Anaerobic biotechnology is commonly used for treating high-strength wastewaters from different industries. Properties of wastewater vary across industries and significantly affect microbiome composition in the anaerobic reactor. Methanogenic archaea play a crucial role during anaerobic wastewater treatment.

- industrial wastewater

- anaerobic reactor

- methanogens

- wastewater treatment

- Archaea

1. Introduction

Today, water is an integral part of the course of our lives, from the operation and maintenance of households to extensive industrial and agricultural use. Ecological, political and ethical aspects today force us to constantly think about streamlining processes and managing natural resources as gently as possible. It is now very important to protect the high quality of water as a renewable resource due to the loss of its share under the surface and in the landscape and watercourses.

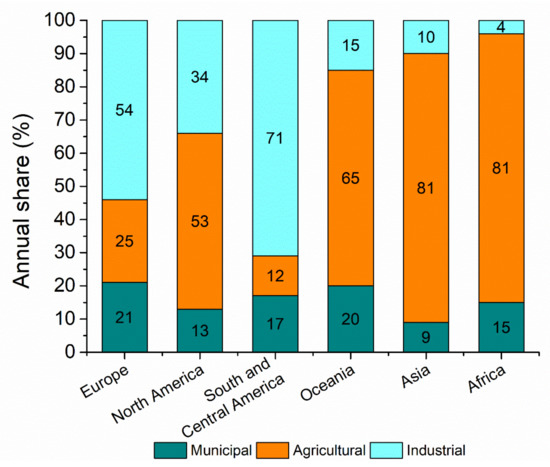

Industrial wastewater is an environmental pressure even if these waters are, in some cases, collected by a local sewer system, treated in an urban wastewater treatment plant (UWWTP) and subsequently released to the environment. There are also cases, however, in which these waters are directly released to a water body, generally after treatment at the industrial facility where the wastewater is generated. There is a large and diverse range of economic activities affecting wastewater production. Global data on water uptake per region in 2016 are presented in Figure 1. It shows that industry in Europe is a major consumer of water in relation to other sectors.

Figure 1. Annual share of global water uptake by activity and region.

The release of industrial wastewater is regulated in Europe both directly as part of the environment law on industry and indirectly by the EU policies that tackle water issues horizontally. Industrial wastewater generation and management is regulated by Water Framework Directive (WFD, 2000/60/EC). Industry’s direct or indirect releases of pollution to the environment are among the key aspects regulated by the Industrial Emissions Directive (IED, 2010/75/EU). Currently, the IED regulates 31 industrial sectors and over 50,000 installations in Europe.

The anaerobic wastewater treatment system has been known and used since the end of the 19\( \)th century[1]. Systematic research work and deeper anaerobic process understanding caused anaerobic digestion (AD), a biological process in which organic matter is converted to CH4 and CO2, to become a more attractive technology for wastewater treatment due to its low capital and operation cost compared to the other technologies available in last decades. Today, anaerobic techniques are generally utilized in industries with high level of soluble and readily biodegradable organic material. Many types of industrial wastewaters believed to be unsuitable for anaerobic treatment are today treated with advanced anaerobic reactor systems[2]. The role of microorganisms and their formation into complex communities is an essential pillar of the whole anaerobic biotechnology, but so far there are few laboratories and publications that deal with this issue in detail. Interactions between microorganisms, their co-operation or competition, with other aspects, have a significant impact on the final functionality of the whole process. Therefore, in addition to an external understanding of processes and technological parameters, it is important to examine the composition of microbial communities. Awareness of the general composition of the microbial community may be very important in the future for the typing of anaerobic biotechnologies, their implementation in industrial areas and the potential solution of functional defects and problems.

