Greenhouse cultivation includes two types: conventional and hydroponic (cultivation substrate in soil, and cultivation substrate in water-based nutrient solution, respectively). Greenhouse cultivation systems have garnered substantial attention due to their ability to create a controlled environment for crop growth, resulting in higher yields, improved quality, and reduced water usage.

- life cycle assessment

- energy consumption

- greenhouse structure

1. Introduction

|

Open field cultivation |

Greenhouse Cultivation |

|

Large cultivation area is needed |

Optimal use of water |

|

The need for natural minerals |

Off-season cultivation |

|

Hard weed removal |

Higher yield and nutrient content |

|

Water wastage |

Control of environmental conditions |

2. Conventional Cultivation

|

Items |

Energy Equivalent (MJ unit−1) |

References |

|---|---|---|

|

Human labor (h) |

1.96 |

|

|

Diesel fuel (L) |

56.31 |

[71] |

|

Electricity (kwh) |

11.93 |

|

|

Transportation (tone.km) |

3.05 |

[73] |

|

Chemical pesticides (kg) |

101.2 |

[74] |

|

Chemical fertilizer (kg) |

- |

|

|

Nitrogen |

78.1 |

[75] |

|

Phosphate |

17.4 |

[75] |

|

Potassium |

13.7 |

[76] |

|

Micronutrients (kg) |

120 |

[77] |

|

Manure (kg) |

0.3 |

[78] |

|

Water (m3) |

1.02 |

[75] |

|

Natural gas (m3) |

49.5 |

[79] |

|

Machinery (kg) |

62.7 |

|

|

Nylon (kg) |

17.91 |

[80] |

|

Steel (kg) |

27.73 |

[81] |

|

Plastic general (kg) |

90 |

|

|

Cucumber (kg) |

0.8 |

[82] |

|

Refs. |

Titles |

Purpose and Review |

Results |

|---|---|---|---|

|

[35] |

Energy-efficient operation and modeling for greenhouses: A literature review |

Existing strategies in energy efficiency control operations; Advanced simulations of greenhouse energy |

The result showed that the cost and precision of sensors restrict the adoption of optimal controls by growers. |

|

[85] |

Manufacturing energy and greenhouse gas emissions associated with plastics consumption |

Comparison of energy supply chain requirements; Greenhouse gas emissions caused by plastic production technologies; Development of bioplastic production technologies |

The results indicated that commodity polymers, with a global consumption of 1 MMT per year, cause 3.2 quadrillion Btutus of energy and 104 MMT CO2e of GHG emissions annually in the US alone. |

|

[86] |

Demand side management of energy consumption in a photovoltaic integrated greenhouse |

Analysis of activities in greenhouse production and electrical equipment performance; Particle swarm optimization scheme; Analysis of the energy consumption program in the greenhouse |

The results showed that the optimization plan is useful for directing production activities in greenhouses and building photovoltaic integrated greenhouse systems. |

|

[87] |

Modeling and experimental validation of heat transfer and energy consumption in an innovative greenhouse structure |

Modeling and experimental evaluation of heat and mass transfer functions in a solar greenhouse with a thermal screen |

The results revealed that implementing a thermal screen could decrease both the final cost and air pollution. |

|

[88] |

The potential contribution of food wastage reductions driven by information technology on reductions of energy consumption and greenhouse gas emissions in Japan |

Analysis of the effects of food waste; Reducing energy consumption; Reducing greenhouse gas emissions |

The results showed that the reduction of GHG emissions would be between 5.6 to 7.8 million tons of CO2-eq per year. |

|

[89] |

Methodologies of control strategies for improving energy efficiency in agricultural greenhouses |

Systematic review of control strategies to improve energy efficiency in greenhouses (especially low-energy greenhouses) |

The results showed that 60% of the selected articles on greenhouse climate management consider temperature and humidity as controlled parameters. |

|

[9] |

Energy-economic-environmental cycle evaluation comparing two polyethylene and polycarbonate plastic greenhouses in cucumber production (from production to packaging and distribution) |

Investigation of energy flow, economic benefit, and environmental effects in cucumber greenhouse cultivation; Measurement with two methods of LCA and Cumulative Exergy Demand (CExD) considering different greenhouse structures |

The LCA results showed that the main environmental impacts come from direct emissions due to input consumption (air: carbon dioxide (CO2), and nitrogen oxides (NOx); soil: mercury (Hg), copper (Cu), and lead (Pb)) and indirect emissions induced by the production of chemical fertilizers, greenhouse structures, and chemical pesticides. |

|

[90] |

Impact of environmental factors on the energy balance of greenhouse for strawberry cultivation |

Effects of solar greenhouses on strawberry cultivation in temperate regions; Energy required to heat the greenhouse; Experimental investigation of ambient temperature, solar radiation, and relative humidity |

The result showed that passive solar heating may not suffice in cold regions with extended cloudy weather, requiring additional gas or electricity-based heating systems. |

|

[91] |

Thermo-environomic assessment of an integrated greenhouse with an adjustable solar photovoltaic blind system |

Energy plus modeling as a greenhouse reference in rose cultivation; Validation of the developed greenhouse model with experimental site measurements; Investigating ambient temperature in the greenhouse with a photovoltaic system |

