Insulators, as important components of high-voltage transmission lines, serve the functions of electrical separation and support for conductors. Due to their long-term outdoor exposure to sunlight, rain, climate changes, and chemical corrosion, insulators often suffer from self-exploding defects, causing the disconnection of insulator strings and interfering with their performance, thus affecting the safety and stability of power systems. Insulator detection methods are generally divided into two types. The first is manual inspection, where workers directly observe insulators to identify defective parts. However, this method is time-consuming and not safe. The second is intelligent inspection, which can effectively locate defective parts by carrying edge detection equipment on drones for regular inspection of insulators. This is also the current mainstream inspection method.

1. Introduction

Currently, the implementation of insulator defect detection mainly relies on traditional methods and deep learning methods. Traditional detection methods primarily differentiate insulators from the background based on features such as size, texture, and color of the images

[1]. For example, Tan et al.

[2] takes a fusion algorithm based on insulator contour features and grayscale similarity matching. It can extract the contours of insulator pieces, accurately separate them, and construct a defect detection model based on the spacing between insulator pieces and grayscale similarity matching. Liu et al.

[3] proposed an edge-based segmentation method for insulator strings. It uses a multi-scale morphological gradient algorithm to extract the edges of insulator strings, determine the largest connected region, and provide guidance for addressing the problem of mis-segmentation of iron caps and umbrella discs caused by edge loss in infrared images of insulator strings. However, these traditional detection methods have low efficiency in feature extraction, poor generalization capabilities, and difficulty in recognizing small-scale and high-likelihood objects in images

[4].

To enhance the feature extraction capability and anti-interference ability of insulator detection, traditional detection methods are no longer able to meet modern needs. Many scholars have turned their attention to deep learning methods. For example, Guo et al.

[5] used a lightweight target detection network called CenterNet-GhostNet to address the issue of the large number of parameters in the insulator defect detection model, which makes it difficult for unmanned aerial vehicles to deploy on the edge. This network significantly reduces the number of network parameters while achieving a slight increase in detection accuracy, thereby improving the detection speed of the network. Jia et al.

[6] considered a lightweight detection method called MDD-YOLOv3. The improved YOLOv3 can quickly and accurately recognize and locate insulator defects in complex backgrounds. Li et al.

[7] proposed a method that utilizes multiple-scale feature encoding and dual attention fusion to improve the accuracy and speed of detecting insulator defects in transmission lines. It has a certain reference value for accurate insulator defect detection by unmanned aerial vehicles. In summary, compared with the traditional manual feature extraction of insulators, deep learning-based detection methods can automatically and accurately extract target features and have stronger generalization capabilities.

In recent years, due to the development of “Intelligentization” in the power system, the combination of using drones to collect insulator defect data and computer vision technology has become a popular method for intelligent inspection

[8][9]. However, deep learning-based object detection networks usually require a large number of computational resources and parameters for training and inference, which limits their deployment and usage in practical applications. Therefore, the construction of lightweight detection models has become crucial

[10][11][12].

The existing deep learning detection methods can be mainly divided into two categories. One is the two-stage detection model represented by R-CNN, Faster R-CNN, and Mask R-CNN. These algorithms require two-stage processing: (1) candidate region acquisition and (2) classification and regression of candidate regions. The other is the single-stage detection model represented by the YOLO series, which simultaneously obtains candidate regions and categories through joint decoding. Among them, the Faster R-CNN model, as a representative of two-stage networks, exhibits a more pronounced advantage when it comes to handling high-precision, multi-scale, and small object detection tasks. However, the original Faster R-CNN (ResNet) model suffers from significant drawbacks in terms of detection speed performance. Firstly, its feature extraction capability is relatively poor. This is because the original ResNet cannot effectively extract high-level semantic information and low-level fine-grained features from images, making it difficult for deeper feature maps to learn information about small objects. Secondly, the network’s inference speed is slow. The original model contains a lot of redundant information, resulting in a slow detection speed. Finally, the network parameters are not well optimized. For instance, the original model’s learning rate can easily get stuck in local optima, leading to a decline in the overall model performance.

2. Faster R-CNN

Defect detection involves the following two tasks: defect classification and localization. This paper chooses two-stage Faster R-CNN

[13] as the lightweight base network structure, which exhibits a high accuracy in object detection tasks. Its working principle is to first identify and locate defective insulators in an image, then select them with rectangles, and, finally, mark their belonging categories near the rectangles.

