Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

With the emergence of artificial intelligence (AI) and its integration into various intelligent robotics, the Fourth Industrial Revolution, also known as Industry 4.0, managed to trigger changes. Its need has been emphasized in multiple situations, such as that of the COVID-19 pandemic, entering every area of human life, with Industry 4.0 being more and more involved in production processes. Industry 4.0 is an emerging concept that is multidisciplinary and complex. Leveraging not just one, but a patchwork of technologies that can work individually as well as in combination, Industry 4.0 strives to achieve a more general digital transformation with high expectations both in the production of products and services in real-time. This effort is mainly based on advanced computers with fast processors able to store, manage, process, and analyze a large amount of data, spending less time and resources than ever before.

- machine vision

- computer vision

- Industry 4.0

- Industry 5.0

- industrial revolution

- artificial intelligence

1. Machine Vision

Vision is considered one of the most important human senses; it helps people perceive everything around them differently. The value and importance of vision has always been invaluable. For this reason, researchers since the 1980s have been working on providing machines with this ability, to see and perceive their surroundings, creating a research field widely known as “machine vision”. Machine vision systems can provide numerous automation options to variable manufacturing industries in a fast, efficient, and constant manner. Therefore, the term “machine vision” was directly linked to industry in general but more specifically to electrical engineering and robotics. Later, the term “computer vision” was introduced, but it was not long before both terms were merged into a common scientific field, that of AI, offering countless considerations for their use.

Machine vision, being a scientific subfield of AI, specifically tries to reproduce the sense of vision for machines through algorithms, covering areas even wider than human vision, namely from gamma rays to radio waves [13]. This reproduction is carried out in computers or robots. With the help of image sensors, digital visual data are obtained in diverse modalities such as images, videos, multidimensional images, etc., and along with supporting technologies such as image processing algorithms and communications, machine vision systems are created [14].

Machine vision systems in industry mostly consist of numerous cameras, which are placed according to existing requirements on assembly lines for product observation and data collection. They also provide the ability to read labels and automatically sort products without human intervention. Humans may be prone to errors due to tiredness and lack of adequate expertise. Consistency of automations combined with reduced human participation results in decreased errors and greater accuracy of detection, identification, supervision, measurements, etc. According to Javaid et al. [15], one of the reasons why the need for machine vision is crucial is because machines, systems, and robots have the ability to observe, communicate, and work with more precision, providing more opportunities.

The first milestone for machine vision was in the 1950s, where Gibson developed optical flow of two-dimension imaging towards statistical pattern recognition [16]. In the 1960s, Roberts was the first to formally study 3D machine vision in his PhD thesis at MIT [17]. In the 1970s, Marr from MIT developed an approach for scene understanding through computer vision, marking the beginning of real-word object tracking and low-level vision tasks such as detection and segmentation [18]. The development of both smart cameras and optical character recognition systems, in the 1980s, triggered the wide use of machine vision in ever increasing applications, starting from industrial ones, aiming to read letters and numbers to facilitate shorting and other product-related tasks. In the 1990s, machine vision invaded the industrial environments; companies started to sell commercial machine vision systems, while further technological advances were made from that time onwards, in terms of sensor functions, control architectures, and automation. The latter, along with the decrease in acquisition costs for machine vision systems, making them accessible to everyone, offered enhanced possibilities for machine vision systems to further advance. Therefore, since the early 1990s, machine vision has been developing rapidly. It has been closely connected to the cognitive field of machine learning and vision algorithms performed in real-time, providing significant results in a multitude of critical applications.

In the 1990s, thousands of factories worldwide included machine vision systems in their production lines to automate many of their operations.

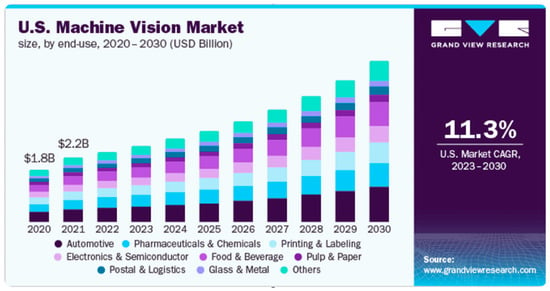

Over the years, both machine vision algorithms and systems have been playing a key role in increasing industries’ financial analytics incrementally in every report or sales survey. In 2017, the share of financial transactions in North America increased by 14.6% compared to the turnover of the previous year. After 5 years, in the year 2022, the global machine vision market was estimated at USD 16.89 billion, while it is estimated to grow by 11.3% within the next seven years (2023–2030), as illustrated in Figure 1 [19].

