Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Mechanical

The solar collector is one of the most cost-effective pieces of equipment used to harvest solar thermal energy. Two main types can be identified: (1) water-based solar collectors (WSCs), an already popular solution for preparing domestic hot water and heating, and (2) air solar collectors (ASCs), used to preheat fresh air and to dry or heat the air inside a room. Thermal energy storage applied to TSC is studied in terms of design criteria, materials technologies, and thermal conductivity. This review highlights the potential of nanomaterial technology integration in phase change materials (PCMs) in terms of thermal performance improvements. The integration of diverse materials such as graphene, graphite, metal oxides, and carbon nanoparticles holds the potential to significantly enhance the thermal conductivity and latent heat value. However, some important aspects need to be further investigated as the highest possible percentage of nanomaterial in the mixture in order to avoid agglomeration.

- phase-change materials

- nanomaterials

- nano-enhanced phase-changing materials transpired solar walls

1. Nanomaterials’ Types

Existing nanomaterials used in TES have been grouped into three categories: nanometals, nanometal oxides, and nanocarbons.

Nanometals represent a class of materials wherein metallic particles are manipulated at the nanoscale, typically with dimensions below 100 nm. It is well known that metals have high thermal conductivities. This reduction in size imparts unique and enhanced properties to these materials compared to their bulk counterparts. Nanometals exhibit remarkable electrical, thermal, and optical characteristics, making them invaluable in various technological applications. They have a large surface area-to-volume ratio.

Silver exhibits the highest thermal conductivity among all metals, excelling in both heat and electricity conduction, with a thermal conductivity value of approximately 430 W/mK. Gold and copper are closely behind silver in terms of thermal conductivity, boasting values that are nearly equivalent. However, silver and gold are characterized by their high cost. In contrast, copper offers a more economical alternative and holds a competitive edge over silver and gold in various applications, as Leong K.Y. et al. notice in [66].

Nanometal oxides, composed of metal cations bonded with oxygen, are another fascinating class of nanomaterials. These materials exhibit diverse properties depending on their composition, size, and structure. They find extensive use in applications such as electronics, energy storage, environmental remediation, and catalysis. Nanometal oxides, like alumina and copper oxides, are good conductors of heat, with a thermal conductivity ranging from 30 to 40 W/mK. They are known for their exceptional surface area and reactivity, making them effective in various chemical processes.

Aluminium oxide nanoparticles (Al2O3) have been investigated for their potential to improve the thermal performance of phase-change materials (PCMs) used in low-temperature TES [66,67,68]. These nanoparticles can enhance heat transfer within the PCM, leading to more efficient energy storage and release.

Nano-titanium dioxide (TiO2) is another metal oxide that has been studied for its applicability in low-temperature TES systems [68,69]. It can serve as a nucleating agent in PCMs, reducing subcooling effects and promoting more controlled phase transitions, thus improving overall TES efficiency. Nano-iron oxide nanoparticles (Fe2O3) have been explored as potential additives to enhance the thermal conductivity of PCMs used in low-temperature TES. Their presence can facilitate better heat transfer and temperature regulation within the storage medium, according to Chaichan M.T. et al. [70]. Nano-zinc oxide (ZnO) is known for its versatile properties and has been considered for low-temperature TES applications. Manoj Kumar P. et al. state that it can be integrated into PCMs to help manage temperature differentials and improve the overall thermal performance of the TES system [71]. Nano-copper oxide (CuO) particles have been investigated for their ability to enhance the thermal conductivity of PCMs in low-temperature TES applications. They can promote more efficient heat transfer and reduce temperature fluctuations [72]. Nano-cobalt oxide (Co3O4) is another example of a metal oxide that has shown promise in low-temperature TES systems. Its use as an additive in PCMs can contribute to better temperature control and improved energy storage capabilities.

Nanocarbons encompass a family of carbon-based nanomaterials, including carbon nanotubes (CNTs), graphene, and fullerenes. These materials have garnered immense attention due to their extraordinary electrical, mechanical, and thermal properties. Carbon nanotubes, for example, exhibit exceptional thermal conductivity, knowing that individual carbon nanotubes can range from 1000 to 3000 W/m·K or even higher and are successfully used in this matter [66]. Graphene, a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice, boasts remarkable mechanical strength, electrical conductivity, and thermal properties and possesses extremely high thermal conductivity, with values exceeding 3000 W/mK. It has the potential to revolutionize various industries, including electronics and energy storage [68].

