Quick and effective point-of-care (POC) devices have the chance to revolutionize healthcare in developed and developing countries since they can operate anywhere the patient is, with the possibility of obtaining and sending the results to the doctor without delay. Significant efforts have focused on developing new POC systems that can screen for biomarkers continuously and non-invasively in body fluids to prevent, diagnose, and manage diseases. However, one of the critical challenges left to address is how to power them effectively and sufficiently. In developing countries and rural and remote areas, where there are usually no well-established electricity grids or nearby medical facilities, and using batteries is unreliable or not cost-effective, alternative power sources are the most challenging issue for stand-alone and self-sustained POC devices.

1. Introduction

Accurate and early stage disease diagnosis is critical for providing the most effective and life-saving treatments while decreasing the turnaround time (TAT). In developed countries, access to high-tech central laboratories with standard protocols and procedures improves the efficiency and accuracy of diagnostic tests due to sophisticated analyzers and imaging techniques.

However, the availability of these tests is limited, as they require complex and time-consuming processes and trained personnel. Moreover, long waiting times at hospitals and slow TATs for obtaining test results lead to higher anxiety and fear from the patient before a final diagnosis is made

[1], worsening the patient experience while slowing down the potential treatment.

Furthermore, these sophisticated diagnostic platforms are mostly not applicable in developing countries since they generally lack all the necessary requirements, such as laboratory infrastructure and equipment, expert personnel, and access to a reliable electrical supply and clean water. So, currently, many people in developing countries die from diseases that can be controlled or cured in developed countries

[1].

From that perspective, point-of-care (POC) testing is valuable for providing immediate healthcare information and in vitro diagnostics. Likewise, it applies in various settings, including accident sites, first-aid posts, doctors’ offices, and emergency vehicles such as ambulances. Additionally, patients can use POC testing to manage and test their health conditions at home, making healthcare more accessible and affordable in developed and developing countries. This technology is critical in less advanced regions, where accurate diagnosis is crucial but often difficult to obtain.

Optimal POC devices should be portable, as small as possible, able to be used by inexperienced patients or personnel, and able to give specific, sensitive, and accurate results, achieving reliable outcomes in a short time and with no sample pretreatment. However, POC tests now face one significant challenge: powering. Ideally, these devices should be self-powered: with the ability to generate their energy, a field of study into which much effort is being put, since, in many cases, access to a suitable traditional power source (electrical grid, batteries) is not straightforward, and the autonomy of these devices could sometimes be more optimal.

2. Key Enabling Technologies

It is crucial to identify the key enabling technologies that drive advancements in self-powered POC devices after describing the most outstanding advances.

A self-powering scenario refers to a process in which the sensing process powers the sensing device. Electrochemical energy conversion is the most common method of self-powered sensing, which involves using an analyte’s chemical source reaction to produce electrical energy. The amount of analyte determines the total energy produced in the response

[1]. Biofuel cells (BFCs) are one of the most prominent examples of this technology.

Conventional fuel cells convert chemical energy from fuel into electrical energy through electrochemical processes. They typically consist of fuel, oxidant, anodic and cathodic substrate materials, and a semipermeable membrane that separates the anode and cathode. However, BFCs differ from conventional fuel cells as they use natural proteins or microorganisms as biocatalysts for the anodic and cathodic substrate materials. These biocatalysts have high electrocatalytic activity at moderate pH and temperature levels, making them renewable and capable of oxidizing various fuels. In recent years, other types of biofuel cells have been developed and can be categorized as follows

[2]:

-

A primary fuel is used by a BFC, generating a material such as hydrogen, which, in turn, is a secondary fuel used by a conventional hydrogen/oxygen fuel cell.

-

An organic fuel, such as glucose, is used in a BFC and directly generates bioelectricity. This BFC can contain enzymes or microorganisms.

-

Photochemically active systems and biological moieties are used to harvest energy from sunlight and convert it to electrical power (energy).

