Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Human errors (HEs) are common problems in manual assembly processes, impacting product quality and resulting in additional costs. HEs refer to mistakes or deviations from intended actions made by individuals when implementing some tasks. These errors can occur due to various reasons, such as a lack of training, fatigue, poor work instructions, etc.

- human errors

- manual assembly

- multi-criteria decision-making

1. Introduction

The term “manual assembly” refers to a process in which human operators use their innate dexterity, aptitude, and judgment to combine pre-existing parts to create a finished product or a unit of a finished product. According to Richardson et al. [1], the activity of manual assembly is a type of spatial problem-solving that requires workers to construct a mental model in order to interpret and engage with spatial input. Work instructions, their presentation, and the worker’s interaction with them are extremely important in manual assembly operations [2][3][4][5]. Work instructions must be clear and unambiguous about which parts to utilize and how they should be built in order to optimize the operators’ mental abilities [4]. It is generally accepted that assembly instructions must be provided in a way that allows everyone to read them and successfully complete the assembly [6]. In this manner, work instructions can help reduce the mental load on the operators, in particular by simplifying the complexity of the tasks. Today, most manual assembly instructions are provided digitally, on a computer display, and include text and visual content [2][3][4][5]. However, Mattsson et al. [7] believed that instructions should be highly perceptual, which necessitates providing the operator with more sophisticated and timely sensory inputs. Using three-dimensional models in work instructions improves their realism, accuracy, and legibility in depicting the assembly process. Perspectives and basic assembly guidelines might be included in these model-based instructions (MBI) [8][9].

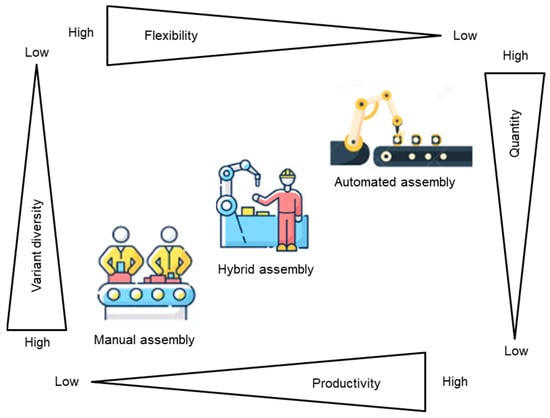

The assembly process is crucial to manufacturing because it guarantees that the final product meets the necessary quality standards. Several factors, such as flexibility, the variety of products, the volume of production, and productivity, are considered by engineers when selecting an appropriate assembly system [6][10]. Despite the lower productivity and production volume in manual assembly systems compared with automatic assembly systems, manual systems have an increased flexibility and variety of products. Worker productivity is a measure of the output or results achieved by an individual worker or a group of workers within a specific time. Figure 1 illustrates the impact of assembly system automation on these factors. Although industrial robots contribute greatly to the automation of manufacturing systems, including assembly systems, the complexity and diversity of the product still represent significant challenges in manufacturing; therefore, manual work remains a viable and irreplaceable alternative [6][11]. These manufacturing fields include electronics, aerospace, automotive, combustion engine assembly, and industrial machinery and equipment [12][13]. Manual assembly requires the precise execution of a number of steps in order to yield a finished product of the requisite quality. Torabi et al. [14] discussed the common human errors in the design, installation, and operation of variable air volume air handling unit systems. They identified that many types of faults can occur, including design, assembly, manufacturing, incorrect operation, maintenance, software, and operator’s faults, and the mistakes that humans directly cause may be referred to as errors. Park et al. [15] have designed a software tool called Foolproof Joint that simplifies the assembly of laser-cut 3D models to reduce assembly errors by modifying finger joint patterns. They [16] developed an intelligent detection approach to detect human errors in the maintenance and assembly of components of a nuclear power plant using artificial intelligence. Wang et al. [17] investigated the vibration characteristics of the spindle system and discovered that the vibrations were caused by assembly errors.

Figure 1. Manual, hybrid, and automated assembly systems.

Furthermore, Miao et al. [18] and Wang et al. [19] mentioned that supporting bearing assembly errors have a significant impact on bearing operating performance and spindle vibration characteristics. Human error (HE) is one of the most common causes of accidents in many industries. Previous studies indicate that HE contributes to 30–90% of all accidents in work environments despite strict safety procedures in those industries [20]. Common types of human errors (HEs) in assembly processes include unsecured links, missing parts, improper part installation, the inadequate application of force to fasteners, breakage during assembly, and contamination by foreign object debris [21][22]. Inadequate cognitive and physical ergonomics have also been found to impact product quality and increase the frequency of errors [11][23].