As a synthesis of the main advantages and disadvantages regarding each type of nanomaterial used in TES, nanometals have advantages such as high thermal conductivity, which leads to improved heat transfer within the storage medium, and increased heat capacity, allowing for more efficient thermal energy storage. The main disadvantages are related to agglomeration issues, which have an adverse effect on heat transfer qualities, as well as the increased cost. When compared to pure metals, nanometal oxides offer more stability and resistance to oxidation. Nevertheless, the thermal conductivity is lower, and the synthesis is more difficult, resulting in higher production costs. Nanocarbons, such as carbon nanotubes and graphene, have high heat conductivity and are lightweight, which might be useful in some applications, particularly if weight is an issue. Also, they show good chemical stability, reducing the possibility of reactions with the storage medium. Nonetheless, achieving uniform dispersion of nanocarbons in the storage medium can be challenging, affecting their performance.

The enhanced performance of nanomodified paraffins using carbon nanotubes was studied in [73,74]. These nanotubes significantly improved thermal conductivity, leading to increased efficiency in charge/discharge regimes. Moreover, the integration of carbon nanotubes enabled the development of robust thermal devices, demonstrating substantial heat flux through controlled thermal contact. Magnetically controlled heat storage materials, modified with carbon nanotubes, exhibited efficiency in practical applications like self-rescue devices.

The development of materials with thermo-optic switching properties, such as paraffin hosting carbon fillers, represents a significant advancement in the field of solar energy utilization. These materials exhibit the ability to alter their optical properties in response to temperature changes, making them valuable for applications in thermal energy storage [75,76]. The integration of nanomaterials, including carbon nanotubes and graphene, into paraffin enhances its thermal conductivity and allows for efficient absorption and release of thermal energy. Notably, nanometals, nanometal oxides, and nanocarbons bring unique characteristics to the composite material, such as enhanced thermal conductivity and adjustable properties, making them promising components for thermal energy storage systems.

The overview highlights the significant role of nanomaterials in overcoming challenges associated with traditional PCMs in solar collectors. The ability of nanomaterials to enhance thermal conductivity, regulate temperature differentials, and improve energy storage efficiency is a recurrent theme. The selection of specific nanomaterials, such as copper and graphene, reflects a consideration of both performance and cost-effectiveness.

Nanometals, nanometal oxides, and nanocarbons emerge as highly promising materials in TES applications. Their distinctive properties, including enhanced thermal conductivity and adjustable characteristics, position them as valuable components in the quest for efficient and effective thermal energy storage. This underlines the potential impact of nanomaterials on advancing the capabilities of solar collectors and expanding their applications in renewable energy systems.

2 Nanomaterials Integration

The present section delves into the diverse methodologies aimed at enhancing the heat transfer of phase-change materials (PCMs) in the context of thermal energy storage for buildings and renewable energies. Various techniques, ranging from macro and micro-encapsulation to the incorporation of metallic fins, materials with high thermal conductivity, and nanoparticles, are explored.

There are many methods that can be used in order to enhance the heat transfer of the PCM elements [77,78,79]: macro-encapsulation of the PCMs in steel cylinders or spheres, micro-encapsulation of the PCMs, the use of metallic fins to increase heat transfer surface, embedding materials with high thermal conductivity, and embedding nanoparticles with high thermal conductivity.

Nanoparticles represent a cutting-edge technological advancement aimed at enhancing heat transfer efficiency [80,81]. Nano-enhanced PCMs have been widely adopted in the fields of thermal energy storage for buildings and renewable energies [82,83]. Li [84] analyzed, via CFD simulations, the heat transfer inside a ventilation system for building heating based on paraffin RT30 integrated into sinusoidal encapsulations.

