Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

A robust and efficient segmentation framework is essential for accurately detecting and classifying various defects in electroluminescence images of solar PV modules. With the increasing global focus on renewable energy resources, solar PV energy systems are gaining significant attention. The inspection of PV modules throughout their manufacturing phase and lifespan requires an automatic and reliable framework to identify multiple micro-defects that are imperceptible to the human eye.

- electroluminescence images

- multi-class semantic segmentation

- deep learning

1. Introduction

Photovoltaic modules play a crucial role in photovoltaic energy systems, which are part of ongoing efforts to transition toward renewable energy resources. This transition aims to minimize carbon dioxide emissions and mitigate their detrimental effects [1,2]. The International Renewable Energy Agency (IRENA) has taken a firm stance on renewable energy, leading to a global investment of USD 282 billion in the renewable energy sector as of 2019 [3]. This growing momentum toward renewable resources has significantly increased the demand for solar photovoltaic (PV) systems compared to other energy generation systems. However, solar cells may exhibit various defects and shortcomings that can affect the overall energy efficiency of the photovoltaic energy system. Consequently, there is a need to investigate solar cells, starting with their manufacturing phase and conducting inspections throughout their lifespan. Given the emerging trends in energy systems, it is essential to establish a viable and robust assessment mechanism for solar photovoltaic (PV) modules to ensure the anticipated energy harvesting through solar PV energy systems.

Solar PV modules are typically designed with protective measures to withstand different weather conditions and ensure resilience against environmental elements. The front side of the modules is shielded by tempered glass, providing resistance to the stresses and intensities of environmental factors. To safeguard against temperature variations, humidity, and corrosion resulting from water contamination, ethylene vinyl acetate is used as an encapsulation agent [4]. Additionally, a backsheet is incorporated as an additional component to provide mechanical stability, further protection against environmental elements, and insulation for the PV modules [5]. However, despite the presence of these supplementary protective components, multiple defects can occur in the modules over their lifespan. Weather conditions and mechanical damage can contribute to surface defects, while artifacts may also arise during the manufacturing phase [6]. The dynamic temperature and irradiance affect certain parameters of photovoltaic modules, acting as obstacles in estimating these parameters, as the overall throughput of a photovoltaic system hinges on their accurate assessment [7]. The authors propose the L-SHADE and L-SHADED techniques, with the latter method focusing on dimensionality reduction. Following this phase, they employ a linear population size reduction-based success history adaptation differential evolution (L-SHADE) method, consequently determining the unknown parameters. PV modules, such as multi-crystalline KC200GT and mono-crystalline SM55, are utilized under varying temperature and irradiance conditions to identify unknown parameters such as the photo-generated current, series resistance, and diode reverse saturation current. Consequently, inspecting and assessing the condition of PV modules become critical in solar energy systems.

Photovoltaic modules are designed to endure approximately 25 years of continuous exposure to challenging environmental conditions [8]. Manual visual inspection of solar PV modules is a laborious task, and even the scrutiny of a specialist may not be effective, as numerous defects are not visible to the naked eye. In the field of imaging, infrared (IR) cameras can be employed for PV module inspection using infrared imaging. Faulty solar cells that fail to convert solar energy into electrical output emit heat, which can be detected using infrared imaging techniques [9]. However, it is important to note that certain micro-defects may not be captured by infrared imaging, and the limited resolution of infrared cameras poses additional limitations when considering this approach for inspection [10].

Electroluminescence (EL) imaging is considered a preferable alternative to infrared (IR) imaging due to its ability to provide high-quality images capable of capturing micro-defects in solar cells. EL images are obtained by capturing emissions induced at a specific wavelength of 1150 nm using a silicon charge-coupled device (CCD) sensor [11]. In these grayscale EL images, micro-cracks are revealed as dark-gray areas where micro-defects occur [12]. However, visual inspection of EL images is a time-consuming and tedious task, even when performed by an expert. Given the growing trends in renewable energy systems, solar energy plays a major role in this domain. Manual visual assessment is impractical for solar PV energy systems, where it is necessary to inspect thousands of PV modules throughout their lifespan. Considering these factors, this manuscript proposes an autonomous assessment method utilizing EL images to detect various defects and features in solar PV modules.

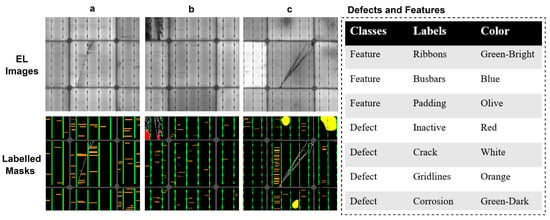

The proposed framework aims to achieve efficient EL image segmentation by utilizing a minimal number of model parameters, resulting in a lightweight system. Figure 1 depicts different EL images of solar PV modules, showcasing the presence of multiple co-occurring defects and features.

Figure 1. Three EL images are shown along with their labeled ground-truth masks (a–c). Defects such as cracks, gridlines, and inactive regions and features, such as busbars, ribbons, and padding, are listed in the figure along with their respective color labels.

