In a broader context, sustainable materials refer to materials that are produced, used, and disposed of in a way that minimizes their impact on the environment, society, and economy. The concept of sustainability involves meeting present needs without compromising the ability of future generations to meet their own needs. Therefore, sustainable materials support ecological balance, conserve resources, and contribute to long-term societal well-being. They could be synthesized by microorganisms (or part of them) under different/ specific environmental conditions known as bio-sourced material or Geo-materials inspired by geological systems originating from the billion years long history of the earth (having geological origin) or even green materials that have a negligible load on the earth's environment and are harmless to human health in the process of raw material collection, product manufacturing, the application process, and after use. In the presence of these materials, conventional materials will be outdated. Their application in novel ways, especially in the building sector, is merely popping out, calling to be explored and applied in research. Using sustainable building materials is a promising alternative in building envelope applications to improve in-use energy efficiency. These materials, having a low environmental impact, the advantage of being renewable, and low embodied energy, contribute to global sustainability. During the last decades, waste management and green energy have gained massive popularity as they act on preserving the environment, reducing waste treatment and disposal costs, and generating alternative materials vulnerable to many industrial applications. These materials are sustainable and will positively affect social well-being as they will be replenished by photosynthesis daily. These pragmatic materials are the unsurpassed alternative as they not only target the reduction in daily carbon dioxide emissions but also offer thermal comfort with less energy consumption for the functioning of the buildings. With everything happening around us, it is vital to take serious measures when moderating and controlling energy consumption everywhere.

- sustainable materials

- energy efficiency

- thermal conductivity

- environmentally friendly

- carbon footprint

- thermal insulation

- Resource Conservation:

- Innovation and Technology

1. Mycelium

2. Coffee Grounds

3. Hemp

4. Straw

5. Flax

6. Reed and Grass

6.1. Reed Plant

6.2. Grass

| Bio-Source | Common Feedstock | Density (kg/m3) |

Thermal Conductivity Value (W·m−1·K−1) |

Specific Heat Capacity (J·kg−1·K−1) |

Porosity (%) | Moisture Buffer Value g/(m2 %RH)) |

Compressive Strength (Pa) |

References |

|---|---|---|---|---|---|---|---|---|

| Mycelium | Mycelia in Fungi Roots | 100–309 | 0.03–0.06 | 10,200 | NOT APPLICABLE | NOT APPLICABLE | P. ostreatus family of Fungii: 0.177 | [1][2][3][4][5][41] |

| Coffee | Coffee Grounds | 308–399 | 0.038–0.054 | 1400 | Green beans: 9.8 Roasted beans: 34.2 | NOT APPLICABLE | NOT APPLICABLE | [1][6] |

| Hemp | Hemp Core, or “Shiv” | 200–800 | 0.1007 | 872.34 | 71.51 | NOT APPLICABLE | 0.2 to 0.12 | [8][9][10][11][12][13][14][15][16][17][18][19][20][21] |

| Straw | Cereal Crop Containing Cellulose, Hemicellulose, Lignin, Ash, and Silica | 100 to 160 | 0.033 and 0.19 | 1338 and 2000 | 46.39–84.24 | 1.853 | NOT APPLICABLE | [1][20][21][22][24][25][26][27] |

| Flax | Flax Shives | 110 | 0.082–0.111 | 1500 to 2700 | 72–76 | ~2 | NOT APPLICABLE | [1][28][29][31][32][33][34][35][36][42] |

| Reed (reed mats) | Reed Plant | 137.6 | 0.056 | 508 | NOT APPLICABLE | NOT APPLICABLE | NOT APPLICABLE | [1][16][20][37][39] |

| Grass | Grass | NOT APPLICABLE | 1.10 | 2.8 × 106 | NOT APPLICABLE | NOT APPLICABLE | NOT APPLICABLE | [1][20][40] |

7. Bioplastics

8. Phase Change Materials (PCMs)

| PCM | Acronym | Formula | Melting/Solidification Temperatures (°C) |

Thermal Conductivity (W·m−1·K−1) |

|---|---|---|---|---|

| Capric Acid | CA | C10H20O2 | 29.6–33.2 | 0.21 |

| Lauric Acid | LA | C12H24O2 | 41–41.5 | 0.15–0.37 |

| Myristic Acid | MA | C14H28O2 | 49–56.1 | 0.17–0.39 |

| Palmitic Acid | PA | C16H32O2 | 58.9–64 | 0.3 |

| Stearic Acid | SA | C18H36O2 | 53.8–70.8 | 0.159–0.35 |

9. Geomaterials

9.1. Earth

The most impactful sectors on the environment are the architectural, engineering, and construction (AEC) sectors, contributing to more than 37% of energy-related CO2 emissions. The construction industry alone is responsible for a quarter of those emissions. Although many improvements and trials have been launched to reduce carbon dioxide emissions from buildings, it has been found that the fraction of stored carbon emissions is rising in the AEC sector, mainly due to the practices involving carbon-containing materials such as cement, steel, and others reducing or elevating the environmental impacts of these carbon-intensive materials is the way to go [82]. With these concerns comes the importance of the earth as a material. Earth is one of the oldest building materials used worldwide. In terms of geo-technique, earth possesses a mechanical behavior that combines cohesion and friction. Colloidal particles, mainly clay minerals, provide this cohesion, whereas friction is achieved by the contact between the particles of the earth, i.e., silts, sands, gravels, and stones. It is also characterized by its unsaturated porous medium that contains adsorbed water and capillary water, making it in equilibrium with the internal and external atmospheric relative humidity [83]. Earth materials have many benefits that encourage their use: they possess high hygrothermal properties, meaning they ensure high indoor air quality; have good environmental performances and hence decrease climate change impacts; and they are infinitely recyclable just by adding water, so the need for extraction and carbon-intensive materials is bypassed. Since soil highly varies between local cultures, various types of earth have been developed, such as cob, rammed earth (RE), compressed Earth Block (CEB), or adobe and wattle and daub [84]. They have been and still are being used due to their high availability, low cost, and environmental sustainability.

Rammed Earth (RE)

Rammed earth (RE) is a subset of earth construction that has long been integrated into traditional structures. Its applications are growing due to its sustainability, availability, and low carbon emission. It is fabricated by creating a mixture of soil, gravel, sand, cement, or lime stabilizers. Layer by layer, rammed earth compacts at the optimum water content in a rigid formwork with a rammer until it becomes 6–10 cm thick. It has high thermal conductivity (1.65 W/m K) and a specific heat capacity of 1218.66 J.kg−1.K−1; however, its thermal diffusivity of 7.42 × 10–7 m2/s suggests that it will delay heat flow even more than concrete [85]. Such engineered walls are implemented for both load-bearing and non-load-bearing structures, and two types of rammed-earth constructions are prominent: stabilized rammed earth (SRE) and unstabilized rammed earth (URE). The basic constituents for URE are soil, sand, and gravel. In addition to the main components, the SRE contains stabilizers like cement or lime, hence its name. The soil ingredient composition determines the compressive strength of URE, and clay plays the role of the binder. Its liability to loss of strength, also known as low compressive strength and erosion due to climactic changes, has limited its applications for structural purposes. Therefore, stabilizers like lime and cement are added to the soil to overcome the limitations. The chief advantages of constructions with rammed earth are (1) its environmentally friendly character, as they have a low energy intensity and carbon emissions; (2) its availability, since materials used are recyclable, and their bulk is available locally within a short distance from the construction area; (3) in the case of stabilized rammed earth walls, the wall thickness and its strength can be easily adjusted [86][87]. Finally, since energy-saving and insulation are the targets, these materials also have excellent thermal performance, contributing to building energy efficiency. As a result of its density (1540 kg/m3), thickness, and soil layers, it can exhibit insulation properties and provide resistance to heat transfer through the walls, thus reducing their thermal conductivity. Moreover, climatic considerations must be regarded, as rammed earth material’s efficiency depends on the local climate of their installed environment. In regions that experience extreme temperature variations, structures constructed with rammed earth can help buffer these temperature changes and their effect, providing a more comfortable interior environment. However, additional insulation measures are needed to attain optimal thermal performance in extremely cold or hot climates. Therefore, it is clear from the literature that the thickness, composition of the soil mix, and design considerations all impact the insulation performance of structures with rammed earth [84][86]. Additionally, RE structures exhibit hygrothermal [88] and acoustic insulation for residents.

Cob

The inclination towards cutting the building industry’s negative environmental and social impacts has renewed interest in earth construction. However, most literature and research papers presented rammed earth or adobe techniques and little tackled cob construction. Nonetheless, various vernacular earth construction processes depend on the cob comprising local materials, replacing rammed earth and adobe in specific geographical conditions [89]. Cob is one of the construction materials being used worldwide and is made up of clay-rich soil and natural fibers such as straw, sand, and water mixed in a plastic state [90]. It is considered a non-toxic and breathable natural material as it does not use chemical additives. It has good breathability, allowing moisture to flow in and out of the walls, preventing moisture buildup and mold issues. Given the reliance of this material in different construction modes, it possesses a wide range of applications. It can be found in numerous configurations, such as adobe bricks, circular, ovoid, and quenches, defined as a clay-based soil mix applied to a woven pattern of fibrous materials. Its malleability and ease of manipulation, low cost, and environmentally friendly building performance encourage further work on it to understand its opportunities [91]. Cob is an earth material subset offering structural stability and insulation properties. Many authors [92] have calculated and demonstrated that corresponding to the straw and water content and density, the thermal conductivity within earth buildings could vary from 0.47 to 1 W.m−1.K−1). In their article, Belarbi et al. [93] highlighted the properties of the cob building material in reference to other commonly used materials and upon the addition of straw (having a low thermal conductivity, between 0.06 and 0.08 W.m−1.K−1 [94]). According to the lambda meter device, cob has a thermal conductivity of 0.180 W.m−1.K−1, which is lower than conventional materials such as concrete; however, it could reach a value of 1.20 W.m−1.K−1. The specific heat capacity measured for cob was between 800 and 900 J/kgK in accordance with the ones found in the literature for raw earth materials (between 800 and 950 J.kg−1.K−1) [95]. At the end of the tests, the moisture buffer value (MBV) value for cob was 1.4 g/(m2·%RH) with an uncertainty of 0.1 [93] and a vapor permeability of 1.08 × 10−11 kg.s−1.m−1.Pa−1. These values are per the values referenced in the existing literature. In his article, Zeghari et al. raged the density of the cob based on its application. For structural walls, the density was from 1107 kg/m3 to 1583 kg/m3, and less than 700 kg/m3 for insulation. It was found that, for the mixes synthesized having a thermal conductivity higher than 0.4 W.m−1.K−1, the respective density and heat capacity was approximately constant; the average density was 1519 kg/m3, and the average heat capacity is 1205 J.kg−1.K−1. During their experiments, the cob integrated for insulation had a thermal conductivity of 0.14 W.m−1.K−1, and the one for construction was 0.74 W.m−1.K−1 [96]. Cob structures exhibit high thermal mass related to their capability to absorb and store heat energy from the surrounding environment. This being said, during sunlight, cob walls absorb heat from the sun’s rays, in contrast to nighttime, when they release the stored heat. This thermal inertia criterion induces a more stable and comfortable internal environment as it regulates the temperatures. Its composition provides natural insulation properties in which the straw particles act as a lightweight, low-conductivity material that reduces heat transfer in the wall. They also initiate air pockets within the cob, which boosts its thermal resistance properties and reduces heat flow [96]. Under the sustainability umbrella, cob is considered a sustainable building material since it embodies low energy levels. This embodied energy is defined as the total energy consumed during a material’s life cycle, including extraction, processing, transportation, and construction. Since cob consists of locally available materials, it needs minimal processing, thus reducing the energy consumption correlated to the manufacturing and transportation steps. Finally, its hygroscopic [88] nature calls for regulating internal humidity levels at around 50% RH. This minimizes the adverse effects on human health from mold spores, dust mites, etc. [97].