Figure 1. US machine vision market [19], available at https://www.grandviewresearch.com/industry-analysis/machine-vision-market (accessed on 5 February 2024).

More recently, machine vision combined with the advancements of the Industrial Internet of Things (IIoT) brought significant changes in the industrial settings. The IioT network can efficiently collect and analyze data from several machines, leading to high-quality production at reduced costs. In addition, when machine vision is embedded in industrial devices connected to IioT, images collected by machines can be used in operation monitoring, computation, and intelligent decision making [20,21,22,23,24,25,26,27]. In particular, machine vision both individually and in combination with other technologies helps to perform a specific task at a time. In the industrial field, the use of machine vision is for the purpose of solving problems of detection, classification, identification, material quality, control, monitoring, maintenance, storage, etc. In fact, the correct exploitation and processing of data coming from connected objects/elements in the production line enables fast, flexible, and more efficient product management, providing products of higher specifications at the lowest possible cost [28].

In order to understand the contribution of machine vision, it is worth presenting its use through specific examples. One example would be its use in problems that require classification and detection, using a deep learning model. In [29], for real-time tile detection in a production line, a deep model was trained with 30,000 images. The model returned better results for tile quality assessment compared to manual processes. Another example could be that of the identification and detection of the textures, decorations, and other characteristics of an ancient building studied in [30]. The manual process would require a lot of time and effort. The authors suggested an approach using a machine vision system, deep learning, and a convolutional neural network to classify building images, resulting in high detection accuracy rates. It is also worth mentioning the effort to build a visual detection platform, where, by photographing certain products, it is possible to directly match them with cloud storage data [31]. In fact, in the context of its transition to production mode, a method of directly creating matching templates using 3D cloud product models is also proposed [31].

Detection of defective materials on the production line can also be performed by using machine vision. Bianconi et al. [32] tested their algorithm on nine image datasets including seven material classes (carpet, concrete, fabric, fused lamination, leather, paper, and wood) of regular and defective samples, outperforming traditional detection methods.

Maintenance of machinery is also a big issue in industrial production. Predictive maintenance can be performed by combining machine vision and neural network models [33]. Low-cost cameras can efficiently support predictive maintenance in industry, at an ever-decreasing cost.

The ability to monitor manual work is also an important aspect of smart industry based on machine vision. Oyekan et al. [34], in the assembly processes in a production line, employed an RGB-D camera, such as a Kinect camera, along with machine vision techniques to acquire big data in real time, towards improving the production line and enabling a more flexible construction.

A factory’s warehouse stocking and inventory operations are largely completed manually by warehouse personnel with a high workload and high risk of error rates. A machine vision-based inventory consisting of a surface detection model of stacked products combined with a quantity calculation algorithm managed to perform better than the traditional manual way of working [35]. Another smart warehouse 4.0 approach suggests the combination of machine vision with the Internet of Things (IoT) [36].

Finally, quality control of production products is an important, time-consuming, but also crucial process for the entire production line. Machine vision managed to automate quality control in a reliable and effective way. A typical example is its use in the automotive industry in quality control of catalytic converters [37], but also in non-contact quality control of welded joints in welding productions in various industries [38].

To this end, it is evident from all aforementioned examples that machine vision is a technology whose size and scope of use in industry are enormous, and its contribution seems to be decisive for many areas of human life.

2. Industry 4.0

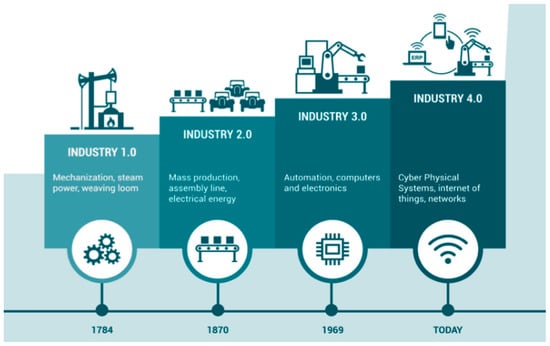

The Fourth Industrial Revolution, also known as Industry 4.0, was first introduced in 2011, promoting a new idea, that of a ‘Smart Factory’, where autonomy in all its aspects would be one of its main characteristics [39]. In fact, production systems would be able to make intelligent decisions in real time. It also came to shape the developments in the social as well as the working sector. The human workers could interact more with technology, which was more open, augmented, and also virtual [6]. The need for more human-centered approaches in the context of this era was evident [40]. Figure 2 illustrates industrial revolutions from the first to the fourth, along with their main characteristics.

Figure 2. The four industrial revolutions [41] are available at https://www.finite.com.au/blog/2018/11/fourth-industrial-revolution/ (accessed on 5 February 2024).

