Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Given their exceptional performance, plastic packaging products are widely used in daily life, and the dramatic expansion in plastic packaging waste (PPW) has exacerbated environmental problems. Many countries have enacted laws and developed recycling technologies to manage plastic packaging waste in consideration of the nature of PPW as both garbage and a resource. As the world’s largest producer and consumer of plastics, China has also taken measures to address this issue.

- plastic packaging waste

- carbon reduction

- management suggestions

- China

1. Introduction

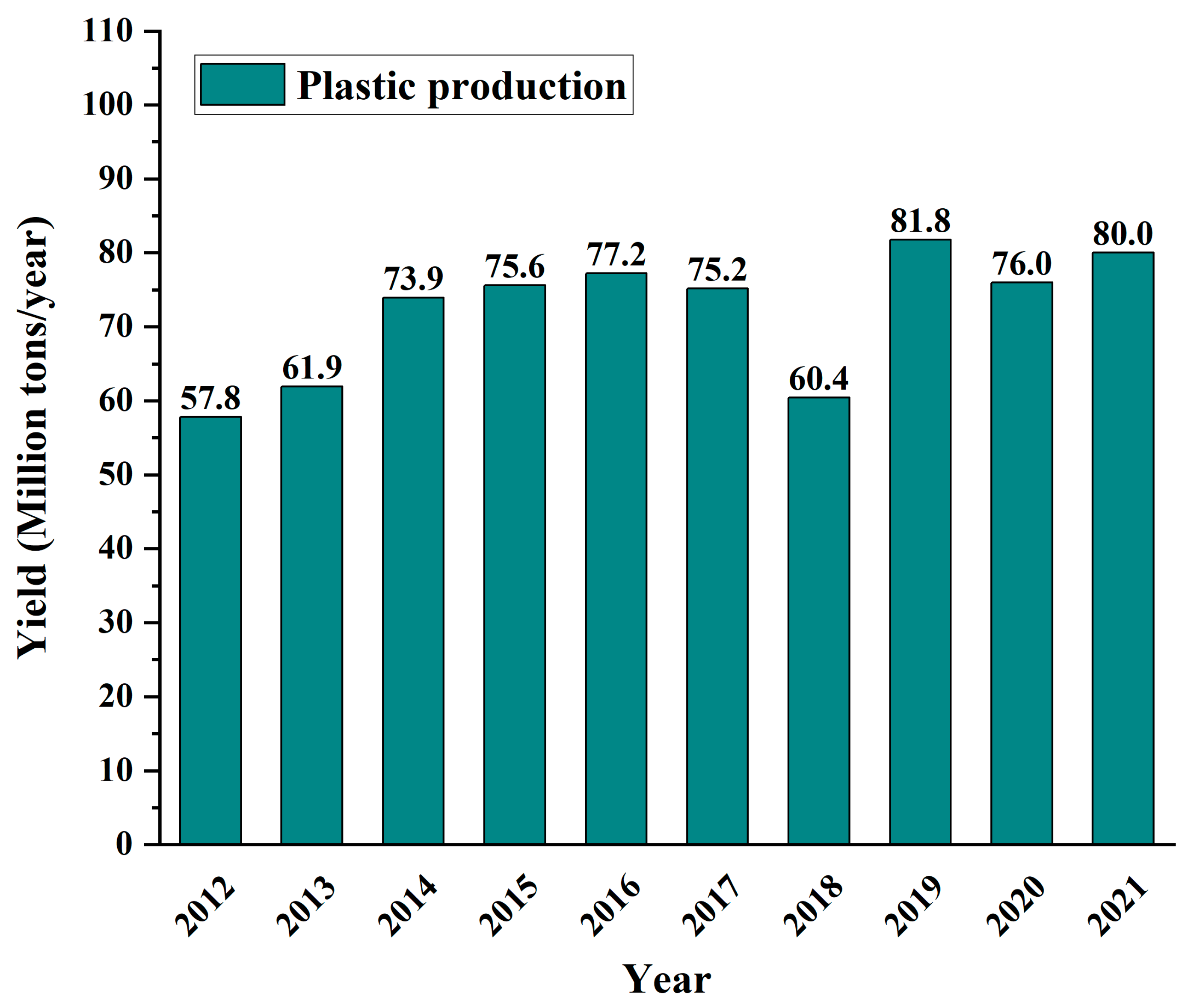

Plastic is an innovative material known for high ductility, durability, stability, lightweight, and portable features [1]. It finds extensive applications in packaging, automobiles, electrical appliances, furniture, and many other industries [2][3]. Since the 1950s, the commercial production of plastics has experienced extraordinary growth [4], reaching 367 million tons/year in 2020 [5]. After decades of development, China’s plastics industry has evolved into a comprehensive, independent manufacturing system that plays a significant role in the national economy. As shown in Figure 1, China’s plastics production has consistently remained high and experienced steady growth in recent years [6].

Figure 1. The yield of plastic products in China in the past decade.

As one of the most important application scenarios for plastics, the production and utilization of plastic packaging have significantly improved people’s living standards and promoted economic and social development. However, plastic packaging products have been developed within a “linear economy” approach in various aspects of human life, neglecting their secondary use or carbon emission impacts [7]. Consequently, escalating amounts of plastic packaging waste (PPW) and its additives are being discarded into the environment, causing increasingly severe damage to the ecosystem and living organisms [8][9]. Plastic products are made from non-renewable resources such as crude oil; recycling PPW can increase the total utilization rate of natural resources, raise the income level of inhabitants, and reduce waste plastic pollution in the ecological environment [10][11]. This also constitutes a crucial aspect of the sustainable growth of plastics-related enterprises. Furthermore, it is essential for the long-term development of plastics-related sectors. On the whole, recycling PPW can not only mitigate environmental pollution and achieve sustainable development but also yield substantial economic advantages.

