The Internet of Things (IoT) is introduced in systems with electrical machines, such as in electric drive systems, wind energy generating systems, and small and special machines, to remote monitor and control the operation for data acquisition and analysis. These systems can integrate with the equipment and retrofit the existing installations. At the end of the control loops there are always motors, or actuators, of big or small ratings, of rotating or linear movements, electrical or nonelectrical, which must produce the motion. With the IoT-based control of induction machine systems operators can remotely monitor parameters and obtain accurate real-time feedback during fast changing duty cycle operation. Thus, IoT creates multipurpose instruments in the remote control of induction machines.

- Internet of Things

- electric drive systems

- wind energy conversion systems

- induction machines

- microprocessors

- sensors

1. Introduction

| Generic Topics | Specifics and Technical Aspects | Citations | Reference Number | |

|---|---|---|---|---|

| Induction Motors | Online monitoring performance of electrical motors using IoT. | Suitability of IoT components. | 2 | [16] |

| Online automatic diagnostic techniques and early failure detection. | Condition monitoring of maintenance with IoT. | 10 | [17] | |

| Induction Generators | WECS to cover load demands and generation requirements related to weather conditions. | Technologies that allow WECS for IoE: remote control, networking, safety. | 117 | [18] |

| WECS with DOIG in smart grids, load-rejection from instabilities of wind and load demand. | Prognostic diagnosis, increased accuracy, and stability. | 6 | [19] | |

| Small machines | Nanogenerators, lightweight and self-driving. | Energy conversion devices for IoT sensors, powered by nanogenerators to replace power supplies. | 0 | [20] |

2. Control System of Induction Machine with IoT

-

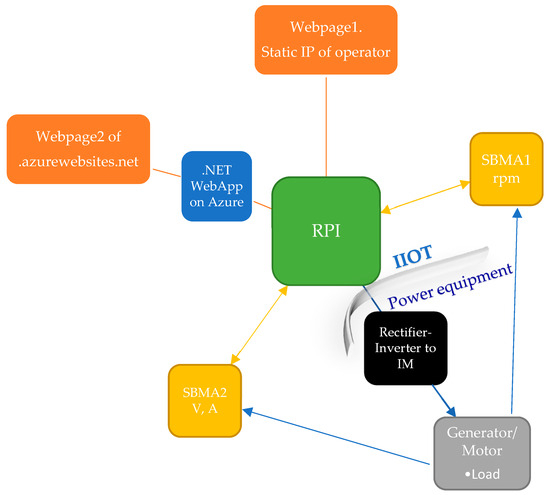

The connectivity of power equipment to the internet, communication with servers, software, and databases. The units directly connected are electric motors, power converters, microcontrollers, sensors, measuring instruments. Other modules are connected indirectly via a gateway, and there is two-way communication with the backend system to register devices and collect data.

-

The data management: the acquisition, conversion, storage, retrieval, analysis, processing, security, visualization, and presentation of data in real time.

-

Azure cloud web page

-

Sensors connected to single-board microcontrollers SBMA1 and SBMA2

-

Rectifier/inverter which drives the induction motor

-

Static control web page for direct access of operator

-

Power efficiency: The RPI is a low-power device, which is important for embedded systems like this one. This means that it can run on a small battery or even be powered directly from the induction machine itself.

-

Computational power: The RPI is a powerful device that can handle the computational tasks required for controlling the induction machine and collecting data from the sensors. This makes it a more versatile option than a simpler microcontroller.

-

Ease of use: The RPI is a relatively easy-to-use device, which makes it a good choice for developers who are not familiar with embedded systems programming. There are a large number of resources available for programming the RPI, and it can be easily connected to a variety of sensors and actuators.

-

Versatility: The RPI can be used for a variety of other tasks besides controlling induction machines, such as running web servers, hosting applications, and running data analysis software. This makes it a good investment for developers who need a versatile platform.

-

Raspberry Pi (RPI): A single-board microcomputer that serves as the central electronic device in the system. It is responsible for collecting data from the sensors, communicating with the cloud and web applications, and controlling the rectifier/inverter.

-

Azure cloud web page: A web page hosted in the Azure cloud that provides a user interface for monitoring and controlling the induction machine. It can be used to access, visualize, and analyze data from the system.

-

Sensors: Sensors that measure various parameters of the induction machine, such as speed, currents, and voltages.

-

Single-board microcontrollers, SBMA1 and SBMA2: Single-board microcontrollers that interface with the sensors and send data to the RPI.

-

Rectifier/inverter: A power converter that converts AC voltage to DC and DC voltage to AC. It is used to drive the speed and direction of the induction machine.

-

Static web page at the operator’s IP: A web page that can be directly accessed by the operator to monitor and control the induction machine. The static web page serves two main purposes in the IoT-based control system for induction machines. (1) Real-time monitoring: The static web page provides a real-time view of the induction machine’s performance parameters. This information can be used by operators to monitor the health and condition of the machine, and to identify any potential problems. (2) Remote control: The static web page can also be used to remotely control the induction machine. Operators can use the web page to set the machine’s speed, and other parameters. This capability is particularly useful for operators who are not physically located near the machine. It offers a more straightforward and accessible interface for operators who may not require the advanced features of the cloud-based interfaces. In addition, the static web page can serve as a backup communication channel in case the internet connection is lost. This ensures that operators can still monitor and control the induction machine even if they are unable to access the cloud-based interfaces. Overall, the static web page plays a crucial role in the overall functionality of the IoT-based control system for induction machines. It provides real-time monitoring and remote-control capabilities to operators, while also complementing the dynamic functionality of the cloud-based interfaces.