2. Industrial Wastewater

2.1. Industrial Wastewater Types

Industrial wastewater varies in composition and cannot be simply characterized. Three major types of wastewater can be defined, processing, cleaning and sanitary. Different industrial sectors generate different compositions and quantities of these wastewaters at the effluent[3]. It may be highly biodegradable or not at all and may or may not contain compounds recalcitrant to treatment. The main concern with industrial wastewater is the increasing amount (in quantity and variety) of synthetic compounds contained in and discharged to the environment. The main industrial wastewater types are presented in Table 1.

Table 1. Industrial wastewater types depending on the industrial sectors[4], edited by the authors.

| Category | Common Features | Pollutants | Typical Industrial Sectors |

|---|---|---|---|

| Minimal contamination (can be land spread) | Wastewater contains no pollutants, nutrients can be useful for agricultural plants development, levels of toxic substances is very low | Nitrogen, phosphorus | Food and drink |

| Equivalent to domestic-type effluents | Organic pollutants similar content as in municipal wastewater | Degradable organic matter | Food and drink |

| Low flow and non-domestic type pollutants at low concentrations | Wastewater containing small concentrations of other pollutants not present in urban effluents | Pesticides, hormones, nano-plastics and endocrine disrupters | Chemicals |

| Metals | Wastewater containing metals or metalloids from industry | Metals | Metal processing and mineral industry |

| High nutrient loading | Wastewater containing high concentrations of nitrogen compounds, phosphates, with higher conductivity | Substances increasing eutrophication | Chemicals: fertilizers |

| Effluent streams requiring pH adjustment | Wastewater streams with very low or very high pH | Acids or alkalis | Chemicals and mineral industry |

| Persistent organics content | Wastewater containing not easily degradable organic pollutants (persistent hydrocarbons or bioaccumulative organic toxic substances | Persistent organics | Textiles and chemicals |

| Emerging substances | Wastewater contains new pollutants or has characteristics that are not currently monitored | New parameters or compounds not frequently measured | Pharmaceuticals |

2.2. Industrial Water Suitable for Anaerobic Treatment and Methane Production

Anaerobic techniques are typically used for high-loaded wastewaters, expressed in chemical oxygen demand (COD), typically greater than 1500–2000 mg/L. The application of anaerobic wastewater treatment is largely confined to relatively heavily polluted wastewater with a COD between 3000 and 40,000 mg/L, e.g., in the sugar, starch, fruit and vegetable and alcoholic drinks sectors. There has recently been some success in using certain anaerobic systems even for less heavily polluted wastewater with a COD between 1500 and 3000 mg/L, e.g., in breweries, dairies and in the fruit juice, mineral water and the soft drinks sectors. Assessment of methane production potential from industrial wastewater streams is based on the concentration of biodegradable organic matter in the wastewater, Table 2 and Table 3 [5][6].

Table 2. Chemical compounds amenable to anaerobic biotechnology.

| Acetaldehyde | Crotonic acid | Isobutyric acid | Isopropyl alcohol |

| Acetic anhydride | Diacetone gulusonic acid | Isopropanol | Propionate |

| Acetone | Dimethoxy benzoic acid | Lactic acid | Propylene glycol |

| Acrylic acid | Ethanol | Maleic acid | Protocatechuic acid |

| Adipic acid | Ethyl acetate | Methyl acetate | Resorcinol |

| Aniline | Ethyl acrylate | Methyl acrylate | Sec-butanol |

| 1-amino-2-propanol | Ferulic acid | Methyl ethyl ketone | Sec-butylamine |

| 4-amino butyric acid | Formaldehyde | Methyl formate | Sorbic acid |

| Benzoic acid | Formic acid | Nitrobenzene | Syringaldehyde |

| Butanol | Fumaric acid | Pentaerythritol | Syringic acid |

| Butyraldehyde | Glutamic acid | Pentanol | Succinic acid |

| Butylene glycerol | Glutaric acid | Phenol | Tert-butanol |

| Catechol | Glycerol | Phthalic acid | Vanillic acid |

| Cresol | Hexanoic acid | Propanal | Vinyl acetate |

| Crotonaldehyde | Hydroquinone | Propanol |

Table 3. Industrial wastes amenable to anaerobic digestion.