Moreover, there are many other kinds of human errors that are capable of occurring throughout the assembly processes. Here are a few common examples:

- (1)

-

Omission errors: These occur when a step or task in the assembly process is missed or skipped over entirely. For example, a worker might forget to install a specific component or tighten a screw;

- (2)

-

Commission errors: Commission errors occur when a worker does an action incorrectly, such as installing a part backward or using the wrong tool;

- (3)

-

Transposition errors: These errors occur when two similar-looking parts or components are confused with each other. For example, two screws of different lengths might look similar, and a worker might accidentally use the wrong one;

- (4)

-

Timing errors: Timing errors occur when a worker completes tasks in the wrong order or sequence, which can cause problems down the line. For example, a worker might install a part before another part that should have gone in first;

- (5)

-

Procedural errors: These errors occur when workers do not follow the correct procedures or instructions for a task. This could be due to a lack of training or understanding of the instructions;

- (6)

-

Communication errors: Communication errors can occur when workers do not communicate effectively with each other or when instructions are unclear or misunderstood;

- (7)

-

Fatigue-related errors: Errors can also occur due to factors such as fatigue or stress, affecting a worker’s attention and decision-making abilities.

It is essential to remember that these errors can frequently be connected to one another and exacerbate one another, which might result in more severe issues throughout the assembly processes. Therefore, it is important to identify these errors and know the factors causing them as early as possible to prevent more significant issues.

With the advent of Industry 4.0, increased product customization will occur in highly flexible production settings [6]. As a result of this widespread personalization, manufacturing is likely to become more complicated, possibly calling for more highly trained employees [23]. Reducing HEs in this situation depends critically on a well-optimized work system. A well-optimized work system refers to an effective arrangement of people, processes, resources, and technology that maximizes productivity, quality, and overall performance. It is designed to streamline workflows and reduce human errors to achieve desired outcomes. Identifying the aspects and factors influencing operator performance is crucial for optimizing assembly processes and minimizing errors. Many factors directly or indirectly influence the assemblers’ errors during the manual assembling processes. Identifying the most critical factors needs much research in the field, which is time-consuming and expensive; moreover, some previous studies focused on defining and identifying some of these factors and did not address identifying which factors are the most influential for these errors.

2. Factors Affecting Human Errors in Manual Assembly Processes

Human errors (HEs) refer to mistakes or deviations from intended actions made by individuals when implementing some tasks. These errors can occur due to various reasons, such as a lack of training, fatigue, poor work instructions, etc. Different types or categories of human errors include slips (unintended actions), lapses (omission), mistakes (knowledge-based errors), rule-based errors (applying incorrect rules), etc. The consequences or impacts of these errors on productivity include delays in production timelines and quality involving defects or rework, while in safety results, accidents lead to injuries.

In recent years, some studies have been conducted to find the influencing factors of human errors in different fields. Lopez et al. [24] classified the influence factors on design errors in construction into personal factors, such as adverse behavior, and organizational factors, such as poor training and quality. Iraj et al. [25] reported that factors affecting HEs in a mining process design are caused by individual factors (lack of knowledge and experience), task factors (multitasking and workload), organizational factors (poor management and training), and environmental factors (inadequate lighting, noise, and poor air quality). Noman et al. [26] have studied some factors affecting inspection and maintenance errors, such as unclear instructions and procedures, stress, task complexity, and lack of experience and training, in addition to other work environmental factors such as noise, lighting, etc., Yaniel et al. [27] analyzed human errors in a complex manual assembly line and identified 31 factors that caused those errors.

A comprehensive survey of the literature was conducted to summarize the main factors affecting HEs in the manual assembly processes, as well as the related sub-factors. These were then reviewed and discussed by academic and industry experts with at least ten years of experience in manual assembly processes. Through a literature review, 51 factors influencing human error were identified. The factors influencing human error were finally classified into five categories, namely individual factors, tool factors, task factors, organizational factors, and environmental factors, as shown in Table 1.