Adobe or Compressed Earth Blocks (CEBs)

Dating back to the old times, molded adobe production was developed in Mesopotamia 7000 years ago and is considered one of the most flexible ways of using earth constructions. These bricks have been employed for thousands of years and are undoubtedly one of the first man-made materials. The word “adobe” stems from a Spanish/Arabic origin [98] and describes construction materials, usually mud bricks or unburned bricks, assembled from moistened earth and sun-dried (ρa = 1300 kg/m3). The drying time depends on the climatic conditions; however, the adobe blocks require several weeks or months to achieve the desired strength and moisture content [98][99]. The adobe bricks could be manufactured from a great category of soils and could be either earth or adobe [100]. The main raw materials that constitute adobe are coarse sand, soil, fibers, straw or sisal, and clay, which, when mixed with water to achieve a plastic consistency, could be cast into the desired form. The different components serve various purposes [101]. Clay-rich soil is the major component, as the clay content grants cohesion and binding properties to the mixture. The clay can vary in type and nature; however, soils with a high clay content are favored since they improve the strength and workability of the adobe. The added clay influences the humidity intake properties of the block, which causes the presence of moisture in the walls and its associated swelling. In this regard, the clay content should be enough to influence the workability but should not exceed a specific limit that causes swelling and shrinking, thus damaging the walls [100]. Sand is added to reduce shrinkage and enhance its structural stability. The sand acts as a filler and boosts the resistance to the compression forces. Straw or other organic fibers are mixed into the adobe. They target its tensile strength and reduce the cracking tendency when left to dry in the sun. These fibers distribute stress within the material and increase its resistance to deformation. Water is added to the mixture to make it practical and induce soil, sand, and straw bonding. A correct moisture content is important to guarantee the proper compaction of the materials and the formation of stable blocks. Many factors influence the calculations of the ingredients’ proportions, which can vary depending on climate, soil composition, and construction techniques. In such instances, a stable adobe has a high sand-to-silt-clay ratio while containing a small quantity of gravel. Soils generally suitable for constructing rigid adobe structures include a percentage of 70 and 80% sand and between 10 and 15% silt and clay. Soil containing large amounts of the latter gets mixed with additional sand to produce a good adobe. Adobe presents many advantages with these materials by serving as a building material [102]. Their thermal properties have a low thermal resistance ranging between 0.42 and 0.71 (W.m−1.K−1), or R-value, meaning they cannot resist heat transfer through the bricks. They can easily store radiated heat and release it when needed, making them suitable for counteracting temperature variations. The well-designed use of insulation causes a drastic increase in the energy performances of these walls. Moreover, adobe walls regulate humidity by soaking the environmental air moisture and releasing it into the structure [98]. Its water vapor permeability ranges from 1.0 to 2.7 × 10−11 kg.s−1·m−1·Pa−1 [95]. In addition, adobe materials fulfill the sustainability requirements as they are environmentally friendly. It is composed of local soil that bypasses the need for transportation and reduces toxic carbon emissions. The waste generated from adobe construction can be left at the extraction site without environmental hazards. Adobe materials are also classified as biodegradable and recyclable [100][103]. The compressed earth blocks (CEBs) are very similar to adobe in composition, just that a hydraulic press is used to compress and mold the earth mixture into uniform blocks instead of sun-drying individual bricks. CEBs have advantages offered through adobe construction, but improved strength and consistency are added. They are flexible in molding and can be easily stacked and mortared to create walls [84].

9.2. Aggregates

In addition to other substances, natural aggregates are granular materials created from smaller particles such as crushed stone, gravel, recycled materials, and sand that can either be loose and naturally occurring or obtained by crushing a bedrock [104][105]. On the basis of their origin, aggregates could be derivatives of (1) primary, naturally occurring sources derived through the disintegration and weathering of rocks to generate sand and gravel or crushed stone resulting from blasted and crushed rock masses or (2) secondary, manufactured/synthetic raw materials. The secondary aggregates could be further broken down into three categories: lightweight from mineral raw materials, by-products, and wastes from diverse industrial processes, and finally, construction and demolition wastes, also known as recycled aggregates [106]. Lightweight mineral raw materials: clay or claystone, perlite, and vermiculite. By-products and wastes from industrial processes: coal combustion products such as bottom ash, fly ash, and boiler slag. Construction and demolition waste: concrete, crushed bricks, crushed construction rubbish. Aggregates are chief components of many applications, such as road bases, bridges, dams, power plants, concrete, and asphalt. Thus, it is present in almost every part of the environment. It is counted to be the number one nonfuel mineral product worldwide in terms of volume and value. Their mode of utilization could be either inbound or unbound and are grouped based on their particle sizes into three categories: coarse aggregates, fine aggregates, or a combination of both. Fine and coarse aggregates integrate into concrete, occupying 75–85% of its mass [104]. By acting as load-bearing components, aggregates provide construction materials with stability, strength, and durability and interfere with the compressive and flexural strengths and resistance to wear and deformation of concrete and asphaltic materials. Thus, they contribute to construction elements’ overall structural and mechanical properties and enhance their resistance to environmental factors. The key and principal parameters that describe the aggregates’ properties are particle size and shape, referred to as geometrical characteristics, soundness, physical properties, mechanical performance, durability, mineralogical composition, petrographic description, and lastly, their resistance to weathering, harmful chemical reactions, and decay. Soundness refers to the ability of the aggregate to tolerate destructive forces generated from severe environmental and climatic conditions like freezing, thawing, salt crystallization, and unwanted chemical reactions of the minerals in the rock [106][107]. The aggregates used in the construction sector must satisfy certain quality standards and specifications that guarantee consistency, performance, and safety. The American Society for Testing and Materials (ASTM) and European Standards (EN) target parameters such as particle size distribution, shape, strength, and durability of the aggregates.

9.3. Gypsum

Modern buildings are inclined to improve thermal efficiency by establishing thermal conditions, optimizing heat flows in and out of the premises, and enclosing structures. Energy-efficient construction and striving to find a suitable heat-insulating material that minimizes building heat loss are gaining attention daily. Therefore, using a suitable heat-insulating material reduces the thickness and the weight of walls as it lowers the percentage of conventional building materials like cement, metals, and bricks. By this, the energy efficiency of the building is enhanced [108]. Gypsum (CaSO4·2H2O) is one of the most common mineral binders and is considered a geomaterial. Its main component is calcium sulfate, which can either be present in a hydrous or non-hydrous compound, for instance, dihydrate (CaSO4·2H2O), hemihydrate (CaSO4·0.5H2O), and anhydrate (CaSO4). Unlike other lime and concrete binders, gypsum has a neutral pH [109][110]. It is a common mineral found in sedimentary rocks, usually in zones with a previous record of shallow seas or saltwater lakes. It can also be present in caves upon the evaporation of water.Binders from gypsum are energy-saving materials since their calcination usually occurs between 135 and 180 °C at lower temperatures than when combined with cement and lime. Therefore, the fuel required for its calcination is lower; hence, little or no emissions of CO2 in manufacturing are generated. Moreover, gypsum sets and hardens rapidly; hence, gypsum-derived products do not demand accelerated curing. Accordingly, gypsum-based products could be classified as environmentally friendly materials. Gypsum has many properties that make it suitable for sustainable construction and offers many advantages as a building material. It is non-toxic, lightweight, has a density of 998 kg/m3 [91], is highly soundproof, has excellent mouldability, and is fire-resistant. According to Espinoza-Herrera et al. [111], gypsum has a thermal conductivity ranging between 0.3004 and 0.353 W.m−1.K−1, a specific thermal conductivity of 5.75 × 10−2 W.m−2.kg−1.K−1, and a heat flux of 1164 W/m2, making them heat-insulating materials. In another study [112], based on Ciemnicka et al.’s experiments, the specific heat for gypsum was found to be 1520 J.kg−1.K−1, along with a thermal diffusivity of 0.1923 mm2/s. Adamopoulos et al. tackled the mechanical properties in addition to the thermal properties. The gypsum they manufactured had a density of 870 kg/m3 with a corresponding compressive strength of 2.51 MPa. As seen, the compressive strength is not as high as other building materials, which justifies why gypsum is usually coupled with other materials [113]. The water-gypsum ratio is one of the most important factors influencing the material’s properties. Due to the water evaporation, capillary pores are formed that cause the gypsum to have a high water absorption rate. To reduce this ratio, high-range water reducers are introduced. Gypsum products have a low water resistance, mainly due to the high solubility of gypsum dihydrate. Lime, or a mix of cement and pozzolanic admixtures such as fly ash and blast furnace slag, is added to enhance and stimulate water resistance. In addition to the ratio, the humidity of gypsum products impacts the properties because any increase in moisture content causes irreversible plastic deformations upon application of a load. Gypsum products are highly durable, but their strength gradually decreases during alternate wetting and drying. Gypsum could be molded into blocks and panels and integrated into partitions and internal walls to replace the traditional ceramic bricks and concrete blocks. In plasters, it could be a replacement for lime and cement [110].

