Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

The utilization of shape memory alloys (SMAs) to reinforce steel structures has been proven to be an efficient and reliable method, the structural strengthening needs can be met without the need for tensioning equipment by activating the SMAs to generate restoring stresses.

- steel structure

- shape memory alloy (SMA)

- shape memory effect

1. Fe-SMA Strip

1.1. Reinforcement Mechanism

Fe-SMAs are often used to replace steel plates for structural reinforcement due to their low price, corrosion resistance, and stable mechanical properties [1][2][3][4]. First, pre-straining was applied to the Fe-SMA strip (step 1), which was subsequently unloaded to a stress-free condition (step 2). Afterwards, the Fe-SMA strip, which was obtained from step 2, was connected to the steel beam (step 3) and heated until the temperature reached the Af (step 4), and it was subsequently cooled (step 5). Due to the anchorage, the shape memory effect of the Fe-SMA strips is restricted (deformation of the strip is restricted), thus providing tensile stresses to the steel beam.

1.2. Mechanical Properties

The method described above is known as the prior activation method and is often used to repair structural cracks and improve the bearing capacity of structures. The method has received much attention from scholars in recent years due to the convenience of applying pre-stress to the structure [5].

Fatigue properties are one of the most important reasons for determining whether a component can be used in a reinforced structure, so many scholars have conducted experimental studies on the fatigue performance of Fe-SMA strips. Ghafoori [6] studied the fatigue properties of Fe-SMA strips under high cyclic loading and proposed a safe design formula for Fe-SMA strips as pre-stressing elements. The experimental results show that Fe-SMA strips have very good fatigue properties. Marinopoulou et al. [7] conducted fatigue tests on Fe-SMA strips under pre-stressing conditions, and the recovered stress of Fe-SMA strips decreased by about 2% compared with that before the test. Hosseini et al. [8] investigated the effect of multiple thermal activations on the pre-stress of Fe-SMA strips and showed that although the pre-stress of Fe-SMA strips subjected to cyclic loading was reduced, it could be restored to its original level by means of secondary thermal activation. This shows that Fe-SMAs have very excellent fatigue properties, and they shall be considered in the design of structural reinforcements.

In addition to the fatigue properties, the pre-strain length and activation temperature of Fe-SMA strips have received much attention from scholars because they are related to the recovery stresses of Fe-SMA strips. Izadi et al. [9] found that the recovery stress of Fe-SMA strips could reach 430 MPa at the pre-strain of 2% and the activation temperature of 260 °C. More data on the recovery stresses of the Fe-SMA strips under different experimental conditions can be found in Table 1. It can be seen that the activation temperature of Fe-SMA strips is within 160–400 °C, which is acceptable for steel structures, but the activation temperature should not be too high for concrete structures, otherwise it may lead to the destruction of the mechanical properties of the concrete. In addition, the size and pre-strain of Fe-SMA strips have an effect on the optimal activation temperature, so the specific parameters of Fe-SMA strips and activation temperature should be determined through experiments in practical applications.

Table 1. Recovery stress of Fe-SMA strips under different experimental conditions.

| Alloy | Size (mm) | Pre-Strain (%) | Activation Temperature (°C) | Recovery Stress (MPa) | Reference |

