Mining in Canada stands as one of the most energy-intensive sectors, playing a pivotal role as a significant provider of copper, nickel, and cobalt to the international market. Anticipated growth in the global population, coupled with the transition of several low-income economies to middle-income status, is poised to escalate the demand for essential raw materials. This surge in demand is expected to drive an increase in energy consumption across various stages of the Canadian mining industry, encompassing exploration, extraction, processing, and refining. Due to their geographical constraints, most Canadian mining operations rely heavily on fossil fuels such as diesel and heavy fuel. Considering the global shift towards decarbonization and the pursuit of net-zero emission targets, exploring avenues for adopting electrification solutions and integrating renewable energy technologies, particularly in sizable surface mines, is imperative.

1. Introduction

The mining industry, which includes a wide range of activities like such as exploration and extraction, as well as processing, sophisticated manufacturing, and recycling, is crucial to Canada. For a variety of Canadian industries, including manufacturing, transportation, construction, and energy, it is a crucial supply of the necessary materials. [

1,

2,

3]. Nevertheless, akin to global trends in mining, the Canadian mining industry stands out for its substantial energy consumption. Notably, as indicated by the Canadian greenhouse gas (GHG) inventory, the industry’s GHG emissions surged from 4.3 million metric tons of CO

2 equivalent to 6.4 million metric tons between 2015 and 2019. This upward trajectory is predicted to persist until 2035, driven by the escalating demand for raw materials and the establishment of new mining sites in remote areas devoid of access to the public power grid [

4]. Energy consumption in the Canadian mining sector can be broadly categorized into two main groups: off-grid and grid-connected operations. In on-site power generation and transportation, off-grid mining activities primarily hinge on diesel fuel usage [

5,

6,

7]. On the other hand, grid-connected mining endeavors exhibit a certain reliance on fossil fuels, particularly in transporting extracted minerals. Nevertheless, these mining operations remain highly sensitive to fluctuations in fossil fuel prices, given that a considerable portion of their expenses is directed towards energy production, a significant fraction of which originates from fossil fuels.

3. Current Active Projects Related to Renewable Energy Development in Canadian Mining

The Research Centre for Energy Resources and Consumption foresees a significant surge in primary energy demand for the global Canadian mining industry over the next decade, specifically in the extraction of copper ores for the renewable energy sector, rare earth for the semiconductor industry, and lithium and nickel ores for the manufacture of electric car batteries. This demand is projected to escalate from 8% of primary energy consumption to 15–20% by 2035 [

19]. This growth prompts the expectation that Canadian renewable energy technologies, the semiconductor industry, and electric vehicle and battery developers will play a pivotal role in delivering adaptable, proven, and low-carbon energy solutions to meet the escalating energy requirements of the mining sector [

20]. However, in this context, it is crucial to assess the potential environmental impact of these mining operations.

In essence, Canadian mining operations have the potential to reduce their energy consumption and greenhouse gas emissions based on diesel fuel consumption through the implementation of energy recovery systems (ERS) [

21], integration of renewable energy (RE) sources [

22], transport electrification, and adoption of carbon capture (CC) technologies [

23]. Additionally, Canadian mines are positioning themselves to cut expenses by curbing diesel usage and carbon emissions, especially as Canada is a pioneer as the first significant mining jurisdiction to enforce a national carbon pricing strategy [

24]. Addressing the energy-related challenges in the mining industry will necessitate a blend of renewable energy solutions and electrification. To facilitate this, the Canadian government has committed CAD 2.3 billion to establish a research and development (R&D) framework, propelling Canada into a leadership role in renewable energy solutions. This framework includes targeted funding initiatives to bolster renewable energy within the mining sector [

25].

Despite the harsh winter conditions in Canada’s northern regions, integrating renewable energy sources has demonstrated compelling cost savings at remote sites. The Raglan Mine project, undertaken by Glencore, stands out as a notable example. This pioneering initiative, led by TUGLIQ Energy, features the world’s first wind project incorporating various energy storage technologies. The project integrates two wind turbines with a total capacity of 6 MW (

Figure 2) alongside diverse storage systems such as hydrogen fuel cells, lithium-ion batteries, and a flywheel [

26]. These two turbines contribute approximately 10% of the mine’s electricity demand, resulting in savings exceeding 4 million liters of diesel annually and a reduction of 12,000 tonnes in emissions such as carbon dioxide (CO

2), nitrogen oxide (NO

X), hydrocarbon (HC), and particulate matter (PM). By incorporating two additional wind turbines, the mine’s renewable energy capacity would scale to 12 MW, its energy storage capacity would increase to 6 MW/2 MWh, and its yearly diesel consumption would plummet by 6.6 million liters [

27].

