Despite the long-term experience in the application of noise walls, the uncertainty in wall panel service life efficiency is almost equal between panels built from established and new materials, which are—because of the desire to increase the sustainability of noise walls—developing at an ever-faster pace. The presented meta-analysis of data collected during a systematic review of concrete, metal, and wood panels’ acoustic and non-acoustic characteristics, long term performance, and cradle-to-gate sustainability aims to reduce this uncertainty and support the process of noise wall design and management by shifting the emphasis in decision making from construction costs to the long-term sustainability of the road traffic noise mitigation project. The multi-criterial analysis showed that when choosing a panel, preference should be given to those using lightweight concrete materials.

- systematic review

- meta-analysis

- wall panel

- material

- multi-criterial analysis

- lightweight aggregate

- cradle-to-grave

1. Introduction

According to the data provided by the European Environment Agency (EEA), noise pollution is a major environmental health problem in Europe [1] that is causing issues like sleep disorders leading to period of unwanted awakening [2], learning impairments [3,4,5,6], hypertension ischemic heart disease [7,8,9], and especially annoyance [10,11]. Road traffic is the dominant noise source in urban and suburban areas. According to the Environmental Noise Directive (END) 2002/49/EC, EU Member States are required to determine exposure to environmental noise from major transport and industry sources by means of strategic noise maps [12]. Strategic noise maps are the basis for the preparation, adoption, and publication of action plans for the prevention and reduction of harmful noise exposure, and the specific measures included in the action plans are decided at the Member State level [12,13].

In the last few years, noise action plans have aimed at raising awareness of noise as an environmental problem and promoting the use of more environmentally friendly modes of transport (electric vehicles, vehicles with quieter engines, and low-noise tires [14]). Moreover, new mitigation systems for road traffic (the main source of noise) were proposed, and several projects have been devoted to producing extended real-time noise measurements to obtain a realistic picture of the noise distribution over urban areas [15]. Still, road traffic noise remains a significant environmental problem: Around 100 million people in EU Member States are exposed to road traffic noise levels above 55 dB(A) Lden, while 32 million are exposed to very high noise levels above 65 dB(A) Lden [1]. Lden is defined as “a descriptor of noise level based on energy equivalent noise level (Leq) over a whole day with a penalty of 10 dB(A) for night-time noise (23.00–7.00) and an additional penalty of 5 dB(A) for evening noise (19.00–23.00)” [16].

Road traffic noise is mainly produced by road–tire interactions [17], and the most important parameters affecting noise emission are the tire model [18], pavement age [19,20], and pavement texture [21,22,23] and mixture [24,25]. Because of the abovementioned factors, a common solution for road traffic noise abatement used both in urban and suburban environments is targeting noise sources through road traffic management, e.g., by replacing road surfaces and introducing low-noise road surfaces, improving the traffic flow, and lowering speed limits. In urban agglomerations, this measure is followed by measures related to land use and urban planning. The second most commonly used measure applied to major roads (“a regional, national or international road, designated by the Member State, which has more than three million vehicle passages a year” [12]) located outside residential areas is changing the noise propagation paths through the construction of noise barriers between the noise source and the receiver [14]. The term “noise barrier” can be used to encompass every type of structure used to reduce noise, including earth mounds, noise walls, and their combinations [26]. New types of noise barriers—sonic crystal noise barriers—were also developed recently [27,28,29]. All these structures differ in terms of their construction elements. An earth mound features a berm at the top and sloping sides, noise walls are constructed from horizontally stacked panels [26], while sonic crystal noise barriers are non-homogeneous structures created from the arrangement of scatterers in a periodic configuration with square, rectangular, or triangular patterns [27].

The application of road traffic noise barriers began more than 50 years ago in both the USA and Europe [30,31]. The noise wall exploitation behavior, repair, and/or replacement frequency of aged or deteriorated wall panels became an important issue in the last decade. However, despite the long-term experience in the application of noise walls (and research on the sustainability of noise barriers as well as other noise abatement measures [32,33,34,35,36]), when deciding on the panel material to be used in the design phase, designers still encounter numerous uncertainties associated with the exploitation behavior of noise walls constructed with panels made from different materials [37], including their stability, durability, and resistance to fire, impacts, and atmospheric influences. The main question is how the imminent degradation of panels will affect the efficiency of the wall structure, its life-cycle costs, and its long-term sustainability in specific locations and conditions. There is a wide range of materials available for the construction of panels (wood, woodcrete, concrete, glass/glasscrete, stone/brick, aluminum/steel, acrylic, etc.), and all panels can be systematized into four basic types: concrete, metal, wood, and transparent. The uncertainty in panel service life quality is almost equal between the panels built from established materials and the panels built from new materials, which are now developing at an ever-faster pace due to the desire to increase the sustainability of noise walls [37].

