Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Traditional meat products are commonly produced in small family businesses. However, big industries are also involved in the production of this kind of product, especially since a growing number of consumers crave the traditional taste and aromas. The popularization of original and organic products has resulted in a return to traditional production methods. Traditional meat products are produced worldwide. However, in such (domesticated) conditions there is a potential danger for mycotoxin contamination.

- dry sausage

- cured meat products

- mycotoxins

- traditional production

- fungi

1. Introduction

Traditional meat products mostly refers to dry-cured meat products produced in a traditional manner. The majority of meat industries try to imitate the traditional production, but such products always show a certain discrepancy in aroma and texture when compared to traditionally produced cured meat products. However, the demand for high-quality and health-safe products enables many small producers to step in the market with traditional meat products. Different dry-cured meat products require high quality meat and production conditions that satisfy basic health and hygienic standards [1].

2. Traditional Dry-Cured Products—Common Fungi

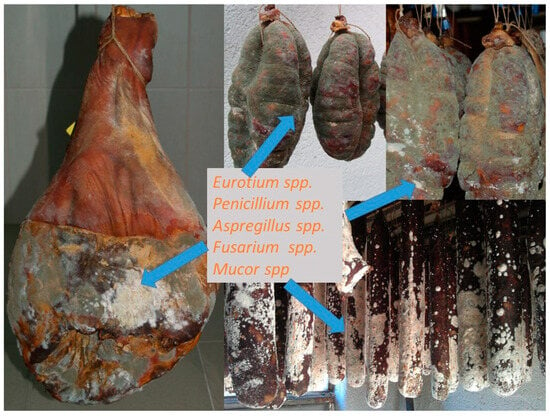

Traditional dry-cured meat products are indigenous to many countries, especially in Europe where molds play an important role in the ripening stage of production (Figure 1). Italy, Spain, France, Hungary, Croatia, and Southern Germany traditionally use white and occasionally green mold cover on the surface of dry-cured products. They are greatly appreciated due to the development of a characteristic taste, flavor, texture, and appearance of dry-cured meat products. The color of the mold cover depends on the species, but often it is influenced by the temperature during the ripening phase. For example, growth above 15 °C stimulated green conidia formation [14]. This is particular for traditional manufacture since they usually do not have controlled humidity and temperature conditions and depend on environmental conditions, thus the resulting molds can sometimes be white and sometimes greenish. Common molds used in some traditional dry-cured meat products are filamentous fungi such as Alternaria, Aspergillus, Cladosporium, Eurotium, Mucor, Penicillium, Rhizopus, and Scopulariopsis, as reported in the studies focused on fermented sausages and dry-cured hams [15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43], as shown in Figure 2. Penicillium was detected and identified in some samples of traditionally produced fermented sausages and only in several samples of dry-cured ham [4,15,17,24,27,31]. In some samples it was identified together with Scopulariopsis [21], Aspergillus [16,20], and Eurotium [6].

Figure 1. Molds on the traditional Croatian dry-cured sausage Slavonski Kulen.

Figure 2. Different molds on traditional dry sausages and dry-cured meat products.

According to several sources, Aspergillus and Eurotium have been shown to be the prevailing molds on dry-cured hams [4,24,26,28,41,42]. Molds belonging to genera Eurotium are xerophilic and prosper on substrates such as dry-cured hams, with surfaces with low water activity (<0.80) [32]. Fermented sausages were commonly contaminated with Penicillium spp. Similarly to Eurotium spp., Penicillium species tolerate low water activity (0.78–0.83) and protein-rich substrates. They proliferate in lower to mid temperatures [42,43,44]. Some species belonging to Penicillium genera, such as Penicillium nalgiovense have been used as mold starter cultures for the industrial production of mold-fermented sausage [14,43]. Penicillium nordicum, as an ochratoxin A producing species, was shown to have a significant share in the studies where it was reported [4,6].