In addition to the Raglan wind-storage hybrid project, Rio Tinto’s Diavik Diamond Mine in Canada’s Northwest Territories has operated with four 2.3 MW wind turbines since 2012. These turbines collectively comprise a wind farm with a demonstrated capacity of 9.2 MW and an annual production of 17 GWh. This setup provides an average of 10% of the mine’s power needs and contributes to a reduction of up to 6% in GHG emissions [

28].

Figure 2. Wind turbines at Raglan were installed in 2014 and 2018 [

29].

Conversely, photovoltaic (PV) solar panels have found promising applications in electrifying isolated Canadian mine sites. A few notable projects include:

-

PV System at Raglan Mine (Quebec): Commencing in July 2021, this study evaluates the efficacy of solar energy production in Canada’s northern regions. The installation, located near the wind turbines at Mine 2, incorporates 108 bifacial panels, generating 40 kilowatt-peak (kWp) energy [

30]. This project is still considered a pilot project in the northern region of Quebec.

-

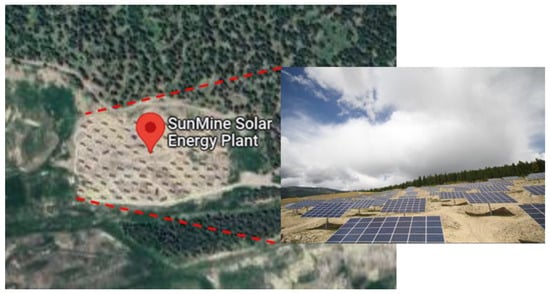

PV System at SunMine (British Columbia): Initiated in 2014, SunMine is a groundbreaking 2 MW solar field connected to the British Columbia grid. Remarkably, it is the first solar farm on a reclaimed abandoned mine site. Teck Resources invested CAD 70 million over five years to reclaim the site following the mine closure. The site continues to manage drainage water, as shown in

Figure 3 [

31,

32].

-

PV System at Snowline Gold’s Forks Camp (Canada): An off-grid system at this remote gold mine encampment encompasses a lithium-ion battery bank, a power rack for equipment organization, and 64 bifacial modules on a ground mount (all rated at 27 kW). This configuration is expected to reduce carbon emissions by 90% and save an estimated 12,527 L of fuel annually by providing power to the 45-person exploration camp and recharging the battery bank [

33].

Figure 3. Aerial view of the SunMine solar energy plant in BC, Canada [

31].

However, forthcoming Canadian mining ventures are embracing the integration of renewable energies in their new exploration sites. By 2025, Sabina Gold & Silver Corp. (now B2Gold) has outlined plans to incorporate renewable energy to power a segment of the Goose gold mine [

34]. The company has proposed the installation of up to 13 wind turbines, collectively generating 4.5 MW of power, as per their submission to the Nunavut Impact Review Board. They also envision a 5 MW solar panel setup with 50 MWh of battery storage. In a similar vein, the Newmont-Goldcorp Éléonore mine, an active mining operation located in the Eeyou Istchee territory of James Bay in northern Quebec, took a significant step in 2020.

4. Opportunities for Integrating RE into Off-Grid Mining Operations

One of the foremost challenges in achieving sustainable development goals within off-grid mining operations stems from the pivotal shift from fossil fuel combustion to cleaner energy sources. Over the past decade, energy generation has witnessed remarkable technological advancements and cost reductions, particularly in wind and solar photovoltaic (PV) generation, thanks to widespread deployment. Recent insights into energy storage and renewable generation advancements suggest that the affordability of green energy is on the rise, attributed to climbing fossil fuel costs, the enforcement of climate change tax policies, and diminishing capital costs of eco-friendly generation and energy storage technology [

39,

40,

41].