| Agriculture wastes | Corn processing wastes | Chemical industry wastes | Seafood and shellfish wastes |

| Alcohol stillage | Dairy wastes | Meat packing wastes | Slaughterhouse and meat packing |

| Animal wastes | Egg processing wastes | Pear wastes | Sugar processing wastes |

| Bagasse | Fruit Leachate | Peat wastes | Tannery wastes |

| Bean blanching water | Giant kelp wastes | Pectin wastes | Vegetable processing wastes |

| Beverage production wastes | Guar gum wastes | Petroleum wastes | Wheat and grain processing wastes |

| Brewery wastes | H2-CO pyrolysis wastes | Pharmaceutical | Wine processing wastes |

| Canning wastes | Heat-treated activated sludge | Potato processing wastes | Wood processing wastes |

| Coking mill wastes | Cheese processing wastes | Pulp and paper wastes | Wool scouring wastes |

The volume of wastewater, and the propensity of the industrial sector to treat their wastewater in anaerobic systems are also important. Using these criteria, major industrial wastewater sources with high methane production potential can be identified as follows:

-

Meat and poultry processing (slaughterhouses)

-

Alcohol, beer, starch production

-

Pulp and paper manufacture

-

Chemical industry waste

-

Other food and drink processing (dairy products, vegetable oil, fruits and vegetables, canneries, juice making, etc.)

The number of wastes that are amenable to anaerobic digestion is quite large (Table 2,3). However, the feasibility of the anaerobic digestion of an industrial waste is determined by several factors. These factors are waste concentration; waste stream temperature; anaerobic process inhibitors presence in waste stream; expected biogas yield and treatment efficiency[5]. The anaerobic process has many advantages over conventionally used and proven aerobic processes. The most significant positive of the technology is the fact that energy is generated in the form of biogas by means of anaerobic decomposition from unnecessary waste in the form of pollutants in the wastewater.

2.3. Composition of Selected Industrial Wastewater

The composition of industrial wastewater will be characterized by both the substance load and the proportion of biodegradable substances and the values of other, more specific parameters (Table 4).

Table 4. Composition characteristics of individual industrial wastewaters (values are given in mg/L except pH).

| Wastewater Type | COD | BOD | TS | SS | VSS | TN | TP | N-NH4+ | pH |

|---|---|---|---|---|---|---|---|---|---|

| Slaughterhouse | 2000–11,588 | 1300–4635 (BOD5) | 6394 | 850–6300 | 660–5250 | 850 | 15–48 | 20–66 | 6.3–6.98 |

| Poultry slaughterhouse | 2790–5520 | 1558–2988 | - | - | - | 62–313 (KN) | - | 16–95 | 6.8–7.8 |

| Poultry processing | 1140 | 570 (BOD5) | - | 264 | - | - | - | 2.7 | - |

| Meat processing | 5160 | - | 2028 | 1820 | 1380 | - | - | - | 7.5 |

| Livestock breeding | 6190–78,600 | 3940–34,600 | - | 1850–29,000 | - | 1530–6500 | 116–1770 | - | - |

| Dairy industry | - | 10,000–50,000 | - | 220–340 | 200–300 | 188 | 100 | 18 | 9–10.5 |

| Milk plant | 2000–6000 | 1200–4000 (BOD5) | - | 350–1000 | 330–940 | 50–60 (KN) | - | - | 8.0–11.0 |

| Butter production | 52,000 | - | - | 1500 | - | 1120 (KN) | - | - | 4.3–5.9 |

| Brewery | 2000–6000 | 1200–3600 | 5100–8750 | 2901–3000 | - | 25–80 (KN) | 10.0–50.0 | - | 3.0–12.0 |