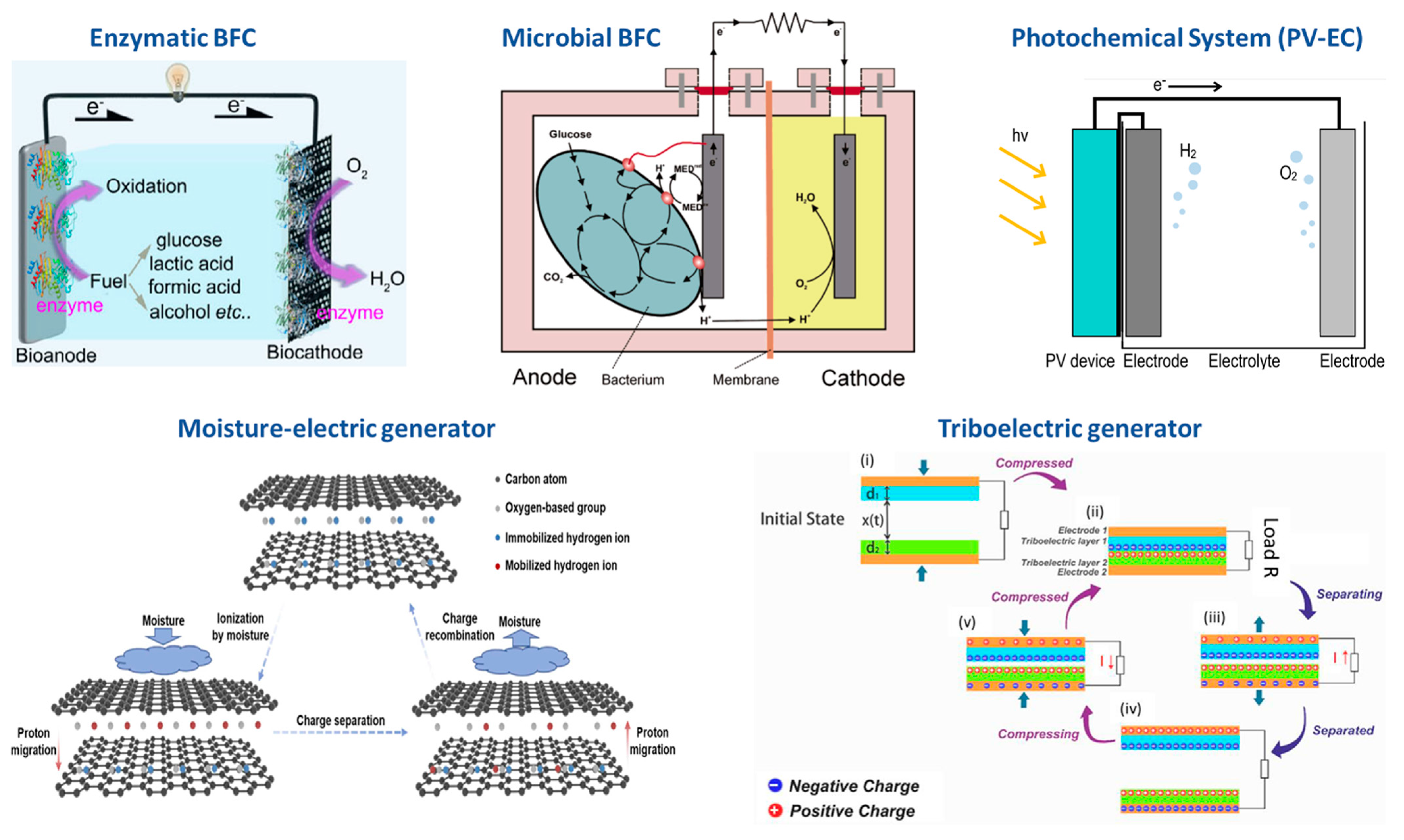

Enzymatic biofuel cells (EBFCs) are a specific type of BFC (

Figure 1) that use biological enzymes as electrode catalysts

[3]. These enzymes are exposed to the reaction system without cell membrane protection, which results in their degradation. Despite this, these biocatalysts are highly specific and can avoid cross-reactions. Additionally, they have high catalytic activity and pose no risks to biological bodies. Due to the advances in biocompatibility, high efficiency, and miniaturization, two cutting-edge applications have emerged: (1) implantable EBFCs, which obtain energy from the blood or similar body fluids to power implanted devices such as pacemakers, and (2) self-powered biosensors that can monitor and regulate health conditions depending only on changes in the EBFC’s power output

[3].

In the last decade or so, the scientific community has been intrigued by microbial fuel cell (MFC) technology (

Figure 1), which shows potential in converting organic waste into electricity through electrochemical reactions catalyzed by microorganisms at the anode and microorganisms, enzymes, or abiotic materials at the cathode

[4]. In MFCs, bacteria oxidize a substrate in the anode, releasing electrons that are transferred to the cathode via a conductive material. In the cathode, the electrons react with oxygen, while the protons diffuse through a proton exchange membrane. For MFCs to work, electrons must be continuously released in the anode and consumed in the cathode. The bacteria’s metabolic energy gain is directly proportional to the difference between the anode and the substrate’s redox potential. The optimal design for an MFC is still under investigation. Currently, researchers are developing different electron materials and more selective membranes for proton exchange to enhance performance

[5].