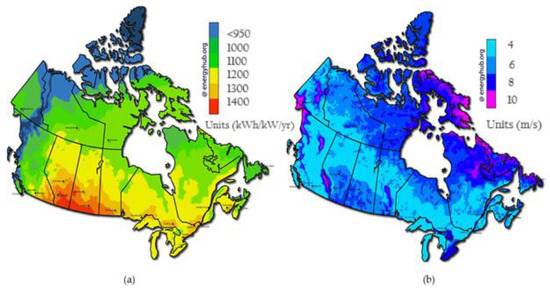

In Canada, the synergy of solar and wind resources presents an attractive solution for electrification and energy storage in remote areas. Notably, Canada’s prime wind resource lies predominantly in the northern regions, where many off-grid mines are located. The solar and wind source maps for Canada, as depicted in

Figure 4 [

42,

43,

44], underscore this distribution. Among the provinces, the prairie provinces emerge as solar energy production hotspots: Saskatchewan leads with 1330 kWh of energy per kW per year, followed by Alberta with 1276 kWh/kW/yr, and Manitoba with 1272 kWh/kW/yr. Comparatively, remote sites in Nunavut can generate around 1092 kWh/kW/yr, Quebec around 1183 kWh/kW/yr, and Ontario around 1166 kWh/kW/yr.

Figure 4. (

a) Canadian solar source map; (

b) Canadian wind source map [

42,

43,

44].

Conversely, Canada’s wind resources showcase considerable promise in its northern regions, aligning with the prevalent locations of remote off-grid sites. Wind speeds in these regions range from 6 m/s to 8 m/s and, in some cases, surge up to 10 m/s at an 80 m hub height. The abundance of such favorable wind resources lays a solid foundation for integrating renewable energies into Canadian mining operations.

4.1. Meeting Electricity and Heating through RE

Diesel fuel finds extensive application across many primary metal and non-metallic mineral manufacturing processes in Canada. Generally, the energy demand for non-metallic mineral production tends to be lower compared to that for metals [

45]. Predominantly, this energy is channeled into heating processes, with a noteworthy proportion sourced from diesel fuel.

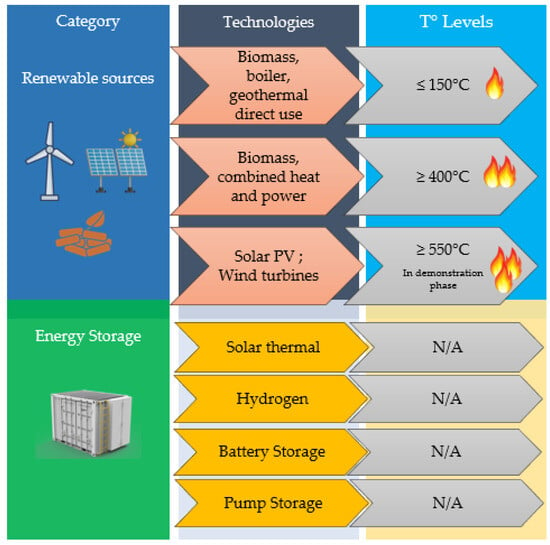

Process heat demand in the mining sector represents a substantial energy consumption factor. This demand spans a spectrum of temperatures, ranging from low to high. In an industrial context, low temperatures refer to those below 150 °C, medium temperatures range from 150 °C to 400 °C, and high temperatures exceed 400 °C [

46]. The choice of technology at a mine site hinges on the fluctuating process heat requisites. For example, the conversion of iron oxide to metallic iron occurs within the temperature span of 800 °C to 1200 °C during steel production. In the copper smelting process, roasting copper ore into copper oxide necessitates a heat source operating from 250 °C to 350 °C.

Commonly, steam is employed to generate low- to medium-temperature heat, while high-temperature heat is generated through direct heat sources, often via the combustion of fossil fuels. Presently, fossil fuels predominantly cater to high-temperature heat demands in mining operations. Figure 5 underscores that most available renewable energy (RE) technologies on the market primarily cater to low- or medium-temperature process heat requirements, rendering them suitable for specific applications. However, for high-temperature heat production beyond 550 °C, wind- and solar-based solutions remain in the research and demonstration phase at experimental sites, and their commercial implementation is yet to be realized.

Figure 5. Current accessible and economical RE technologies.