| Raw distillery wastewater | 80,000–120,000 | 45,000–60,000 | 100,000 | 10,000 | 100–2800 | 100–64,000 | 240–65,000 | - | 3.5–5.2 |

| Sugar factory | 572–6612 | - | 3840–5780 | 30–170 | 560–6470 | - | 2.0–4.0 | 3.7–10.1 | 4.7–5.2 |

| Cellulose Processing | 600–10,400 | 221–3700 | - | 20–3200 | - | - | - | - | 6.3–9.0 |

| Fruits and Vegetables Processing | 1500–4300 | 500–2500 | 400–1200 | 6–10 | |||||

| Vegetable oil mills | 1355–1987 | 712–1136 (BOD5) | - | - | - | - | - | 3.6–14.4 | 0.9–2.3 |

| Olive oil mills | 57,200 | - | 49,100 | - | - | 1600 | 300 | - | 4.9 |

| Refining of vegetable oils | 17,688–24,787 | 4120–4560 (BOD5) | - | 791–3544 | - | <10 | - | <10 | 10.0–10.4 |

| Blackberry processing | 930 | - | 840 | - | - | 92 | - | - | 5.9 |

| Dates processing | 410 | - | 471 | - | - | 37 | - | - | 6.1 |

| Tomato processing | 294 | - | 322 | - | - | 21 | - | - | 5.3 |

| Beetroot processing | 501 | - | 630 | - | - | 43 | - | - | 6.2 |

| Butadiene and styrene | 800–1500 | 4000–8000 (BOD5) | - | 200–500 | - | - | - | - | - |

| Acrylates | 2000–3200 | 1000–2000 (BOD5) | - | 50–100 | - | - | - | - | - |

| Acetaldehyde | 40,000–60,000 | 15,000–25,000 (BOD5) | - | 150–300 | - | - | - | - | - |

| Ketones | 20,000–40,000 | 10,000–20,000 (BOD5) | - | 50–100 | - | - | - | - | - |

| Methyl acrylate acid | 7000–12,000 | - | - | 6000–12,000 | - | - | - | - | - |

| Organic acids | 5000–15,000 | 300–600 (BOD5) | - | 100–200 | - | - | - | - | - |

| Raw materials for the pigment industry | 1000–2000 | 200–400 | - | 80–200 | - | - | - | - | - |

BOD—biochemical oxygen demand; COD—chemical oxygen demand; TS—total solids; SS—suspended solids; VSS—volatile suspended solids; TN—total nitrogen; TP—total phosphorus.

3. Anaerobic Wastewater Treatment

3.1. Aerobic Versus Anaerobic Wastewater Treatment

When aerobic and anaerobic treatment is compared, some advantages which bring appropriate application of anaerobic technology can be found (Table 5). Anaerobic treatment produces up to ten times less biomass, which is related to very low requirements for nutrients and energy in the form of biogas. Excess sludge does not need to be further stabilized, which is a necessary part of aerobic treatment[7].

Table 5. Basic comparison of aerobic and anaerobic treatment.

| Aerobic Treatment | Anaerobic Treatment | |

|---|---|---|

| Transformation of input substrate | 50% microbial biomass 50% CO2 |

5% microbial biomass 95% biogas |

| Energy balance | 60% microbial biomass 40% reaction heat |

90% biogas 5–7% microbial biomass 3–5% reaction heat |

From the bioreactor and the overall cleaning process point of view, anaerobic wastewater purification is an alternative to aerobic technologies. The anaerobic process has mainly been used for sewage sludge stabilization. In anaerobic reactors, a high concentration of biomass is still maintained, which is related to the ability to treat wastewater with a very high material load. On the other hand, anaerobic microorganisms grow very slowly, which is why it is still necessary to maintain their high concentration and leave the substrate in the anaerobic reactor for a long time >15 days[5]. However, one of the biggest advantages of this is that the high sludge retention time in the reactor promotes the growth of microorganisms with a long generation time, which are able to degrade pollutants that cannot be degraded in aerobic conditions or are toxic to aerobic microorganisms. Finally, we cannot omit the price of operation, which is significantly lower for anaerobic technologies[7].