9.4. Clay

One of the most valuable old dating industries worldwide is the construction industry, and it is one of the leading materials in all market economies. It is generally known that the construction industry is based on several essential materials such as concrete, aggregates, cement, clay, etc., and the choice of the raw material is highly dependent on the application, required properties, environment, and, most importantly, the cost [114]. Intending to promote sustainability in construction materials manufacturing and the increasing demand for such materials to be formed using environmentally friendly techniques, clay materials have been a subject of great interest in recent years due to their ability to fulfill the many requirements and properties in several industrial and environmental fields. Zooming in on those materials, clays are naturally occurring sedimentary materials primarily composed of fine-grained minerals called clay minerals. In a broader sense, they are defined as hydrated aluminosilicates belonging to the phyllo-silicates family comprising two-dimensional infinite sheets [115]. As a consequence of its water content, geometry, and particle size, clay can develop plasticity and be molded into any form when it retains water and turns into a coherent, stiff, hardened, and non-plastic material upon its firing [114]. The justification for this serious attention invested in this material is its recyclability, simple accessibility, easy transportation, abundance in nature, means, and colloidal, physicochemical, mineralogical, mechanical, rheological properties [115], thermal, and acoustic [116]. Clay formation is straightforward and can occur either from the simple decomposition under erosion’s effect or through the combination of substances transported by soil or water under the influence of degradation or aggradation. Many different types of clay exist, such as kaolinite, montmorillonite illite, bentonite, ball and fire clay, smectite, talc, chlorite, and vermiculite. Nevertheless, kaolinite, montmorillonite (MMT), and illite are the most frequently used [117]. Kaolinite is a material with the chemical composition Al2Si2O5(OH)4. It is usually white and has a soft, earthy feel. It is produced from the weathering of aluminum silicate minerals. Rocks with kaolinite in their composition are called kaolin. Kaolin is a widely used material in many applications such as the paper industry, cracking catalysts, rubber and plastic fillers, cosmetics, oil adsorbents, medicine, and ceramics, and it is a raw material in the production of Metakaolin (MK) needed for the synthesis of geopolymer materials [118][119]. Clay containing kaolinite is the best type in tropical and subtropical environments [117]. Another major clay is the lightweight expanded clay aggregate (LECA) since the raw material is clay, which is abundant worldwide. Expanded clay is generated as a product of firing natural clay, which expands at 1000–1200 °C due to the action of the gases created inside it [120]. It is well known for its thermal and acoustic insulation and moisture impermeability. It is uncompressible under permanent pressure and gravity loads, does not decompose in severe conditions, and is resistant to fire, freezing, and thawing [121]. The lightweight property is attributed to the relatively high proportion of pores. Due to the LECA’s easy accessibility, it could be integrated into a wide range of applications, such as construction to manufacture concrete blocks, slabs, lightweight concrete, water treatment facilities, and the agricultural sector. In many studies, for instance, Sousa et al. [122] showed that by coupling normal-weight sand with 0.14 m3 and 0.73 m3 LECA, the thermal conductivity reached 0.5 W.m−1.K−1. The masonry units had high sound and thermal insulation. A. Bastos et al. [123] mentioned that within the mixture that contains 214 kg/m3 of cement, the addition of 65%, 70%, and 80% LECA as coarse aggregates yielded thermal conductivities of 0.51, 0.44, and 0.33 W.m−1.K−1, respectively, in the concrete blocks. Zach et al. [124] demonstrated, with the hot-wire method, that the different types of LECA concrete showed thermal conductivities of 0.1376, 0.1521, and 0.1649 W.m−1.K−1. Grabois et al. [125] mentioned that the incorporation of LECA as coarse aggregates having sizes in the range of 0.4–20 mm and 0.06–10 mm, instead of normal weight sand, can lower the thermal conductivity by 60% while increasing the specific heat by 3.62%. A high percentage of residential buildings are constructed using clay brick materials. In his article, Alam et al. [126] performed hygrothermal transfer studies on a constructed clay brick wall in Egypt by measuring the hygrothermal properties and performing experimental tests. It has a low thermal conductivity of 0.41 W.m−1.K−1 and high specific heat of capacity Cp = 780 J.kg−1.K−1. That means clay can be considered a good insulator since it takes time to absorb more heat before it actually heats up. The moisture diffusivity is Dw = 6 × 10−10 m2/s, and the water vapor permeability is = 1.62 × 10−11 kg.s−1.m−1.Pa−1, which indicates its ability to transfer moisture under a certain vapor pressure gradient. This means that the permeability levels for the clay are not as high; however, it possesses a porous structure. The manufactured and tested clay brick wall, on the other hand, has a dry density of 1980 kg/m3 [93]. In conclusion, it is safe to say that the quantity of LECA and the thermal properties are proportional. As LECA’s content in a mixture increases, the thermal insulation increases. Also, its thermal conductivity is lower than that of normal-weight aggregate. This is presumed because LECA has a lower density and a higher porosity than the normal weight aggregate, leading to a minor thermal conductivity or higher thermal isolation. The formed interconnected pores in the LECA pellets reduce the material’s thermal conductivity since the air in pores is a good insulation material. The attractive thermal insulation properties of LECA in construction improve buildings’ energy performance and influence energy reduction [127].

10. Emerging Green Materials

10.1. Bamboo

Bamboo plants are being deeply studied as a green material due to their many benefits and fast regeneration. It is a resourceful and adaptable natural material used in construction for centuries. Bamboo is gaining interest as it is a fast-growing, sustainable, renewable, recyclable, and biodegradable plant. It is capable of shooting up to 91 centimeters in just 24 hours. This rapid growth allows its sustainable and abundant supply without exerting unnecessary strain on natural resources. Moreover, bamboo cultivation needs less water, insecticides, and fertilizers than other plants. Also, no harmful chemicals are required for its processing, like in other building materials, causing bamboo to have a significantly lower environmental impact than many traditional construction and manufacturing materials. It is characterized by low density, falling between 200 and 850 kg/m3 [134][181], and high mechanical strength, having compressive, tensile, and flexural strengths between 51–56 MPa and 150–263 MPa, and 210.3 MPa, respectively . Noting that the durability of bamboo is relatively low, it can be commonly used in manufacturing composites. It made its way through construction due to its multiple uses, such as structural support: being strong enough to support heavy loads, and it can be used to build entire structures, flooring and decking, wall and ceiling coverings, roofing, fencing, screening, and furniture.

On the other hand, bamboo has a low thermal conductivity (0.55–0.59 W.m−1.K−1), meaning it is an excellent heat insulator [135]. It maintains warm buildings in the winter and cool in the summer, thus decreasing energy consumption and costs and improving comfort levels. It is also a good sound insulation material that reduces noise pollution from outside buildings and between rooms. This is very useful in commercial buildings, where noise reduction is essential for the comfort and productivity of the residentials. From a sustainability point of view, bamboo is a renewable resource that multiplies without demanding a high input of water or fertilizer. It is also biodegradable and can be composted at the end of its useful life. Integrating bamboo for insulation can help reduce the environmental impact of construction projects. Finally, it is distinguished by its fire resistance properties. It has natural fire-resistant assets, which causes it to prevent the spread of flames in case of a fire. This makes it a safe choice for insulation in buildings [136][137][138].

10.2. Geopolymers

Geopolymers are inorganic polymeric materials generated from mixing a dry solid with an alkaline solution and sometimes, if needed, other materials. The solution is usually sodium or potassium hydroxide or silicate, which are soluble alkali metals. The major component is the source material, which must be rich in Silicone (Si) and Aluminium (Al) [139]. Since aluminum is an abundant substance, there exist many raw materials to create geopolymers, such as calcinated clays, specifically kaolinite, which was the first widely used material in geopolymer synthesis, industrial waste (such as slag and fly ash) [140], waste glass [141], aluminum mine tailings, natural silicoaluminates, red mud, and zeolites. They harden quickly, achieving 70% of the final compressive strength in the first 4 hours. Geopolymers possess volume stability, a lower shrinkage ratio than Portland cement, high strength, excellent durability and attainment of their properties almost after decades, low thermal conductivity, and high fire resistance. These properties make them suitable for many applications, such as thermal insulation [142], fire-resistant materials, low-tech building materials, cement and concrete [143], low-energy ceramic tiles, repair infrastructures, strengthening composites, etc. [144]. Geopolymer foams are porous materials introduced in buildings to achieve thermal insulation [145]. They are formed by adding a foaming agent such as hydrogen peroxide, NaOCl, silica fumes, or metal powders (aluminum) to our paste. These agents increase mortars’ porosity by releasing gases [146]. The heat conductivity of a geopolymer is usually in the range of 0.24 W.m−1.K−1 to 0.3 W.m−1.K−1, compared to the lightweight refractory bricks with a conductivity of 0.3 W.m−1.K−1 to 0.438 W.m−1.K−1 [144]. In their article, Vaou and Panias [147] showed that the thermal conductivity of foamy geopolymeric materials as a paste is indirectly proportional to the quantity of the foaming agent. It was lowered substantially from 0.053 W.m−1.K−1 to 0.03 W.m−1.K−1 when hydrogen peroxide (H2O2) content increased from 0.7% to 2.02% [142]. In order to improve their insulation properties even more, additives to the geopolymers were introduced, and positive results were obtained. For instance, upon coupling it with a potassium titanate whisker (PTW), improvements in the thermal insulation of the metakaolin-based geopolymer were observed. The results indicated that adding PTW could significantly enhance the porous geopolymer’s thermal insulation and compressive strength properties [146]. Also, Huang [148], in his article, prepared an aerogel and geopolymer composite that turned out to be a hydrophobic, lightweight, and superb thermal insulating matrix. He achieved a thermal insulation value of 0.0480 W.m−1.K−1, and the composite materials exhibited great potential in the field of thermal insulation. Based on research, due to their low thermal conductivity and improved mechanical properties, geopolymers have a great application when fireproof or adiabatic insulation is required. In addition, they are molded into foamed plates and integrated as thermal insulation in the construction field [149].