Alternatively, solar energy can be converted into chemical fuels through photochemical systems such as H

2 and carbon-based fuels. H

2 can be produced by splitting water, while carbon-based fuels can be synthesized by reducing CO

2. Research on solar-to-fuel (STF) production has rapidly developed over the past few decades, leading to the emergence of several techniques such as photocatalytic, photovoltaic-electrochemical (PV-EC) (

Figure 1), photo-electrochemical (PEC), and solar thermochemical systems. In these systems, solar energy is harnessed to directly drive chemical reactions or indirectly drive them after being converted into other forms of energy, such as electrical or thermal

[6].

These systems (and derivations of BFCs) generate bioelectricity through renewable energy sources, making them safer and more efficient than Li-ion batteries and direct methanol fuel cells and able to produce a higher energy density. These features enable various applications, making them the next generation of energy devices. In their recent study, Álvarez-Carulla et al. (2021)

[7] proposed a novel electronic architecture approach that utilizes a fuel cell to extract power and perform a sample concentration measurement simultaneously. The system employs a maximum power point tracking (MPPT) algorithm to extract power efficiently. The proposed approach addresses three critical issues related to self-powered POC devices that use a single fuel cell as both a sensor and a power source: (1) simultaneous power extraction and sample concentration measurement, (2) efficient power extraction, and (3) fuel cell biasing. Thus, the system solves three major issues in the current state-of-the-art. The entire architecture manages the powering, biasing, and measuring, and it also can control the processing and the output data interface for a POC. The device demonstrated its ability to prioritize energy extraction in terms of efficiency and extract concentration measurements for various scenarios. The efficiency, start-up time, transfer functions, and concentration detections of ethanol, lactate, and methanol-based fuel cells were thoroughly characterized. The minimum efficiency of ethanol-based fuel cells was 95%, while lactate-based fuel cells were 90% efficient, and methanol-based fuel cells were 80% efficient. The maximum start-up time was 10 s, 12 s, and 0.5 s, respectively. All fuel cells had a power consumption lower than 36 μW.

One step further, moisture-electric generators (MEGs) have recently gained attention as a viable source of clean energy due to their ability to harvest and convert moisture into electricity (

Figure 1). They have a simple device setup and are eco-friendly, making them an attractive option for energy conversion. It is estimated that 50% of the absorbed solar energy on Earth is used for water evaporation, making MEGs an excellent opportunity to capture this renewable energy and convert it into electricity

[8]. MEGs work by absorbing water molecules from moisture and releasing mobilized ions to generate separated charges for the generation of electricity. Currently, most MEGs use carbon-based materials such as carbon nanotubes, carbon nanoparticles, and graphene oxide (GO), which are abundant on Earth and good for the environment. GO shows the most promising potential of all the materials due to its high specific surface area, abundant oxygen-based groups, excellent moisture absorption, and good mechanical features. Although the MEG is still under research, an Australian company, Strategic Elements, has already developed a self-rechargeable battery, called Energy Ink

TM, that generates electricity from moisture, either from the air or the skin surface

[9].

Finally, in recent years, mechanical energy harvesters such as piezoelectric generators and triboelectric (TEGs) have become increasingly popular for high-efficiency energy harvesting. They are used to develop self-powered systems and as sensors

[10]. These systems charge a material surface when it comes into proximity or contact with another material. When two different materials meet, they develop equal and opposite charges based on their surface properties. The opposite charges are formed on the back electrodes via electrostatic induction, which redistributes electrical charges due to the influence of nearby charges, resulting in a potential difference. In turn, it helps to produce an AC output by allowing the flow of electrons between the electrodes. TEGs can be treated as devices whose capacitance varies, and they produce electricity through physical contact, which can be solid–solid or solid–liquid contact. To date, triboelectric generators (TEGs) have four operating modes: vertical contact separation (C-S), lateral sliding (LS), single electrode (SE), and freestanding layer triboelectric (FT) generators (

Figure 1). Although these modes work similarly, they differ in design, relative motion, applied force, and performance

[11].

Figure 1. Overview of technologies for self-powering POC scenarios: the enzymatic BFC

[3], microbial BFC

[12], photochemical converter

[13], moisture generator

[8], and triboelectric effect generator

[10].

This entry is adapted from the peer-reviewed paper 10.3390/s23239453