With the rise of individualism as a social trend and the wide use of the Internet and social media, today’s customers increasingly want to design and build unique products that fit their individual preferences and needs. Mass individualization is defined as a manufacturing paradigm that aims to produce individualized products cost-effectively. This paradigm differs from the previous paradigms in which the manufacturing company designed and manufactured the products, and the customer chose a product. In the mass individualization paradigm, the customers will be actively involved in product design, and the manufacturer will produce a unique product for each customer at a reasonable cost and of reliable quality. Due to the need for smooth communication and interactions between the buyer and the factory, new factories for individualized products will be located near potential buyers, which will have a significant impact on local economies. This entry explores the relationship between mass individualization and other emerging manufacturing paradigms and concepts in the Industry 4.0/5.0 era, and discusses how smart factories can improve manufacturing efficiency and facilitate the realization of the mass individualization paradigm.

1.1. Evolution and Trends for Modern Manufacturing

The history of modern manufacturing has experienced several paradigms. These paradigms are driven by the needs of customers and society in different eras and are enabled by the scientific and technical developments in the corresponding era. The first manufacturing paradigm was the craft production paradigm, where products were made by skilled workers using general-purpose tools and relatively simple machines without employing a manufacturing system. These products were usually one of a kind. The invention of the moving assembly line by Henry Ford in Dearborn, Michigan, in 1913 is usually viewed as the start of the mass production paradigm, where identical products can be manufactured in the same factory at a high throughput and a low cost. The development of the Computer Numerical Control (CNC) machines in the mid-1970s and Flexible Manufacturing Systems (FMSs) in the 1980s enabled the mass customization paradigm, where multiple product variants could be manufactured using the same manufacturing system. However, the structure of FMSs could not be changed in response to the rapidly changing market demand that began in the last decade of the 20th century, and therefore the FMS is not appropriate for the auto powertrain industry (that produces engines and transmissions) or other large industries.

In response to production requirements such as a shorter product lifetime and frequently changing customer demands in a global market, the Reconfigurable Manufacturing System (RMS) was invented in 1998. Three pioneering US patents (reconfigurable manufacturing system, reconfigurable manufacturing machine, and reconfigurable inspection machine) legally define the RMS invention

[1]. The RMS provides exactly the capacity and functionality needed, and exactly when needed. The RMS factory is a sustainable “live factory” that can be reconfigured rapidly and cost-effectively to quickly respond to changing market demands

[2]. By combining the advantages of dedicated manufacturing lines and FMS, the RMS strikes a delicate balance between cost-effectiveness and the product variants that the manufacturing companies decide to offer. The customization of RMS is carried out around a family of products, or generations of products of the same product family.

In the recent decade, there has been an increasing trend for companies to shift focus from shareholders to customers

[3]. According to an industry survey conducted in

[4], involving customers in product design will make end products more creative and innovative, and will improve the motivation and willingness of the customers to purchase the products. With the rise in individualism as a social trend, today’s customers have an increasing desire to design and build unique products that can reflect their individual preferences and special needs. With the wide use of the Internet and social media, it is easy for customers to come up with new design ideas

[5]. With the increased popularity and affordability of additive manufacturing, many hobbyists today have a 3D printer at home and can print a product of their own design. However, this can only be carried out for simple products. The more professional and complex individualized products (e.g., the ones with high quality or functionality requirements, or those with more complicated structures) still need to be produced by professionals. To address such a need, a new type of factory is needed—mass individualization factories that can simultaneously produce a variety of individualized products at a reasonable cost. In mass individualization factories, the factory staff should be able to discuss and negotiate with customers on a personal level to propose better alternatives to the customers’ needs. Consequently, a new manufacturing paradigm—mass individualization—is emerging

[6].