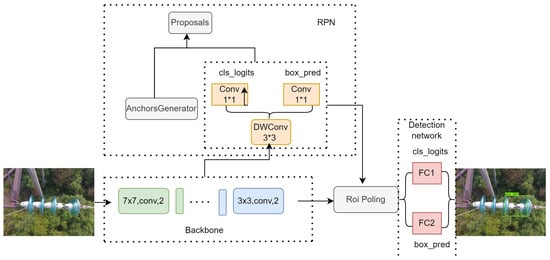

Faster R-CNN is a two-stage object detection network proposed by Ross B. Girshick, building upon the foundations of R-CNN and Fast R-CNN. As shown in Figure 1, the Faster R-CNN network structure consists of four parts: the backbone network, the Region Proposal Network (RPN), the Region of Interest (RoI) pooling, and the detection network. The backbone network is a ResNet network stacked with multiple 7 × 7 convolutions of stride 2 and 3 × 3 convolutions of stride 2. The RPN is a feature-processing part composed of two parallel 1 × 1 convolutions by 3 × 3 deep separable convolutions (DWConv). The detection network consists of two parallel fully connected layers (FC).

Figure 1. The original Faster R-CNN network structure.

The entire algorithm process is divided into several parts. First, the backbone network extracts features from preprocessed images by capturing multi-scale information with inter-channel interactions. Then, these features are used as input for the RPN, which generates candidate boxes. The candidate boxes are mapped to the feature map output by the backbone network. The obtained feature matrix is passed through the RoI Pooling layer, resulting in a 7 × 7 feature map. Finally, the detection network utilizes the feature map to obtain class information and bounding box regression parameters. The candidate boxes are adjusted using the bounding box regression parameters to obtain the final target position.

To address the low accuracy and slow speed issues of the original model in insulator defect detection, we propose a lightweight defect detection model based on Faster R-CNN-tiny. The aim is to make the original detection model more suitable for future edge deployment requirements.

3. ResNet

ResNet, which stands for Deep Residual Network, is a landmark convolutional neural network (CNN) that uniquely solves the problems of gradient disappearance and explosion in deep neural networks.

In 2015, ResNet won the ILSVRC (ImageNet Large Scale Visual Recognition Challenge) championship and significantly improved error accuracy in the ImageNet classification task. This is mainly due to ResNet’s “shortcut connections”, also known as “skip connections”. Through this connection method, the output of the deep network can be directly added to some layers of the shallow network, which helps the gradient to be directly transmitted to the shallow network. This design allows the network to train deep networks with dozens or even hundreds of layers.

4. EfficientNet

EfficientNet, proposed by Google in 2019, constructs models through compound scaling to improve model efficiency. It is composed of one ordinary convolutional layer and sixteen mobile inverted bottleneck convolution modules (MBConv). Among them, the MBConv module is its core component, which mainly draws inspiration from the residual structure of MobileNetv3

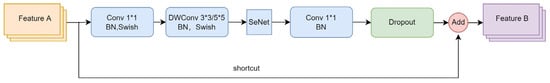

[14]. As shown in

Figure 2, it has the following functional features: firstly, a Swish activation function

[15] is used instead of a ReLU activation function, and Swish performs better on deep models. Secondly, a squeeze-and-excitation networks (SENet)

[16] attention mechanism is added to each MBConv module to strengthen the extraction of small-scale target features and suppress useless feature information. Thirdly, dropout layers are introduced. When there are shortcut branches (shortcuts), the main branch of the whole module will be randomly dropped, leaving only the shortcut branch, making the network lighter and improving the detection speed of the model.

Figure 2. The MBConv module in the EfficientNet network.

The main difference between the two lies in their network structure and optimization strategies. EfficientNet adopts a deeper and wider network structure, while using compound scaling to adjust the depth, width, and resolution of the network. This makes EfficientNet reduce the number of parameters and computations, thereby improving the efficiency of the model. On the other hand, ResNet mainly solves the vanishing and exploding gradient problems using residual blocks, with a relatively simple network structure.

This entry is adapted from the peer-reviewed paper 10.3390/s24010290