The results showed that covering 19.2% of the roof can reduce natural gas consumption, electricity demand, and CO2 emission by 3.57%, 45.5%, and 30.56 kgm−2 annually, without affecting plant canopy illumination levels. |

|

[92] |

Nanomaterials application in greenhouse structures, crop processing machinery, packaging materials, and agro-biomass conversion |

Application of nanomaterials in agricultural products; Investigating nanotechnology in climate control and photosynthesis of plants in the greenhouse |

The reviewed work indicated that nanotechnology has the potential to enhance agricultural production. |

|

[52] |

Energy-sustainable greenhouse crop cultivation using photovoltaic technologies |

Examining the important aspects of greenhouse cultivation and the electricity required; Studying state-of-the-art photovoltaic systems in the greenhouse and their shading effects on plants; A vision for sustainable greenhouses with photovoltaic technologies |

The results showed that solar cells can be used in greenhouses to generate electricity, but the shading from photovoltaic panels can impact plants below. |

3. Hydroponic Cultivation

|

Refs. |

Titles |

Purpose and Review |

Results |

|---|---|---|---|

|

[2] |

Recycling drainage effluents using reverse osmosis powered by photovoltaic solar energy in hydroponic tomato production: Environmental footprint analysis |

Measuring the environmental benefits and trade-offs of reverse osmosis integration; Recycling of greenhouse drainage effluents using photovoltaic solar system; Comparison of the environmental footprint of tomato production in two types of conventional and hydroponic cultivation; Comparison of three independent sources of irrigation |

The results showed that using brackish groundwater as a substitute for desalinated seawater can reduce the global warming footprint by 27%. |

|

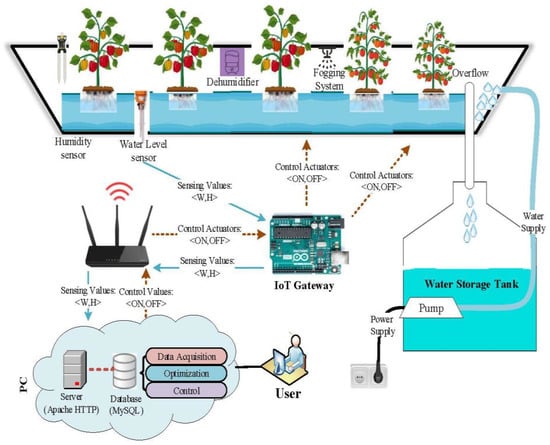

[17] |

Hydroponic and Aquaponic Farming: Comparative Study Based on Internet of things IoT technologies |

Comparison of hydroponic and aquaponic cultivation systems; Using the automatic technology of the Internet of Things (IoT) |

The results showed that implementing a depth-camera module in the system offered an advantage, and a mobile application to maintain the ecological balance of the environment. |

|

[103] |

Validation of a building energy model of a hydroponic container farm and its application in urban design |

Validation of Energy Plus model in container hydroponic culture; Continuation of experiments for nine months and data collection; Studying energy consumption and its optimization |

The results showed that stakeholders can reliably predict annual container farm energy use by representing plant–air interactions within EnergyPlus. |

|

[1] |

Autonomous greenhouse microclimate through hydroponic design and refurbished thermal energy by phase change material |

Evaluation of the microclimate of hydroponic greenhouse cultivation without heating; Hydroponic design evaluation; Comparison of environmental conditions inside the greenhouse during the day and night |

The results showed that hydroponic greenhouses offer better conditions than conventional ones, with temperatures above 18 °C and a humidity range of 20–35% during the day. |

|

[104] |

Hydroponic system and desalinated seawater as an alternative farm-productive |

Comparison of energy consumption of lettuce production in two types of conventional and hydroponic greenhouse cultivation; Investigating the amount and emission of greenhouse gases; Comparison of different percentages of desalinated seawater for irrigation |

The results showed that desalinated seawater with hydroponic systems can sustain agriculture but relies heavily on energy. |

|

[21] |

Comparison of soil and hydroponic cultivation systems for spinach irrigated with brackish water |

Measurement of differences in the water status of spinach plants; Using brackish water to grow plants in covered soil, non-covered soil, and hydroponic cultivation system; Investigating the leaf water and osmosis potential of the product and also its regulation |

The results showed that the spinach plant adjusts to salinity with adaptive strategies by increasing osmotic adjustment and leaf succulence, reducing leaf water potential. Sodium concentration in leaves and fresh weight are highest in hydroponic cultivation, especially with brackish water. |

|

[56] |

Evaluation of hydroponic systems for the cultivation of Lettuce (Lactuca sativa L., var. Longifolia) and comparison with protected soil-based cultivation |

Investigating the suitability of hydroponic cultivation of lettuce in replacing greenhouse soil-based cultivation; Study of two hydroponic techniques including deep-water culture and nutrient film technique and compare them with conventional greenhouse cultivation; Using Tukey’s test to investigate crop performance, water consumption and economy |

The results indicated that hydroponic techniques outperformed soil-based systems with a higher yield, simplicity, ease of operation, economic feasibility, and nutritionally superior produce. |

|

[33] |

A new method for green forage production: Energy use efficiency and Environmental sustainability |

Evaluating energy and water consumption in hydroponic fodder production; Study of environmental indicators |

The results showed that despite the many benefits of hydroponic fodder on livestock nutrition, its greenhouse cultivation imposes many adverse environmental effects. |

This entry is adapted from the peer-reviewed paper 10.3390/su16031273