10.3. Recycled Glass

By definition, glass is a solid material formed by exposing a mixture of normal sand (silicon dioxide), soda (sodium carbonate), and limestone (calcium carbonate) to a high temperature until a liquid is formed and left to cool to ensure that solidification occurs without crystallization. Glass could be transparent, translucent or brittle, with the simplest being composed of only soda, sand, and lime. It is one of the materials that individuals depend on as it exists through various manufactured products like sheet and float glass, bottles, glassware, laminated and toughened glass, heat-resistant glass, and many more [150]. Glass has many applications, such as energy saving and insulation, construction, containers and vessels, nanotechnology, etc. [151][152]. However, in its present form, glass is not a green material as tremendous amounts of CO2 get released during manufacturing. Moreover, due to glass’s excessive dissolving temperatures and the decay of nitrogen compounds in the batch substances, nitrogen oxides (NOx) influence the acidification and development of serious air pollution, also known as SMOG. Numerous problems arise due to its contamination of the water bodies, its basis on un-replenishable raw materials, and its generation of solid wastes and volatile organic compounds [153]. In order to satisfy the ‘Green’ conditions, glass has to be recycled. Therefore, the most interesting type is recycled glass, which possesses different forms obtained from various sectors [150]. Glass is an infinitely recyclable material that does not lose its quality and value along the processes. Its remanufacturing is environmentally friendly since it lowers the quantity of needed raw materials and cuts the total energy consumed during the manufacturing process, as the recycled glass’s melting point is way beneath the original raw materials that make up the glass [154]. Accordingly, many applications have arisen to integrate this recycled glass, such as green polymer and translucent concrete, as a raw material for geopolymers, foamed waste glass, ultra-lightweight fiber-enforced concrete, production of hot mix asphalt, and geopolymeric tiles [153]. Suitable and proper insulation is a critical issue that helps minimize the transmitted heat flow, saving heating/cooling energies and lowering the associated emissions from fossil fuel combustion. The traditional insulators in the market are usually from primary raw materials, such as minerals, rocks, and fossil fuels (organic foams). The emergence of secondary or renewable raw materials is paramount to fulfilling ecological and sustainability requirements, and insulating materials from natural sources or recycled materials are being increasingly evaluated [155]. The literature showed that glass could be altered to form foams. Glass foams [156][157] are reported to be thermally insulating, lightweight, compression-resistant, sound insulation, non-flammable, and water and steam-resistant. They are appealing for their chemical and thermal stability, low density, high surface area, and permeability due to their high porosity, freeze-thaw tolerance, and longer lifespan compared to conventional thermal insulating materials [158]. In their article, Yu et al. [159] investigated the engineering properties of ultra-lightweight fiber-reinforced concrete (ULFRC) in which they replaced the natural aggregates with expanded waste glass to manufacture a material with low thermal conductivity (around 0.165 W.m−1.K−1) and insulating properties and a low density to be integrated into buildings that involve load-bearing devices, floating structures, or insulating materials [153][154]. In addition to the above, glass powder was also integrated into the concrete as per the article of Boukhelf et al. [160], in which the effect of the semi-replacement of cement by materials derived from the waste glass on the concrete’s hygrothermal behavior was investigated. Glass powder has a density of 2710 kg/m3. According to the SEM tests, the glass powder (GP) has multi-sized and irregularly shaped particles, varying from 8 μm to 50 μm. Upon substituting 20% and 30% of cement with glass powder, the porosity of the concrete increased by 7.9 and 16.7%, respectively. This is mainly because the fineness of the GP is lower than that of cement substituted and due to the formation of new ranges of micro and macro pores. Regarding the compressive strength of the synthesized material, it was lower than that of concrete alone (36–41 Mpa); however, it remains sufficient for structural application as a consequence of the dilution resulting from the substitution of cement—a more reactive powder with GP—a less reactive powder. Concerning the hygrothermal properties, the porosity increase for concretes with GP led to a decrease in the thermal conductivity by 3.7% and 8.9%, for the addition of 20% and 30% GP. The incorporation of glass powder increased the concrete moisture storage capacity (Cm), which is attributed to the effect of porosity on this intrinsic mass transfer parameter; however, its lower permeability slows down the diffusivity and storage of moisture. Finally, the results feature a significant upward shift in water vapor permeability with the replacement of cement by 30% GP from 9.51 × 10−13 kg.s−1.m−1.Pa−1 to 2.87 × 10−12 kg.s−1.m−1.Pa−1. This is justified by the changes in the microstructure of concrete.10.4. Lime

Dating back, lime is a binding material used for building infrastructure; however, cement binder has replaced it to meet the needs of speedy construction. The lime mortar hardens through a carbonation reaction that calls for atmospheric CO2 to enter the lime’s porous medium and connect with the moisture present inside it, thus converting calcium hydroxide (Ca(OH)2) to calcium carbonate (CaCO3). Many factors affect the carbonation process: the ambient temperature, relative humidity, nature of used raw material, aggregate-to-water ratio, and CO2 concentration. Of the many materials that emerged nowadays, lime is considered green since its sustainability and eco-friendly properties characterize it. It is renewable, abundant, and recyclable since it is made of limestone, a naturally occurring mineral in the earth’s crust that does not affect the natural reserves with a 3340 kg/m3 density. It possesses low embodied energy, as its production needs significantly less than other building materials, such as cement. Even though the calcination process needs elevated temperatures, it is still lower than the energy production of cement. Lime can absorb carbon dioxide, leading to a reduced carbon footprint since it re-absorbs the CO2 it generates during its formation in the kiln during the carbonation process. For this reason, lime building materials are counted as carbon neutral [161]. In a mixture, lime is added due to its plasticity and workability. The major drawback of lime is that in pure lime mortar, its setting and hardening processes are slow because they depend on the reaction of calcium hydroxide with atmospheric carbon dioxide. Many additives have been added to the lime matrix to improve this feature and its durability, workability, and thermal properties [162]. Sandaka et al. [163] found that the thermal conductivity at the decomposition temperature range 900–1200 °C varies between 0.4 and 0.9 W.m−1.K−1. One of the added materials is the hemp shives, the inner part of the hemp stalk, which are chemically similar to the wood pulp due to their lignin content. Hemp shives are a byproduct of hemp cultivation, as their primary purpose is to obtain fiber and seeds. They are characterized by their superior moisture and smell absorption capabilities. Because of their porous nature, they could be employed as fillers in thermal insulating biocomposites, thus contributing to the material’s moisture-regulating capabilities and low thermal conductivity [164]. Many studies showed that the formed hempcrete’s hygrothermal and mechanical properties depend on many factors. The essential elements are the compaction level, binder-to-hemp ratio, water content, and binder mix design [165][166]. In their article, Lawrence et al. [167] found the thermal conductivity of hemp and lime mixtures to be in the range of 0.06−0.11 W.m−1.K−1 when the dry densities ranged from 200 to 400 kg/m3 and hemp/binder ratios varied between 1:1, 1:1.5, and 1:2. When the values for the hemp/binder ratio and densities were increased, higher thermal conductivity was measured. The mixture’s water content and thermal conductivity are directly proportional, so any increase in water content tends to increase the thermal conductivity of the hempcrete mixes. In order to further improve the properties of the hemp-lime, recycled crushed brick as a pozzolan is being added to the mix to increase composites’ availability, performance, and thermal and moisture properties while reducing their environmental impact [168]. Another additive to the lime is waste paper (AWP) aggregates. After processing the waste paper into aggregates, it was mixed with lime and water to design lightweight bricks (AWPL) for building insulation. The mix’s mechanical and insulating properties were tested to check their suitability. The AWPL materials exhibited a noticeable deformation without breaking under a compressive load. Good adhesion between the fiber and the matrix is due to the cellulosic fibers responsible for its fibrous structure and high porosity. It is also recorded that the lime content increases this adhesion. Moving on to its thermal properties, the thermal conductivity of the different types of AWPL increased from 0.097 W.m−1.K−1 to 0.12 W.m−1.K−1 with the increase in porosity. The experiments showed that all samples have low thermal conductivity and that the AWPL materials could be insulating materials [169]. A detailed listing of the exploited values from the existing research for green and geomaterials is tabulated.

10.5. Cork

One of the naturally occurring emerging vegetable resources that are sustainable and renewable is harvested periodically every 9–12 years and can be used to improve energy efficiency and thermal insulation in buildings. Cork is the cork oak tree’s outer layer in Southern Europe and Northern Africa [170][. Three types of cork are generated during its life cycle, mainly virgin cork ( 160–240 kg/m3) from the first stripping, reproduction cork ( 120–180 kg/m3) from the second stripping, and reproduction cork from later strips [172]. This material has various characteristics that make it popular in the industrial sector. Its lightness, elasticity, impermeability to gases and liquids, excellent thermal insulation, and acoustic properties are all due to its cellular structure. It has a macro-porous structure, attributed to its good insulation capacity [170][171][173]. Algeria is one of the major cork producers, reaching 1900 tons/year of granular material and 5600 tons/year of powder cork. The corresponding waste is either dumped in disposal landfills or incinerated, encouraging new applications, such as incorporating natural and expanded cork granules in cementitious composites. Recently, virgin cork has been used as aggregates in concrete at different volumes, remarkably improving cement’s porosity, capillary absorption, and thermal conductivity while decreasing its workability and plastic viscosity. Having said this, cork concretes may be utilized in nonstructural applications such as filling blocks and insulation screeds [172][174]. Authors discussed that the compressive strength of these lightweight screeds fell between 0.12 and 1.98 MPa at 28 days, while their thermal conductivity oscillated between 0.195 W.m−1.K−1 and 0.318 W.m−1.K−1 depending on cement amount. In their study, Borges et al. [175] formulated cement mixtures with fly ash and expanded cork and/or clay. It was shown that the quantity of cork was inversely proportional to the mortars’ thermal conductivity and mechanical properties, passing them as thermal mortars. Also using expanded cork, Novais et al. [176] also incorporated them as lightweight aggregates yielding products having a density of 260 kg/m3 and thermal conductivity of 0.072 W.m−1.K−1. In their recent article, Tedjditi et al. [172] used virgin cork to fabricate and develop a novel lightweight concrete. The materials, in accordance with the other articles, showed good thermal properties, low density, and weak mechanical properties. Depending on the aggregate cork size that could be within any range, 0–4 mm, 4–8 mm, and 8–16 mm, the apparent density of the cork was between 83.8 and 88.9 kg/m3, the particle density 184–223 kg/m3, the range for the water absorption was 68.89–168.67%, and finally, the inter-particle porosity was varying between 54.5 and 61.4, respectively. The cork has a low thermal conductivity of 0.045 W.m−1.K−1, a thermal diffusivity of 1 × 10–6 m2/s, and a specific heat of 350 J.kg−1.K−1, so it could be a good candidate for thermal insulation. Its water diffusion coefficient ranges between 1 × 10–11 and 4 × 10–10 m2/s [171]. Upon its addition to the cement, the compressive strength went between 0.48 and 8.35 MPa; therefore, the virgin cork composites show good mechanical properties as non-structural materials. Also, for high amounts of virgin cork (50, 75, and 100%), the produced concrete had a thermal conductivity ranging the produced concrete had a thermal conductivity ranging between 0.041 and 0.56 W.m1.K-1 [172][173][174][175][176].

This entry is adapted from the peer-reviewed paper 10.3390/en16217440

References

- Yadav, M.; Agarwal, M. Biobased building materials for sustainable future: An overview. Mater. Today Proc. 2021, 43, 2895–2902.

- Jones, M.; Mautner, A.; Luenco, S.; Bismarck, A.; John, S. Engineered mycelium composite construction materials from fungal biorefineries: A critical review. Mater. Des. 2020, 187, 108397.

- Appels, F.V.; Camere, S.; Montalti, M.; Karana, E.; Jansen, K.M.; Dijksterhuis, J.; Krijgsheld, P.; Wösten, H.A. Fabrication factors influencing mechanical, moisture- and water-related properties of mycelium-based composites. Mater. Des. 2019, 161, 64–71.

- Ashby, M.F.; Johnson, K. Materials and Design: The Art and Science of Material Selection in Product Design; Butterworth-Heinemann: Oxford, UK, 2013.

- He, J.; Cheng, C.M.; Su, D.G.; Zhong, M.F. Study on the Mechanical Properties of the Latex-Mycelium Composite. Appl. Mech. Mater. 2014, 507, 415–420.