Table 1. Identification and classification of factors influencing human error.

| Category | Influencing Factors Affecting HEs |

|---|---|

| Individual factors | Gender [28], age [28], lack of experience [29], lack of knowledge [30][31][32][33][34], fatigue [25], stress [2], body physique [35], poor health [36], poor memory [36], personal life problems [36], personality type [25], disappointment [25], lack of motivation [25], depression [25], fear of failure [37], poor error visual error perception [25], financial problems [25][38], haste in doing work [39], low intelligence coefficient [25][38], job dissatisfaction [39], lack of trust in performance [25], misunderstanding [39], unintentional unsafe acts [39], sleep deprivation/disorder [6][27][40], risk-taking [41], and understanding roles and responsibilities [25][38]. |

| Tool factors | Lack of necessary tools and using inappropriate tools [36][39]. |

| Task factors | Poor instructions and procedures [42], task complexity [43], time pressure [28], workload [2], repetitive task [35][44], and multitasking [45][46][47][48]. |

| Organizational factors | Poor management type [25], lack of training [25], poor planning [39], poor organization culture [25], failure to address the error-causing problem [39], poor resource allocation [25][39], poor supervision [25][39], improper quality control [39], and poor communication between worker and organization [36][39]. |

| Environmental factors | Noise [49][50], inappropriate lighting [49][50], improper temperature and humidity [49][50], poor indoor air quality [25], poor ergonomics design of the workplace [28], accessibility problems [25], and poor workplace layout [25]. |

In the field of manufacturing, manual assembly processes play a crucial role in ensuring product quality and efficiency. However, human errors are an inherent risk factor that can significantly impact productivity, quality assurance, and worker safety. Therefore, it is essential to understand the determining factors that contribute to human errors in manual assembly processes in order to develop effective strategies for error prevention and process improvement. Two Multi-Criteria Decision-making (MCDM) techniques—Fuzzy Delphi (FDM) and DEMATEL methods—can be used to accurately determine the factors affecting human errors in manual assembly processes and identify the relationships among them. These methods are often used to solve fuzzy complex issues based on experts’ opinions. Therefore, the MCDM techniques are analytical tools used to handle complex decision-making problems by simultaneously considering multiple criteria or factors. These techniques provide a systematic framework for evaluating alternatives based on various qualitative or quantitative attributes. In the context of determining factors affecting human errors in manual assembly processes, MCDM methods offer a structured approach for gathering expert opinions and constructing cause-and-effect models.

Many MCDM techniques have been used by researchers and decision-makers in the literature. The selection of an appropriate MCDM technique depends on the specific characteristics of the decision problem, the available data, decision-maker preferences, and the objectives of the decision-making process. According to the study of Taherdoost and Madanchian [51], the twenty most-cited MCDM methods from 2012 to 2022 (based on the “ScienceDirect” database) are shown in Table 2.

Table 2. The twenty most-cited MCDM methods during 2012–2022 [51].

| Method | Description | Reference |

|---|---|---|

| AHP | It decomposes complex decision problems into a hierarchical structure, allowing pairwise comparisons of criteria and alternatives. | Saaty [52] |

| DEA | It is a non-parametric technique that evaluates the relative efficiency of alternatives in relation to multiple criteria. | Charnes and William [53] |

| FST | Dealing with decision-making in the presence of uncertainty and imprecise data by representing degrees of membership and non-membership using fuzzy sets. | Zadeh [54] |

| TOPSIS | It compares alternatives against ideal and anti-ideal solutions based on multiple criteria. | Hwang et al. [55] |

| GP | It is an optimization-based technique aiming to simultaneously achieve multiple goals or objectives. | Charnes and William [56] |

| CBR | It involves solving new decision problems by retrieving and adapting solutions from similar historical cases. | Kolodner [57] |

| GRA/GRM | Measuring the relationship between alternatives and criteria by analyzing the grey correlation coefficients. | Deng [58] |

| ANP | It extends the AHP to handle dependencies and feedback among criteria and alternatives. | Thomas [59] |

| FUZZY AHP | It extends the AHP method by incorporating fuzzy logic to handle uncertainties and vagueness in decision-making. | Laarhoven and Pedrycs [60] |

| ELECTRE | It eliminates alternatives that do not meet certain criteria thresholds and ranks the remaining ones. | Benayoun et al. [61] |

| PROMETHEE | It evaluates alternatives by considering criteria and decision-maker’s preferences. | Brans et al. [62] |

| VIKOR | Identifying the compromise solution among alternatives. | Opricovic [63] |

| FUZZY TOPSIS | Based on TOPSIS under a fuzzy environment. | Chen [64] |

| DEMATEL | Analyzing causal relationships relationships/interdependence among different criteria. | Gabus and Fontela [65] |

| PRAGMA | It aggregates individual preferences to determine a collective ranking of alternatives. | Matarazzo [66] |

| SAW | It aggregates criteria scores by applying weights and sums them to obtain a total score for each alternative. | Churchman and Ackoff [67] |

| MAUT | It quantifies the preferences of decision-makers by assigning utility functions to criteria and alternatives. | Keeney et al. [68] |

| BWM | It is a technique for ranking and prioritizing criteria based on their relative importance or preference. | Rezaei [69] |

| SMART | It combines weighted scores of criteria to evaluate and rank alternatives. | Edwards [70] |

| Fuzzy ANP | Fuzzy expression of criteria weights in ANP method. | Ludmil and Madan [71] |