The use of diesel fuel in power-reliant Canadian mining activities can be gradually supplanted, at least partially, by harnessing renewable energy sources. Comminution is a significantly energy-consuming mining process that involves mechanically reducing minerals and/or rock to predetermined sizes [

48]. As per [

49], comminution constitutes approximately 15% of the energy consumption for iron mining and around 21% for gold extraction. Interestingly, transitioning to renewable energy sources is relatively straightforward for these processes because comminution is predominantly electric.

Renewable energy (RE) sources, encompassing solar, wind, and geothermal energy, are increasingly emerging as viable solutions for off-grid and remote mining operations. The successful integration of clean energy to power the Diavik and Raglan mines in Canada’s Arctic region exemplifies the potential of this approach. Another instance is the repurposed SunMine mine in British Columbia, which capitalizes on solar energy. Furthermore, geothermal energy as a sustainable power source has demonstrated its efficacy, as evidenced by the Éléonore mine project in Quebec, which can cover up to 35% of mining energy requirements.

4.2. Replacing Diesel with RE for Transportation

To illustrate, a notable fraction of approximately 10% of the energy requisites for both iron ore and gold mining is allocated to transportation and hauling operations [

52]. Since diesel fuel remains a prominent energy source for these functions, particularly in truck hauling, integrating renewables into material handling presents notable challenges. In Canada, employing biodiesel within mining encounters certain hurdles. High biodiesel blends, particularly those derived from non-soy substrates, may undergo gelation in cold weather conditions [

53]. However, strategies that are employed to counteract cold-sensitive compounds can also be applied to circumvent gelling issues. Several biodiesel exporters currently employ this approach to warm personalized train carriages.

4.3. Making Hydrogen with RE

Hydrogen plays a multifaceted role within the mining sector, serving various purposes such as high-temperature heat generation, electricity production, feedstock, fuel for vehicles and mining equipment, and energy storage. Currently, the dominant sources of hydrogen production are oil, coal, and natural gas [

55]. Surplus energy can be efficiently transformed into hydrogen and stored for later utilization. Notably, excessive electricity can undergo conversion into hydrogen and be stockpiled for deployment in other mining operations that possess the capacity to integrate intermittent-output renewable energy technologies, such as solar and wind.

4.4. Electrifying Communities Nearby

Mining enterprises have historically erected essential infrastructure to cater to the needs of remote mining communities, including electricity supply for housing employees. By leveraging this existing infrastructure, mining companies possess the potential to significantly enhance electrification efforts by extending these services to nearby villages [

57].

Capitalizing on economies of scale, mining entities can leverage their substantial power consumption and financial capabilities to establish larger-scale power plants than required for mining operations. This approach enables the extension of electricity access to adjacent communities at an economically viable rate. This endeavor could manifest as a novel micro-grid initiative, where electricity generation from renewable sources is designed to serve both the mine site and the neighboring populace.

5. Electrification Alternatives in Canadian Mines

The shift towards electrification within the Canadian mining sector is already underway. Both ongoing and upcoming mining ventures in Canada are actively transitioning to renewable energy sources and incorporating battery energy storage to meet their electricity demands. Numerous forward-thinking Canadian enterprises are channeling investments into fully electric or hybrid electric vehicles to substitute diesel vehicles, curtail costs, diminish pollution, and embrace clean technologies for a more prosperous and ecological future [

59,

60,

61,

62,

63,

64,

65]. However, this transition also ushers in infrastructure, maintenance, and operational challenges mine operators must contend with. Currently, a predominant focus within Canadian mining operations centers around electrifying their haulage systems. This initiative is highlighted by converting several heavy-duty truck prototypes into electrically powered alternatives actively integrated into service.

5.1. Installation of a Trolley-Assist System for Diesel-Electric Trucks

Trolley-assist technology has been in existence for a considerable duration. During the energy crisis of the 1970s, sparked by events such as the Yom-Kippur War in 1973 and the Iranian Revolution in 1979, which disrupted oil supplies and led to scarcity and price surges for Western nations reliant on Middle Eastern energy exports, various mining companies explored trolley assist as a means to reduce their dependency on diesel fuel [

66]. Although trolley assist offers advantages such as emission reduction, enhanced cycle times, and increased productivity, it failed to gain widespread traction. Multiple factors have contributed to the limited adoption of trolley assist, as outlined in [

66]. Historically, diesel prices remained lower than today, and until recently, the mining industry lacked substantial incentives to mitigate its environmental impact.