The choice of panel material is influenced by several factors, including the noise wall dimensions, location and local environmental conditions, aesthetic requirements (including local architectural considerations, public perception, and acceptance of the structure), and price [38]. According to [39], different approaches are taken when choosing the panel material within various countries in the EU. In northern EU countries, the landscape approach is the most prominent, in central EU countries, the technical approach (functionality and durability of the wall) is employed first, followed by the architectural approach, and, in southern EU countries, a cost-wise approach (lowest price criterion) dominates when choosing a panel material [39].

2. Background

Despite the availability of various types of construction materials, the European market is dominated by three noise wall panel types: concrete, metal, and wood [44]. Over 80% of EU member states use one of these three major types of materials or their combinations [45]. The same situation is noted in the USA, where, according to the Federal Highway Administration (FHWA) Inventory [46], walls constructed with a single material (either concrete, metal, or wood) make up 84% of all noise walls. Concrete panels consist of two layers: load-bearing panels, up to 20 cm thick, a reinforced concrete layer, and an absorbing layer made of lightweight porous concrete (with 3–5 mm aggregate grains of expanded clay, wood fibers, and rubber granules), usually up to 15 cm thick. Metal panels are made of (galvanized) steel, stainless steel, or aluminum and consist of two lacquered plates, 0.5 or 1 mm thick, between which stone wool (50, 80, or 100 mm-thick) is installed. Wooden panels are made of solid or laminated wood or plywood. Panels with a willow front and stone-wool interior are also considered to be wooden in some publications. Due to the above, the present review of the literature and standards is limited to wall panels made primarily of concrete, metal, and wood.

2.1. Characteristics of Concrete, Metal, and Wood Panels

When designing road traffic noise walls, all EU Member States must respect the CEN/CENELEC Internal Regulations European Standards for Road Traffic Noise Reducing Devices Acting on Airborne Sound Propagation written by CEN/TC 226/WG 6 [47]. This package can be subdivided into four main sub-packages: acoustic characteristics, non-acoustic characteristics, long-term performance, and sustainability of road traffic noise reducing devices [38,44,48]. The following is an overview of the characteristics required by these packages, based on which a further comparison of the efficiency and sustainability of noise walls with respect to the materials of their panels is given.

2.1.1. Acoustic Characteristics

The sound absorption ability of wall panels is crucial for the effectiveness of noise walls. The greater the ability of the panel to absorb the sound, the lower the reflection of the sound wave from the wall towards the objects on the opposite side of the road and back towards the vehicles (the noise source). Panels whose DLα is greater than 10 dB are considered to have good absorption properties [38]. Non-absorbing or reflecting noise walls will allow the sound to travel over the noise wall after repeated reflections between the wall and the vehicles. Due to this sound wave behavior, the use of panels with few or no absorption properties (such as transparent panels) can cause the sound level to increase in the vicinity of the receiver behind the noise wall. An increase in noise levels at the receiver due to such reflections can be as high as +3 dB(A) [38].

The sound insulation property is defined by the loss of sound energy, which occurs when a sound wave passes directly through a wall. The sound insulation provided by a barrier is dependent upon many factors, such as surface density, stiffness, loss factors, and the angle of incidence of the sound. The most significant of these is the surface density of the barrier [26]. A panel is considered to have sufficient insulating properties if its surface density is 20 kg/m2 or higher [49].

Insertion loss is defined as the reduction of the noise level in dB(A) at a given location due to the placement of a noise reduction device in the sound path between the sound source and that location. A properly designed noise wall should attain an IL approaching 10 dB(A), which is equivalent to a perceived halving of loudness for the first row of homes directly behind the wall [50]. Field investigations performed in [51] showed that the correlation between wall insertion loss and material type is the greatest among the observed location and walls characteristics, such as a wall’s height and its distance from the roadway, air temperature and humidity, total traffic volume, and average speed.

