 1 h of immersion, respectively). The presence of the extract increased the activation energy for the corrosion process and slowed the corrosion rate down, even in long immersion experiments (up to 120 h of immersion time).

This entry is adapted from the peer-reviewed paper 10.3390/f11121342

References

- Le Maitre, D.C.; Gaertner, M.; Marchante, E.; Ens, E.-J.; Holmes, P.M.; Pauchard, A.; O’Farrell, P.J.; Rogers, A.M.; Blanchard, R.; Blignaut, J.; et al. Impacts of invasive Australian acacias: Implications for management and restoration. Divers. Distrib. 2011, 17, 1015–1029, doi:10.1111/j.1472-4642.2011.00816.x.

- Ferreira, S.; Gil, N.; Queiroz, J.A.; Duarte, A.P.; Domingues, F.C. An evaluation of the potential of Acacia dealbata as raw material for bioethanol production. Bioresour. Technol. 2011, 102, 4766–4773, doi:10.1016/j.biortech.2011.01.051.

- Carneiro, M.; Moreira, R.; Gominho, J.; Fabião, A. Could control of invasive acacias be a source of biomass for energy under mediterranean conditions? Chem. Eng. Trans. 2014, 37, 187–192, doi:10.3303/CET1437032.

- Souza-Alonso, P.; Rodríguez, J.; González, L.; Lorenzo, P. Here to stay. Recent advances and perspectives about Acacia invasion in Mediterranean areas. Ann. For. Sci. 2017, 74, doi:10.1007/s13595-017-0651-0.

- Seigler, D.S. Phytochemistry of Acacia-Sensu lato. Biochem. Syst. Ecol. 2003, 31, 845–873, doi:10.1016/S0305-1978(03)00082-6.

- Jæger, D.; O’Leary, M.C.; Weinstein, P.; Møller, B.L.; Semple, S.J. Phytochemistry and bioactivity of Acacia sensu stricto (Fabaceae: Mimosoideae). Phytochem. Rev. 2019, 18, 129–172, doi:10.1007/s11101-018-9583-z.

- Pereira, F.B.M.; Domingues, F.M.J.; Silva, A.M.S. Triterpenes from Acacia dealbata. Nat. Prod. Lett. 1996, 8, 97–103, doi:10.1080/10575639608043247.

- Subhan, N.; Burrows, G.E.; Kerr, P.G.; Obied, H.K. Phytochemistry, Ethnomedicine, and Pharmacology of Acacia. In Studies in Natural Products Chemistry; Elsevier BV: Amsterdam, The Netherlands, 2018; Volume 57, pp. 247–326, ISBN 9780444640574.

- Lorenzo, P.; Reboredo-Durán, J.; Muñoz, L.; Freitas, H.; González, L. Herbicidal properties of the commercial formulation of methyl cinnamate, a natural compound in the invasive silver wattle (Acacia dealbata). Weed Sci. 2019, 68, 69–78, doi:10.1017/wsc.2019.68.

- Ogawa, S.; Yazaki, Y. Tannins from Acacia mearnsii De Wild. Bark: Tannin determination and biological activities. Molecules 2018, 23, 1–18, doi:10.3390/molecules23040837.

- Yazaki, Y. Utilization of flavonoid compounds from bark and wood: A review. Nat. Prod. Commun. 2015, 10, 513–520, doi:10.1177/1934578x1501000333.

- Chan, J.M.; Day, P.; Feely, J.; Thompson, R.; Little, K.M.; Norris, C.H. Acacia mearnsii industry overview: Current status, key research and development issues. South. For. 2015, 77, 19–30, doi:10.2989/20702620.2015.1006907.

- Bridson, J.H.; Kaur, J.; Zhang, Z.; Donaldson, L.; Fernyhough, A. Polymeric flavonoids processed with co-polymers as UV and thermal stabilisers for polyethylene films. Polym. Degrad. Stab. 2015, 122, 18–24, doi:10.1016/j.polymdegradstab.2015.10.002.

- Taflick, T.; Maich, É.G.; Dias Ferreira, L.; Bica, C.I.D.; Rodrigues, S.R.S.; Nachtigall, S.M.B. Acacia bark residues as filler in polypropylene composites. Polimeros 2015, 25, 289–295, doi:10.1590/0104-1428.1840.

- Shashanka, R.; Kumara Swamy, B.E. Biosynthesis of silver nanoparticles using leaves of Acacia melanoxylon and their application as dopamine and hydrogen peroxide sensors. Phys. Chem. Res. 2020, 8, 1–18, doi:10.22036/pcr.2019.205211.1688.

- Devi, S.M.; Nivetha, A.; Prabha, I. Superparamagnetic Properties and Significant Applications of Iron Oxide Nanoparticles for Astonishing Efficacy—a Review. J. Supercond. Nov. Magn. 2019, 32, 127–144, doi:10.1007/s10948-018-4929-8.

