1. Integrated Distribution System Management

Management concepts that use the term “integrated” can be misunderstood unless the system elements to be integrated are specified explicitly. As an example, the framework of Integrated Water Resources Management (IWRM) has become popular, but the water management community lacks a common understanding of it [

15]. In a similar way, researchers and users can understand the concept of IDSM in different ways. It is explained here as part of the family of management systems that a water utility must organize and manage. A system must have a boundary to contain its core interacting elements, and the distribution system is distinct from the other infrastructure systems of the water utility. In that sense, IDSM means to manage the interacting components that deliver water downstream of the water source and treatment plant and make it available for service lines or other diversions that are not part of the distribution system itself.

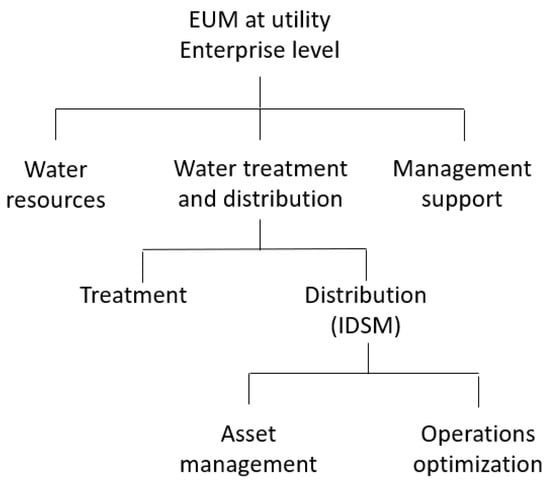

The distribution system is thus within a hierarchy of systems required from top to bottom in utility management. The conceptual framework presented in Figure 1 offers a comprehensive approach that shows how IDSM fits with best practices for utility management as well as with the technical methods specific to distribution systems. Treatment and distribution systems are linked because they are interconnected, and treatment outcomes affect the distributed water and the pipeline infrastructure. IDSM is shown to comprise capital, represented by asset management, and operations, where optimization is the goal. The model also shows the support systems for the utility, including finance, workforce, customers, community, and work with other stakeholders, which are emphasized in EUM.

Figure 1. Hierarchy of utility management systems.

The EUM framework has ten attributes, with product quality as an integrated metric meant to capture total performance of the utility. Two attributes relate to operation of the water source and infrastructure (operational optimization and infrastructure strategy and performance) and another addresses water resource sustainability. The other six attributes address the organizational issues shown as management support in Figure 1.

The elemental arenas of an integrated approach to distribution system management are collections of tools for capital and operations management. For the capital side, asset management is an organizing framework for tools like risk-based prioritization and condition assessment. For operations, performance measurement for optimization, modeling, and water loss control are examples of tool categories.

2. Comprehensive Frameworks for Utility Management

A framework for utility management processes organizes them into an overall group that works in an integrated way. A general example is the enterprise management system, which is used often to describe integration of software systems for digital management. For water utilities, the EUM program is a general framework, also referred to as an approach, a set of approaches, and a management program [

16]. EUM is a high-level integrated approach and IDSM is a subset of it. As most utility infrastructure is in distribution systems, IDSM is the most capital intensive and extensive technical system managed within EUM.

Among water utilities, the search for a general framework of distribution system management began before the year 2000. Prior to that time, little research was published even about the capital or operating needs of water distribution systems. The increase in attention to distribution systems was driven by convergence of the disclosures about serious problems and development of new technologies. Examples of problem disclosures were the need to control lead and copper releases from distribution systems [

17] and the frequency of water main breaks, which open distribution systems to contamination and threaten health [

18]. Examples of new technologies were the development of distribution system simulation models [

19,

20] and availability of data technologies to support emerging asset management systems [

21].