2.1.2. Non-Acoustic Characteristics

The required non-acoustic characteristics of road traffic noise reducing devices are given in a set of EN 1794 standards [47]. The general required technical characteristics of noise walls include mechanical resistance and stability and safety characteristics.

Safety characteristics address fire resistance, light reflection, the risk of falling debris, and emergency escapes. The required fire resistance of a noise wall is reflected in the limitations set for the use of both flammable and non-flammable materials, which could develop toxic gases or wind-borne embers if affected by open flames from a forest fire or traffic accidents. Fire resistance is a major safety issue for wood panels. In the case of the smooth metal panels, a major safety issue is the reflection of light, e.g., glare that can disturb road users. This negative phenomenon is more pronounced when using lighter colored panels and occurs both during the day (in the morning and evening when the sun rays are at a small angle) and at night (due to the use of lights, which is especially pronounced if the panel surface is wet). The use of panels with rougher surfaces and deeper relief designs, like concrete panels, can reduce or eliminate this problem.

The mechanical performance and stability requirements for noise walls are ensured by the proper design and installation of the wall elements (panels, columns, and foundations). A constant load in the form of the panel’s own weight, which mainly depends on the panel’s material, is especially important when designing walls on viaducts, bridges, retaining, and abutment structures. If it is not possible to make alterations in such structures that would ensure their higher load-bearing capacity, lightweight panels are usually chosen. In addition to a constant load, the greatest load that the wall structure can resist is defined by the wind. The wind load depends on the geographical location of the structure and may also depend on the ratio of the altitude of the location and the surrounding topography. If the wall is located very close to the road, additional dynamic loads must be taken into account, such as aerodynamic forces due to the passage of heavy vehicles, forces due to the possible impact of vehicles and airborne debris on the structure and horizontal pressure from snow accumulated along the lower parts of the wall structure after clearing snow from the road.

Concrete panels have many advantages, including high durability, stability, and resistance, as well as numerous fastening and panel design options. They can also be molded into a wide range of different shapes so that they can easily be incorporated into any landscape. The significant weight of concrete panels, although favorable in terms of the resistance and stability of the final structure (especially in locations with high wind loads), can be a problem. This weight can increase the transport costs over long distances and often require special installation techniques and equipment. Their weight also makes such panels unsuitable for installation on viaducts and bridges. The standard panel width of 4 m (column spacing) requires lower costs for the construction of foundations and columns. The manipulation of heavy concrete panels requires the use of cranes that, if mounting is done from the carriageway, obstruct traffic during installation.

Metal panels, due to their lower weight, are the usual choice for installation on bridges and viaducts, on existing retaining walls with a limited load-bearing capacity, and when there is a need to increase the height of existing noise walls. The costs of delivering these panels to the construction site are small in comparison to the costs related to concrete walls. When installing aluminum panels, care must be taken to prevent direct contact of the aluminum with other metals (primarily steel) since aluminum reacts similarly to zinc in galvanizing processes, i.e., it acts as a “sacrificial” element that will shortly disintegrate. Anti-corrosion coatings on metal panels are mandatory in cases of high exposure to salt and moisture. Moreover, since all metal panels are conductive, their installation is not desirable near electrical lines if the proper grounding of all metal components cannot be ensured. Metal panels are easily installed using cranes. The possible closure of road traffic during the construction of such walls is rather short in duration, but for the execution of fastenings, it is necessary to provide scaffolding whose installation can require a significant amount of space, work, and time. The usual length of metal panels of 3 m requires higher costs for foundation and column construction compared to concrete panels.

Wood panels are often the first choice for landscape architects; due to their low weight, their transportation costs to the construction site are small. Wood panels are inserted between posts and then fastened together with nails or screws, which are preferably made of non-corrosive metal (stainless steel or aluminum). The main advantage of this method of fastening is the possibility of the quick and easy assembly and disassembly of the noise wall, which is why traffic closures during construction are short. These panels are easily installed with the use of cranes, but, as with metal panels, it is necessary to provide scaffolding for the execution of the fastenings.

2.1.3. Long-Term Performance

Standardized procedures for the assessment of the long-term acoustic and non-acoustic performance of road traffic noise reducing devices were published in 2015 in a set of EN 14389 standards. In general, the panel material and wall construction design should provide long term durability against the effects of weathering and varying climate change, a long service life with minimal maintenance (or no maintenance), the efficient removability of the wall for repair or at the end-of-life, and consistent acoustic performance throughout the panel’s service life.