|---|---|---|---|---|---|

| Fe-17Mn-5Si-10Cr-4Ni-1Vc | 0.7 × 3 | 4 | 225 | 380 | [10] |

| 4 | 160 | 330 | |||

| 0.9 × 3 | 4 | 160 | 580 | [11] | |

| 1.7 × 14 | 4 | 160 | 266 | [12] | |

| — | 4 | 160 | 350 | [13] | |

| 1.5 × 10 | 2 | 160 | 372 | [6] | |

| 1.7 × 25 | 2 | 160 | 177~200 | [14] | |

| 0.8 × 52.5 | 2 | 260 | 406 | [15] | |

| 1.5 × 100 | 2 | 160 | 292 | [16] | |

| 2 | 180 | 330 | |||

| Fe-28Mn-6Si-5Cr-0.53Nb-0.06C | — | 4 | 397 | [17] | |

| Fe-28Mn-6Si-5Cr | — | 3 | 300 | 255 | [18] |

| Fe-18Mn-8Cr-4Si-2Ni-0.36Nb-0.36N | 185 | ||||

| Fe-Mn-Si alloy | 1.5 × 20 | 2 | 160 | 308 | [19] |

| 4 | 160 | 348 | |||

| 1.5 × 15.8 | ≈3 | 155 | 268~295 | [20] |

1.3. Connection and Activating Methods

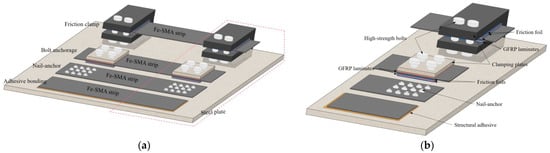

A reliable connection between Fe-SMA strips and parent steel components is required when strengthening structures. Connecting methods that have been proposed include bolt anchorage, nail-anchor, friction clamp, and adhesive bonding [9][21][22][23], as shown in Figure 1 [24].

Figure 1. Connection methods between steel plate and Fe-SMA strips [24]: (a) reinforcing of steel plates; (b) configuration details.

Izadi et al. [15] proposed a mechanical anchorage system for the anchoring of Fe-SMA strips to steel plates or steel beams and verified the effectiveness of the system using fatigue tests. The results show that the parent structure under this system has better integrity with the Fe-SMA strips, and the Fe-SMA strips exhibit very excellent fatigue performance. Fritsch et al. [25] used nails to anchor Fe-SMA strips to steel beams and experimentally analyzed the effectiveness of different nails and their distributions. Wang and Li [26][27][28] proposed a two-component epoxy adhesive SikaPower-1277 to bond the parent structure with Fe-SMA strips in order to minimize the damage of the parent steel structure. Furthermore, thermal activation methods for Fe-SMAs include a flame-spraying gun, infrared heating, electric heating furnace, electric ceramic, and electrical resistance heating [14][29][30][31]. It is worth noting that although nail and bolt anchors have the advantage of being stronger, damage to the parent structure due to anchoring is unavoidable. Therefore, when selecting the choice of an anchoring method adhesive bonding and friction clamps should first be considered.

2. SMA/CFRP Composite Patch

2.1. Reinforcement Mechanism

The effectiveness of pre-stressed Carbon Fiber Reinforced Polymer (CFRP) panels for reinforcing steel structures has been demonstrated by a number of studies [32][33][34][35][36], but how to conveniently apply pre-stress is a big challenge. To solve this problem, some scholars have proposed the concept of SMA/CFRP composite patches [37]; NiTi-SMA wires are frequently employed in these studies, and the term “SMA wire” refers to an NiTi-SMA wire, unless specified otherwise. First, pre-straining was applied to the SMA wires (step 1), which was subsequently unloaded to a stress-free condition (step 2). Afterwards, the SMA wires, which were obtained from step 2, and CFRP materials were glued together to form the SMA/CFRP composite patches (step 3). Then, the SMA/CFRP composite patch was anchored to the steel beam and heated until the temperature reached the Af (step 4) and subsequently cooled (step 5).

2.2. Bonding Performance between SMA and CFRP

It can be seen that the SMA/CFRP composite patch does not require large tensioning equipment and its pre-stressing is applied to the structure using the shape memory effect of the SMA. However, effective bonding between the SMA and CFRP is a prerequisite for the patch to work properly. Currently, epoxy resins are commonly used as an adhesive between SMA and CFRP, and many studies have demonstrated their effectiveness [38][39][40][41][42][43]. Furthermore, Zheng et al. [44] bonded SMA wires to CFRP with an epoxy resin and experimentally investigated the bonding performance of the patches, and the results showed that a reasonable selection of the number of SMA wires could effectively avoid the debonding of the two. El-Tahan et al. [45] showed that for the patch, debonding can be effectively prevented by increasing the anchorage length between the SMA wire and CFRP. In addition, Gu et al. [46] pointed out that debonding between the SMA and CFRP in SMA/CFRP composite patches is the main reason for the degradation of their mechanical properties, and in order to solve this problem, they proposed the idea of fabricating new specimens with orthogonally embedded SMA wires and sandwiched two-dimensional SMA film lattices, which is expected to solve the debonding risk.