2.1. Structure of Electric Drive System of Induction Motor with IoT

-

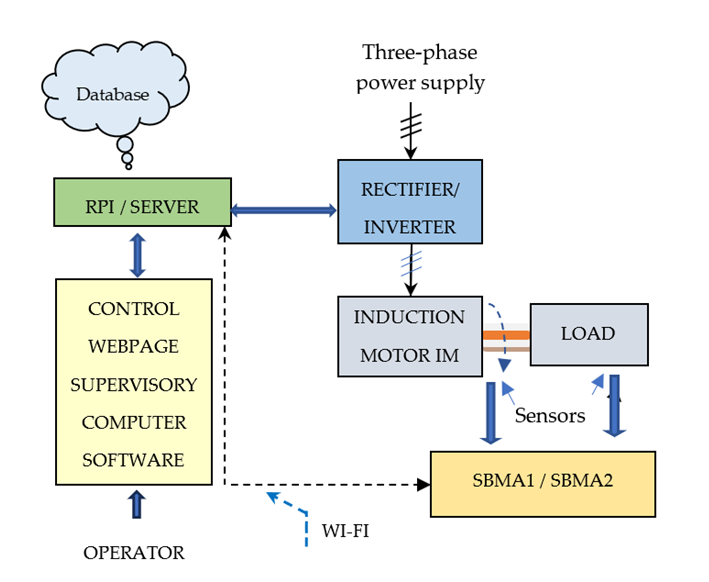

The control system from Figure 2 consists of the following structural modules:

-

The three-phase induction motor is supplied by one digitally controlled three-phase rectifier-inverter, which controls the stator frequency and produces motion of rotation, which is transmitted to mechanical load.

-

The control system: one Control Webpage, one supervisory computer with access to the Control Webpage, one single-board microcomputer Raspberry Pi (RPI) linked to the rectifier-inverter which acquires the data from sensors through single-board microcontrollers SBMA1/SBMA2, and software. The RPI has the role of the local server which communicates with database by a web application in Azure cloud with an SQL database for data storage, data processing, and remote control.

-

Data acquisition: The rotational speed sensor and load current sensor of the induction motor transmits data to microcontrollers SBMA1 and SBMA2, respectively.

-

Networks: The IoT-based control system for induction machines has installed wired and wireless networks, including internet, local area Wi-Fi networks, and serial connections. The Internet serves to the users of the static web page hosted on the RPI. The system uses internet to connect the RPI to the Azure cloud web page. Bluetooth connectivity is established between RPI and microcontrollers. The RPI communicates with the rectifier/inverter via a serial connection; the sensors transmit data to the microcontrollers through serial connection.

-

the frequency command for forward rotation

-

the reverse direction command to rotate backwards

-

the command to start the rotation

-

the end of rotation command

2.2. Structure of Double Output Induction Generator with IoT-Based Control System for WECS

-

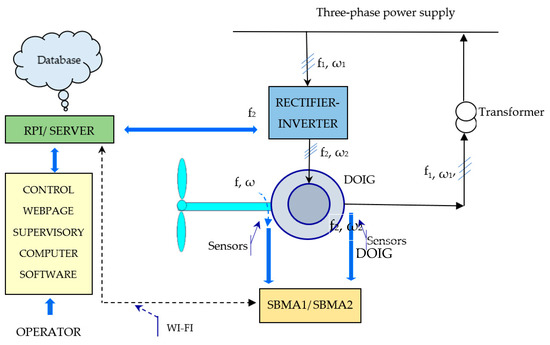

The rotor excitation voltage and frequency permit a bi-directional flow of electric power in the rotor, and a slip power recovery, instead of being lost by heating the windings. This increases generated energy, and efficiency too, are a consequence of an increased quantity of converted wind power.

-

At variable wind speed, the rotor excitation voltage controls the DOIG and generates constant frequency at the demanded value of the grid. Also, the active power is generated from the wind power at any time instant, under or above synchronous speed. The DOIG provides control of reactive power, close to unitary power factor, and eliminates the need for capacitor banks. Power quality improves because DOIG connects and disconnects from the grid, without high transient currents during cut-in or cut-out. The instabilities of wind generate higher order harmonics [48,49], which impacts the generated power quality, especially in fast transient states of the wind, and also, in weak or isolated autonomous grids [35,48]. With the DOIG, the higher order harmonics are reduced due to the high switching frequency of the power converter in the rotor, and the levels of the 5th and 7th harmonics are lower [50,51]. Causes of generated distortion and noise at different operating points can be the negative or close to zero power values when wind speed is above cut-in speed or with scattered data [48,51].

-

The power converter in the rotor has lower ratings because the rotor draws up to 35% of the rated power of DOIG.

-

Mechanical loading reduces because the operation at variable speeds produces lower stress transferred through the coupling components than in the case of fixed speed generators.

-

f1 is the power network frequency and produces the synchronous speed of air-gap magnetic field ω1

-

f is the angular rotational frequency of the shaft, which is imposed by the driving force of the wind, and is computed from the mechanical rotational speed of rotor ω,

-

f2 is the slip frequency of the voltage injected in the rotor windings and produces the rotational speed ω2 of the magnetic field of the rotor

This entry is adapted from the peer-reviewed paper 10.3390/en17030645