Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Materials Science, Biomaterials

Food packaging plays an imperative role in the food processing sector by safeguarding foods from their point of harvesting until the moment of consumption.

- food packaging

- biopolymers

- polysaccharides

- aliphatic polyesters

- biopackaging

1. Introduction

According to the World Health Organization (WHO), there are an estimated 600 million cases of foodborne diseases and 420,000 deaths yearly due to contaminated and unsafe food [1]. Therefore, it is crucial to intake safe and nutritious food to maintain a long and healthy life. Food can be contaminated at various stages throughout the production chain, from farm to consumption. Maintaining food safety is a top priority for public health and essential for attaining food security. Moreover, food safety and quality control systems are vital not only for protecting the health and well-being of consumers but also for supporting economic growth and boosting livelihoods by providing access to local and global markets.

Advanced food processing and packaging techniques are important to maintain a safe food supply worldwide. Food packaging is a key player in the food processing industry by safeguarding foods from their point of harvesting to the time of consumption. Food packaging protects its content from physical, biological, enzymatic, and biochemical damage. Beyond preservation, packaging also provides containment, utility, and communication [2]. The most used conventional food packaging materials include plastics, glass, metal, paper and paperboards, wood, and composites. These materials have long been the basis of the packaging industry as they have various properties that meet food preservation requirements [3]. Even though conventional packaging materials fortify foods from different contaminants, other factors related to production costs and social and environmental aspects have raised many concerns over the past few decades.

Furthermore, single-use packaging materials prepared from conventional raw materials are the most widely employed in the food industry. They are predominantly disposed of right after use, causing numerous environmental concerns. For instance, over two-thirds of the total production of single-use packaging materials is used in the food sector alone. Due to changes in food production and consumption habits and the growing population, this number continues to rise [4]. Consequently, accumulating packaging waste in large quantities has made it extremely difficult to handle solid waste sustainably. Surprisingly, around 30–35% of municipal solid waste comes from global packaging waste, and food packaging accounts for approximately 60% of total solid municipal waste [5]. Hence, to address issues related to conventional food packaging, sustainable packaging materials with better thermal, mechanical, and barrier properties have significant importance in the food industry [6]. Interestingly, many investigations are underway to develop alternative food packaging materials due to increased consumer awareness about health, food quality, food safety, and environmental sustainability pertaining to food packaging [7].

2. Conventional Food Packaging

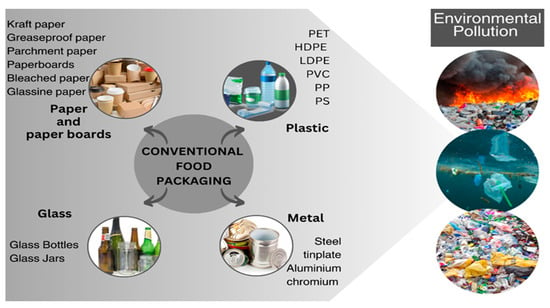

Food packaging is a complex system that protects food until it arrives at its destination in perfect condition through transportation, distribution, and storage. Various packaging materials have been introduced to provide the desirable functionality of a packaging system for different food items. The selection of proper packaging materials is essential for maintaining product quality until usage, as well as fulfilling product requirements such as barrier properties and economic, environmental, and social factors [14]. Generally, conventional packaging can be divided into three categories based on their application: primary, secondary, and tertiary. Primary packaging comes directly into contact with the food product and provides a protective barrier, secondary packaging stores several primary packagers, and tertiary packaging is employed for bulk storage and transportation [3]. Paper and paperboard, plastics, glass, and metal are the primary packaging materials utilized for most commercial food products, and a combination of more than two packaging materials is used to provide the best protection for food products, as shown in Figure 1. The following section discusses the conventional packaging materials and their pros and cons.

Figure 1. Main types of conventional food packaging materials.

2.1. Paper and Paperboard

Paper and paperboard represent over 30% of the worldwide packaging industry and are commonly applied in the food industry for product containment and preservation [15]. Paper and paperboard packages can be recognized as environmentally friendly due to their biodegradability, which promotes their usage in the food industry. Many paper and paperboard packages are available, from lightweight packages such as infusible tissues for tea bags to heavy tertiary packaging boxes. Paper and paperboard have been utilized for food packaging since the seventeenth century, and usage increased in the late nineteenth century [16]. Of total paper production, more than 92% is made from wood pulp and the remaining 8% is generated from agricultural by-products such as bagasse, straw, flax, and corn husks [17]. The quality of the paper depends on the type of raw materials used for paper development and their fiber and pulp properties [18]. Cellulose is responsible for providing a fiber-forming ability with long and straight fibers, hemicellulose in wood pulp is responsible for bond development during the paper-beating process, and lignin acts as a natural binding component for the paper development process [15]. After the pulping process, all unit operations, such as bleaching, beating, refining, and final treatments, are responsible for manufacturing paper with different qualities and appearances [19]. Table 1 summarizes the various types of paper packaging used in the food industry.