2. Recycling Strategies of PPW in China

2.1. Green Design of Plastic Packaging

The design of many plastic packaging products is currently diverse and complex in terms of materials, colors, labels, and even shapes in order to meet consumer demand and ensure product novelty [12][13]. These factors significantly influence the efficiency and quality of post-waste recycling and the improvement of the waste plastic recycling rate. Likewise, PPW recycling typically requires de-mixing and sorting, and the use of materials and labels for plastic products significantly impacts this procedure [14][15][16]. For instance, the metal materials in plastic products should be sorted or separated, and the trademarks of different materials on the surface of plastic products should be peeled off; the binder used to affix the trademarks affects the ease of peeling, and the use of harmful substances affects the environmental friendliness of the product [17]. Hence, it is evident that the selection of plastic products and their other accompanying constituent materials impact their recycling.

China has long advocated for eco-friendly design principles, which have found applications in various industries. However, marketing plastic products has proven to be challenging given their intricate nature [18]. To address this issue effectively, a strategy that commences with a waste plastic recycling system and a regeneration phase, while also considering the ease of recycling and regeneration during the design of plastic products, holds the potential to significantly increase recycling rates and reduce the generation of PPW [19].

The Green Recycled Plastics Supply Chain Joint Working Group (GRPG) unveiled the “General guidelines for assessing the design of plastic products for enhanced recyclability and regeneration” in January 2021. This regulation was introduced to address the challenges associated with recycling PPW and to tackle the issue of plastic waste pollution more comprehensively. The primary objective of this standard is to optimize recycling rates and facilitate the high-value utilization of recycled plastics. It represents China’s fully autonomous design standard system for recyclable and regenerative plastic products. The forthcoming implementation of this standard will encompass certification, testing procedures, and the establishment of a safe product list and a green supply ecosystem.