However, the landscape has shifted with Canada’s recent adoption of stringent climate change regulations and the implementation of carbon taxes. This has prompted the emergence of trolley-assist system installations in mines across the globe, including notable instances such as the Boliden Aitik mine in Sweden [

67].

With the recent implementation of the trolley-assist system at the Copper Mountain mine, there are optimistic expectations regarding fuel savings and emissions reductions. The company anticipates that each truck will be able to displace approximately 400 L of diesel per hour or around a tonne of CO2 emissions. Despite the substantial CAD 40 million investment required for the integration of this innovative system into their operations, the company has identified compelling justifications for this endeavor:

-

Increasing Carbon Taxes: Adopting trolley assist can substantially mitigate Copper Mountain’s carbon tax liabilities as these taxes continue to rise.

-

Escalating Diesel Costs: Using the trolley-assist system, each hybrid Komatsu haul truck consumes 400 L of diesel (equivalent to 1 ton of CO2) per hour. Additionally, transitioning to clean power sourced from BC Hydro offers a more predictable cost structure than diesel’s unpredictable availability and pricing fluctuations.

-

Enhanced Efficiency: Deploying hybrid trucks equipped with trolley assist translates to more efficient mineral transportation within shorter time frames.

-

Reduced Environmental Impact: With the support of the BC Government, Copper Mountain is aligning with efforts to bestow “responsible metals” credentials on their products as they traverse the supply chain. This designation positions these items for premium trading, ultimately augmenting their value.

5.2. Integration of In-Pit Crushing and Conveying Systems

In-Pit Crushing and Conveying (IPCC) systems consist of various components, including crushers, entirely mobile in-pit conveying systems, stationary conveyors, conveyor junctions, waste-spreading tripper cars, waste-spreading slewing spreaders, and mineralized material radial stackers [

70]. Alternatives to the IPCC framework exhibit diverse configurations. There are three primary types of IPCC systems, each characterized by its distinct attributes.

Compared to truck shovel (TS) options, IPCC systems offer a range of advantages supported by research reviews and real-world production experiences at mine sites [

75,

76,

77]. The benefits of IPCC systems include:

-

Energy Savings: Conveying minerals through conveyors inherently demands less energy per unit weight than transporting them via trucks [

78]. Notably, only 39% of the energy utilized in a truck cycle is dedicated to moving the payload, with the remaining 61% allocated to moving the vehicle’s weight. Additionally, by relying on electricity-based methods, IPCC systems can reduce a mine’s reliance on diesel fuel.

-

Environmental Impact (Dust and Noise): Implementing IPCC systems can reduce noise pollution as conveyors generate less noise than conventional diesel-powered trucks. Moreover, reducing the number of trucks on the road can significantly diminish the dust emissions sources, positively impacting the environment [

78].

-

CO

2 Emissions: IPCC systems can substantially reduce CO

2 emissions by facilitating fuel switching. A noteworthy example is found in a Brazilian iron ore mine that has integrated two fully mobile IPCC systems, collectively capable of handling 7800 t/h, resulting in an estimated reduction of 60 million liters of diesel consumption annually [

79]. This approach aligns with utilizing renewable energy sources, such as hydroelectric, solar, and wind-based electricity, to transform IPCC into a decarbonized transport mining system.

-

Operational Costs: As mining activities escalate, waste dumps grow, and the pit becomes deeper. This progression leads to longer truck haul cycles and increased demand for additional trucks to meet production requirements. Truck hauling is frequently perceived as more costly than IPCC methods, particularly with increased distances and elevation [

80]. Embracing an IPCC system over a truck haulage system can significantly reduce material transport operating expenses (OPEX), owing to potential savings from energy conservation, workforce reduction, enhanced weight efficiency, and lower maintenance costs.

-

Production Efficiency: The continuous transportation approach offered by IPCC systems often translates to increased production rates. This approach involves transporting ore or waste materials to designated locations consistently and efficiently [

81].