Durability and resistance against the possible impacts of climate change affect the acoustic and non-acoustic performance of noise walls and determine how often they require major repairs or replacement. The selection of an appropriate panel material depends primarily on the obligations of the designer to follow the prescribed technical requirements to ensure the long service life of the structure in local conditions. In doing so, it is necessary to consider the resistance of the material to possible freezing and thawing phenomena, the influence of road water, the impact of UV radiation, and the behavior of the material at local temperature extremes.

The service life of a noise wall can be defined as the time over which the wall continues to optimally fulfil its task. This is the carefree period [37] featuring no major changes in the acoustic and physical properties or appearance of the panels—i.e., the time from wall construction to the time that the wall needs to be replaced. This time mostly depends on the panel material: The expected service life of concrete panels is 40 years, that of metal steel is 20 to 25 years, that of metal aluminum is 30 years, and that of wood is 20 or more years, depending on the protection type [44,52].

Maintenance of a noise wall is vital to ensure its optimum performance during its service life and to ensure that any necessary repairs resulting from natural weathering or physical damage are made. While most EU member states have some form of a general maintenance programme for maintaining existing roads, less than 20% of them have specific protocols for the maintenance of noise walls [45]. The following exploitation behaviors and maintenance issues during the noise wall service life were reported in [44,51,53,54,55].

Concrete panels are very resistant to damage caused by vehicle and debris impacts, pressure from snow removal deposits, and other phenomena during maintenance. The rough surfaces of these panels do not attract graffiti artists because they require the use of a larger amount of paint, which is why vandalism is usually not a problem. Because they withstand extreme temperature changes, UV radiation, moisture, ice, and salt very well, maintenance related to the structural and aesthetic integrity of such a wall structure is rarely carried out. In the case of an absorbent layer made with wood fibers, damage to this layer in the lower parts of the structure (1 m from the ground surface) due to moisture is possible. The absorbent layer made with an expanded clay aggregate can also peel off due to impact and is not resistant to freezing.

Metal panels gradually rust, which is a result of the large amounts of moisture and salt in the air. If the panels are not coated with anti-corrosion paint or galvanized, the rust from the panels will very quickly spread to other elements of the wall. Even at low panel stresses caused by normal temperature changes, warping can occur if there are no reinforcing rods inside the panel. In addition, the low resistance and small thickness of the metal plates make these panels very susceptible to damage due to vandalism, debris, or vehicles; regular road maintenance; and snow clearing. Due to their smooth surfaces, they are a frequent target of graffiti artists.

Wood panels are not structurally strong and shatter easily in the event of a vehicle impact. Moreover, they are not dimensionally stable; they warp and shrink over time due to atmospheric influences (sun, moisture) or insect attacks. This causes cracks to appear along joints, especially if the wood was not dried enough before the panel was produced, which reduces wall effectiveness of the panel’s noise protection. The warping problem during exploitation is proportional to the thickness of the panels. Although impregnated wood is used in their production, wood panels require periodic coatings, primarily to ensure the protection of the panels from moisture and insects but also due to the fading of their original color. Repairs or replacements of damaged parts are intrusive unless they are carried out using elements that were procured at the same time as the wall was installed and were exposed to the same weather conditions over that time. There is a high possibility that metal fastenings will react chemically adversely over time when in contact with certain types of protective coatings. Wood impregnation or coating is a major problem in the case of fire due to the emissions of harmful gases into the environment.

2.1.4. Cradle-to-Gate Sustainability

The Construction Product Regulation (305/2011/EU-CPR) [56], in force from the second half of 2013, promotes a new approach in product qualification based on a declaration of performance against seven essential requirements. The sustainability of construction products has been specifically addressed as the new seventh basic requirement. Sustainability as a topic entered the EU noise reduction device standards framework in 2014, but no standards have yet been published [47].