Anaerobic treatment also has its disadvantages. The total loss of organic matter is still not achieved in anaerobic processes and it is often necessary to treat the wastewater aerobically. Another major disadvantage is the high sensitivity of anaerobic organisms, especially methanogenic archaea, and their long generation time, which is associated with a long time to start the operation of reactors.

3.2. Anaerobic Digestion

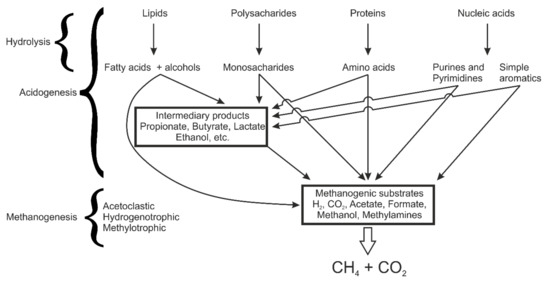

Anaerobic digestion is a complex process (Figure 2) that consists of a number of biochemical processes and is mediated by systematically interconnected microorganisms mainly from the Bacteria and Archaea domains[8] and also to a lesser extent by Eukaryotes and a very small percentage of viruses[9]. By means of individual biochemical transformations, complex organic compounds are decomposed into as many oxidized and reduced forms of carbon as possible, i.e., carbon dioxide and methane[10].

Figure 2. Scheme of reactions during anaerobic decomposition of polymeric materials[11], edited by authors.

The anaerobic process usually takes place in mesophilic (35–50 °C) or thermophilic (50–60 °C) cultures of microorganisms, and, in terms of biogas yield, thermophilic cultures show higher biogas production. The biogas produced consists mainly of carbon dioxide and methane. Typical methane content in biogas ranged from 50 to 85%vol. Other gases (H2S, NH3 and water vapor) are usually present in biogas in the hundreds or thousands of ppm. In addition to methanogenic communities, bioreactors can also contain bacteria that can compete with methanogens for the available substrate and thus negatively affect biogas production. These are facultatively anaerobic bacteria that can use molecular oxygen as an electron acceptor, denitrifying bacteria that use nitrates, sulfate-reducing bacteria (SRB) using sulfides and sulfates, or bacteria that reduce iron ions.

3.3. Anaerobic Bioreactors

Anaerobic processes for the treatment of wastewaters and sludges are well over 100 years old[12]. In the last 50 years, anaerobic reactor technology evolved from localized lab-scale trials to worldwide successful implementations at a variety of industries. Since the 1970s, when Lettinga et al.[13] first described the Upflow Anaerobic Sludge Blanket (UASB) process, a lot of progress has been made in the anaerobic wastewater treatment. Today, different types of high-rate anaerobic reactors characterized by short hydraulic retention time, high pollutant removal efficiency and high applicable volumetric loading rates are commonly used across the industry worldwide.

Anaerobic bioreactors initial drawbacks (biomass slow growth rate, susceptibility to toxic compounds, huge reactors volumes, etc.) were overcome. The new generation of reactors with a short hydraulic retention time (HRT) (2 h to 48 h) and the ability to process high organic loading rates (4 to 40 kg COD/m3 reactor per day) was developed (Table 6). In these reactors, the problem of slow growth rate was turned by capturing the biomass in the form of biofilms on static or moving supports but also by selecting well settling flocculating biomass. This development resulted in much smaller reactors volume but also in a much more stable operation than before.