- Lachheb, A.; Allouhi, A.; El Marhoune, M.; Saadani, R.; Kousksou, T.; Jamil, A.; Rahmoune, M.; Oussouaddi, O. Thermal insulation improvement in construction materials by adding spent coffee grounds: An experimental and simulation study. J. Clean. Prod. 2019, 209, 1411–1419.

- Oliveros, N.O.; Hernández, J.; Sierra-Espinosa, F.; Guardián-Tapia, R.; Pliego-Solórzano, R. Experimental study of dynamic porosity and its effects on simulation of the coffee beans roasting. J. Food Eng. 2017, 199, 100–112.

- Zouaoui, Y.; Benmahiddine, F.; Yahia, A.; Belarbi, R. Hygrothermal and Mechanical Behaviors of Fiber Mortar: Comparative Study between Palm and Hemp Fibers. Energies 2021, 14, 7110.

- Bennai, F.; Ferroukhi, M.Y.; Benmahiddine, F.; Belarbi, R.; Nouviaire, A. Assessment of hygrothermal performance of hemp concrete compared to conventional building materials at overall building scale. Constr. Build. Mater. 2022, 316, 126007.

- Sawadogo, M.; Benmahiddine, F.; Hamami, A.E.A.; Belarbi, R.; Godin, A.; Duquesne, M. Investigation of a novel bio-based phase change material hemp concrete for passive energy storage in buildings. Appl. Therm. Eng. 2022, 212, 118620.

- Collet, F.; Pretot, S. Thermal conductivity of hemp concretes: Variation with formulation, density and water content. Constr. Build. Mater. 2014, 65, 612–619.

- Rode, C.; Peuhkuri, R.H.; Mortensen, L.H.; Hansen, K.K.; Time, B.; Gustavsen, A.; Ojanen, T.; Ahonen, J.; Svennberg, K.; Arfvidsson, J.; et al. Moisture Buffering of Building Materials; Technical University of Denmark, Department of Civil Engineering: Lyngby, Denmark, 2005.

- Bennai, F.; El Hachem, C.; Abahri, K.; Belarbi, R. Microscopic hydric characterization of hemp concrete by X-ray microtomography and digital volume correlation. Constr. Build. Mater. 2018, 188, 983–994.

- Benmahiddine, F.; Belarbi, R.; Berger, J.; Bennai, F.; Tahakourt, A. Accelerated Aging Effects on the Hygrothermal Behaviour of Hemp Concrete: Experimental and Numerical Investigations. Energies 2021, 14, 7005.

- Benmahiddine, F.; Belarbi, R. Effect of Immersion/Freezing/Drying Cycles on the Hygrothermal and Mechanical Behaviour of Hemp Concrete. Constr. Technol. Archit. 2022, 1, 555–562.

- Benmahiddine, F.; Bennai, F.; Cherif, R.; Belarbi, R.; Tahakourt, A.; Abahri, K. Experimental investigation on the influence of immersion/drying cycles on the hygrothermal and mechanical properties of hemp concrete. J. Build. Eng. 2020, 32, 101758.

- Sassoni, E.; Manzi, S.; Motori, A.; Montecchi, M.; Canti, M. Experimental study on the physical–mechanical durability of innovative hemp-based composites for the building industry. Energy Build. 2015, 104, 316–322.

- Walker, R.; Pavia, S.; Mitchell, R. Mechanical properties and durability of hemp-lime concretes. Constr. Build. Mater. 2014, 61, 340–348.

- Sadrolodabaee, P.; Claramunt, J.; Ardanuy, M.; de la Fuente, A. A Textile Waste Fiber-Reinforced Cement Composite: Comparison between Short Random Fiber and Textile Reinforcement. Materials 2021, 14, 3742.

- Jones, D. Introduction to the performance of bio-based building materials. In Performance of Bio-Based Building Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 1–19.

- Bedi, S. Materials Matter: Sustainable Preservation Practices. Ph.D. Thesis, Pratt Institute, Brooklyn, NY, USA, 2022.

- Sandak, A.; Sandak, J.; Brzezicki, M.; Kutnar, A. Bio-Based Building Skin; Springer Science and Business Media LLC: Dordrecht, The Netherlands, 2019; ISBN 9789811001093.

- ModCell: BaleHaus at Bath. Available online: https://www.modcell.com/projects/balehaus-at-bath/ (accessed on 4 October 2023).

- Vardy, S.; MacDougall, C. Concentric and Eccentric Compression Experiments of Plastered Straw Bale Assemblies. J. Struct. Eng. 2013, 139, 448–461.

- Cascone, S.; Rapisarda, R.; Cascone, D. Physical Properties of Straw Bales as a Construction Material: A Review. Sustainability 2019, 11, 3388.

- Tlaiji, G.; Ouldboukhitine, S.; Pennec, F.; Biwole, P. Thermal and mechanical behavior of straw-based construction: A review. Constr. Build. Mater. 2022, 316, 125915.

- González, A.D. Energy and carbon embodied in straw and clay wall blocks produced locally in the Andean Patagonia. Energy Build. 2014, 70, 15–22.

- Dubois, V.; Leblanc, A.; Carpentier, O.; Alhaik, G.; Wirquin, E. Performances of flax shive-based lightweight composites with rapid hardening. Constr. Build. Mater. 2018, 165, 17–27.

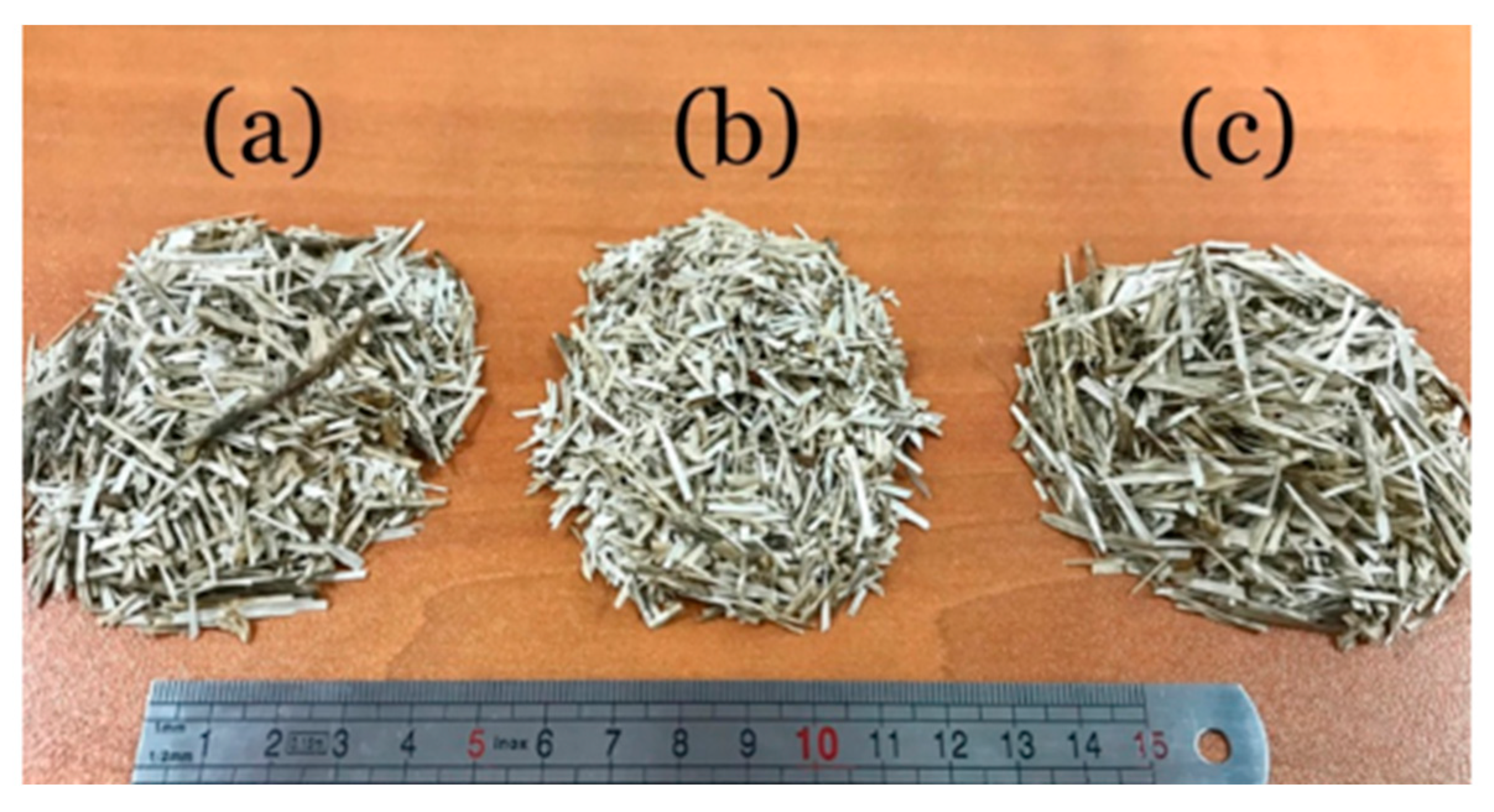

- Benmahiddine, F.; Cherif, R.; Bennai, F.; Belarbi, R.; Tahakourt, A.; Abahri, K. Effect of flax shives content and size on the hygrothermal and mechanical properties of flax concrete. Constr. Build. Mater. 2020, 262, 120077.

- Brzyski, P.; Kosiński, P.; Zgliczyńska, A.; Iwanicki, P.; Poko, J. Mass Transport and Thermal Conductivity Properties of Flax Shives for Use in Construction Industry. J. Nat. Fibers 2021, 18, 995–1006.

- Babenko, M.; Estokova, A.; Savytskyi, M.; Unčík, S. Study of Thermal Properties of Lightweight Insulation Made of Flax Straw. Slovak J. Civ. Eng. 2018, 26, 9–14.

- Brzyski, P.; Barnat-Hunek, D.; Suchorab, Z.; Łagód, G. Composite Materials Based on Hemp and Flax for Low-Energy Buildings. Materials 2017, 10, 510.

- Barnat-Hunek, D.; Smarzewski, P.; Brzyski, P. Properties of Hemp–Flax Composites for Use in the Building Industry. J. Nat. Fibers 2017, 14, 410–425.

- Rahim, M.; Douzane, O.; Tran Le, A.; Promis, G.; Laidoudi, B.; Crigny, A.; Dupre, B.; Langlet, T. Characterization of flax lime and hemp lime concretes: Hygric properties and moisture buffer capacity. Energy Build. 2015, 88, 91–99.

- Rentsen, B. Characterization of Flax Shives and Factors Affecting the Quality of Fuel Pellets from Flax Shives. Ph.D. Dissertation, University of Saskatchewan, Saskatoon, SK, Canada, 2010.