The sustainability of noise reduction devices during their whole lifecycle (in the planning and design, manufacturing and construction, maintenance and repair, removal, and demolition phases) was addressed in the QUIESST project [43], where guidelines were presented for the first viable method to assess a noise reduction device’s sustainability. However, due to the lack of available data on the use, maintenance, and removal of noise walls related to the panel material, only the effect of panel production, i.e., cradle-to-gate sustainability, in quantities corresponding to a wall length of 1 km and a height of 2 m were analyzed in this project [44]. The panel production carbon footprint, water footprint, primary energy use (defined by natural resources before they are subject to change by and for human needs), and energy consumption due to panel transport (assuming transport by rail over 1 km) were analyzed. The analysis considered the calculated average acoustic damping, thickness, weight, and surface density of the panel with respect to the material, with additional considerations of material recyclability and assumed durability. The following conclusions were made in the QUIESST project about the cradle-to-gate sustainability of panels and their impact on the environment during production.

The production of concrete panels has the largest carbon footprint but, at the same time, the smallest water footprint. The production of wood willow panels has the smallest carbon footprint but, at the same time, the largest water footprint. The production of metal panels also requires a significant amount of water. Primary energy consumption is the lowest for wood panels. The negative effect of transport in the form of energy consumption is the most pronounced for concrete panels due to the maximum total weight of materials needed for their production. It was concluded that, from a sustainability point of view, the most unfavorable process is the production of wood panels due to the very small amount of recyclable materials that can be used in the production process and the large amounts of water needed for the growth and processing of this natural resource.

All materials considered in the analysis can either be recycled or use recycled components, but special disposal procedures need to be provided for aluminum, steel, and wood panels because they contain minerals or stone wool, a non-recyclable material. The problem of recyclability is most pronounced in wood panels. Removing and disposing of wood panels can be dangerous for the environment because of the various protective coatings that are used in the production and maintenance of such panels. Wood panels also burn like any other wood, and the smoke and ash that are released into the environment due to the combustion of treated wood (arsenic, benzene, chromium, creosote, and pentachlorophenol) are considered toxic. At the end of their lifecycle, due to their exposure to weather conditions, wood panels are usually not of sufficient quality for reuse or recycling. Moreover, the issue of deforestation has been raised recently.

2.2. Panel Material Trends

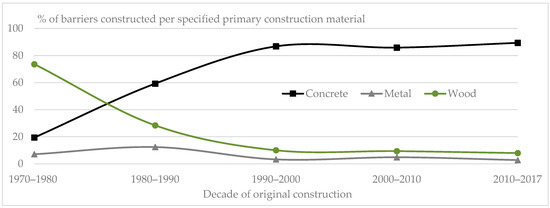

Noise walls have been established as noise management solutions on major roads in EU member states and in the USA for many years, and their positive and negative characteristics recorded during that time reflect the trends in their application. Since no systematized historical data on the application of a certain type of panel on road infrastructure at the EU level was found, in this research, the historical data (from 1973 to 2017) from the publicly available FHWA inventory of noise walls were used [46]. The results of the data analysis regarding the year the walls were originally constructed and the specified primary construction material (concrete, metal, or wood) are shown in Figure 1.

It is clear from the Figure 1 that the trend in the choice of materials shifted completely from wood to concrete panels in the last decades, even though, from a sustainability point of view, concrete panels’ cradle-to-gate carbon footprints are the worst among the observed types of panels. According to previous research, if the entire lifecycle is considered, the main environmental impact of concrete panels is related to the production processes of the binder and, to a lesser extent, the aggregate. A possible way to reduce the environmental impact of the production of concrete is to use secondary raw materials as source materials for concrete, either as binders (pulverized fly ash or ground granulated blast furnace slag) or as aggregates (polyurethane foam scrap, iron-free tire rubber granulate, mixed plastics aggregate, or expanded mixed plastics) [57,58,59,60]. In addition, as the lowest minimal average values were reported for the sound absorption of concrete panels, further investigations should be focused on the characteristics of absorbing lightweight concrete panels.

2.2.1. Lightweight Concrete Panels

Currently, sound absorbing (porous) lightweight concrete is a common material for the construction of the sound absorbing non-structural layers of concrete noise walls, and its noise abatement characteristics and applications in civil engineering fields have been researched in detail [61,62,63,64,65,66,67,68,69].