6. Challenges for RE and Transport Electrification in Canadian Mines

6.1. Technical Challenges

The foremost technical challenges associated with solar and wind energy pertain to their inherent unpredictability and variability. These renewable energy sources can only be harnessed during sunny or windy conditions, with power generation contingent upon factors such as cloud cover and wind speed. This poses a significant incongruity with the continuous and stable power supply demanded by mining operations [

82]. In addition, icing is another challenge for wind turbines and solar panels, due to very cold and long winter temperatures (up to −40 °C). This may significantly reduce energy production and affect maintenance due to restricted access. The evolving landscape of battery storage costs can potentially revolutionize the intermittency and variability quandary. However, in the immediate term, battery storage is not poised to entirely supplant diesel utilization in off-grid scenarios [

83].

6.2. Expertise and Logistics

While mining enterprises exhibit an unwavering commitment to elevating health and safety standards—entrenched within the industry’s ethos—this diligence does not uniformly translate to power management systems and energy conservation initiatives. Mining conglomerates face a shortage of essential technical proficiency in renewable energy (RE) and hybrid systems. The expertise in designing, operating, repairing, and maintaining diesel-powered systems prevalent in off-grid mining operations lies predominantly within the purview of mining professionals and established suppliers. Regrettably, this scenario constrains the seamless integration of renewable power [

91]. Although power providers catering to the sector are gradually introducing hybrid options, only a few mines in Canada, such as Raglan and Diavik, have embarked on the journey of amassing experiential knowledge in RE implementation.

In logistics, Canadian mining corporations have mastered the formidable challenge of supplying heavy fuel oil or diesel to remote mine sites, a feat particularly pronounced in border regions such as the Arctic. Notably, the Diavik mine exemplifies this feat, where ice roads remain the exclusive conduit for truckers and heavy machinery during certain winter weeks. Integrating renewables in such locales can alleviate logistical complexities and expenses associated with fuel transportation [

92].

6.3. Financing

The initial capital outlay for establishing a renewable energy plant surpasses the cost of incorporating generators into a diesel-based facility, and this cost differential is projected to persist in the foreseeable future [

98,

99,

100]. This financial aspect assumes considerable significance from a cash flow perspective, especially when contemplating a self-generation setup. The higher upfront costs associated with renewable solutions could extend the timeline for recovering the initial invested capital. Such a capital investment shortfall could be particularly detrimental, considering the benefits of augmenting renewable energy penetration or disseminating electricity to proximate communities [

101].

While there are economies of scale to be gained by constructing large-scale solar and wind installations, these advantages are still intertwined with augmented initial capital outflows, subsequently deferring capital recouping. This is further compounded if the mining enterprise shoulders the distribution expenses tied to local electrification efforts, leading to escalated capital expenditures [

102].

To circumvent hefty capital expenses, one viable avenue is outsourcing the renewable project to an Internal Power Producer (IPP). However, financial constraints become a significant hurdle when transferring renewable energy (RE) project ownership to an IPP [

103]. Many RE IPPs lack the equity to underwrite the project’s initial capital requirements. This predicament could result in banks rejecting loan requests for the RE project due to insufficient capital or imposing elevated interest rates to mitigate investment risks.

6.4. Research and Development

The Canadian mining sector needs cost-effective solutions to embrace affordable, long-duration energy storage systems for scaling up renewable energy adoption, as well as for incorporating clean heat sources at high temperatures. Additionally, green hydrogen production emerges as a promising avenue for low-emission heating or feedstock purposes, offering the potential for research and innovation [

106,

107,

108]. Similar prospects lie in developing lighter batteries with enhanced autonomy for industrial applications [

109]. Furthermore, the integration of Blockchain technology, which remains largely underutilized in Canadian mines, could enhance transparency, simplicity, and security in investments. Blockchain could also enable the tracing of “green” minerals, thereby contributing to mining sector operations [

110,

111].

6.5. Business Models

The limited availability of flexible renewable energy solutions and the financial constraints many mining corporations face, especially smaller to medium-sized enterprises, contribute to a sense of caution. Policy support will be pivotal in shaping agreements, such as power purchase agreements, aligning incentives and legal frameworks, and fostering net metering for grid-connected mining operations. Analyzing the advantages and disadvantages of RE incorporation can aid governments and stakeholders, including the financial sector, in making informed decisions to support these endeavors.

This entry is adapted from the peer-reviewed paper 10.3390/en16196967