Table 6. Typical processes and performance data of anaerobic technologies used for industrial wastewater treatment.

| Process | Inflow COD | Hydraulic Retention Time | Organic Loading Rate | COD Removal Efficiency |

|---|---|---|---|---|

| (mg/L) | (h) | (kgCOD/m3 per day) | (%) | |

| Anaerobic lagoons | N.A. | 24–1200 | 0.04–1 | 30–50 |

| Anaerobic contact process | 1500–5000 | 2–14 | 0.5–5.3 | 75–90 |

| Fixed Bed reactor | 10,000–70,000 | 24–48 | 1–15 | 75–85 |

| Upflow Anaerobic Sludge Blanket (UASB) reactor | 5000–90,000 | 4–12 | 4–12 | 75–85 |

| Expanded Granular Sludge Bed (EGSB) reactor | 1000–90,000 | 5–10 | 5–30 | 80–85 |

| Internal Circulation (IC) reactor | 5000–90,000 | 3–25 | 5–40 | 80–87 |

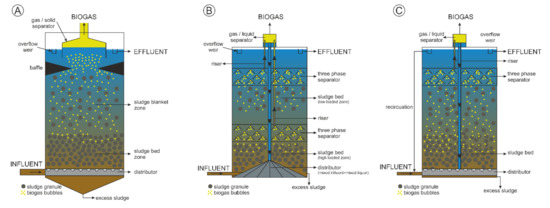

Most widespread technologies for anaerobic wastewater treatment reactors are upflow Anaerobic Sludge Blanket Process (UASB), Internal Circulation (IC) and Expanded Granular Sludge Bed (EGSB) (Figure 3A–C). The UASB reactor is a suspended-growth reactor that maintains a very high concentration of microbial biomass by promoting granulation. The anaerobic granules are 1–3 mm in diameter and dense enough to settle down in the reactor. The biomass concentration in the UASB reactor reaches 50 g/L or higher and thus maintains a very long sludge retention time >15 days irrespective of the short hydraulic retention time of 4–12 h. Upflow velocity typically ranges from 0.5 to 1.0 m/h, 4.5 to 6.5 m high[14]. The EGSB reactor was developed from UASB reactors. It has a high recycle ratio, and the upflow of this reactor is typically maintained higher than 6 m/h, 12 to 16 m high[14]. The IC reactor is a new concept being mostly used for the treatment of industrial effluents of high strength. The higher OLR of the IC reactor is mainly due to its internal circulation, which allows for an improved contact between the biomass and the influent[14].

Figure 3. Scheme of an Upflow Anaerobic Sludge Blanket (UASB) reactor (A), an Internal Circulation (IC) reactor (B) and an Expanded Granular Sludge Blanket (EGSB) reactor (C).

Many reactors operate despite the same names on the same or similar principles. Due to the evolving technology, only specific modifications are made to the basic structures due to several design companies. The potential of anaerobic reactors in wastewater treatment is now great but will increase as the parameters are unified and the technology is universalized.

4. Methanogenic microorganisms in industrial wastewaters

The composition of microorganisms in anaerobic bioreactors will be affected by many factors. These are, reactor design, temperature, pH, C:N ratio, wastewater composition, organic loading rate, hydraulic retention time, agitation[5]. A very important fact is that anaerobic bioreactors during start up are usually seeded with inoculum from other biotechnology. Wide range of anaerobic bacteria are reported inhabiting anaerobic fermenters. These belongs mainly to the Proteobacteria, Firmicutes, Actinobacteria, Bacteroidetes, Spirochaetes, Chloroflexi, Planctomycetes a Synergistes. Archaea represents approximately 5-6% of total microbial population in anaerobic fermenters.

4.1 Inhibitors and methanogenic activity

Anaerobic digestion is particularly susceptible to the strict control of the environmental conditions, as the process requires an interaction between fermentative and methanogenic organisms [5]. Anaerobic biodegradability and methanogenic toxicity are strongly dependent on wastewater characteristics. Toxic substances present in wastewater can interfere with the metabolism of readily biodegradable substrates[15]. There is a lot of industrial wastewaters amenable to anaerobic biotechnology. Nevertheless, these effluents may have properties that can cause process inhibition. The main influencing properties are temperature, pH, alkalinity, volatile acids concentration, redox potential, salinity, macro and micro nutrient deficiency, presence of specific cations (Ca2+, Na+, K+, Mg2+, NH4+), hydrogen, sulphide, heavy metals, bleaching and dyeing agents, antibiotics.