2.3. Mechanical Properties

In order to prove the effectiveness of this method, many studies have been conducted. Yang et al. [47] investigated the fracture behavior of SMA/CFRP composites using bending and charpy impact tests. Their findings indicated that incorporating an SMA alloy into conventional composites enhances the ductility and impact resistance of the hybrid composite. Gu et al. [46] showed that embedding SMA wires into CFRP can effectively improve the energy absorption capacity and toughness of CFRP. Abdy et al. [39] developed a self-pre-stressing CFRP/SMA composite patch and verified its effectiveness through tests. The results demonstrated that it can be used as simple and effective solutions to significantly enhance the fatigue life of cracked steel structures. Furthermore, El-Tahan et al. [48] proposed an SMA/CFRP composite patch and investigated its fatigue properties experimentally, which showed that the patch retained more than 80% of its pre-stress after undergoing 2 million loadings. Deng et al. [49] also compared an SMA/CFRP composite patch, CFRP sheet, and SMA patch reinforcement through experiments, and the results showed that the SMA/CFRP composite patch was better. Russian et al. [50] investigated the effect of surface preparation on the effectiveness of SMA/CFRP composite patches for reinforcing steel structures. The results show that smoother steel surfaces resulted in less effective reinforcement with SMA/CFRP composite patches.

3. SMA-Based Damper and Brace

SMA dampers can provide stiffness and are usually used in conjunction with an anti-lateral brace. SMA dampers typically utilize the superelastic and damping effects of the SMA to provide energy dissipation to a structure while reducing its lateral displacement and providing the ability of self-centering [51][52]. Liu et al. [53] designed a tension–compression SMA damper and obtained its characteristic parameters through tests. The experimental results demonstrated the distinct effectiveness of SMA dampers in reducing the displacement and acceleration responses of structures. Han et al. [54] proposed an NiTi-SMA wires-based damper capable of tension, compression, and torsion simultaneously. Qiu et al. [55] proposed a new type of damper, which combines SMA elements with steel dampers based on a bending steel plate. Ma et al. [56] proposed a new SMA-based damper mainly consisting of pre-tensioned SMA wires and two pre-compressed springs; the damper shows both good energy dissipation capacity and re-centering capability. Fang et al. [57] proposed a new damper based on SMA ring spring. Sui et al. [58] proposed a novel SMA-based damper making use of SMA wire, and the construction is designed so that the SMA wire is always stretched, whether the damper is in compression or tension. Qiu et al. [59] proposed an SMA-based anti-buckling damper by combining SMA bolts with a variable friction mechanism. It can be seen that whether the damper is in tension or compression, the SMA bolts is in tension, thus effectively avoiding the problem of SMA bar buckling. Jia et al. [60] proposed an innovative double SMA damper system. In the proposed system, double SMA elements with different phase-transition temperatures are arranged in parallel. Fang et al. [61] proposed a shear damper based on an Fe-SMA. In comparative tests with a mild steel damper, it was found that the Fe-SMA dampers offer improved ductility and fatigue properties.

In addition, the SMA-based self-centering restrainers have also made great progress in research. Miller et al. [62] used SMA bars in BRB to reduce the residual deformation of the brace. It was found that the brace had good energy-dissipation and self-centering ability, and the self- centering ability was related to the SMA bars. Yang et al. [62] evaluated the performance of hybrid seismic bracing with a core consisting of SMA wires and energy-consuming struts, where the SMA wires were designed to be within a maximum strain of 6%. Numerical analysis shows that the frame structure with hybrid damping bracing can have similar energy-dissipation capacity as the BRB bracing system, and at the same time, it has better self-centering capacity. Shi et al. [63] proposed a brace based on SMA cables, and the cables are configured within a bracing system in a way that they are only subjected to tensile loads regardless of the loading direction of the bracing itself. Ozbulut et al. [64] proposed a method to optimize the design of SMA-based braces, and using this, the best SMA parameters can be obtained. In order to prevent buckling of SMA rods during compression, Cao et al. [65] proposed an anti-buckling system and designed long-stroke SMA restrainer(LSR). Study shows that the LSR can exhibit stable energy dissipation capabilities with excellent self-centering ability both under tension and compression loading. In addition, the numerical results show that the energy dissipation capacity, self-resetting capacity and limiting capacity of SMA rods in compression are much higher than those in tension.