- Garikapati, K.P.; Sadeghian, P. Mechanical behavior of flax-lime concrete blocks made of waste flax shives and lime binder reinforced with jute fabric. J. Build. Eng. 2020, 29, 101187.

- Greef, J.M.; Brischke, C. Reed. In Performance of Bio-Based Building Materials; Jones, D., Brischke, C., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 124–128.

- Jones, D.; Brischke, C. Performance of Bio-Based Building Materials; Elsevier BV: Amsterdam, The Netherlands, 2017; ISBN 9780081009826.

- Tsapko, Y.V.; Tsapko, A.Y.; Bondarenko, O.P. Modeling of thermal conductivity of reed products. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; p. 012057.

- Yaghoobian, N.; Kleissl, J.; Krayenhoff, E.S. Modeling the Thermal Effects of Artificial Turf on the Urban Environment. J. Appl. Meteorol. Clim. 2010, 49, 332–345.

- Elsacker, E.; Vandelook, S.; Brancart, J.; Peeters, E.; De Laet, L. Mechanical, physical and chemical characterisation of mycelium-based composites with different types of lignocellulosic substrates. PLoS ONE 2019, 14, e0213954.

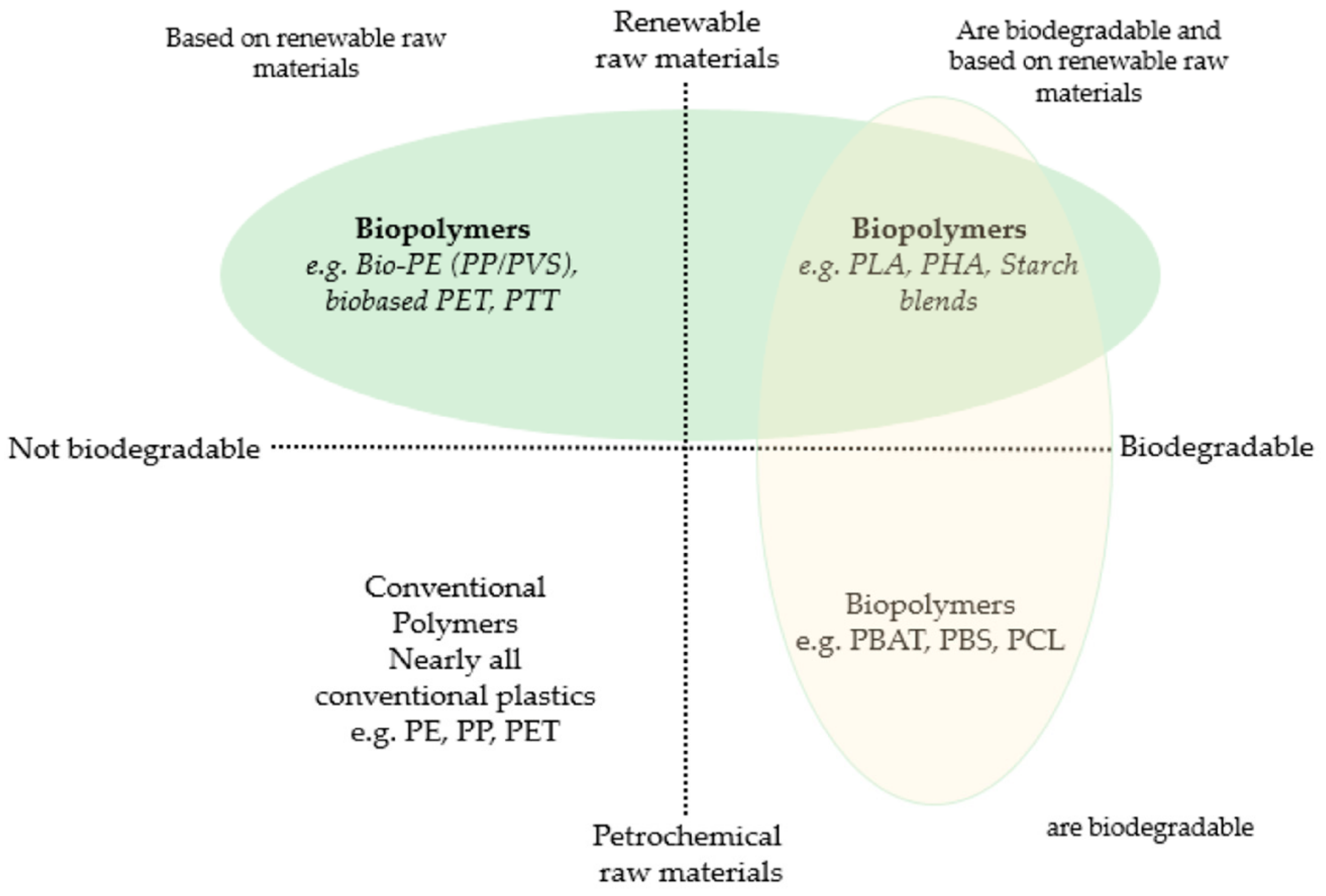

- Garrison, T.F.; Murawski, A.; Quirino, R.L. Bio-Based Polymers with Potential for Biodegradability. Polymers 2016, 8, 262.

- Luengo, J.M.; Garcı, B.; Sandoval, A.; Naharro, G.; Olivera, E.R. Bioplastics from microorganisms. Curr. Opin. Microbiol. 2003, 6, 251–260.

- Ibrahim, N.I.; Shahar, F.S.; Sultan, M.T.H.; Shah, A.U.M.; Safri, S.N.A.; Yazik, M.H.M. Overview of Bioplastic Introduction and Its Applications in Product Packaging. Coatings 2021, 11, 1423.

- Goel, V.; Luthra, P.; Kapur, G.S.; Ramakumar, S.S.V. Biodegradable/Bio-plastics: Myths and Realities. J. Polym. Environ. 2021, 29, 3079–3104.

- Narancic, T.; Cerrone, F.; Beagan, N.; O’connor, K.E. Recent Advances in Bioplastics: Application and Biodegradation. Polymers 2020, 12, 920.

- Boey, J.Y.; Lee, C.K.; Tay, G.S. Factors Affecting Mechanical Properties of Reinforced Bioplastics: A Review. Polymers 2022, 14, 3737.

- Pilla, S. Handbook of Bioplastics and Biocomposites Engineering Applications; John Wiley & Sons: Hoboken, NJ, USA, 2011.

- Coppola, G.; Gaudio, M.T.; Lopresto, C.G.; Calabro, V.; Curcio, S.; Chakraborty, S. Bioplastic from Renewable Biomass: A Facile Solution for a Greener Environment. Earth Syst. Environ. 2021, 5, 231–251.

- Ashothaman, A.; Sudha, J.; Senthilkumar, N. A comprehensive review on biodegradable polylactic acid polymer matrix composite material reinforced with synthetic and natural fibers. Mater. Today Proc. 2023, 80, 2829–2839.

- Cinar, S.O.; Chong, Z.K.; Kucuker, M.A.; Wieczorek, N.; Cengiz, U.; Kuchta, K. Bioplastic Production from Microalgae: A Review. Int. J. Environ. Res. Public Health 2020, 17, 3842.

- Manger, C. “Landing Page”, European Bioplastics e.V. Available online: https://www.european-bioplastics.org/ (accessed on 4 October 2023).

- Wang, T.; Hosseinzadeh, M.; Cuccagna, A.; Alakenova, R.; Casademunt, P.; Rovatti, A.R.; López-Rubio, A.; Porte, C. Comparative toxicity of conventional versus compostable plastic consumer products: An in-vitro assessment. J. Hazard. Mater. 2023, 459, 132123.

- Vroman, I.; Tighzert, L. Biodegradable Polymers. Materials 2009, 2, 307–344.

- Kong, U.; Rawi, N.F.M.; Tay, G.S. The Potential Applications of Reinforced Bioplastics in Various Industries: A Review. Polymers 2023, 15, 2399.

- Raoux, S. Phase Change Materials. Annu. Rev. Mater. Res. 2009, 39, 25–48.

- Ghani, S.A.A.; Jamari, S.S.; Abidin, S.Z. Waste materials as the potential phase change material substitute in thermal energy storage system: A review. Chem. Eng. Commun. 2021, 208, 687–707.

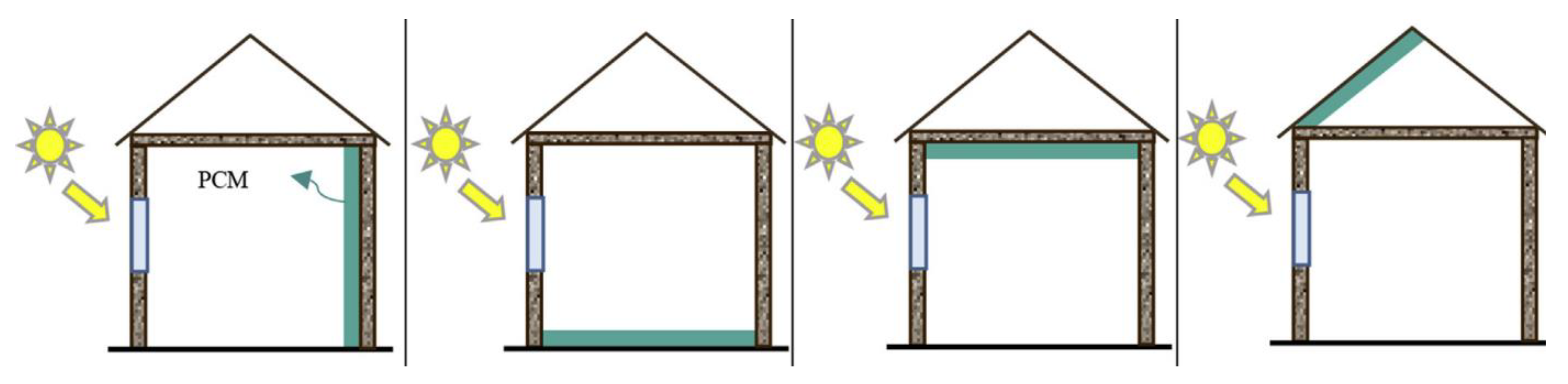

- Kuznik, F.; David, D.; Johannes, K.; Roux, J.-J. A review on phase change materials integrated in building walls. Renew. Sustain. Energy Rev. 2011, 15, 379–391.

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Phase change materials for building applications: A state-of-the-art review. Energy Build. 2010, 42, 1361–1368.

- Ke, H. Phase diagrams, eutectic mass ratios and thermal energy storage properties of multiple fatty acid eutectics as novel solid-liquid phase change materials for storage and retrieval of thermal energy. Appl. Therm. Eng. 2017, 113, 1319–1331.