Note: AHP: Analytic Hierarchy Process; DEA: Data Envelopment Analysis; FST: Fuzzy Set Theory; TOPSIS: Technique for Order of Preference by Similarity to Ideal Solution; GP: Goal Programming; CBR: Case-Based Reasoning; GRA/GRM: Grey Relational Analysis/Grey Relational Model; ANP: Analytic Network Process; ELECTRE: Elimination Et Choice Translating Reality; PRO-METHEE: Preference Ranking Organization Method for Enrichment of Evaluations; VIKOR: VIseKriterijumska Optimizacija I Kompromisno Resenje; DEMATEL: Decision-Making Trial and Evaluation Laboratory; PRAGMA: Preference Ranking Global Frequencies in Multicriterion Analysis; SAW: Simple Additive Weighting; MAUT: Multi-Attribute Utility Theory; BWM: Best–Worst Method; and SMART: Simple Multi-Attribute Rating Technique.

The DEMATEL method is one of the MCDM techniques employed for analyzing causal relationships among different criteria. It was first used by Lin in 2008 in a fuzzy environment study [72]. It involves constructing a cause-and-effect relationship model based on expert opinions gathered through a questionnaire-based survey. The fuzzy DEMATEL method uses the total-relation matrix to identify the criteria that are effective (cause) and affected (effect) and looks into how these criteria relate to each other [25].

The Fuzzy DEMATEL method was selected depending on the specific context and requirements of the decision problem at hand. While various MCDM techniques are available, the Fuzzy DEMATEL offers certain advantages that make it suitable for certain types of decision-making problems. The Fuzzy DEMATEL is particularly useful when the decision problem involves complex interdependencies among criteria or factors [25]. It allows decision-makers to analyze the cause-and-effect relationships between criteria and identify the strength and direction of these relationships [25][73]. This helps in understanding the interdependencies and their impact on the decision problem.

The FDM is a potent instrument that helps researchers in a particular field of study obtain a consensus based on expert viewpoints [74]. It is considered to be one of the most common and reliable techniques for collecting expert opinions and carrying out questionnaires [75][76]. In addition, it is one of the most commonly utilized methodologies for solving an extensive variety of group decision-making problems through choosing and/or ranking factors, standards, questionnaire factors, or calculating index factors [77]. Combining the traditional Delphi method (DM) with fuzzy set theory led to the development of a more robust FDM [25]. The FDM has some advantages, such as the ability to combine expert opinions in order to establish a consensus [56], time and cost reduction compared with the DM [3], and the reduction in rounds of expert-opinion gathering [38].

Moreover, the most notable characteristics of the FDM are that the answers gathered are unexplored and unidentified, that it is dependent on a conditional phased statistical processing operation, and that it is based on processes that can be counted, limited, and repeated while being controlled and managed by a phase focused on a results feedback process. The FDM outputs also represent uniform, updated, and collective statistical scores. Its other distinguishing features are its ability to address qualitative difficulties depending on nature through multiple survey rounds, to develop consensus opinions, and to facilitate efficient decisions. As a result, the FDM has been extensively used in a wide variety of interdisciplinary research to compile a consistent and evolving set of responses from expert respondents in the course of numerous rounds of surveying [75][76][77].

Recently, in identifying factors affecting HEs, the Delphi method has been used in some studies. Iraj et al. [25] have used the FDM to determine the factors affecting HEs in a mining process design. In addition, they used the DEMATEL method to identify the relationships among those factors. In the studies of Adel et al. [36], the FDM was used to identify the influencing factors that lead to accidents as a result of HEs during the construction of industrial park projects. The results of the survey showed that the specific factors had a significant impact on the incidence of those accidents caused by HEs. In a similar study for determining the factors affecting HEs in the construction industry using the Delphi method, the study conducted by Daniel et al. [39] showed that most influencing factors affecting construction industry errors were evaluated from medium to strong. The study of Cheryl et al. [78] used a two-round Delphi technique to identify human factors affecting nursing errors.

Comparing the fuzzy Delphi and DEMATEL methods reveals their distinct strengths and limitations: The fuzzy Delphi method offers a systematic approach for expert consensus building, ensuring comprehensive coverage of potential influential factors through iterative feedback rounds. On the other hand, the DEMATEL method allows researchers to visualize complex cause-and-effect relationships among identified factors while highlighting key drivers or bottlenecks within the network. However, it is important to note that both methods heavily rely on expert opinions, which may introduce biases based on individual knowledge or experience levels.