5. Methanogens presence in selected industrial wastewaters

Anaerobic wastewater treatment is highlighted in many sources as a very efficient and ecological alternative to aerobic technologies. Today, this technology is already used in many industries, especially in the food industry. Based on the literature review, it is possible to conclude at least that a relatively permanent part of the community of methanogenic archaea in anaerobic sludge, with a few exceptions, are genera Methanothrix and Methanosarcina, acetoclastic representatives of methanogens (Table 7). The diversity of methanogens is reflected in the different growth conditions, temperature, pH and osmolarity. Most of the methanogens grow optimally around neutral pH. Higher wastewater pH can be tolerated by halotolerant strains of methanogens. For example, in dairy wastewater Methanocalculus sp. was reported as part of methanogenic community. On the other hand, moderately acidic environments can be inhabited by methanogens as, for example, Methanoregula sp. Methanosarcina sp. and Methanococcus sp. Salt concentration may also be an important physiological parameter for methanogens. In high salinity brewery, paper and dairy wastewaters representants of Methanobacterium sp., Methanosarcina sp. and Methanothrix sp. can be found. We can prove the theories that Methanothrix sp. plays a key role in granulation and in the core of the granules function as nucleation centers that initiate granule development.

Table 7. Methanogens prevailed in anaerobic bioreactors treating industrial wastewater

|

Genera of methanogens |

Methanogenic metabolic pathway |

Industry |

|||||||

|

|

|

Slaughterhause |

Brewery |

Distillery |

Paper |

Dairy |

Vegetable Oil |

Fruit and Vegetable |

Chemical |

|

Methanothrix |

acetoclastic |

● |

● |

● |

● |

● |

● |

● |

● |

|

Methanosarcina |

acetoclastic hydrogenotrophic methylotrophic |

● |

● |

● |

|

● |

● |

● |

● |

|

Methanomicrobium |

hydrogenotrophic |

|

|

|

|

● |

|

|

● |

|

Methanobrevibacter |

hydrogenotrophic |

● |

|

|

|

● |

|

|

● |

|

Methanocalculus |

hydrogenotrophic |

|

|

|

|

● |

|

|

|

|

Methanoculleus |

hydrogenotrophic |

● |

|

● |

|

● |

|

● |

● |

|

Methanofollis |

hydrogenotrophic |

● |

|

|

|

● |

|

|

|

|

Methanobacterium |

hydrogenotrophic |

● |

|

|

● |

● |

|

● |

● |

|

Methanoregula |

hydrogenotrophic |

● |

|

|

|

|

|

|

● |

|

Methanococcus |

hydrogenotrophic |

|

● |

|

|

|

|

|

|

|

Methanospirillum |

hydrogenotrophic |

● |

● |

|

|

|

|

● |

● |

|

Methanocorpuscullum |

hydrogenotrophic |

● |

|

|

|

|

|

|

● |

|

Methanogenium |

hydrogenotrophic |

● |

|

|

|

|

|

|

|

|

Methanimicrococcus |

methylotrophic |

● |

|

|

|

|

|

|

|

|

Methanosphaera |

hydrogenotrophic |

● |

|

|

|

|

● |

|

|

|

Methanothermobacter |

hydrogenotrophic |

|

|

● |

|

|

|

|

|

|

Methanolinea |

hydrogenotrophic |

|

|

|

|

|

|

● |

● |

|

Methanomethylovorans |

methylotrophic |

|

|

|

|

|

|

● |

|

|

Methanomassiliicoccus |

methanol + H2 |

|

|

|

|

|

|

● |

|

This entry is adapted from the peer-reviewed paper 10.3390/pr8121546

References

- A S Bal; N N Dhagat; Upflow anaerobic sludge blanket reactor--a review.. Indian journal of environmental health 2001, 43, 1-82, .