This entry is adapted from the peer-reviewed paper 10.3390/buildings13112760

References

- Gu, X.L.; Chen, Z.Y.; Yu, Q.Q.; Ghafoori, E. Stress recovery behavior of an Fe-Mn-Si shape memory alloy. Eng. Struct. 2021, 243, 112710.

- Cladera, A.; Weber, B.; Leinenbach, C.; Czaderski, C.; Shahverdi, M.; Motavalli, M. Iron-based shape memory alloys for civil engineering structures: An overview. Constr. Build. Mater. 2014, 63, 281–293.

- Yeon, Y.M.; Nam, H.K.; Lee, J.; Sangwon, J. Evaluation of Corrosion Behavior for Fe-based Shape Memory Alloy. J. Korean Soc. Adv. Compos. Struct. 2021, 12, 50–56.

- Hosseini, A.; Michels, J.; Izadi, M.; Ghafoori, E. A comparative study between Fe-SMA and CFRP reinforcements for prestressed strengthening of metallic structures. Constr. Build. Mater. 2019, 226, 976–992.

- Hong, K.; Lee, S.; Han, S.; Yeon, Y. Evaluation of Fe-Based Shape Memory Alloy (Fe-SMA) as Strengthening Material for Reinforced Concrete Structures. Appl. Sci. 2018, 8, 730.

- Ghafoori, E.; Hosseini, E.; Leinenbach, C.; Michels, J.; Motavalli, M. Fatigue behavior of a Fe-Mn-Si shape memory alloy used for prestressed strengthening. Mater. Des. 2017, 133, 349–362.

- Marinopoulou, E.; Katakalos, K. Thermomechanical Fatigue Testing on Fe-Mn-Si Shape Memory Alloys in Prestress Conditions. Materials 2023, 16, 237.

- Hosseini, E.; Ghafoori, E.; Leinenbach, C.; Motavalli, M.; Holdsworth, S.R. Stress recovery and cyclic behaviour of an Fe-Mn-Si shape memory alloy after multiple thermal activation. Smart Mater. Struct. 2018, 27, 025009.

- Izadi, M.; Hosseini, A.; Michels, J.; Motavalli, M.; Ghafoori, E. Thermally activated iron-based shape memory alloy for strengthening metallic girders. Thin-Walled Struct. 2019, 141, 389–401.

- Dong, Z.Z.; Klotz, U.E.; Leinenbach, C.; Bergamini, A.; Czaderski, C.; Motavalli, M. A Novel Fe-Mn-Si Shape Memory Alloy With Improved Shape Recovery Properties by VC Precipitation. Adv. Eng. Mater. 2009, 11, 40–44.

- Leinenbach, C.; Kramer, H.; Bernhard, C.; Eifler, D. Thermo-Mechanical Properties of an Fe-Mn-Si-Cr-Ni-VC Shape Memory Alloy with Low Transformation Temperature. Adv. Eng. Mater. 2012, 14, 62–67.

- Czaderski, C.; Shahverdi, M.; Bronnimann, R.; Leinenbach, C.; Motavalli, M. Feasibility of iron-based shape memory alloy strips for prestressed strengthening of concrete structures. Constr. Build. Mater. 2014, 56, 94–105.

- Lee, W.J.; Weber, B.; Leinenbach, C. Recovery stress formation in a restrained Fe-Mn-Si-based shape memory alloy used for prestressing or mechanical joining. Constr. Build. Mater. 2015, 95, 600–610.