From the literature, it can be found that there are a lack of in-depth studies to determine the factors affecting HEs in the field of manual assembly processes and identify the relationships between these factors using MCDM techniques. Previous studies focused mainly on factors affecting HEs in nursing [78], the construction of industrial park projects [36][39][79], and mining process design [25]. Previous researchers used either the FDM method for identifying factors affecting HEs or the DEMATEL method for identifying the relationships among the factors affecting HEs.

This entry is adapted from the peer-reviewed paper 10.3390/sym15111967

References

- Richardson, M.; Jones, G.; Torrance, M.; Baguley, T. Identifying the task variables that predict object assembly difficulty. Hum. Factors 2006, 48, 511–525.

- Brolin, A.; Thorvald, P.; Case, K. Experimental study of cognitive aspects affecting human performance in manual assembly. Prod. Manuf. Res. 2017, 5, 141–163.

- Bavafa, A.; Mahdiyar, A.; Marsono, A.K. Identifying and assessing the critical factors for effective implementation of safety programs in construction projects. Saf. Sci. 2018, 106, 47–56.

- Li, D.; Mattsson, S.; Salunkhe, O.; Fast-Berglund, Å.; Skoogh, A.; Broberg, J. Effects of information content in work instructions for operator performance. Procedia Manuf. 2018, 25, 628–635.

- Bäckstrand, G.; Thorvald, P.; De Vin, L.J.; Högberg, D.; Case, K. The impact of information presentation on work environment and product quality: A case study. In Proceedings of the 40th Annual Conference of the Nordic Ergonomics Society, Reykjavík, Iceland, 11–13 August 2008.

- Torres, Y.; Nadeau, S.; Landau, K. Classification and quantification of human error in manufacturing: A case study in complex manual assembly. Appl. Sci. 2021, 11, 749.

- Mattsson, S.; Fast-Berglund, Å.; Li, D. Evaluation of guidelines for assembly instructions. IFAC-PapersOnLine 2016, 49, 209–214.

- Lichtner, D.; Senesac, C.J.; Hagan, R.J.; Gandhi, F. Three-dimensional model based manufacturing work instructions. In Proceedings of the 65th Annual Forum Proceedings-AHS International, Grapevine, TX, USA, 27–29 May 2009; pp. 2115–2120.

- Geng, J.; Zhang, S.; Yang, B. A publishing method of lightweight three-dimensional assembly instruction for complex products. J. Comput. Inf. Sci. Eng. 2015, 15, 031004.

- Lotter, B.; Wiendahl, H.-P. Changeable and reconfigurable assembly systems. In Changeable and Reconfigurable Manufacturing Systems; Springer: Berlin/Heidelberg, Germany, 2009; pp. 127–142.

- Dinlersoz, E.; Wolf, Z. Automation, labor share, and productivity: Plant-level evidence from U.S. Manufacturing. Econ. Innov. New Technol. 2022.

- BEUß, F.; Sender, J.; Flügge, W. Ergonomics simulation in aircraft manufacturing–methods and potentials. Procedia CIRP 2019, 81, 742–746.

- Judt, D.; Lawson, C.; Lockett, H. Experimental investigation into aircraft system manual assembly performance under varying structural component orientations. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 234, 840–855.

- Torabi, N.; Gunay, H.B.; O’Brien, W.; Barton, T. Common human errors in design, installation, and operation of VAV AHU control systems–A review and a practitioner interview. Build. Environ. 2022, 221, 109333.

- Park, K.; Lempert, C.; Abdullah, M.; Katakura, S.; Shigeyama, J.; Roumen, T.; Baudisch, P. FoolProofJoint: Reducing Assembly Errors of Laser Cut 3D Models by Means of Custom Joint Patterns. In Proceedings of the 2022 CHI Conference on Human Factors in Computing Systems, New Orleans, LA, USA, 29 April–5 May 2022; pp. 1–12.

- Gursel, E.; Reddy, B.; Khojandi, A.; Madadi, M.; Coble, J.B.; Agarwal, V.; Yadav, V.; Boring, R.L. Using artificial intelligence to detect human errors in nuclear power plants: A case in operation and maintenance. Nucl. Eng. Technol. 2023, 55, 603–622.

- Wang, P.; Yang, Y.; Wen, B.; Ma, H.; Han, Q.; Luo, Z.; Li, X.; Wen, B. Numerical and experimental analysis of vibration characteristics of spindle system under bearing assembly errors. Mech. Based Des. Struct. Mach. 2023, 1–28.