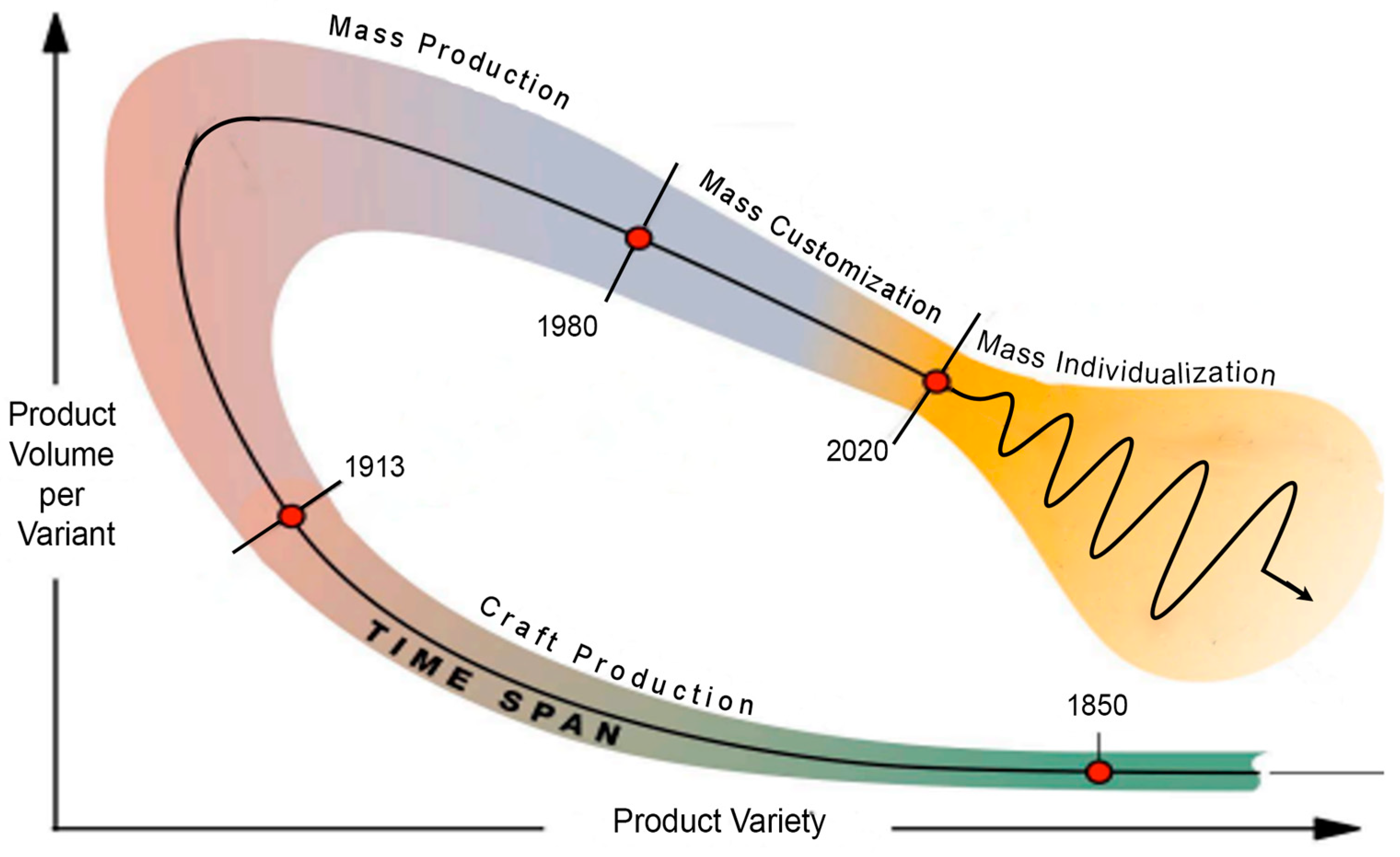

Mass individualization is defined as a manufacturing paradigm that aims to produce a large variety of “market-of-one” (or “one-of-a-kind”) products at a reasonable price that are affordable for the general public. From the “product variety vs. product volume per variant” relationship (as shown in Figure 1), one can see that the societal shift from craft production to mass production, mass customization, and now mass individualization is coming towards a full circle, but from market-of-one products for the wealthy to market-of-one products for an ordinary buyer. Also, compared to the products in the craft production paradigm that were made by skilled workers manually, mass-individualized products are usually much more complex and are made in factories with advanced manufacturing capabilities and automation technologies.