The search for an overall management approach was evident in early research sponsored by the American Water Works Research Foundation (AwwaRF), now named the Water Research Foundation (WRF). A 1995 AwwaRF report explained a general approach to address capital and operations in terms of performance categories of adequacy, dependability, and efficiency. Metrics for these were established in categories of structural, hydraulic aspects, water quality, and customer perception. Adequacy addressed operational concerns like pressure and water quality, dependability focused more on capital issues like main breaks and inoperable valves, and efficiency addressed water losses and energy consumption [

22]. While the recommended approach did not gain traction, it provided background thinking for two management frameworks that emerged soon afterwards. These frameworks were AWWA’s G200 management standard for distribution systems [

23] and DSO, which was to support AWWA’s Partnership for Safe Water (PSW) program [

24].

Actions by the US Environmental Protection Agency (USEPA) and several standard organizations led to the creation of the G200 standard, which was developed by an industry task force [

23]. The standard addresses “critical requirements for the operation and management of potable water distribution systems, including maintenance of water quality, system management programs, and operation and maintenance of facilities”.

Management standards establish consensus requirements for utility management practices and adoption by the utility industry is voluntary. Options to encourage adoption by the industry were discussed in the National Research Council (NRC) report, such as to create or adapt federal regulations about key activities, use building and plumbing codes, link loans from the State Revolving Fund to adherence, and require them for access to capital and better bond ratings. Small water systems have particular issues with financial, administrative, and technological challenges and require an incremental approach with technical assistance and further incentives [

1]. Most recent changes in G200 involve information technologies for data management, monitoring and control, failure risk management, and maintenance management.

In parallel with the G200 standard, the PSW supported development of DSO. Optimization in this sense is like process optimization or monitoring and controlling all subsystems in an integrated way to meet performance goals. The PSW program was a co-sponsor of the WRF project that developed the DSO method [

24]. The NRC study recommended the integration of physical, water quality, and hydraulic performance [

1] and DSO provided an integrative platform to merge these systemically with a few parameters. Physical, hydraulic, and water quality integrity were to be indicated by metrics for main breaks, pressure, main breaks, and chlorine residual. Utility operators were guided to track them with numeric criteria and prepare certified self-assessment checklists.

The WRF study to develop the DSO method was comprehensive and featured extensive utility participation. By introducing the term optimization without laying groundwork for it, ambiguity remained, and most research papers still used the term optimization to refer to management tasks other than performance checking [

25].

Among distribution system managers, the concept of DSO has been adopted by only a few utility types, likely because it is still evolving and not required by regulators [

14]. There is lack of understanding of the concept in the operation of utilities, which is caused by both unfamiliarity with research literature and association programs and the ambiguity in how the term optimization is understood. Neither the NRC report nor the WRF project defined DSO explicitly. They use the term optimization in different contexts, like for treatment plants, placement of sensors, water quality management, or hydraulic network design [

26].

While it is not always identified as such, the concept of an intelligent system can provide an overall framework for distribution system management. Alternative terms are smart or digital systems, but the term intelligent seems to have more traction. Intelligent systems can merge capital and operating decisions into master control systems that manage information for operations, system condition, and customer alerts in an integrated manner.

The outcomes of AWWA Water 2050, a recent series of visioning workshops, support movements toward intelligent systems along the lines explained by the WRF [

26,

27,

28]. This was evident from outcomes of the sustainability work group, which called for implementation of a new water utility paradigm to stress a total and integrated approach to water management, and those of the technology work group, which called for accelerated innovation and to transform water services through next-generation technology.

Intelligent distribution systems can extend the concepts of existing supervisory control and data acquisition (SCADA) systems by adding information technology tools. Systems are controlled by actuators (like pumps and valves), where system data (like pressure, flow, and quality) are fed into a decision process that is informed by a model which could be part of a “digital twin”. The sensors provide information about system condition to aid management decisions. Meters can provide information on water usage, and automated meter reading (AMR) has become practically a standard among utilities. Advanced metering infrastructure (AMI) systems can provide information for decisions like water loss controls. The concept of intelligent systems can be extended to end users via the Internet of Things (IoT).