- Miao, H.; Wang, C.; Li, C.; Yao, G.; Zhang, X.; Liu, Z.; Xu, M. Dynamic modeling and nonlinear vibration analysis of spindle system during ball end milling process. Int. J. Adv. Manuf. Technol. 2022, 121, 7867–7889.

- Xu, H.; Wang, P.; Ma, H.; Yang, Y.; Li, X.; Luo, Z.; Han, Q.; Wen, B. Dynamic behaviors and contact characteristics of ball bearings in a multi-supported rotor system under the effects of 3D clearance fit. Mech. Syst. Signal Process. 2023, 196, 110334.

- Farhadi, S.; Mohammadfam, I.; Kalatpour, O.; Ghasemi, F. Determining performance shaping factors to assess human error in the emergency response team in chemical process industries: A case study. Int. J. Occup. Saf. Ergon. 2023, 29, 294–305.

- Wong, Y.C.; Wong, K.Y.; Ali, A. Key practice areas of lean manufacturing. In Proceedings of the 2009 International Association of Computer Science and Information Technology-Spring Conference, Singapore, 17–20 April 2009; pp. 267–271.

- Weyer, S.; Schmitt, M.; Ohmer, M.; Gorecky, D. Towards Industry 4.0-Standardization as the crucial challenge for highly modular, multi-vendor production systems. IFAC-PapersOnLine 2015, 48, 579–584.

- Thoben, K.-D.; Wiesner, S.; Wuest, T. “Industrie 4.0” and smart manufacturing-a review of research issues and application examples. Int. J. Autom. Technol. 2017, 11, 4–16.

- Lopez, R.; Love, P.E.; Edwards, D.J.; Davis, P.R. Design error classification, causation, and prevention in construction engineering. J. Perform. Constr. Facil. 2010, 24, 399–408.

- Mohammadfam, I.; Khajevandi, A.A.; Dehghani, H.; Babamiri, M.; Farhadian, M. Analysis of factors affecting human reliability in the mining process design using Fuzzy Delphi and DEMATEL methods. Sustainability 2022, 14, 8168.

- Noman, M.A.; Alqahtani, F.M.; Al-Harkan, I.; Alabdulkarim, S.A.; Alasim, F. A New Integrated Risk-Assessment Model for Minimizing Human-Machine Error Consequences in a Preventive Maintenance System. IEEE Access 2023, 11, 25253–25265.

- Torres, Y.; Nadeau, S.; Landau, K. Applying AcciMap and STAMP to the analysis of human error in complex manual assembly. Hum. Factors Ergon. Manuf. Serv. Ind. 2022, 32, 462–481.

- Saptari, A.; Leau, J.X.; Mohamad, N.A. The effect of time pressure, working position, component bin position and gender on human error in manual assembly line. In Proceedings of the 2015 International Conference on Industrial Engineering and Operations Management (IEOM), Dubai, United Arab Emirates, 3–5 March 2015; pp. 1–6.

- Nordqvist, M.; Lindblom, J. Operators’ Experience of Trust in Manual Assembly with a Collaborative Robot. In Proceedings of the 6th International Conference on Human-Agent Interaction, Southampton, UK, 15–18 December 2018; pp. 341–343.

- Müller, B.C.; Reise, C.; Duc, B.M.; Seliger, G. Simulation-games for learning conducive workplaces: A case study for manual assembly. Procedia CIRP 2016, 40, 353–358.

- Lavric, T.; Bricard, E.; Preda, M.; Zaharia, T. Exploring low-cost visual assets for conveying assembly instructions in AR. In Proceedings of the 2021 International Conference on INnovations in Intelligent SysTems and Applications (INISTA), Kocaeli, Turkey, 25–27 August 2021; pp. 1–6.

- Lavric, T. Methodologies and Tools for Expert Knowledge Sharing in Manual Assembly Industries by Using Augmented Reality. Ph.D. Thesis, Institut Polytechnique de Paris, Palaiseau, France, 2022.

- Miqueo, A.; Torralba, M.; Yagüe-Fabra, J.A. Lean manual assembly 4.0: A systematic review. Appl. Sci. 2020, 10, 8555.

- Krugh, M.; Garimella, R.S.; Baburaj, A.; Wescoat, E.; Mears, L. Closed loop feedback mechanism effect pilot investigation on manual assembly time and process variation. Procedia Manuf. 2020, 48, 95–104.