2. Autonomous Multi-Defect Segmentation in Electroluminescence Images

Electroluminescence (EL) imaging, first experimented with in 2005, has been widely used to capture the degradation patterns of silicon solar cells [13]. In a study by Fuyuki et al. [14], EL imaging was deployed to determine the size of crystalline silicon solar cells and identify cracks and defects, which appeared as darker regions. The study successfully identified inadequate areas in the crystalline silicon solar cells using EL imaging. In another work by Deitsch et al. [15], various defects in mono-crystalline and poly-crystalline PV modules were detected by manually extracting features and employing a Support Vector Machine (SVM) classifier. To further improve defect classification, convolutional neural networks (CNNs) were employed using a dataset of 1968 solar cell images extracted from EL images of PV modules. The CNNs achieved higher classification accuracy compared to the SVM classifier, although the CNNs tended to be more resource-intensive in terms of hardware complexity. Shujaat et al. [16] exploited the practicality of CNNs to identify the promoters responsible for carrying out the transcription of genes.

Similarly, in a comparative study, Karimi et al. [17] evaluated the performance of CNNs against machine learning-based SVM and random forest classifiers. The objective of the study was to categorize solar cell images acquired from EL imaging of PV modules into three defined categories. The framework also incorporated data augmentation techniques to increase the overall dataset size, which consisted of 5400 solar cell images.

In a study by Tsai et al. [18], a Fourier image reconstruction approach was employed to identify defective solar cells using EL images obtained from poly-crystalline PV modules. The method presented in the study provided a reliable means to ascertain the presence of defects in solar cells. Furthermore, in a separate investigation, Anwar et al. [19] combined image segmentation techniques with anisotropic diffuse filtering to detect micro-cracks in solar cells. The study utilized a dataset of 600 EL images and demonstrated the effectiveness of the proposed approach in accurately discerning micro-cracks.

Deep learning has emerged as a potent method for autonomous decision making in several domains, allowing for accurate and fast object and region-of-interest identification [20,21]. In the field of biomedical image segmentation, the U-Net architecture, proposed in [22], has become a widely adopted model due to its effectiveness. It is made up of an encoder–decoder structure that forms a U-shaped network with a contracting and expanding route. Several U-Net design versions have been developed for specialized segmentation tasks in biomedical imaging [23,24]. These include Attention U-Net [25], Dilated Inception U-Net [26], Unet++ [27], SegR-Net [28], RAAGR2-Net [21], and R2U-Net [29]. These variants try to improve the U-Net model’s performance in certain scenarios. DeepLabv3+ is another well-known semantic segmentation framework, which expands the DeepLabv3 paradigm [30] by combining encoder–decoder blocks with Xception and ResNet-101 as the network backbones [31]. This architecture was created specifically for semantic segmentation tasks and has performed well. In biomedical imaging, dual-encoder- and dual-decoder-based DL frameworks are employed for aiding in the diagnosis of colorectal cancer through polyp segmentation from colonoscopy images [32]. In another work, Wooram et al. [33] adopted a neural network based on convolutional operations, along with atrous spatial pyramid pooling and separable convolutions integrated with a decoder module, to carry out the real-time segmentation of external cracks in structures.

The literature includes a variety of deep learning approaches aimed at classifying cells and modules into a wide range of flaws while accounting for the varied severity of these problems in solar PV modules [34,35]. In one work, Rahman et al. [36] adapted the U-Net architecture to identify flaws in poly-crystalline solar cells using EL pictures. The study proved the modified U-Net’s accuracy in segmenting and finding flaws in solar cells. Deqiang et al. [37] proposed a U-Net-based framework for single image super-resolution (SISR), with the sole purpose of image reconstruction from bristly textures to finer details. The approach is termed anti-illumination, as it effectively subdues the noise in images while captivating the illuminance details.

Another paper [38] by Chen et al. reported the segmentation of fractures in EL pictures of multi-crystalline solar cells. The study presented a unique approach for identifying and isolating fractures in photographs, which helped to characterize the faults. In order to extract global features, Ruixuan et al. [39] introduced a transformer-based architecture, LF-DET, for light-field spatial super-resolution. The model comprises two subsets. The first part introduces convolutional layers before self-attention modules, consequently obtaining global features. Further, in the second part, feature representations from macro areas are obtained at various levels using angular modeling across multiple scales. Furthermore, Pratt et al. [40] used EL pictures of PV modules to detect flaws in mono-crystalline and multi-crystalline silicon solar cells through a U-Net-based image semantic segmentation framework. The suggested framework yielded encouraging results in detecting and segmenting faults in solar cells. For crack segmentation, Young et al. [41] proposed a convolutional neural network-based DL model, comparing it to image processing edge detection approaches such as Canny and Sobel detection. Another work by Young et al. [42] reported the adaption of a faster region-based convolutional neural network (Faster R-CNN) for automatically detecting five different types of damage in the visual probing of structures.

This entry is adapted from the peer-reviewed paper 10.3390/en16237726

This entry is offline, you can click here to edit this entry!