Figure 1. Four manufacturing paradigms have been driven by changes in technology and customer needs (schematic diagram by Koren, adapted with permission from Ref.

[7], Copyright 2010 John Wiley & Sons, Inc., Hoboken, NJ, USA).

1.2. An Example: Interior Design of Automobiles

The idea of mass individualization originated from the consideration of the interior design of cars. The Ford Model T automobile that was introduced by Henry Ford in 1908 had seats for the driver and a passenger in the front, and a seat for passengers in the rear. In the last 115 years, the car engine, transmission, etc., have dramatically changed, but we still have the driver’s seat and a passenger’s seat in the front, and a bench for passengers in the back. Why not let car buyers design the interior of their new cars? A driver who takes his/her two children to school needs a different car interior than a person who drives 100 km every day to work. Therefore, on 5 January 2006, we applied for the patent “Method and Apparatus for Reconfigurable Vehicle Interior”

[8].

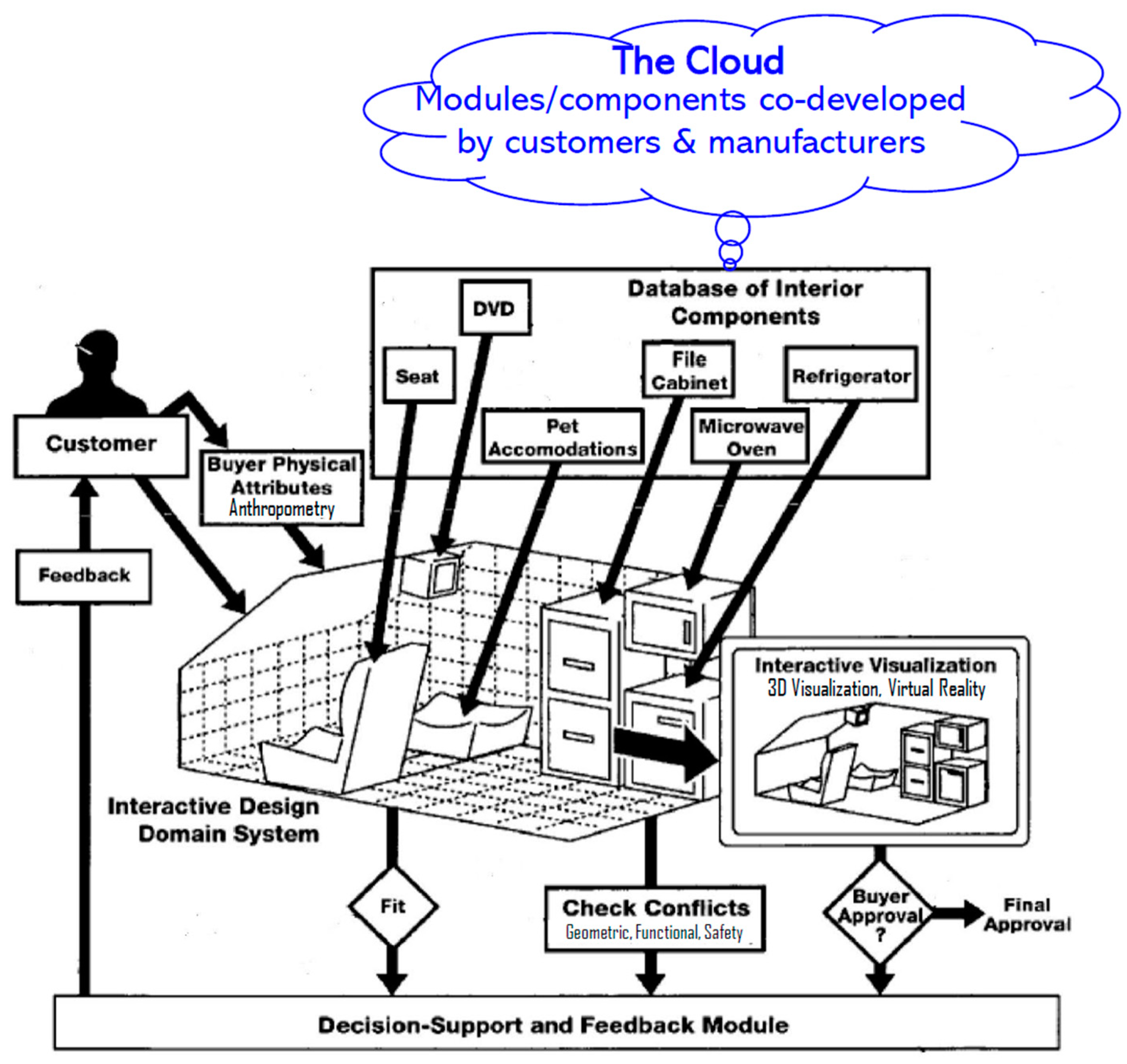

Figure 2 is adapted from this patent application, and it shows how the buyer could use a database for designing a unique car interior prior to purchasing an automobile. (The patent has 11 drawings to convey this new interior design.)

Figure 2. Example of car interior design (adapted from Ref.

[8]).

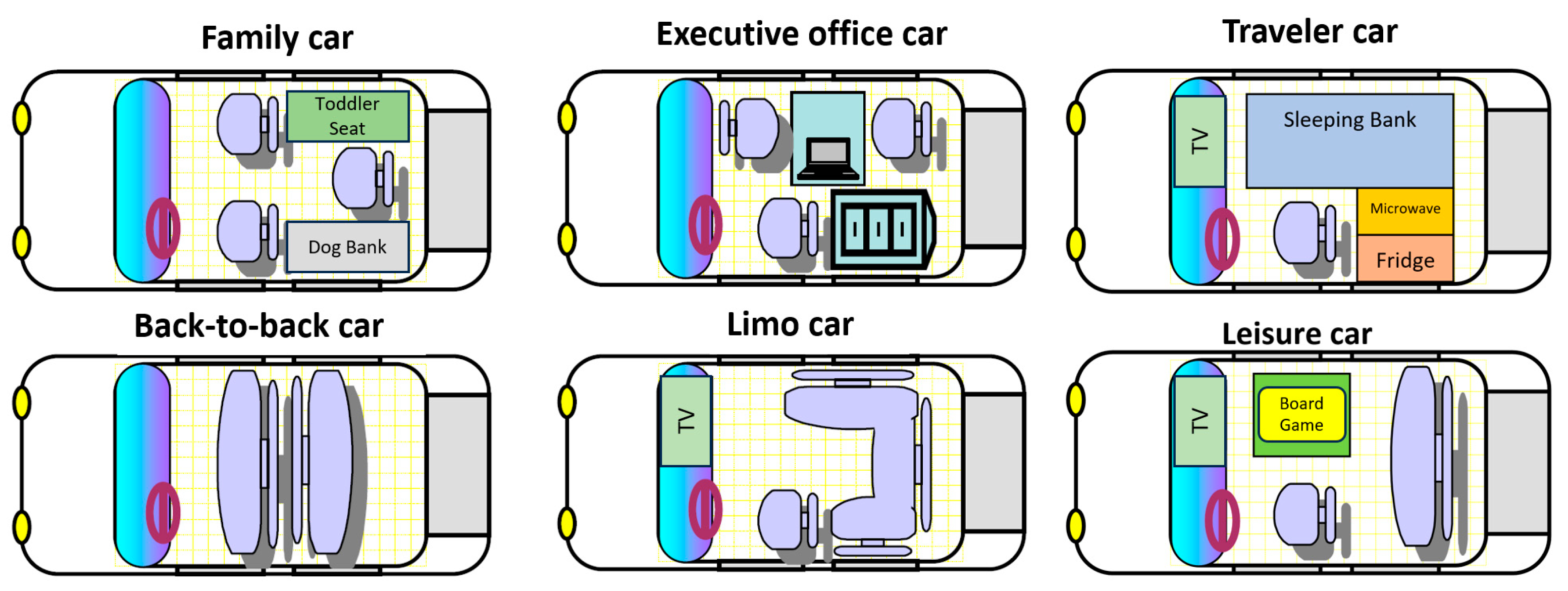

The user views an empty space version of the car interior and populates it with interior components at will through drag and drop operations. A variety of possible interior components can be selected, with several options for each such component. With such an interface, the user can design various interior configurations, as demonstrated in Figure 3.