- Morais, C.; Estrada-Lugo, H.D.; Tolo, S.; Jacques, T.; Moura, R.; Beer, M.; Patelli, E. Robust data-driven human reliability analysis using credal networks. Reliab. Eng. Syst. Saf. 2022, 218, 107990.

- Rafieyan, A.; Sarvari, H.; Beer, M.; Chan, D.W. Determining the effective factors leading to incidence of human error accidents in industrial parks construction projects: Results of a fuzzy Delphi survey. Int. J. Constr. Manag. 2022, 1–13.

- Dhanalakshmi, C.S.; Madhu, P.; Hemachandran, M.N.; Muthukumar, M.V.; Arvinth, L.H. Design and Fabrication of Robotic Arm for the assembly of Phase Selector Switch. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1059, 012032.

- Mohammadfam, I.; Aliabadi, M.M.; Soltanian, A.R.; Tabibzadeh, M.; Mahdinia, M. Investigating interactions among vital variables affecting situation awareness based on Fuzzy DEMATEL method. Int. J. Ind. Ergon. 2019, 74, 102842.

- Chan, D.W.; Baghbaderani, A.B.; Sarvari, H. An empirical study of the human error-related factors leading to site accidents in the Iranian urban construction industry. Buildings 2022, 12, 1858.

- Liu, L.; Liu, Y.; Zhang, J. Learning-based hand motion capture and understanding in assembly process. IEEE Trans. Ind. Electron. 2018, 66, 9703–9712.

- Winkelhake, U. Challenges in the digital transformation of the automotive industry. ATZ Worldw. 2019, 121, 36–43.

- Wang, Z.; Bai, X.; Zhang, S.; Billinghurst, M.; He, W.; Wang, P.; Lan, W.; Min, H.; Chen, Y. A comprehensive review of augmented reality-based instruction in manual assembly, training and repair. Robot. Comput.-Integr. Manuf. 2022, 78, 102407.

- Bläsing, D.; Bornewasser, M. Influence of increasing task complexity and use of informational assistance systems on mental workload. Brain Sci. 2021, 11, 102.

- Fruggiero, F.; Fera, M.; Iannone, R.; Lambiase, A. Revealing a frame to incorporate safe human behaviour in assembly processes. IFAC-PapersOnLine 2018, 51, 661–668.

- Pankok, C., Jr.; Zahabi, M.; Zhang, W.; Choi, I.; Liao, Y.-F.; Nam, C.S.; Kaber, D. The effects of interruption similarity and complexity on performance in a simulated visual-manual assembly operation. Appl. Ergon. 2017, 59, 94–103.

- Turk, M.; Pipan, M.; Šimic, M.; Herakovič, N. Simulation-based time evaluation of basic manual assembly tasks. Adv. Prod. Eng. Manag. 2020, 15, 331–344.

- Kolbeinsson, A.; Thorvald, P.; Lindblom, J. Coordinating the interruption of assembly workers in manufacturing. Appl. Ergon. 2017, 58, 361–371.

- Ribbe, M.W.; Górecki, K.; Grosch, M.; Solomon, J.B.; Quechol, R.; Liu, Y.A.; Lee, C.C.; Hu, Y. Nitrogenase Fe Protein: A Multi-Tasking Player in Substrate Reduction and Metallocluster Assembly. Molecules 2022, 27, 6743.

- Bläsing, D.; Bornewasser, M. Influence of complexity and noise on mental workload during a manual assembly task. In Proceedings of the Human Mental Workload: Models and Applications: 4th International Symposium, H-WORKLOAD 2020, Granada, Spain, 3–5 December 2020; Proceedings 4; pp. 147–174.

- Anghel, D.-C.; Niţu, E.-L.; Rizea, A.-D.; Gavriluţă, A.; Gavriluţă, A.; Belu, N. Ergonomics study on an assembly line used in the automotive industry. MATEC Web Conf. 2019, 290, 12001.

- Taherdoost, H.; Madanchian, M. Multi-criteria decision making (MCDM) methods and concepts. Encyclopedia 2023, 3, 77–87.

- Saaty, R.W. The analytic hierarchy process—What it is and how it is used. Math. Model. 1987, 9, 161–176.

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444.

- Zadeh, L.A. Fuzzy sets. Inf. Control 1965, 8, 338–353.

- Hwang, C.-L.; Yoon, K. Methods for multiple attribute decision making. In Multiple Attribute Decision Making: Methods and Applications a State-of-the-Art Survey; Springer: Berlin/Heidelberg, Germany, 1981; pp. 58–191.

- Charnes, A.; Cooper, W.W. Management models and industrial applications of linear programming. Manag. Sci. 1957, 4, 38–91.