- Shahverdi, M.; Czaderski, C.; Motavalli, M. Iron-based shape memory alloys for prestressed near-surface mounted strengthening of reinforced concrete beams. Constr. Build. Mater. 2016, 112, 28–38.

- Izadi, M.R.; Ghafoori, E.; Shahverdi, M.; Motavalli, M.; Maalek, S. Development-of an iron-based shape memory alloy (Fe-SMA) strengthening system for steel plates. Eng. Struct. 2018, 174, 433–446.

- Michels, J.; Shahverdi, M.; Czaderski, C. Flexural strengthening of structural concrete with iron-based shape memory alloy strips. Struct. Concr. 2018, 19, 876–891.

- Dong, Z.Z.; Sawaguchi, T.; Kajiwara, S.; Kikuchi, T.; Kim, S.H.; Lee, G.C. Microstructure change and shape memory characteristics in welded Fe-28Mn-6Si-5Cr-0.53Nb-0.06C alloy. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2006, 438, 800–803.

- Soroushian, P.; Ostowari, K.; Nossoni, A.; Chowdhury, H. Repair and Strengthening of Concrete Structures Through Application of Corrective Posttensioning Forces with Shape Memory Alloys. Transp. Res. Rec. 2001, 1770, 20–26.

- Hong, K.; Lee, S.; Yeon, Y.; Jung, K. Flexural Response of Reinforced Concrete Beams Strengthened with Near-Surface-Mounted Fe-Based Shape-Memory Alloy Strips. Int. J. Concr. Struct. Mater. 2018, 12, 45.

- El-Hacha, R.; Rojob, H. Flexural strengthening of large-scale reinforced concrete beams using near-surface -mounted self-prestressed iron-based shape-memory alloy strips. PCI J. 2018, 63, 55–65.

- Izadi, M.R.; Ghafoori, E.; Motavalli, M.; Maalek, S. Iron-based shape memory alloy for the fatigue strengthening of cracked steel plates: Effects of re-activations and loading frequencies. Eng. Struct. 2018, 176, 953–967.

- Izadi, M.; Motavalli, M.; Ghafoori, E. Iron-based shape memory alloy (Fe-SMA) for fatigue strengthening of cracked steel bridge connections. Constr. Build. Mater. 2019, 227, 116800.

- Qiang, X.; Duan, X.; Jiang, X.; Lu, Q.; Zhou, G.J.E.S. Experimental study on mechanical properties of bolted joints between Fe-SMA and steel plates. Eng. Struct. 2023, 297, 116980.

- Qiang, X.H.; Wu, Y.P.; Wang, Y.H.; Jiang, X. Research Progress and Applications of Fe-Mn-Si-Based Shape Memory Alloys on Reinforcing Steel and Concrete Brdiges. Appl. Sci. 2023, 13, 3404.

- Fritsch, E.; Izadi, M.; Ghafoori, E. Development of nail-anchor strengthening system with iron-based shape memory alloy (Fe-SMA) strips. Constr. Build. Mater. 2019, 229, 117042.

- Wang, W.D.; Li, L.Z.; Hosseini, A.; Ghafoori, E. Novel fatigue strengthening solution for metallic structures using adhesively bonded Fe-SMA strips: A proof of concept study. Int. J. Fatigue 2021, 148, 106237.

- Li, L.Z.; Chatzi, E.; Ghafoori, E. Debonding model for nonlinear Fe-SMA strips bonded with nonlinear adhesives. Eng. Fract. Mech. 2023, 282, 109201.

- Li, L.Z.; Wang, W.D.; Chatzi, E.; Ghafoori, E. Experimental investigation on debonding behavior of Fe-SMA-to-steel joints. Constr. Build. Mater. 2023, 364, 129857.

- Choi, E.; Ostadrahimi, A.; Kim, W.J.; Seo, J. Prestressing effect of embedded Fe-based SMA wire on the flexural behavior of mortar beams. Eng. Struct. 2021, 227, 111472.