The most common fungi and mycotoxins detected on different meat products are shown in Table 1. As can be seen, different fungal species can be found on meat products. Various mycotoxins can be produced by fungi, but some can be found in combination, which is called co-occurrence. This is an especially health-concerning topic for scholars since multiple toxins can be detrimental to human health with a combination of side-effects.

Table 1. Most common fungi and mycotoxins detected on different meat products (adopted from [45]).

| Fungi | Mycotoxin |

|---|---|

| Aspergillus spp. | |

| A. flavus | Aflatoxin B1, cyclopiazonic acid, 3-nitropropionic acid |

| A. niger | Ochratoxin A, fumonisin B2 |

| A. ochraceus | Ochratoxin A, penicillic acid, xanthomegnin, viomellein, vioxanthin |

| A. versicolor | Sterigmatocystin |

| Penicillium spp. | |

| P. aurantiogriseum | Penicillic acid, verrucosidin, terrestric acid, nephrotoxic glycopeptides |

| P. brevicompactum | Botryodiploidin |

| P. chrysogenum | Secalonic acid, PR toxin, roquefortine C |

| P. citrinum | Citrinin |

| P. commune | Cyclopiazonic acid |

| P. crustosum | Terrestric acid, penitrems, roquefortine C |

| P. expansum | Patulin, citrinin, chaetoglobosins, communesins, roquefortine C |

| P. glabrum | Citromycetin |

| P. griseofulvum | Patulin, griseofulvins, roquefortine C, cyclopiazonic acid |

| P. nordicum | Ochratoxin A, viridic acid |

| P. oxalicum | Secalonic acids, roquefortine C |

| P. palitans | Cyclopiazonic acid |

| P. roquefortii | PR toxin, roquefortine C |

| P. rugulosum | Rugulosin |

| P. variabile | Rugulosin |

| P. verrucosum | Ochratoxin A, citrinin |

| P. viridicatum | Penicillic acid, xanthoemegnins, viridic acid |

Environmental contamination of meat products can occur via conidia, ascospores, or mycelium fragments, but not many of them can grow on meat products, especially dry-cured ones [42]. According to [29] Cladosporium was found to be the dominating contaminant in the fermented sausages.

3. Mycotoxins in Dry Sausages and Dry-Cured Meat Products

Mycotoxins can end up in dry-cured products through different pathways. Most commonly they end up in animals via contaminated feed. The addition of spices in the meat and/or stuffing can also contribute to the contamination. However, many scientific investigations have aimed to clarify the origin of mycotoxins in dry-cured meat products and relied on the thesis that molds growing on the surface of the meat product can be the source of contamination. Even though EU legislation does not yet include mycotoxins in meat and meat products, OTA has currently been under consideration by the EFSA’s scientific opinions. More will be described in the following sections.

Mycotoxins enter the food supply chain and end up in markets which can be detrimental to human health. There are two ways for mycotoxins to enter the food and feed chain: direct and indirect [46,47]. Meat as a raw material can be contaminated via the feed used for animal feeding (carry-over effects), and consequently, can indirectly contribute to human exposure. In addition, spices used for meat products’ production are reportedly a potential direct source of mycotoxins [48,49]. Comi and Iacumin [50] reported OTA in hams, probably as a result of direct contamination with molds. This can also be explained by indirect contamination as described by several authors [51,52,53]. Similarly, OTA can be found in sausages. The pathway of contamination can be identified as indirect transmission via pigs’ feed and by direct contamination via molds which can grow on raw meat after slaughter [54,55]. The environment in which the production is carried out can also be a source of fungi that can proliferate in meat products during the ripening phase. This phase is particularly important since it involves high humidity and favorable temperatures for fungal growth.