Intelligent systems can seem like an ephemeral concept only to be replaced later by a new one. However, they are innovative because they introduce a new paradigm for information access and operational control of distribution systems. The concept is evolving, and the water industry is experimenting with new approaches [

29]. Its structure is being worked out as most utilities have some automation and remote data collection and/or communication systems. Presently, AMI is used in few utilities, and the prevailing attitude seems to be to wait and see. This is consistent with the WRF study that found that intelligent technologies are not embraced in the utility industry as rapidly as in other industries despite potential benefits. The utility industry reports that data issues like false positives, along with cost and maintenance are important factors when implementation of intelligent systems is considered [

29].

Like with IWRM itself [

30], the tool categories used in IDSM are scattered, and it is challenging to develop an overall framework. DSO and G200, the two existing frameworks that span capital and operations, are not used widely in water utilities [

14]. The lack of awareness of them is concerning, but distribution system managers focus on daily problems and may not voluntarily adopt new tools and research results. This is especially the case in smaller utilities which struggle to sustain operations. Intelligent systems may create pathways for more such utilities to benefit from comprehensive approaches that incorporate emerging technologies such as sensors, digital twins, and artificial intelligence. As more experience becomes available, AMI can provide useful information for capital and operations. Interest in it signals a bright future for an integrated approach for distribution system management through intelligent systems that support the broader framework of EUM.

3. Sub-Processes of Integrated Distribution Systems Management

Clusters of management tools serve specific purposes within a comprehensive management framework and identifying them can improve understanding of the overall management [

31]. An example is found in tool clusters for construction projects, such as for scheduling, cost estimating, quality and change management. These clusters can involve different stakeholders and involve different management sub-processes in the overall process of construction management [

32].

For distribution systems, the sub-processes are for management of capital assets and operations. For capital, asset management is an organizing framework for tools like risk-based prioritization and condition assessment. On the operations side, optimization, modeling, and water loss control are examples of tool clusters.

As a general term, asset management can mean an accounting method used in any sector, beginning with financial assets. Within the infrastructure sectors, it has come to mean a method to coordinate management activities for all types of capital facilities or “fixed assets” in accounting rules [

33]. Such accounting for fixed assets is practiced in diverse ways across all infrastructure sectors, and it is especially evident in the transportation and water sectors [

34,

35].

For water and wastewater systems, asset management is considered a data-centric framework of tools for managing systems like distribution networks. USEPA identified its main processes to be assessment of condition, determination of goals, identification of critical assets, determination of minimum lifecycle costs, and development of a financing plan. This basic model has been adopted widely as a framework for the processes within asset management as used in the water sector [

35].

The research trajectory of asset management started with the rapid rise of data management and geographic information technologies, which provided new ways to keep records and schedule work. These same tasks are needed across industry sectors, so an ISO standard has been developed to express a general model of how asset management works [

36].

The research base for asset management is broad. The WRF has conducted over 300 projects relating to it, much of it in cooperation with research agencies in other countries. An early WRF project developed a research roadmap for it and additional research has filled in the knowledge base [

37]. The WRF is now aligning the asset management concept with the One Water approach to address a unified collection of water systems including wastewater, drinking water, recycled water, and stormwater [

38].

Two focal points of comprehensive research about asset management have been assembled of the WATERiD knowledge base [

39], which is a platform for utilities to share information on asset management, and the Sustainable Infrastructure Management Program Learning Environment (SIMPLE), which was designed as a hub for asset management tools [

40]. Currently, WateriD remains operational but SIMPLE is not active.

While asset management is a powerful tool, its status of implementation remains incomplete, as shown in an AWWA survey [

41]. A lack of commitment to it was evident, although some of its tools are used in utilities. Only a few states have asset management requirements for drinking water utilities. A survey showed that in most utilities, the use of asset management systems was reported, with around half using software packages, but the sample was biased toward leading utilities. Without a standardized reporting framework, asset management may not be used comprehensively in utilities, and simpler approaches may be appropriate [

42].