Table 1. Major types of paper used in food packaging.

| Paper Type | Properties | Application | Ref. |

|---|---|---|---|

| Kraft paper | Type of coarse, high-strength, economical, porous, tear-resistant paper with a rough surface that can be coated or laminated | Beverage carriers, boxes, sacks, cartons, packages for flour, dried fruits, sugar | [15] |

| Greaseproof paper | Translucent, machine-finished, resistant to oils | Wraps cookies, confectionary, snack foods, highly oily foods | [20] |

| Parchment paper | Made from acid-treated pulp, not heat sealable, poor air and moisture barrier properties, high wet strength, greaseproof | Layer between pastry or meat slices, labels for fatty foods, cheese wrapping | [15] |

| Glassine paper | Glassy, smooth surface; transparent sheet; good grease and oil resistance; high density | Liner for baked goods, biscuits, cookies, cooking fats | [21] |

| Bleached paper | Soft and white, weaker compared to unbleached paper, expensive | Food labels, flour, sugar, fruits and vegetables | [22] |

| Paperboards | Thicker than paper, rigid, foldable; different types are available: whiteboard, liner board, food board, carton board, chipboard, corrugated board | Rigid boxes, beverage cartons, boxes for fruits and vegetables | [22,23] |

Paper and paperboard packaging possesses several advantages, including low production cost, biodegradability, lightweightness, flexibility, printability, and recyclability [24]. However, they are also associated with environmental and health issues. For instance, chemicals added during pulping and coating to enhance the properties of final packages may migrate into foods, resulting in adverse health effects. Organic and inorganic dyes, mineral oil phthalates, and polyfluorinated substances are some of those migrants, and high mineral oil migration has been reported with recycled papers [15]. Other than that, many researchers have found that printing inks used for paper packages could cause cancer [25]. Moreover, the paper-making process requires a large volume of water and is energy-intensive, giving rise to vast amounts of wastewater and pollutants.

2.2. Plastic

Plastics are synthetic polymers with macromolecular structures obtained from repeating units of low molecular weight monomers [26]. During the last few years, plastics have become versatile and essential materials in the food industry. They are the second most used packaging material due to their flexibility, chemical resistance, low cost, lightweightness, and physical and optical properties. Plastics are commonly recognized as single-use packaging materials, contributing immensely to the environment and human health [27,28]. Global annual plastic production was estimated at 360 million tons in 2018 and it is projected that the worldwide production of plastics will reach 25 billion tons by 2050 [29]. Single-use plastic accounts for nearly 40% of overall plastic usage [30]. Moreover, it was estimated that China is the world’s top producer of plastic materials, meeting around 29.4% of global demand, followed by Europe and North America, with 18.5% and 17.7% of the global market, respectively [31]. In the packaging sector, 50% of the plastics for the food packaging industry are obtained from fossil fuels, and these fossil fuel-derived plastics take many years to degrade [4]. Thermoplastics are popular in food packaging applications. A thermoplastic is any polymer that becomes pliable or rubber-like above a specific temperature, known as glass transition temperature (Tg), and solidifies below Tg after cooling. The transition from the rubber-like state to the glass state is a key characteristic of polymer behavior, providing significant changes in the physical properties, including elasticity and hardness. Table 2 summarizes different types of plastics and their applications in food packaging.

Table 2. Major types of plastics used in food packaging.

| Plastic | Properties | Application | Ref. |

|---|---|---|---|

| Polyethylene terephthalate (PET) | Good barrier to gases and moisture; resistant to heat, mineral oils, solvents, and acids; transparent; tough |

Beverage and mineral water bottles, jars, tubes, trays | [32,33] |

| High-density polyethylene (HDPE) | Good barrier to solvents and moisture, high tensile strength, opaque, high-temperature capability |

Beverage and milk bottles, shopping bags, ice cream containers | [30,34] |

| Polyvinyl chloride (PVC) | High resistance to chemicals, high strength, good oil barrier properties, good heat sealability | Bottles, food wraps | [35] |

| Low-density polyethylene (LDPE) | Good heat sealing; resistant to acid, oils, and bases; rigid; flexible; transparent | Bakery, frozen, fresh produce, and meat packing; soft squeeze bottles | [36] |

| Polypropylene (PP) | Good water vapor barrier, resistant to gases and odors, high strength, puncture resistance | Containers for ice cream, margarine, yogurt, snack packs, and biscuit packs | [34] |

| Polystyrene (PS) | Brittle, rigid, poor barrier to moisture and gases, good insulation properties | Cutlery, food insulation boxes, meat trays, egg containers | [37,38] |