The production of traditional meat products, especially dry sausages, relies on the addition of different spices to deliver the familiar aromas and taste. The most used spices are pepper (white, red, and black), sweet and spicy ground paprika, and garlic. Certain traditional products can be spiced with laurel and rosemary [56]. Despite the antifungal activity that many of these spices display, they can be contaminated with molds as well [57]. Common contaminants found in spices belong to Aspergillus and Penicillium genera [58,59,60,61,62]. Due to poor production conditions (drying spices on the ground) spices such as chili, nutmeg, and paprika powders can contain aflatoxins (AFs), OTA, and certain different mycotoxins. Some samples even exceed the maximum EU legislative limits. Spices sold at farmers markets can even have significantly higher mycotoxin concentrations than those bought at supermarkets [56,63,64]. Spices such as paprika and black pepper can contain significant amounts of AFs and OTA [65,66,67,68,69]. According to Gambacorta et al. [65], AFB1 concentrations in paprika can reach 155.7 µg/kg, and in black pepper it can be up to 75.8 µg/kg [66]. High values of OTA can also be found in paprika, amounting to 177.4 µg/kg [65] and 79.0 µg/kg in black pepper [67]. A higher prevalence of OTA in prosciutto samples was sometimes linked to pepper spiking; namely, pepper often becomes contaminated with Aspergillus molds, out of which A. niger produces OTA [20,60]. However, some studies have revealed that spices may also inhibit mold growth [61], resulting, for instance, in lower OTA contamination in some meat products [20].

OTA can also be found in certain prosciutto samples due to pepper used for coating, since molds such as Aspergillus spp. commonly contaminate pepper [70]. OTA can be found in dry-cured hams, as well. However, according to the literature, this contamination probably occurs during ripening, due to direct contamination with molds, presumably because of the inadequate environmental conditions, i.e., increased air humidity and higher temperatures [2,3,4,7].

Sometimes, damages to the outer casing can enable the entrance of molds and mycotoxins into sausages (stuffing) (Figure 3), and in significant amounts, according to [7,70,71].

Figure 3. Molds inside a dry sausage due to damaged casing.

However, Iacumin et al. [6] reported OTA contamination of the casings (outer layer) while the inner layer was not contaminated. According to [8] this can also present health hazard since casings are usually sliced together and consumed with the stuffing.

OTA is a natural contaminant in different foodstuff and is often detected in meat products. Aspergillus ochraceus and Penicillium verrucosum are the most common producers of OTA concerning the meat industry. Direct contamination usually occurs via animal feed [72,73,74]. OTA is fat-soluble and can mostly be found in the kidney, lung, liver, blood, spleen, heart, and adipose tissue of pigs [74,75]. A study conducted by Perši et al. [48] showed that pigs who were given 300 μg/kg/day of OTA for 30 days, accumulated it in the kidneys, lungs, and fat tissue. OTA was then detected in different meat products such as blood sausages, liver sausage, and pâté [76]. Even though OTA is not legally regulated in the EU, some countries have recognized the importance of strict limits for this mycotoxin and have set the limit to 5 μg/kg in pig liver, kidneys, and meat (Romania). In Italy the limit is much lower, set at 1 μg/kg in pig meat and meat products [76]. Suppression of OTA in meat products can be carried out by proper prevention via food safety management systems. In cases where prevention is not sufficient, then a set of diverse methods of physical and chemical treatments can be applied in order to reduce the contamination. However, chemicals used for decontamination can impair the sensory properties of dry-cured products which can drive the customers away. Much research has been devoted to finding a biological prevention method, and so far, essential oils have been meticulously investigated for this purpose. Even though essential oils can significantly affect the sensory properties of such products, the involvement of novel encapsulation technologies could help reduce such changes [77]. So far, oregano, garlic, sage, peppermint, rosemary, neem, and eucalyptus have been identified as being successful in suppressing mold growth and OTA production [78,79,80].