Alumina (Al2O3) nano-sized material was added to the paraffin with a fraction of 0.04 to enhance the conductivity of the latent heat storage. The most time-efficient method uses alumina nanopowders, with results showing a decrease in solidification time of 5.49%. The combination of Al2O3 nanoparticles with metallic fins in PCM storages [85,86] has shown even better results; indeed, solidification and melting time can be reduced by 12 and 6.4%, respectively. The findings from [70] indicate that the inclusion of nano-Fe2O3 at any mass fraction leads to a higher viscosity and density of the resulting mixture. The introduction of nano-Fe2O3 into paraffin wax results in a notable enhancement of thermal conductivity, with improvements of 10.04%, 57.14%, 76.19%, and 78.57% observed when mass fractions of 0.5%, 1%, 2%, and 3% are added, respectively. The outcomes of the study [71] demonstrated that the dispersion and distribution of zinc oxide nanoparticles within the paraffin did not disrupt its chemical structure. Additionally, the nanoparticles substantially improved the thermal stability of the paraffin and increased its thermal conductivity by up to 41.67% when incorporating 2% nano-ZnO particles. In [72], copper oxide (CuO) particles with a mean size of 40 nm were dispersed within the phase-change material (PCM) at three different weight percentages: 2%, 5%, and 10%. As a result of this dispersion, the thermal conductivity of the composite increased by 6%, 6.7%, and 7.8% in its liquid state. Simultaneously, the dynamic viscosity showed enhancements of 5%, 14%, and 30% as the mass fraction of CuO nanoparticles increased. During the solidification process, the heat transfer coefficient exhibited an increase of approximately 78% at the maximum flow rate [72].

Several types of materials have been investigated, but continuous research is needed. The integration of nanocarbon and nanococonut shells has been investigated by Sun Liu et al. [87]. Oleic acid and span 80 have been used to mitigate the agglomeration of nanoparticles during melting phases. The optimal concentration of nanoparticles was 0.02 wt%, and combined with oleic acid, a shorter melting time of 21% was reached compared to pure paraffin. Despite a more sustainable profile, the nanococonut shell was less effective than the nanocarbon. A challenging problem that arises in this domain is the design of more sustainable PCM and nanoparticles. Xie et al. [88] fixed one of these two issues using an organic PCM; nevertheless, they still used expanded graphite to improve the thermal characteristics of thermal energy storage. A new approach is therefore needed to develop more sustainable thermal energy storage.

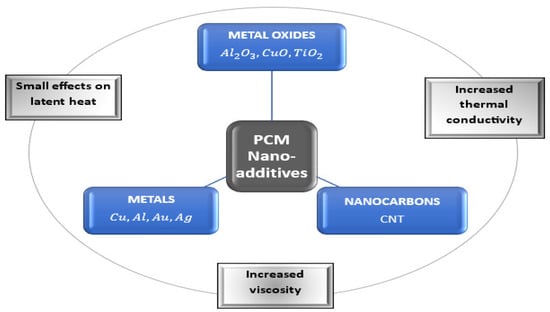

Integrating nano-enhanced phase-changing materials (nePCMs) into solar walls offers a promising strategy [65]. Several studies conducted emphasize that using fins, metallic foams, or nanoparticles increases heat transfer efficiency and thermal backup time [3,48,89] in the case of integrating PCMs within solar collectors. There are several types of nanoparticles that can be used: metal, metal oxides, metal foams, carbon nanotubes, carbon nanoparticles, graphene, and graphite, and the current nanotechnology has led to the production of even more materials of various types at the nanoscale level [66]. Different types of micro/nano-PCMs for solar thermal applications are presented in research conducted by Qiu L. et al. in [90], and a comprehensive image indicating nanomaterials with high conductivity for increasing the thermal performance of latent heat thermal energy storage systems can be seen in the Jegadheeswaran S. study [91]. The main implications of using different types of nanomaterials are presented in Figure 1.

Figure 1. Nanomaterials with high conductivity for increasing the thermal performance of latent heat thermal energy storage systems.

In [92], a composite bio-phase-change material (PCM) was investigated by Yu S. et al. by incorporating carbon nanoparticles at varying mass fractions of 1%, 3%, and 5%. The findings revealed a substantial enhancement in the thermal conductivity of the composite PCM with the inclusion of carbon nanomaterials. Moreover, the composite PCM exhibited impressive latent heat properties, featuring suitable phase change temperatures and robust thermal durability. Notably, the highest increase in thermal conductivity, reaching 336%, was observed at a concentration of 5.0 wt%, while a substantial increase of 166% was recorded at 1.0 wt%.

The utilization of nanomaterials in solar walls holds the potential to significantly enhance their performance. The integration of diverse materials such as graphene, graphite, metal oxides, and carbon nanoparticles can pave the way for improved thermal conductivity. Research has shown that even small concentrations, like 3 wt% of graphene and graphite, can lead to a remarkable 101.2% increase in thermal conductivity [93], according to Dsilva Winfred Rufuss D. et al. [93].