In Industry 4.0, automation seems to play a decisive role. The appearance of robots combined with many novel technologies came to meliorate all aspects of human life, including industrial automation. The concept of human–robot collaboration (HRC) is critical in modern smart manufacturing. In particular, it was stated that the new vision of this era is a production environment that mainly includes machine-to-machine communication, networking, productivity, and intelligence without human intervention [42]. Moreover, this new era includes reducing production costs, saving time, and increasing production and precision in the quality of final products, while ensuring maximum worker safety in dangerous industrial environments [43].

The main possibility of this era, however, is the constructive cooperation of computers and machines, so that after storing, managing, and processing a large amount of information, they allow efficient decision making without human intervention [44]. With AI, robotics, IoT, AR and VR, 3D printers, neural networks, cyber-physical systems, cloud computing, and many other technologies, new possibilities and perspectives are emerging, towards changing the concept of time [45], as well as the spiritual and living standards of humans in a more autonomous and intelligent era.

3. Industry 5.0

While one would expect that the end of one era would bring the beginning of another, this is not the case with the era of Industry 5.0. Already, within ten years of the advent of Industry 4.0, the European Commission brought to the fore and talked about Industry 5.0, outlining a series of implementation strategies from investment, marketing, and governance dimensions to promote it [46]. Until now, the response from other governments and industries is still limited. However, academia quickly embraced Industry 5.0; the Journal of Manufacturing Systems, the International Journal of Production Research, and the IEEE Transactions on Industrial Informatics established related special topics to encourage Industry 5.0 research in 2021. The Technical Committee (TC) on Digital Manufacturing and Human-Centered Automation also highlighted its relevance to Industry 5.0 [47]. Future technologies of Industry 5.0 (Figure 3) are summarized in the following:

Figure 3. The future technologies of Industry 5.0 [46].

-

Personalized human–machine interaction technologies that interconnect and combine the advantages of both humans and machines.

-

Bio-inspired technologies and smart materials, which enable recyclable materials with built-in sensors and improved features.

-

Digital twins and simulation to achieve modelling of entire systems.

-

Technologies related to transmission, storage, and analysis of data, with data processing and system interoperability.

-

Artificial intelligence to detect losses in complex dynamic systems, leading to actionable insights.

-

Environmentally friendly technologies (energy efficiency, renewable energy sources, storage, and autonomy).

Based on the above, it appears that the advent of Industry 5.0 is not just a technology-driven revolution, but is driven by values that will lead to purposeful technological transformation [48].

In Industry 5.0, operators and robots come together and collaborate to implement complex projects in a variety of scenarios with heterogeneous and dynamic conditions. Humans can work interactively with robots, by assigning them to repetitive or dangerous tasks. Less physical work and more safety are therefore guaranteed for human workers [49].

In the development of these models, a decisive and unique role is played by machine vision as a means of sensing, providing reception and processing of visual information about the environment, analysis of images of the workplace, transfer of relevant information to the control center, and decision making. In this way, the task of recognizing the actions of a human operator, in order to apply the extracted knowledge towards an effective human–robot cooperation system, becomes important [50].

A typical example of the above collaboration between humans and robots is provided by Wagner et al. [51] for an Industry 5.0 application of an end-to-end edge system based on machine vision. More specifically, a machine vision system is presented, which relies on cloud services for data storage and training of AI-based models, for the application of bin collection in industrial facilities. The system is intended to work with Universal Robots Collaborative Robots, namely cobots. In industry, bin collection refers to picking and moving objects (bins) to predetermined locations within the cobot’s work area. In the case study of Wagner et al. [51], the robot is constantly encountering objects it has never seen before; thus, it needs to learn them. The new objects are displayed to the robot by the human operator, posing an incremental learning challenge, towards automatically labeling the new training data to avoid time-consuming and expensive labeling processes.

Typical development of an object detection system involves training a model on a dataset in the cloud. After the model is successfully trained, it is used on an edge device in the production line. However, there are several cases where the system should learn new objects in the production line, without forgetting the previous ones [52]. Wang et al. [52] in their study used 100 photos to train the model and 25 photos for each old object. The proposed system, by retraining on a small set of samples, managed to achieve high-quality performance using all-in-one and stepwise learning.

Extended Reality (XR) includes various technologies (augmented, virtual, and mixed reality). Mixed reality in particular is a key technological component of Industry 5.0. The results of the use of augmented reality are improved customer experience, advanced training (industrial and academic), immediate ability to diagnose faults in industries, and improved safety in industrial settings [53].

This entry is adapted from the peer-reviewed paper 10.3390/app14041471

This entry is offline, you can click here to edit this entry!