Condition assessment research for management purposes and technological products has been active. It is divided into general concepts and specific methods. General concepts refer to classifications such as non-destructive evaluation (NDE) versus methods like controlled destructive evaluation [

43,

44]. A comprehensive classification was provided in [

45] with categories as conditions inferred from samples and conditions directly measured. The samples can include external direct assessments and statistical methods that consider pipeline data such as age and break history. Conditions directly measured include in-pipe condition assessment like leak detection and non-invasive methods such as pressure testing. All methods except statistical studies can use NDE technologies such as ultrasonic and electromagnetic.

Like asset management, implementation of condition assessment is developing piecemeal. Distribution systems involve so many components that use of NDE is affordable only on critical components. No comprehensive report has been identified to assess overall levels of implementation, and condition assessment technologies are not used in utilities on a systematic basis [

46].

Condition information is needed to inform risk-based prioritization, which provides a method to identify the most urgent needs to be addressed within available funding. The innovation is the use of data-centric risk analysis methods considering the location of critical facilities and the likelihood and consequences of failures. The process was not developed by research projects, although its methods such as risk assessment methods and pipe break simulation models were developed in formal projects. The use of such risk assessments for distribution system capital planning dates to about 2000. At that time, three general levels of prioritization were recognized, including voting, ranking, and system analysis, which requires the most data [

47]. Economic models were developed to estimate costs of failure [

48], although studies of cost data showed that little data were available [

49]. Risk models were developed to use structural properties and statistical parameters like age [

50]. Research continues, and models are beginning to incorporate artificial intelligence and machine learning [

51].

No studies to assess the degree of implementation of risk-based methods for prioritization were identified in the literature review. However, the general state of management in the water utility industry indicates that the informal voting method is mostly used when prioritization is carried out at all. Sometimes, structured approaches like prioritization spreadsheets are used [

52], but the more complex system analysis method is rarely implemented. The survey showed that most utilities lack formal prioritization methods, and regular capital improvement data such as street paving, coordination with other utilities, and system expansion are used [

14]. In the survey, the use of a pipe break simulation model was reported in only two utilities to predict the remaining life of the pipelines. Data issues apparently discourage the utility industry from using such modeling methods, and risk assessments may also be neglected by boards addressing broad needs, including social equity [

53].

The concept of optimizing the daily operation of distribution systems is evolving but is more complex and less structured than treatment plant optimization. The licensing of distribution system operators, for example, is a more recent development than for operators of treatment plants [

54]. Research papers on distribution system operation focus on strategies such as control of system components like pumps, valves, and tanks [

55]. Sometimes the papers address broader topics, like design and failure prevention [

56]. More papers address mathematical approaches to optimization of performance, but there is little evidence that the outcomes are being implemented in utilities on a broad basis [

57,

58,

59,

60].

As an operations management method, water loss control has become popular due to the emergence of new methods and data, along with needs for greater efficiency in water management. It is a complex method because distribution systems comprise large arrays of pipelines, fittings, controls, and appurtenances for access, fire suppression, metering, and other functions. The challenges to control all leakage are daunting, and problems become more difficult in systems with management challenges [

61].

The international water community banded together to develop a new method for water loss control. They were able to build on early work on flow analysis of water mains and later work on “Unaccounted-for Water” [

62]. By the 1990s, this set the stage to assemble the tools and methods for a comprehensive approach. Work was organized via committees of IWA and AWWA. The first edition of AWWA’s Manual of Practice M36 on Water Audits and Leak Detection was released in 1991 [

63]. The new method was developed, and IWA announced a standard method in 2000 and an AWWA Water Loss Control Committee adopted the method in 2003 [

64].

The approach involves an analysis component (defining and calculating components of the water balance) and a management component (selecting indicators for non-revenue water and losses). The ratio of real losses to an estimate of uncontrollable losses determines the main performance indicator, the Infrastructure Leakage Index (ILI). The uncontrollable losses stem from many small leaks in water mains and service lines and estimates are based on regression equations that were developed from research.

This entry is adapted from the peer-reviewed paper 10.3390/w16040524