Figure 3. Several options for car interior design (adapted with permission from Ref.

[6], copyright 2022 Taylor & Francis, Oxfordshire, UK).

Apparently, the car interior assembly factory will need to create the new role of Design Advisor for brainstorming ideas and opportunities with the car buyers. To compromise between the buyer’s wishes and production limitations, the factory Design Advisor should have both production engineering knowledge and social negotiations skills

[9]. Furthermore, if the buyer’s needs change in the future, or when the buyer sells the car, there is the option to change the interior of the car. Today, some of these features are becoming a reality in the auto industry. For example, the XPeng P5 model has an optional full-width projection screen, rear center console mini-fridge, and 220 V third-party appliances

[10].

1.3. Types of Mass-Individualized Products

There are two types of individualized products that differ in their product architecture and their main manufacturing processes.

For the first type of product, the individualization comes from their manufacturing operations (e.g., additive manufacturing, CNC machining, die-based manufacturing

[11]) within the manufacturing system. These can be standalone products that are manufactured by a single machine (such as a bone implant or a 3D accessory toy produced by a 3D printer), or more complex products that need additional operations using other machines in the manufacturing system (e.g., adding metal fittings to hold the product together, quality inspection

[12]).

The second type of product is built on an open-architecture platform with modular components that can be added, such as the car interior example mentioned above, where the individualization comes from its modular design and assembly. Another example is the production of a modular hospital bed, in which modules that fit the patient’s situation and illness may be integrated into the hospital bed. The hardware modules may be manufactured by various companies. Big manufacturing companies can design and build the open-architecture platform with defined mechanical, electronic, and information interfaces, while the modules may be designed and produced by small companies (and even by the customers themselves). The final assembly can either be carried out by the customers themselves (if there is no safety concern) or by an assembly factory (for more complex products or products that need more professional operations). These types of products are called open-architecture products (OAPs)

[13]. The software equivalent to open-architecture products is the smartphone, where big companies develop the mobile operation system (e.g., iOS, Android) that enables the integration of various apps (i.e., software modules) developed by different companies.

1.4. Study Scope

Mass individualization is centered around buyers and can improve their experience. It can create new jobs for the design and manufacture of individualized products and for providing services (e.g., maintenance, product upgrades) during the entire life cycle of new individualized products

[14]. New factories (e.g., a car interior assembly factory) will be built near potential customers to facilitate smooth and timely communication and interaction between the customers and manufacturers, which will benefit local economies as well as innovation ecosystems

[15].

Mass individualization factories have already started to appear in industries such as apparel

[16], furniture

[17], and electronics (e.g., printed circuit boards)

[18]. To facilitate the realization of mass individualization and make it applicable for more products, there is a need for further technological developments in their design and manufacture. Due to recent technological advancements, especially developments in automation and information and communication technology (ICT), many new manufacturing paradigms and concepts are emerging. Terms such as Industry 4.0 and Industry 5.0 are introduced to demonstrate how such new technologies can revolutionize the manufacturing industries to meet the needs of modern society.

This paper explores the relationship between mass individualization and other emerging manufacturing paradigms and concepts in the Industry 4.0/5.0 era with regard to their goals and focus. By discussing the architecture of manufacturing systems for mass individualization and how characteristics and techniques in smart factories can improve the cost-effectiveness of individualized production, this paper contributes to the identification of key enabling technologies that facilitate the realization of mass individualization.

This entry is adapted from the peer-reviewed paper 10.3390/encyclopedia4010028