2.2. The Full-Chain Recycling Process of Plastic Packaging Waste

The New Plastics Economy Global Commitment (NPEGC), the Clean Up Plastics Initiative (CUPI), and the European Union Global Commitment on Plastics (EUGCP) have been implemented since the launch of the EU Plastic Strategy. China and Southeast Asian countries have announced plastic bans in response to the EU Plastic Strategy’s launch in January 2018. Governments and businesses are implementing measures to reduce waste and achieve a circular economy and sustainable social development throughout the product life cycle. Discarded plastics can be recycled into recycled plastics, thereby increasing the utilization of recycled plastics. Other environmentally friendly materials have been incorporated into the environmental commitments of brand companies in the automotive, electronics, electrical appliance, and packaging industries.

Plastic life cycle management [20] is used to track the entire process from the initial raw material development, product design, manufacturing, and consumption application to the final recycling and to assess the potential carbon emission impacts of all its inputs and outputs throughout its life cycle [13][21]. In addition, based on application and disposal methods, the results of plastic life cycle management direct synthesis and processing, improve processes, and enhance management in order to recycle plastics and reduce plastic pollution. Employing efficient methods in plastic’s life cycle management and developing integrated technologies for the sustainable use of resources can enhance the effectiveness of plastics and mitigate their carbon emission impacts [22].

It is crucial to underscore that, within the comprehensive waste plastic recycling process, priority must be accorded to the front-end design of plastics, preceding all other stages encompassing the production, utilization, and recycling of plastic products. Beginning with the perspective of ease of recyclability and renewability in plastic products, the evaluation and guidance of plastic product design are centered on the interrelation between product design and recycling performance. Drawing on existing green packaging products in the market, one Chinese study explored the essence of green ecological design. It analyzed various methods of green design, focusing on the visual representation of product packaging, environmentally friendly materials, and structural design [23]. This strategic approach aims to surmount the obstacles hindering the enhancement of PPW recycling rates in China.

Considering the current development situation in China, the primary focus should be placed on advancing eco-friendly physical recycling technologies, enhancing chemical recycling and processing techniques for single-material waste plastics, and addressing the challenges associated with recycling and processing mixed PPW [24]. Additionally, measures should be taken to incinerate and manage hazardous PPW and plastic medical waste. [25].

In the context of China’s commitment to achieving its dual-carbon goals, it is crucial to emphasize that the prevention of plastic pollution must adhere to the fundamental principles of resource conservation and environmental protection. This involves evaluating and analyzing the entire life cycle of plastic products, including their design, processing, application, and waste recycling stages. Through the development of original designs for plastic packaging products, manufacturing technology substitution, high-value utilization, and end disposal, as well as other measures, the entire PPW recycling chain can be completed.

This entry is adapted from the peer-reviewed paper 10.3390/recycling8060090

References

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126.

- Alam, O.; Billah, M.; Ding, Y. Characteristics of plastic bags and their potential environmental hazards. Resour. Conserv. Recycl. 2018, 132, 121–129.

- Ragossnig, A.M.; Agamuthu, P. Plastic waste: Challenges and opportunities. Waste Manag. Res. 2021, 39, 629–630.

- Andrady, A.L.; Neal, M.A. Applications and societal benefits of plastics. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 1977–1984.

- Plastics Europe. Plastics—The Facts 2021. 2021. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2021/ (accessed on 10 July 2023).

- China National Bureau of Statistics. The Plastic Products Output in China from 2012 to 2021. Available online: https://data.stats.gov.cn/easyquery.htm?cn=A01&zb=A02090X&sj=201212 (accessed on 30 January 2023).

- Horodytska, O.; Valdes, F.J.; Fullana, A. Plastic flexible films waste management–a state of art review. Waste Manag. 2018, 77, 413–425.

- Dahlbo, H.; Poliakova, V.; Myllari, V.; Sahimaa, O.; Anderson, R. Recycling potential of post-consumer plastic packaging waste in Finland. Waste Manag. 2018, 71, 52–61.