- H. Macarie; Overview of the application of anaerobic treatment to chemical and petrochemical wastewaters. Water Science and Technology 2000, 42, 201-214, 10.2166/wst.2000.0515.

- B.J. Cisneros; Safe Sanitation in Low Economic Development Areas. Treatise on Water Science 2011, Epub 2011, 147-200, 10.1016/B978-0-444-53199-5.00082-8.

- Kripa Shankar Singh; Hideki Harada; T. Viraraghavan; Low-strength wastewater treatment by a UASB reactor. Bioresource Technology 1996, 55, 187-194, 10.1016/0960-8524(96)86817-9.

- Gary F. Bennett; The Microbiology of Anaerobic Digesters Michael H. Gerardi, Wiley, Somerset, NJ, 2003, 186 pp., US$ 49.95 (Paperback), ISBN 0-471-20693-8. Journal of Hazardous Materials 2004, 106, 177, 10.1016/j.jhazmat.2003.10.001.

- Richard E. Speece; Anaerobic biotechnology for industrial wastewater treatment. Environmental Science & Technology 1983, 17, 416A-427A, 10.1021/es00115a725.

- Rumana Riffat; M. Wahid Sajjad; Somchai Dararat; Anaerobic processes. Water Environment Research 1998, 70, 518-540, 10.2175/106143098x134235.

- Angela Cabezas; Juliana Calabria De Araujo; Cecilia Callejas; Amandine Galès; Jérôme Hamelin; Antonella Marone; Diana Z. Sousa; Eric Trably; Claudia Etchebehere; How to use molecular biology tools for the study of the anaerobic digestion process?. Reviews in Environmental Science and Bio/Technology 2015, 14, 555-593, 10.1007/s11157-015-9380-8.

- Carolina Senés-Guerrero; Franco A. Colón-Contreras; Javier F. Reynoso-Lobo; Benito Tinoco-Pérez; Jorge H. Siller-Cepeda; Adriana Pacheco; Biogas‐producing microbial composition of an anaerobic digester and associated bovine residues. MicrobiologyOpen 2019, 8, e00854, 10.1002/mbo3.854.

- Damien J. Batstone; Bernardino Virdis; The role of anaerobic digestion in the emerging energy economy. Current Opinion in Biotechnology 2014, 27, 142-149, 10.1016/j.copbio.2014.01.013.

- H.-P. Schau; K. T. Holland, J. S. Knapp and J. G. Shoesmith, Anaerobic Bacteria (Tertiary Level Biology). IX + 206 S., 50 Abb., 28 Tab. The Blackie Publishing Group. Glasgow—London 1989. £11.95. ISBN: 0–216–92000–0. Journal of Basic Microbiology 1990, 30, 379-379, 10.1002/jobm.3620300515.

- P.L. Mccarty; The development of anaerobic treatment and its future. Water Science and Technology 2001, 44, 149-156, 10.2166/wst.2001.0487.

- G. Lettinga; A.Th. Van Der Geest; S. Hobma; J.V.D. Laan; Anaerobic treatment of methanolic wastes. Water Research 1979, 13, 725-737, 10.1016/0043-1354(79)90236-7.

- S.K. Khanal; B. Giri; S. Nitayavardhana; V. Gadhamshetty; Anaerobic Bioreactors/Digesters. Current Developments in Biotechnology and Bioengineering 2017, 10, 261-279, 10.1016/b978-0-444-63665-2.00010-2.

- Orhan Yenigun; Burak Demirel; Ammonia inhibition in anaerobic digestion: A review. Process Biochemistry 2013, 48, 901-911, 10.1016/j.procbio.2013.04.012.