- Ren, M.; Wen, X.; Gao, X.; Liu, Y. Thermal and mechanical properties of ultra-high performance concrete incorporated with microencapsulated phase change material. Constr. Build. Mater. 2021, 273, 121714.

- Sabbah, R.; Kizilel, R.; Selman, J.; Al-Hallaj, S. Active (air-cooled) vs. passive (phase change material) thermal management of high power lithium-ion packs: Limitation of temperature rise and uniformity of temperature distribution. J. Power Source 2008, 182, 630–638.

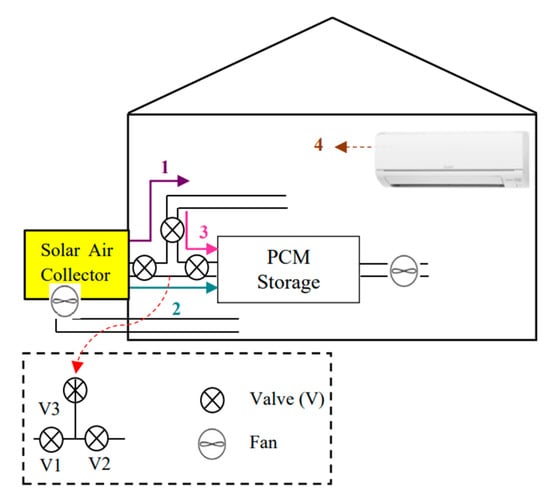

- Sawadogo, M.; Duquesne, M.; Belarbi, R.; Hamami, A.E.A.; Godin, A. Review on the Integration of Phase Change Materials in Building Envelopes for Passive Latent Heat Storage. Appl. Sci. 2021, 11, 9305.

- Sawadogo, M.; Godin, A.; Duquesne, M.; Lacroix, E.; Veillère, A.; Hamami, A.E.A.; Belarbi, R. Investigation of eco-friendly and economic shape-stabilized composites for building walls and thermal comfort. J. Affect. Disord. 2023, 231, 110026.

- Saffari, M.; de Gracia, A.; Ushak, S.; Cabeza, L.F. Passive cooling of buildings with phase change materials using whole-building energy simulation tools: A review. Renew. Sustain. Energy Rev. 2017, 80, 1239–1255.

- Akeiber, H.; Nejat, P.; Majid, M.Z.A.; Wahid, M.A.; Jomehzadeh, F.; Famileh, I.Z.; Calautit, J.K.; Hughes, B.R.; Zaki, S.A. A review on phase change material (PCM) for sustainable passive cooling in building envelopes. Renew. Sustain. Energy Rev. 2016, 60, 1470–1497.

- Gholamibozanjani, G.; Farid, M. A comparison between passive and active PCM systems applied to buildings. Renew. Energy 2020, 162, 112–123.

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345.

- Khudhair, A.M.; Farid, M.M. A review on energy conservation in building applications with thermal storage by latent heat using phase change materials. Energy Convers. Manag. 2004, 45, 263–275.

- Cao, V.D.; Pilehvar, S.; Salas-Bringas, C.; Szczotok, A.M.; Rodriguez, J.F.; Carmona, M.; Al-Manasir, N.; Kjøniksen, A.-L. Microencapsulated phase change materials for enhancing the thermal performance of Portland cement concrete and geopolymer concrete for passive building applications. Energy Convers. Manag. 2017, 133, 56–66.

- Gao, H.; Wang, J.; Chen, X.; Wang, G.; Huang, X.; Li, A.; Dong, W. Nanoconfinement effects on thermal properties of nanoporous shape-stabilized composite PCMs: A review. Nano Energy 2018, 53, 769–797.

- Umair, M.M.; Zhang, Y.; Iqbal, K.; Zhang, S.; Tang, B. Novel strategies and supporting materials applied to shape-stabilize organic phase change materials for thermal energy storage—A review. Appl. Energy 2019, 235, 846–873.

- Suttaphakdee, P.; Dulsang, N.; Lorwanishpaisarn, N.; Kasemsiri, P.; Posi, P.; Chindaprasirt, P. Optimizing mix proportion and properties of lightweight concrete incorporated phase change material paraffin/recycled concrete block composite. Constr. Build. Mater. 2016, 127, 475–483.

- Li, X.; Zhou, Y.; Zhang, X.; Zheng, W.; Chang, C.; Ren, X.; Zeng, J.; Hai, C.; Shen, Y. Experimental investigation of thermal and mechanical properties of magnesium oxychloride cement with form-stable phase change material. Constr. Build. Mater. 2018, 186, 670–677.

- Shi, J.; Tan, J.; Liu, B.; Liu, Y.; Xu, H.; Wang, Z.; Xiong, T.; Shi, J. Thermal and mechanical properties of thermal energy storage lightweight aggregate mortar incorporated with phase change material. J. Energy Storage 2020, 32, 101719.

- Boussaba, L.; Lefebvre, G.; Makhlouf, S.; Grados, A.; Royon, L. Investigation and properties of a novel composite bio-PCM to reduce summer energy consumptions in buildings of hot and dry climates. Sol. Energy 2021, 214, 119–130.

- Dehmous, M.; Franquet, E.; Lamrous, N. Mechanical and thermal characterizations of various thermal energy storage concretes including low-cost bio-sourced PCM. Energy Build. 2021, 241, 110878.

- Ingham, J. Petrography of geomaterials: A review. Q. J. Eng. Geol. Hydrogeol. 2011, 44, 457–467.

- Fookes, P.; de Freitas, M.; Culshaw, M. Discussion of ‘The first engineering geological publication in the UK?’ by M. G. Culshaw Quarterly Journal of Engineering Geology and Hydrogeology 37, 227–231. Q. J. Eng. Geol. Hydrogeol. 2005, 38, 105–108.

- Přikryl, R.; Török, Á.; Theodoridou, M.; Gomez-Heras, M.; Miskovsky, K. Geomaterials in construction and their sustainability: Understanding their role in modern society. Geol. Soc. Lond. Spéc. Publ. 2016, 416, 1–22.

- Rempel, A.R.; Rempel, A.W. Rocks, Clays, Water, and Salts: Highly Durable, Infinitely Rechargeable, Eminently Controllable Thermal Batteries for Buildings. Geosciences 2013, 3, 63–101.

- Giesekam, J.; Barrett, J.; Taylor, P.; Owen, A. The greenhouse gas emissions and mitigation options for materials used in UK construction. Energy Build. 2014, 78, 202–214.

- Morel, J.-C.; Charef, R.; Hamard, E.; Fabbri, A.; Beckett, C.; Bui, Q.-B. Earth as construction material in the circular economy context: Practitioner perspectives on barriers to overcome. Philos. Trans. R. Soc. B Biol. Sci. 2021, 376, 20200182.

- Pelé-Peltier, A.; Charef, R.; Morel, J.-C. Factors affecting the use of earth material in mainstream construction: A critical review. Build. Res. Inf. 2023, 51, 119–137.

- Tinsley, J.; Pavía, S. Thermal performance and fitness of glacial till for rammed earth construction. J. Build. Eng. 2019, 24, 100727.

- Reddy, B.; Kumar, P.P. Embodied energy in cement stabilised rammed earth walls. Energy Build. 2010, 42, 380–385.

- Ghasemalizadeh, S.; Toufigh, V. Durability of Rammed Earth Materials. Int. J. Géoméch. 2020, 20, 04020201.

- Giada, G.; Caponetto, R.; Nocera, F. Hygrothermal Properties of Raw Earth Materials: A Literature Review. Sustainability 2019, 11, 5342.

- Hamard, E.; Cazacliu, B.; Razakamanantsoa, A.; Morel, J.-C. Cob, a vernacular earth construction process in the context of modern sustainable building. J. Affect. Disord. 2016, 106, 103–119.

- Ben-Alon, L.; Loftness, V.; Harries, K.A.; DiPietro, G.; Hameen, E.C. Cradle to site Life Cycle Assessment (LCA) of natural vs. conventional building materials: A case study on cob earthen material. Build. Environ. 2019, 160, 106150.

- Gomaa, M.; Carfrae, J.; Goodhew, S.; Jabi, W.; Reyes, A.V. Thermal performance exploration of 3D printed cob. Arch. Sci. Rev. 2019, 62, 230–237.

- Minke, G. Building with Earth-Design and Technology of a Sustainable Architecture; Walter de Gruyter GmbH: Berlin, Germany, 2012.

- Belarbi, Y.E.; Sawadogo, M.; Poullain, P.; Issaadi, N.; Hamami, A.E.A.; Bonnet, S.; Belarbi, R. Experimental Characterization of Raw Earth Properties for Modeling Their Hygrothermal Behavior. Buildings 2022, 12, 648.

- Costes, J.-P.; Evrard, A.; Biot, B.; Keutgen, G.; Daras, A.; Dubois, S.; Lebeau, F.; Courard, L. Thermal Conductivity of Straw Bales: Full Size Measurements Considering the Direction of the Heat Flow. Buildings 2017, 7, 11.

- Cagnon, H.; Aubert, J.; Coutand, M.; Magniont, C. Hygrothermal properties of earth bricks. Energy Build. 2014, 80, 208–217.

- Zeghari, K.; Louahlia, H.; Leguern, M.; Boutouil, M.; Gualous, H.; Marion, M.; Schaetzel, P.; Goodhew, S.; Streif, F. Comparison of the Thermal Performance between Conventional and Cob Building. 2019, Volume 111. Available online: https://pearl.plymouth.ac.uk/bitstream/handle/10026.1/14230/Annual%20energy%20consumption%20between%20conventional%20and%20cob%20buildings (accessed on 15 May 2023).

- Goodhew, S.; Boutouil, M.; Streiff, F.; Le Guern, M.; Carfrae, J.; Fox, M. Improving the thermal performance of earthen walls to satisfy current building regulations. Energy Build. 2021, 240, 110873.

- Austin, G.S. Adobe as a building material. New Mex. Geol. 1984, 6, 69–71.

- Patel, P.; Patel, A. Use of sustainable green materials in construction of green buildings for sustainable development. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 785.

- Costa, C.; Cerqueira, Â.; Rocha, F.; Velosa, A. The sustainability of adobe construction: Past to future. Int. J. Arch. Herit. 2018, 13, 639–647.

- Silveira, D.; Varum, H.; Costa, A.; Martins, T.; Pereira, H.; Almeida, J. Mechanical properties of adobe bricks in ancient constructions. Constr. Build. Mater. 2012, 28, 36–44.

- Brown, P.W.; Clifton, J.R. Adobe I: The properties of adobe. Stud. Conserv. 1978, 23, 139–146.

- Christoforou, E.; Kylili, A.; Fokaides, P.A.; Ioannou, I. Cradle to site Life Cycle Assessment (LCA) of adobe bricks. J. Clean. Prod. 2016, 112, 443–452.