- Groh, K.J.; Backhaus, T.; Carney-Almroth, B.; Geueke, B.; Inostroza, P.A.; Lennquist, A.; Leslie, H.A.; Maffini, M.; Slunge, D.; Trasande, L.; et al. Overview of known plastic packaging-associated chemicals and their hazards. Sci. Total Environ. 2019, 651, 3253–3268.

- Geueke, B.; Groh, K.; Muncke, J. Food packaging in the circular economy: Overview of chemical safety aspects for commonly used materials. J. Clean. Prod. 2018, 193, 491–505.

- Schyns, Z.O.G.; Shaver, M.P. Mechanical recycling of packaging plastics: A review. Macromol. Rapid Commun. 2021, 42, e2000415.

- Masanet, E.; Auer, R.; Tsuda, D.; Barillot, T.; Baynes, A. An assessment and prioritization of “design for recycling” guidelines for plastic components. In Proceedings of the 2002 IEEE International Symposium on Electronics & the Environment, Conference Record, San Francisco, CA, USA, 6–9 May 2002; pp. 5–10.

- Ding, Q.; Zhu, H.P. The key to solving plastic packaging wastes: Design for recycling and recycling technology. Polymers 2023, 15, 1485.

- Mayumi, K.; Kikuchi, Y.; Nakatani, J.; Hirao, M. Decision support for plastics recycling system design based on individual fossil resource consumption. Kagaku Kogaku Ronbunshu 2010, 36, 243–254.

- Keller, J.; Scagnetti, C.; Albrecht, S. The relevance of recyclability for the life cycle assessment of packaging based on design for life cycle. Sustainability 2022, 14, 4076.

- Tanksale, A.N.; Das, D.; Verma, P.; Tiwari, M.K. Unpacking the role of primary packaging material in designing green supply chains: An integrated approach. Int. J. Prod. Econ. 2021, 236, 108133.

- Dogu, O.; Pelucchi, M.; Van de Vijver, R.; Van Steenberge, P.H.M.; D’Hooge, D.R.; Cuoci, A.; Mehl, M.; Frassoldati, A.; Faravelli, T.; Van Geem, K.M. The chemistry of chemical recycling of solid plastic waste via pyrolysis and gasification: State-of-the-art, challenges, and future directions. Progr. Energy Combust. Sci. 2021, 84, 100901.

- Zhao, Q.; Chen, M. Automotive plastic parts design, recycling, research, and development in China. J. Thermoplast. Compos. Mater. 2015, 28, 142–157.

- Hatti-Kaul, R.; Nilsson, L.J.; Zhang, B.; Rehnberg, N.; Lundmark, S. Designing biobased recyclable polymers for plastics. Trends Biotechnol. 2020, 38, 50–67.

- Gandhi, N.; Farfaras, N.; Wang, N.-H.L.; Chen, W.-T. Life cycle assessment of recycling high-density polyethylene plastic waste. J. Renew. Mater. 2021, 9, 1463–1483.

- Hou, P.; Xu, Y.; Taiebat, M.; Lastoskie, C.; Miller, S.A.; Xu, M. Life cycle assessment of end-of-life treatments for plastic film waste. J. Clean. Prod. 2018, 201, 1052–1060.

- Shen, C.; Deng, Y.; Zhang, J.; Zhang, C. Improve life cycle management of plastic pollution in China. Res. Environ. Sci. 2021, 34, 2026–2034.

- Li, J.; Wang, Y. Application of the green ecological design in packaging design. Packag. Eng. 2014, 35, 5–8,16.

- Zheng, J.; Suh, S. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Chang. 2019, 9, 374.

- Matthews, C.; Moran, F.; Jaiswal, A.K. A review on european union’s strategy for plastics in a circular economy and its impact on food safety. J. Clean. Prod. 2021, 283, 125263.

This entry is offline, you can click here to edit this entry!