- Khan, M.Y.; Mangrich, A.S.; Schultz, J.; Grasel, F.S.; Mattoso, N.; Mosca, D.H. Green chemistry preparation of superparamagnetic nanoparticles containing Fe3O4 cores in biochar. J. Anal. Appl. Pyrolysis 2015, 116, 42–48, doi:10.1016/j.jaap.2015.10.008.

- Missio, A.L.; Mattos, B.D.; Ferreira, D. de F.; Magalhães, W.L.E.; Bertuol, D.A.; Gatto, D.A.; Petutschnigg, A.; Tondi, G. Nanocellulose-tannin films: From trees to sustainable active packaging. J. Clean. Prod. 2018, 184, 143–151, doi:10.1016/j.jclepro.2018.02.205.

- Ismail, A.; Hilal, N.; Jaafar, J.; Wright, C. Nanofiber Membranes for Medical, Environmental, and Energy Applications; Ismail, A., Hilal, N., Jaafar, J., Wright, C., Eds.; CRC Press: Boca Raton, FL, USA, 2019; ISBN 9781351174046.

- Martins, A.F.; Facchi, S.P.; da Câmara, P.C.F.; Camargo, S.E.A.; Camargo, C.H.R.; Popat, K.C.; Kipper, M.J. Novel poly(ε-caprolactone)/amino-functionalized tannin electrospun membranes as scaffolds for tissue engineering. J. Colloid Interface Sci. 2018, 525, 21–30, doi:10.1016/j.jcis.2018.04.060.

- dos Santos, C.; Vargas, Á.; Fronza, N.; dos Santos, J.H.Z. Structural, textural and morphological characteristics of tannins from Acacia mearnsii encapsulated using sol-gel methods: Applications as antimicrobial agents. Colloids Surf. B Biointerfaces 2017, 151, 26–33, doi:10.1016/j.colsurfb.2016.11.041.

- Grasel, F. dos S.; Behrens, M.C.; Strassburger, D.; Einloft, S.; Diz, F.M.; Morrone, F.B.; Wolf, C.R.; Ligabue, R.A. Synthesis, characterization and in vitro cytotoxicity of acacia mearnsii proanthocyanidin-loaded plga microparticles. Braz. J. Chem. Eng. 2019, 36, 239–250, doi:10.1590/0104-6632.20190361s20170154.

- Taflick, T.; Schwendler, L.A.; Rosa, S.M.L.; Bica, C.I.D.; Nachtigall, S.M.B. Cellulose nanocrystals from acacia bark–Influence of solvent extraction. Int. J. Biol. Macromol. 2017, 101, 553–561, doi:10.1016/j.ijbiomac.2017.03.076.

- Sulyman, M.; Namiesnik, J.; Gierak, A. Low-cost adsorbents derived from agricultural by-products/wastes for enhancing contaminant uptakes from wastewater: A review. Pol. J. Environ. Stud. 2017, 26, 479–510, doi:10.15244/pjoes/66769.

- De Gisi, S.; Lofrano, G.; Grassi, M.; Notarnicola, M. Characteristics and adsorption capacities of low-cost sorbents for wastewater treatment: A review. Sustain. Mater. Technol. 2016, 9, 10–40, doi:10.1016/j.susmat.2016.06.002.

- Silva, J.S. da; Rosa, M.P. da; Beck, P.H.; Peres, E.C.; Dotto, G.L.; Kessler, F.; Grasel, F.S. Preparation of an alternative adsorbent from Acacia Mearnsii wastes through acetosolv method and its application for dye removal. J. Clean. Prod. 2018, 180, 386–394, doi:10.1016/j.jclepro.2018.01.201.

- Singh, J.; Sharma, R.; Ali, A. Application of Acacia karroo charcoal for desalinating Ni(II) and Zn(II) from aqueous solutions through batch mode. J. Water Reuse Desalin. 2013, 3, 268–276, doi:10.2166/wrd.2013.164.

- Beckinghausen, A.; Reynders, J.; Merckel, R.; Wen, Y.; Marais, H.; Schwede, S. Post-pyrolysis treatments of biochars from sewage sludge and A . mearnsii for ammonia ( NH 4 -n) recovery. Appl. Energy 2020, 271, 115212, doi:10.1016/j.apenergy.2020.115212.

- Taşkıran, F.; Uzunoğlu, D.; Özer, A. Biosynthesis, characterisation and determination of adsorbent properties of silver nanoparticles with cyprus acacia (acacia cyanophylla) leaf extract. Anadolu Univ. J. Sci. Technol. A Appl. Sci. Eng. 2017, 18, 733–745, doi:10.18038/aubtda.299006.

- Yildiz, S.; Gürgen, A.; Can, Z.; Tabbouche, S.A.; Kiliç, A.O. Some bioactive properties of Acacia dealbata extracts and their potential utilization in wood protection. Drewno 2018, 61, 81–97, doi:10.12841/wood.1644-3985.255.03.

- Avci, G.; Keleş, Y. Aqueous extract of Acacia cyanophylla leaves as environmentally friendly inhibitor for mild steel corrosion in 1 M H2SO4 solution. Surf. Interface Anal. 2011, 43, 1311–1317, doi:10.1002/sia.3714.