From 1950 to 2018, 6.3 billion tons of plastics were produced; only 9–12% were recycled and incinerated and the remaining 79% were accumulated in the environment [39]. Due to their recalcitrant nature, plastic packages remain in the environment for decades, causing soil, water, and air pollution. The leaching of many hazardous chemicals in plastic packaging materials into the soil, underground, and into other water sources is an enormous consequence of landfilling after use [40]. Plastics also release significant amounts of greenhouse gases upon oxidation and incineration [41]. Different types of additives in plastics, such as bisphenol A, poly-fluorinated chemicals, phthalates, and brominated flame retardants, are toxic and potential carcinogens [30,42]. Also, synthetic packages are petroleum-based, contributing to the depletion of nonrenewable petroleum resources [4]. Furthermore, photodegradation causes these plastics to break into tiny fragments, eventually forming microplastics. Microplastics have long been known for their role in environmental implications and may enter the marine and human food chains, leading to health risks.

2.3. Glass

Glass is one of the oldest food packaging methods and dates back to 2500 BC. According to the American Society for Testing and Materials (ASTM), glass is an amorphous inorganic product of fusion that has been cooled to a rigid condition without crystallizing [43]. Glass is made of silica, which is naturally found in silica sand, with different additives by fusion at high temperatures [44]. Recycled glasses can be used as a substitute for virgin materials, reducing energy usage during glass production [45]. Glass bottles and jars are employed primarily in the food industry and generally contain 68–73% of silica, 10–13% of limestone, 12–15% of soda ash, and 1.5–2% of alumina [46].

Glass is applied in food packaging because of its excellent barrier properties, heat resistance, transparency, moldability, rigidity, and strength [47]. However, the main disadvantages of glass packages are their production costs, heavy weight, light permeability, and fragility. When comparing the interaction of food packaging material with packaged food, it was discovered that glass is the only packaging material that prevents toxic substances from being transferred from the package to the food and maintains the best quality of the food product [44]. However, the most notable setbacks of glass packaging include the high energy requirement and air pollution during glass production, which is three-fold higher than for plastic production [44].

2.4. Metal

Metals are widely employed in the food industry for various applications and, amongst the total usage packaging materials, 15% is accounted for by metal packaging [48]. Excellent barrier properties, good physical protection, recyclability, formability, heat resistance, and decorative ability enhance consumer preferences for metal packaging [49]. Steel, tinplate, aluminum, and chromium are metals used for packaging dairy products, fruits, vegetables, beverages, meat-based products, bakery, and confectionary products [48]. Steels provide a barrier to gases, odors, moisture, and light; coating improves heat sealability due to ductility [50]. Steel coated with tin is one of the most used materials in food packaging and is utilized to produce cans and sheets for bulk products [51]. Aluminum can be formed into different forms, such as cans, foils, and laminated films; they are lighter and weaker and can be alloyed and shaped easily compared to tinplate [22].

The main food safety issue of metal packaging is the migration of materials, including metallic compounds and their interaction with food. Bisphenol A, lead, chromium, aluminum, cadmium, mercury, and nickel coatings are some migrants from metal packaging to food [48]. Metal packaging causes minimal direct impact on the environment compared to plastic packaging other than landfilling. However, metal packaging contributes to drainage blockage and the pollution of aquatic sources and requires high energy during production; additionally, chronic metal and polyaromatic hydrocarbon co-exposure may lead to cancer [48]. Table 3 compares the advantages and disadvantages of mainstream packaging materials.

Table 3. Advantages and disadvantages of conventional packaging materials.

| Packaging Material |

Advantages | Disadvantages | References |

|---|---|---|---|

| Paper and paperboard | Low production cost, biodegradable, lightweight, flexible, printable, renewable, and recyclable | Combined with other packing materials, limited barrier properties, less durable, susceptible to damage, and unsustainable | [15,24] |

| Plastic | Versatile, lightweight, flexible, chemically resistant, low-cost, better physical properties, inert characteristics, easily processed, and recyclable | Non-biodegradable, causes environmental pollution, leaches many hazardous chemicals into foods, and dependent on fossil fuels | [22,41,44] |

| Glass | Durable, chemically inert, recyclable, transparent, good barrier properties, heat-resistant, and high-strength | Fragile, heavier than other materials, high production cost, and more energy consumption in production | [44,47] |

| Metal | Durable, excellent barrier properties, good physical protection, recyclable, good formability, good heat resistance, and versatility | High production cost, corrosive, and non-biodegradable | [48,50] |

This entry is adapted from the peer-reviewed paper 10.3390/jcs8030114

This entry is offline, you can click here to edit this entry!