- Langer, W. Sustainability of aggregates in construction. In Sustainability of Construction Materials; Elsevier: Amsterdam, The Netherlands, 2016; pp. 181–207.

- Přikryl, R. Special issue on construction aggregates. Bull. Eng. Geol. Environ. 2021, 80, 8825–8829.

- Přikryl, R. Geomaterials as construction aggregates: A state-of-the-art. Bull. Eng. Geol. Environ. 2021, 80, 8831–8845.

- Mitchell, C. Construction aggregates: Evaluation and specification. In Proceedings of the Third International Forum for Industrial Rocks & Mining Conference & Exhibition, Fujairah, United Arab Emirates, 30 March–1 April 2015.

- Khamidov, A.; Akhmedov, I.; Shavkat, Y.; Jalalov, Z.; Umarov, I.; Xakimov, S.; Aleksandr, K. Application of heat-insulating composite gypsum for energy efficient construction. Spectr. J. Innov. Reforms Dev. 2022, 10, 77–84.

- Karni, J.; Karni, E. Gypsum in construction: Origin and properties. Mater. Struct. 1995, 28, 92–100.

- Lushnikova, N.; Dvorkin, L. Sustainability of gypsum products as a construction material. In Sustainability of Construction Materials; Elsevier: Amsterdam, The Netherlands, 2016; pp. 643–681.

- Espinoza-Herrera, R.; Cloutier, A. Thermal degradation and thermal conductivity of gypsum-cement particleboard. Wood Fiber Sci. 2009, 41, 13–21.

- Prałat, K.; Ciemnicka, J.; Koper, A.; Buczkowska, K.E.; Łoś, P. Comparison of the thermal properties of geopolymer and modified gypsum. Polymers 2021, 13, 1220.

- Adamopoulos, S.; Foti, D.; Voulgaridis, E.; Passialis, C. Manufacturing and Properties of Gypsum-Based Products with Recovered Wood and Rubber Materials. BioResources 2015, 10, 5573–5585.

- Singh, N.B. Clays and Clay Minerals in the Construction Industry. Minerals 2022, 12, 301.

- Belghazdis, M.; Hachem, E.-K. Clay and Clay Minerals: A Detailed Review. Int. J. Recent Technol. Appl. Sci. 2022, 4, 54–75.

- Asdrubali, F.; Horoshenkov, K.V. The Acoustic Properties of Expanded Clay Granulates. Build. Acoust. 2002, 9, 85–98.

- Mousavi, S.S.; Bhojaraju, C.; Ouellet-Plamondon, C. Clay as a Sustainable Binder for Concrete—A Review. Constr. Mater. 2021, 1, 134–168.

- Kumar, A.; Lingfa, P. Sodium bentonite and kaolin clays: Comparative study on their FT-IR, XRF, and XRD. Mater. Today Proc. 2020, 22, 737–742.

- Faqir, N.M.; Shawabkeh, R.; Al-Harthi, M.; Wahhab, H.A. Fabrication of Geopolymers from Untreated Kaolin Clay for Construction Purposes. Geotech. Geol. Eng. 2019, 37, 129–137.

- Kilinç, K.; Karasu, B.; Kaya, G.; Kivrak, S. A Preliminary Research On The Properties of Lightweight Expanded Clay Aggregate. J. Aust. Ceram. Soc. 2008, 44, 23–30.

- Vijayalakshmi, R.; Ramanagopal, S. Structural concrete using expanded clay aggregate: A review. Indian J. Sci. Technol. 2018, 11, 1–12.

- Sousa, H.; Carvalho, A.; Melo, A. A new sound insulation lightweight concrete masonry block. Design and experimental characterization. In Proceedings of the 13th International Brick and Block Masonry Conference, Amsterdam, The Netherlands, 4–7 July 2004.

- Bastos, A.; Sousa, H.; Melo, A. Methodology for the Design of Lightweight Concrete with Expanded Clay Aggregates. 2005. Available online: https://www.semanticscholar.org/paper/Methodology-for-the-Design-of-Lightweight-Concrete-Bastos-Sousa/69781e79fb8b90c57730d901514049eac8406a57 (accessed on 5 July 2023).

- Zach, J.; Hubertova, M.; Hroudova, J. Possibilities of determination of thermal conductivity of lightweight concrete with utilization of non stationary hot-wire method. In Proceedings of the 10th International Conference of the Slovenian Society for Non-Destructive Testing; Application of Contemporary Non-Destructive Testing in Engineering, Ljubljana, Slovenia, 1–3 September 2009.

- Grabois, T.M.; Cordeiro, G.C.; Filho, R.D.T. Fresh and hardened-state properties of self-compacting lightweight concrete reinforced with steel fibers. Constr. Build. Mater. 2016, 104, 284–292.

- Allam, R.; Issaadi, N.; Belarbi, R.; El-Meligy, M.; Altahrany, A. Hygrothermal behavior for a clay brick wall. Heat Mass Transf. 2018, 54, 1579–1591.

- Rashad, A.M. Lightweight expanded clay aggregate as a building material—An overview. Constr. Build. Mater. 2018, 170, 757–775.

- Illampas, R.; Ioannou, I.; Charmpis, D.C. Adobe: An environmentally friendly construction material. WIT Trans. Ecol. Environ. 2009, 120, 245–256.

- Franzoni, E. Materials Selection for Green Buildings: Which Tools for Engineers and Architects? Procedia Eng. 2011, 21, 883–890.

- Castro-Lacouture, D.; Sefair, J.A.; Flórez, L.; Medaglia, A.L. Optimization model for the selection of materials using a LEED-based green building rating system in Colombia. Build. Environ. 2009, 44, 1162–1170.

- Pulselli, R.; Simoncini, E.; Pulselli, F.; Bastianoni, S. Emergy analysis of building manufacturing, maintenance and use: Em-building indices to evaluate housing sustainability. Energy Build. 2007, 39, 620–628.

- Hoang, C.P.; Kinney, K.A.; Corsi, R.L. Ozone removal by green building materials. Build. Environ. 2009, 44, 1627–1633.

- Mokal, A.B.; Shaikh, A.I.; Raundal, S.S.; Prajapati, S.J.; Phatak, U.J. Green Building Materials—A Way. Int. J. Appl. Or Innov. Eng. Manag. 2015, 44, 244–249.

- Kaur, P.J. Bamboo availability and utilization potential as a building material. For. Res. Eng. Int. J. 2018, 2, 240–242.

- Shah, D.U.; Bock, M.C.D.; Mulligan, H.; Ramage, M.H. Thermal conductivity of engineered bamboo composites. J. Mater. Sci. 2016, 51, 2991–3002.

- Jones, D. Introduction to the performance of bio-based building materials. In Performance of Bio-Based Building Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 1–19.

- Sharma, P.; Dhanwantri, K.; Mehta, S. Bamboo as a Building Material. Int. J. Civ. Eng. Res. 2014, 5, 249–254.

- Syeda, A.; Kumar, B.S.J. A Case Study on Bamboo as Green Building Material. Int. J. Eng. Adv. Technol. 2014, 4, 78–82.

- Saba, M.; Assaad, J.J. Effect of recycled fine aggregates on performance of geopolymer masonry mortars. Constr. Build. Mater. 2021, 279, 122461.

- El-Wafa, M.A.; Fukuzawa, K. Early-Age Strength of Alkali-Activated Municipal Slag–Fly Ash–Based Geopolymer Mortar. J. Mater. Civ. Eng. 2018, 30, 04018040.

- Tho-In, T.; Sata, V.; Boonserm, K.; Chindaprasirt, P. Compressive strength and microstructure analysis of geopolymer paste using waste glass powder and fly ash. J. Clean. Prod. 2018, 172, 2892–2898.

- Azimi, E.A.; Yong, H.C.; Hussin, K.; Aziz, I.H. Processing and properties of geopolymers as thermal insulating materials: A review. Rev. Adv. Mater. Sci. 2016, 44, 273–285.

- Shehata, N.; Mohamed, O.A.; Sayed, E.T.; Abdelkareem, M.A.; Olabi, A.G. Geopolymer concrete as green building materials: Recent applications, sustainable development and circular economy potentials. Sci. Total Environ. 2022, 836, 155577.

- Burduhos Nergis, D.D.; Abdullah, M.M.A.B.; Vizureanu, P.; Faheem, M.T.M. Geopolymers and Their Uses: Review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 374, 012019.

- Ghauch, A.; Saba, M.; Sayet, T. Characterization of Porous Geopolymers Mortars for the Production of a Sustainable Material. IOP Conf. Ser. Earth Environ. Sci. 2022, 1123, 012062.

- Alam Zaidi, S.F.; Haq, E.U.; Nur, K.; Ejaz, N.; Anis-Ur-Rehman, M.; Zubair, M.; Naveed, M. Synthesis & characterization of natural soil based inorganic polymer foam for thermal insulations. Constr. Build. Mater. 2017, 157, 994–1000.

- Vaou, V.; Panias, D. Thermal insulating foamy geopolymers from perlite. Miner. Eng. 2010, 23, 1146–1151.

- Huang, Y.; Gong, L.; Pan, Y.; Li, C.; Zhou, T.; Cheng, X. Facile construction of the aerogel/geopolymer composite with ultra-low thermal conductivity and high mechanical performance. RSC Adv. 2018, 8, 2350–2356.

- Wu, Y.; Lu, B.; Bai, T.; Wang, H.; Du, F.; Zhang, Y.; Cai, L.; Jiang, C.; Wang, W. Geopolymer, green alkali activated cementitious material: Synthesis, applications and challenges. Constr. Build. Mater. 2019, 224, 930–949.

- Gautam, S.P.; Srivastava, V.; Agarwal, V.C. Use of glass wastes as fine aggregate in Concrete. J. Acad. Indus. Res. 2012, 1, 320–322.

- Edwards, K.L.; Axinte, E.; Tabacaru, L.L. A critical study of the emergence of glass and glassy metals as “green” materials. Mater. Des. 2013, 50, 713–723.

- Brow, R.K.; Schmitt, M.L. A survey of energy and environmental applications of glass. J. Eur. Ceram. Soc. 2009, 29, 1193–1201.

- Ogundairo, T.; Adegoke, D.D.; I Akinwumi, I.; Olofinnade, O.M. Sustainable use of recycled waste glass as an alternative material for building construction—A review. IOP Conf. Ser. Mater. Sci. Eng. 2019, 640, 012073.

- Mohajerani, A.; Vajna, J.; Cheung, T.H.H.; Kurmus, H.; Arulrajah, A.; Horpibulsuk, S. Practical recycling applications of crushed waste glass in construction materials: A review. Constr. Build. Mater. 2017, 156, 443–467.

- Cozzarini, L.; Marsich, L.; Ferluga, A.; Schmid, C. Life cycle analysis of a novel thermal insulator obtained from recycled glass waste. Dev. Built Environ. 2020, 3, 100014.