Lightweight concrete is defined as concrete with an oven-dry density between 800 and 2000 kg/m3. This property is achieved either by replacing dense natural aggregates with lightweight aggregates (lightweight aggregate concrete), by inducing voids within the concrete, or by eliminating the fine aggregate from the concrete mix [70,71]. The porosity of this type of concrete is achieved by creating open voids in the material that are developed by either removing or reducing the fine aggregates and lowing the binder contents. While sound waves propagate in these open voids, their energy is changed to heat energy, thus reducing the noise at the receiver end [64].

Lightweight aggregates used in the production of lightweight concrete are defined as any aggregates with a particle density of less than 2.0 Mg/m3 or a dry loose bulk density of less than 1200 kg/m3 [70]. Lightweight aggregates can be divided into two groups: those that are ready to use only with mechanical treatment, i.e., crushing, cutting, grinding, and sieving (such as pumice, diatomite, scoria, volcanic cinders, waste rubber granules, and plastic granules) and those whose production requires thermal treatments (like expanded clay, shale, slate, slag, diatomaceous shale, perlite, and vermiculite) [71,72].

From a noise-wall sustainability perspective, there remains a large selection of aggregates used in the manufacture of absorbing porous layers of the concrete wall panels facing the carriageway. The next section gives a more detailed review of the characteristics of materials used in the production of lightweight concrete panels.

2.2.2. Lightweight Aggregate Types

Lightweight expanded clay aggregates and lightweight plant biomass aggregates are common types of lightweight aggregates used today in the production of the sound absorbing, non-structural layer of noise walls. The use of recycled tire rubber aggregates as a sustainable solution to produce lightweight concrete has received increasing attention in recent years [60,73,74,75,76,77].

Lightweight expanded clay aggregates are produced from special plastic clay with no or very little lime content. In the production process, the clay is dried, heated, and burned in rotary kilns at 1100–1300 °C. Gas is released inside the pellets during heating and entrapped in the pellets during cooling, while the organic compounds burn off, forcing the pellets to expand. This process results in the production of ceramic pellets with porous, lightweight, and high crushing resistance properties, as well as a uniform pore structure and round shape due to the kiln’s circular movement. Lightweight expanded clay aggregates can have different sizes suitable for fine or coarse aggregates [78,79].

Lightweight plant biomass aggregates include waste produced by timber industries obtained from the cutting, sawing, or grinding of timber in the form of particles (hardwood or softwood sawdust, shavings, trimmings, and bark) or wood chips produced from roundwood logs. Wood is a highly porous and very durable material that needs to be treated before being used as an aggregate. Untreated plant biomass affects the hardening process of the cement, resulting in mixtures that have great difficulties in obtaining a fixed composition [80,81,82,83].

Recycled tire rubber aggregates are produced through the processing of end-of-life vehicle tires by a mechanical pulverization process or by a cryogenic pulverization process. The production of pulverized tires by the mechanical pulverization process includes three steps of mechanical size reduction, wherein the tires are torn to pieces and, through gradual grinding, undergo a separation process. In this process, the basic components of vehicle tires (rubber parts, steel, and textile fibers) are separated. After that, the rubber parts enter a granulator where they are processed into aggregates of different gradings. The production of pulverized tires by the cryogenic pulverization process includes two steps of mechanical size reduction. The first step is mechanical size reduction, and the second step is a further size reduction to the pulverized material under cryogenic conditions, through which it is easier to obtain the desired particle size [57,60,84].

The noise walls presented and compared in the following paragraphs include Liadur, Faseton, and RUCONBAR. Liadur is a noise wall whose panels incorporate lightweight concrete from the Liapor MLB 2 aggregate (750 kg/m3) in the absorption layer. Liapor is a lightweight aggregate with a German trademark and origin. While manufactured from an argillaceous resource of excavated shale in Germany, expanded clay is used under license in the production of Liapor MLB 2 aggregates [78]. The sound absorptive layers of Faseton noise wall panels are made from wooden cement that contains wood chips of various sizes. RUCONBAR was developed by The Faculty of Civil Engineering at the University of Zagreb during a project that was conducted under the umbrella of the Eco-Innovation initiative and the Executive Agency for the Competitiveness and Innovation Framework Programme (CIP). RUCONBAR panels have a sound absorptive layer that contains 40% rubber granules obtained through a waste tire mechanical recycling process [75].