According to the same author, the thermal conductivity of the nePCM (nano-enhanced phase-changing materials) is affected by particle concentration, dispersion, size, shape, and temperature. Moreover, using graphite nanomaterials with concentrations between 0 and 10 wt%, the thermal conductivity of PCMs can be improved by about 540 to 1000%, but the incorporation of metal foams may also be a promising technique [94]. According to Mumtaz et al. [3], nanoparticles were first used in solar applications in 2009 and can lead to an overall efficiency increase. In a study conducted by Saw et al. [95], by using nano-enhanced PCMs, a flat plate collector’s efficiency was improved by 8.4%. Moreover, adding 1 wt% and 2 wt% copper nanoparticles in organic PCM improved the thermal conductivity of a pure PCM by up to 24% and 46.3%, respectively [96].

Despite advancements in developing new PCMs and improving their characteristics for use in solar walls, some limitations persist. The incorporation of nanoparticles into PCMs has shown promise in addressing these challenges. According to Kasaeian et al. [48], by embedding nanoparticles in PCM, the melting and solidification rate can improve, and the phase change time period can be reduced. As can be observed from the previous state-of-the-art survey, researchers have been concentrating on investigations mainly concerned with developing new PCMs or improving their characteristics and implementation into building components [48]. These advancements, however, have not overcome some major limitations, including the reduced potential for solidification and melting in order to discharge the accumulated heat indoors.

Nano-structuring the PCM could provide better thermal conductivity. However, other factors related to the geometry, quantity, and size of the implemented materials could have an impact on the properties of the mixture. Thus, the thermal characteristics of nePCMs should be measured, factoring in different geometries and loading ratios. By implementing various techniques, the nePCMs’ thermal properties can be controlled [97,98]. However, the non-homogeneous distribution due to high concentrations of the nanoparticles in the PCMs could reduce the melting performance, as Amidu, M.A. et al. observe, and the thermal performance overall [99]. The literature data suggest that the use of PCMs and nePCMs in buildings could increase energy storage efficiency and building performance. A reduction in temperature fluctuations and internal thermal stability can also be achieved with the implementation of these materials.

On the other hand, active walls with PCM and nePCM are inefficient in very hot climates where a higher temperature gradient is required and when the differences at high temperatures are significant. Therefore, additional solutions are required.

Several studies emphasize the application of nanoparticles in solar collectors, indicating that the incorporation of PCMs within these systems can lead to increased heat transfer efficiency and extended thermal backup time. Table 1 presents a brief synthesis of the results collected from various studies about the impact of adding nanoparticles to PCM.

Table 1. Results regarding nano-enhanced phase-changing material (nePCM) properties.

| Author | Investigation | Results |

|---|---|---|

| Keshteli et al. [85], Chen et al. [86] |

Combination of Al2O3 nanoparticles with metallic fins in PCM storage | Solidification and melting time can be reduced by 12 and 6.4%, respectively. |

| Sun Liu et al. [87] | Integration of nanocarbon and nanococonut shell | Shorter melting time of 21% was reached compared to pure paraffin. The nanococonut shell was less effective than the nanocarbon. |

| Li W et al. [78] | Metal foam or nanoparticle integration in PCM | Increased heat transfer efficiency and thermal backup time. |

| Jegadheeswaran S. [91] | Nanomaterials integration in PCMs | Enhanced thermal performance of latent heat thermal energy storage systems. |

| Yu S. et al. [92] | Incorporate carbon nanoparticles at varying mass fractions of 1%, 3%, and 5% in PCMs | The highest increase in thermal conductivity, 336%, was observed at a concentration of 5.0 wt%, while a substantial boost of 166% was recorded at 1.0 wt%. |

| Dsilva Winfred Rufuss D. et al. [93] | Integration of diverse materials such as graphene, graphite, metal oxides, and carbon nanoparticles in solar walls | At concentrations of 3 wt% of graphene and graphite, a 101.2% increase in thermal conductivity was identified. |

| Saw et al. [95] | Use of nano-enhanced PCMs in a flat plate collector | Efficiency was improved with 8.4% |

| Al-Kayiem, H.H. [96] | Addition of 1 wt% and 2 wt% copper nanoparticles in organic PCM | The thermal conductivity of the pure PCM improved by up to 24% |

| Amidu M.A. et al. [99] | High concentrations of the nanoparticles in the PCMs | Melting performance and the thermal performance reduction |

Although progress has been achieved, challenges emerge, such as the non-homogeneous distribution in high-concentration nanoparticle integration. The importance of a detailed understanding of the thermal properties of nePCMs should be investigated further, taking into account varied geometries and loading ratios.

This entry is adapted from the peer-reviewed paper 10.3390/en17051239

This entry is offline, you can click here to edit this entry!