- Shahverdi, M.; Czaderski, C.; Annen, P.; Motavalli, M. Strengthening of RC beams by iron-based shape memory alloy bars embedded in a shotcrete layer. Eng. Struct. 2016, 117, 263–273.

- Wang, C.P.; Wen, Y.H.; Peng, H.B.; Xu, D.Q.; Li, N. Factors affecting recovery stress in Fe-Mn-Si-Cr-Ni-C shape memory alloys. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2011, 528, 1125–1130.

- Wang, Z.Y.; Wang, Q.Y.; Li, L.H.; Zhang, N. Fatigue behaviour of CFRP strengthened open-hole steel plates. Thin-Walled Struct. 2017, 115, 176–187.

- Aljabar, N.J.; Zhao, X.L.; Al-Mahaidi, R.; Ghafoori, E.; Motavalli, M.; Powers, N. Effect of crack orientation on fatigue behavior of CFRP-strengthened steel plates. Compos. Struct. 2016, 152, 295–305.

- Chen, T.; Gu, X.L.; Qi, M.; Yu, Q.Q. Experimental Study on Fatigue Behavior of Cracked Rectangular Hollow-Section Steel Beams Repaired with Prestressed CFRP Plates. J. Compos. Constr. 2018, 22, 04018034.

- Colombi, P.; Fava, G.; Sonzogni, L. Fatigue crack growth in CFRP-strengthened steel plates. Compos. Part B-Eng. 2015, 72, 87–96.

- Colombi, P.; Fava, G. Experimental study on the fatigue behaviour of cracked steel beams repaired with CFRP plates. Eng. Fract. Mech. 2015, 145, 128–142.

- Xu, Y.; Otsuka, K.; Toyama, N.; Yoshida, H.; Nagai, H.; Oishi, R.; Kikushima, Y.; Yuse, K.; Akimune, Y.; Kishi, T. Fabrication technique of SMA/CFRP smart composites. In Proceedings of the Conference on Transducing Materials and Devices, Brugge, Belgium, 30 October–1 November 2002; pp. 35–46.

- Li, L.Z.; Chen, T.; Gu, X.L.; Ghafoori, E. Heat Activated SMA-CFRP Composites for Fatigue Strengthening of Cracked Steel Plates. J. Compos. Constr. 2020, 24, 04020060.

- Abdy, A.I.; Hashemi, M.J.; Al-Mahaidi, R. Fatigue life improvement of steel structures using self-prestressing CFRP/SMA hybrid composite patches. Eng. Struct. 2018, 174, 358–372.

- Jang, B.K.; Xu, Y.; Oishi, R.; Nagai, H.; Yoshida, H.; Akimune, Y.; Otsuka, K.; Kishi, T. Thermomechanical characterization and development of SMA embedded CFRP composites with self-damage control. In Proceedings of the Smart Structures and Materials 2002 Conference, San Diego, CA, USA, 18–21 March 2002; pp. 182–190.

- Xue, Y.J.; Wang, W.W.; Wu, Z.H.; Hu, S.W.; Tian, J. Experimental study on flexural behavior of RC beams strengthened with FRP/SMA composites. Eng. Struct. 2023, 289, 116288.

- Xu, Y.; Otsuka, K.; Toyama, N.; Yoshida, H.; Jang, B.K.; Nagai, H.; Oishi, R.; Kishi, T. Fabrication of TiNi/CFRP smart composite using cold drawn TiNi wires. In Proceedings of the Smart Structures and Materials 2002 Conference, San Diego, CA, USA, 18–21 March 2002; pp. 564–574.

- Xue, Y.J.; Wang, W.W.; Tian, J.; Wu, Z.H. Experimental study and analysis of RC beams shear strengthened with FRP/SMA composites. Structures 2023, 55, 1936–1948.

- Zheng, B.T.; El-Tahan, M.; Dawood, M. Shape memory alloy-carbon fiber reinforced polymer system for strengthening fatigue-sensitive metallic structures. Eng. Struct. 2018, 171, 190–201.