Aflatoxins are commonly produced by Aspergillus spp. (A. flavus and A. parasiticus). Aflatoxin B1 (AFB1) is known for its high potential for carcinogenic and genotoxic properties. Its metabolite is AFM1, an aflatoxin that can be found in milk, where it ends up through ingestion of contaminated feed. AFB1 is not often determined in meat foods, and when it is, its concentrations are much lower than OTA. It can also be found in different tissues such as liver, muscle, and fat tissue [81]. According to the IARC (International Agency for Research on Cancer) it belongs to Group 1 (human carcinogen) and is associated with the occurrence of liver cancer [82,83]. Even though AFB1 is not as common as OTA, it can still be found in different processed meat products [84]. Similarly, like OTA, AFs can be efficiently suppressed by using essential oils. As an effective agent, onion has been designated as an effective AF inhibitor in the meat industry [85]. Saffron, Shirazi thyme, estragon, basil, black cumin, coriander, dill seeds, and Arabian incense can suppress AF production [86,87,88,89,90,91,92,93,94].

Zearalenone (ZEA) is designated as the oestrogenic mycotoxin, according to the IARC it is described as a Group 3 carcinogen. ZEA causes hormonal disbalance related to cervical, ovarian, and prostate cancer [95,96]. Its derivate, α-zeranol, can be used as a cattle growth agent, but so far, the EU has not approved this [77]. ZEA is commonly found in chicken meat [97], sheep meat, and beef meat [98]. To reduce ZEA levels lemon, grapefruit, eucalyptus, and palmarosa essential oils were investigated, but the activity of these oils cannot be interpreted as being significantly effective [99].

According to some authors, citrinin (CIT) can be found in dry-cured traditional meat products as well [100]. Citrinin displays hepatic and nephrotoxic effects, and is generally produced by Penicillium spp., but specifically by Penicillium citrinum. Aspergillus, and Monascus genera can also synthesize this mycotoxin, originally named monascidin. CIT can be found in kidneys, causing renal degeneration associated with weight loss [101,102]. According to the IARC it belongs to Group 3 [103]. Even though it can be found in different meats and meat products including dry-cured meat products [100,104,105], there is a minimal contribution to increased CIT intake in humans, given the low rate of CIT transfer from feed to tissue for consumption [106,107].

Patulin (PAT) is mycotoxin synthesized by several species belonging to genera Penicillium, Aspergillus, and Byssochlamys. It displays toxigenic properties [108]. PAT has carcinogenic potential, being classified as being in Group 3 by the IARC as well [109]. In meat products PAT usually co-appears with other mycotoxins. PAT and OTA were detected in dry-cured hams [110]. Since PAT is not incidental, very few studies have been conducted regarding the usage of essential oils in patulin suppression in meat products [77].

Sterigmatocystin (STC) is in Group 2B, according to the IARC [111]. It can be found in pork muscle [112].

Fusarenon-X (FX) is designated as a trichothecene belonging to group B, and the IARC classified it as Group 3. It can often be found in food and feed. In livers and kidneys, it can be converted to nivalenol. The IARC has classified these toxins as belonging to Group 3 [113,114].

T-2 toxin is often found in cereals and cereal based products and is a metabolic product from Fusarium, Myrothecium, and Stachybotrys genera [115]. T-2 was detected in back muscle, pig back fat, and chicken muscle in concentrations less than 0.5 μg/kg [75].

Deoxynivalenol (DON) causes acute emesis, gastroenteritis, diarrhea, and reduced food consumption with chronic implications. It can be found in pig back fat, muscles, and liver [11,116].

Cyclopiazonic acid (CPA) is characterized as a dangerous mycotoxin that can cause damage to the digestive organs, the myocardium, and the skeletal muscles, and cause neurological disorders. Its producers belong to Penicillium and Aspergillus spp., specifically Penicillium commune [33,34,35] which was isolated from the surfaces of different meat products, including European dry-fermented sausages and prosciuttos [17,24,36,117,118,119].

This entry is adapted from the peer-reviewed paper 10.3390/life13112211

This entry is offline, you can click here to edit this entry!