- Kolodner, J.L. Understanding creativity: A case-based approach. In European Workshop on Case-Based Reasoning, Proceedings of the Topics in Case-Based Reasoning, First European Workshop, EWCBR-93, Kaiserslautern, Germany, 1–5 November 1993; Springer: Berlin/Heidelberg, Germany, 1994; pp. 1–20.

- Ju-Long, D. Control problems of grey systems. Syst. Control Lett. 1982, 1, 288–294.

- Saaty, T.L. Decision Making with Dependence and Feedback: The Analytic Network Process; RWS Publications: Pittsburgh, PA, USA, 1996; Volume 4922.

- Van Laarhoven, P.J.; Pedrycz, W. A fuzzy extension of Saaty’s priority theory. Fuzzy Sets Syst. 1983, 11, 229–241.

- Benayoun, R.; Roy, B.; Sussman, N. Manual de Reference du Programme Electre; Note de Synthese et Formation 25; Direction Scientifique SEMA: Paris, France, 1966.

- Brans, J.-P.; Nadeau, R.; Landry, M. L’ingénierie de la décision. Elaboration d’instruments d’aide à la décision. La méthode PROMETHEE. In L’Aide à la Décision: Nature, Instruments et Perspectives d’Avenir; Presses de l’Université Laval: Québec, QC, Canada, 1982; pp. 183–213.

- Opricovic, S. Multicriteria optimization of civil engineering systems. Fac. Civ. Eng. Belgrade 1998, 2, 5–21.

- Chen, C.-T. Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets Syst. 2000, 114, 1–9.

- Gabus, A.; Fontela, E. World problems, an invitation to further thought within the framework of DEMATEL. Battelle Geneva Res. Cent. Geneva Switz. 1972, 1, 12–14.

- Matarazzo, B. Preference ranking global frequencies in multicriterion analysis (PRAGMA). Eur. J. Oper. Res. 1988, 36, 36–49.

- Churchman, C.W.; Ackoff, R.L. An approximate measure of value. J. Oper. Res. Soc. Am. 1954, 2, 172–187.

- Keeney, R.L.; Raiffa, H.; Rajala, D.W. Decisions with multiple objectives: Preferences and value trade-offs. IEEE Trans. Syst. Man Cybern. 1979, 9, 403.

- Rezaei, J. Best-worst multi-criteria decision-making method. Omega 2015, 53, 49–57.

- Edwards, W. The engineering economic summer symposium series. Soc. Util. 1971, 6, 119–129.

- Mikhailov, L.; Singh, M.G. Fuzzy analytic network process and its application to the development of decision support systems. IEEE Trans. Syst. Man Cybern. Part C (Appl. Rev.) 2003, 33, 33–41.

- Wu, W.-W.; Lee, Y.-T. Developing global managers’ competencies using the fuzzy DEMATEL method. Expert Syst. Appl. 2007, 32, 499–507.

- Yazdi, M.; Moradi, R.; Pirbalouti, R.G.; Zarei, E.; Li, H. Enabling Safe and Sustainable Hydrogen Mobility: Circular Economy-Driven Management of Hydrogen Vehicle Safety. Processes 2023, 11, 2730.

- Häder, M.; Häder, S. Delphi und Kognitionspsychologie: Ein Zugang zur theoretischen Fundierung der Delphi-Methode. ZUMA Nachrichten 1995, 19, 8–34.

- Skulmoski, G.J.; Hartman, F.T.; Krahn, J. The Delphi method for graduate research. J. Inf. Technol. Educ. Res. 2007, 6, 1–21.

- Boulkedid, R.; Abdoul, H.; Loustau, M.; Sibony, O.; Alberti, C. Using and reporting the Delphi method for selecting healthcare quality indicators: A systematic review. PLoS ONE 2011, 6, e20476.

- Alghawli, A.S.A.; Al-khulaidi, A.A.; Nasser, A.A.; AL-Khulaidi, N.A.; Abass, F.A. Application of the Fuzzy Delphi Method to Identify and Prioritize the Social-Health Family Disintegration Indicators in Yemen. Int. J. Adv. Comput. Sci. Appl. 2022, 13, 680–691.

- Roth, C.; Brewer, M.; Wieck, K.L. Using a Delphi method to identify human factors contributing to nursing errors. Nurs. Forum 2017, 52, 173–179.

- Rafieyan, A.; Sarvari, H.; Chan, D.W. Identifying and evaluating the essential factors affecting the incidence of site accidents caused by human errors in industrial parks construction projects. Int. J. Environ. Res. Public Health 2022, 19, 10209.

This entry is offline, you can click here to edit this entry!