2.2.3. Acoustic Characteristics

From a traffic noise management and abatement perspective, the most important property of the described noise walls is their ability to absorb noise. Testing of their absorbing properties in accordance with the standards HRN EN ISO 354:2004 and HRN EN 1793-1:1999 was conducted on samples of the abovementioned systems in the scope of the RUCONBAR project in 2013. The analyzed samples had similar absorbing surface cross-sections and absorbing layers 10 cm in thickness. According to the measurement results, all three analyzed noise wall panels are listed under the A2 class of sound absorption based on a sound absorption value ranging from 4.4 to 7 dB [73,74]. Higher classes of sound absorption are achieved when various cross-sections of the absorption surface are used, as shown in Table 1 [85,86,87].

Table 1. Classes of sound absorption for various cross-sections of the absorption surface.

| Product | Shape of Surface | Absorbing Layer Thickness (cm) | DLα (dB) | Sound Absorption Class 1 |

|---|---|---|---|---|

| Liadur | flat | 15 | 8 | A3 |

| low wave | 11 | 8 | A3 | |

| medium wave | 13 | 10 | A3 | |

| high wave | 22 | 16 | A5 | |

| Faseton | block | 7, 9 | 10 | A3 |

| low wave | 11 | 10 | A3 | |

| high wave | 12 | 18 | A5 | |

| mushroom | 16 | 15 | A4 | |

| RUCONBAR | flat | 20 | 6 | A2 |

| trapezoidal | 13 | 9 | A3 | |

| high wave | 12 | 9 | A3 |

1 A2: 4–7 dB, A3: 8–11 dB, A4: 12–15 dB; A5: >15 dB.

2.2.4. Cradle-to-Gate Sustainability

Previous studies have shown that the CO2-eq emission factors of manufacturing concrete components for the analysed noise walls are as follows. The CO2-eq emission factor for wood chips produced from roundwood logs is 7.9 g CO2-eq/kg [88], that for expanded clay aggregates amounts to 320 g CO2-eq/kg [59], and that for mechanically pulverized scrap tires amounts to 122 g CO2-eq/kg [84].

Research conducted in [59] showed that the carbon footprint of 1 m3 of concrete blocks (density of 1000 to 1400 kg/m3) with the expanded clay aggregate Liapor amounts to 290 kg CO2-eq based on a cradle-to-gate assessment and that the energy consumption of clay expansion is largely responsible for this value. At the same time, the carbon footprint of concrete blocks with tire rubber aggregates amounts to 205 kg CO2-eq.

3. Discussion

Among the observed panels, concrete panels have the highest mechanical resistance, longest service life, lowest lifecycle costs, and lowest water footprint. They also address all the required safety characteristics very well, i.e., they provide good fire resistance (with practically no toxic gases or wind-borne ember emissions in the case of a fire), have no light reflection (glare that can disturb road users is a common problem for metal panels), and possess only a small risk of falling debris in the case of a vehicle impact (they do not shatter like metal or wood panels). Furthermore, analysis of the historical data on the application of different types of noise walls showed that the choice of materials used in the production of panels shifted completely from wood to concrete in recent decades. Consequently, further investigations were focused on the concrete panel characteristics, specifically for panels with sound absorptive layers made with commonly used lightweight aggregates (expanded clay and plant biomass) and recycled tire rubber aggregates.

Based on the available data, the carbon footprints of concrete blocks with expanded clay aggregate are five times higher than the carbon footprints of concrete blocks with tire rubber aggregates in the cradle-to-grave approach. At the same time, the cradle-to-grave approach in a comparative lifecycle assessment of panels with an average absorption layer thickness of 7 cm and an identical structural layer resulted in significantly smaller differences in carbon footprints. This was caused by the exclusion of the environmental benefits from using recycled rubber (avoiding impacts from the disposal processes of old tires) from the analysis.

The results of the performed analysis are based mainly on publicly available data on noise walls constructed in Northern and Central Europe and the United States and, as such, may not be specific enough to give detailed insights into South European practices and experiences. To provide better insight into the service life efficiency of noise walls and panels and to improve the process of noise wall design and management in South European countries, further data analysis of panel production, application, and disposal will be conducted while focusing on those countries. Moreover, to further investigate the potential benefits and limitations of lightweight concrete panel application, the influence of the shape and thickness of the sound absorptive layer on the acoustic properties of these panels, as well as the impact of climate change on their durability, should be addressed in detail.

This entry is adapted from the peer-reviewed paper 10.3390/su13020536