- El-Tahan, M.; Dawood, M. Bond behavior of NiTiNb SMA wires embedded in CFRP composites. Polym. Compos. 2018, 39, 3780–3791.

- Gu, X.J.; Su, X.Z.; Wang, J.; Xu, Y.J.; Zhu, J.H.; Zhang, W.H. Improvement of impact resistance of plain-woven composite by embedding superelastic shape memory alloy wires. Front. Mech. Eng. 2020, 15, 547–557.

- Yang, S.Y.; Goo, B.C.; Kim, H.J. Mechanical behavior of shape memory alloy composites. In Advances in Fracture and Strength, Pts 1–4; Kim, Y.J., Bae, H.D., Kim, Y.J., Eds.; Trans Tech Publications: Stafa, Switzerland, 2005; Volume 297–300, pp. 1551–1555.

- El-Tahan, M.; Dawood, M. Fatigue behavior of a thermally-activated NiTiNb SMA-FRP patch. Smart Mater. Struct. 2016, 25, 015030.

- Deng, J.; Fei, Z.Y.; Li, J.H.; Li, H. Fatigue behaviour of notched steel beams strengthened by a self-prestressing SMA/CFRP composite. Eng. Struct. 2023, 274, 115077.

- Russian, O.; Belarbi, A.; Dawood, M. Effect of surface preparation technique on fatigue performance of steel structures repaired with self-stressing SMA/CFRP patch. Compos. Struct. 2022, 280, 114968.

- Fang, C.; Liang, D.; Zheng, Y.; Lu, S.Y. Seismic performance of bridges with novel SMA cable-restrained high damping rubber bearings against near-fault ground motions. Earthq. Eng. Struct. Dyn. 2022, 51, 44–65.

- Farhangi, V.; Jahangir, H.; Eidgahee, D.R.; Karimipour, A.; Javan, S.A.N.; Hasani, H.; Fasihihour, N.; Karakouzian, M.J.A.S. Behaviour investigation of SMA-equipped bar hysteretic dampers using machine learning techniques. Appl. Sci. 2021, 11, 10057.

- Liu, A.R.; Yu, Q.C.; Zhang, J.P.; Xie, S.F.; Guo, Y.Z. Study on Vibration Control of Long Cable with Shape Memory Alloy Damper. Adv. Sci. Lett. 2011, 4, 3023–3026.

- Han, Y.L.; Yin, H.Y.; Xiao, E.T.; Sun, Z.L.; Li, A.Q. A kind of NiTi-wire shape memory alloy damper to simultaneously damp tension, compression and torsion. Struct. Eng. Mech. 2006, 22, 241–262.

- Qiu, C.X.; Wang, H.Y.; Liu, J.W.; Qi, J.; Wang, Y.M. Experimental tests and finite element simulations of a new SMA-steel damper. Smart Mater. Struct. 2020, 29, 035016.

- Ma, H.W.; Cho, C.D. Feasibility study on a superelastic SMA damper with re-centring capability. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2008, 473, 290–296.

- Feng, W.K.; Fang, C.; Wang, W. Behavior and design of top flange-rotated self-centering steel connections equipped with SMA ring spring dampers. J. Constr. Steel Res. 2019, 159, 315–329.

- Sui, J.Y.; Xu, C.M.; Liu, W.F. Study of a new type sma damper. In Proceedings of the 1st International Conference on Civil Engineering, Architecture and Building Materials (CEABM 2011), Haikou, China, 18–20 June 2011; pp. 2897–2901.

- Qiu, C.X.; Liu, J.W.; Du, X.L. Cyclic behavior of SMA slip friction damper. Eng. Struct. 2022, 250, 113407.

- Jia, Y.Q.; Wang, C.; Zhang, R.F.; Li, L.Z.; Lu, Z.D. A Double Shape Memory Alloy Damper for Structural Vibration Control. Int. J. Struct. Stab. Dyn. 2021, 21, 2150098.

- Fang, C.; Wang, W.; Ji, Y.Z.; Yam, M.C.H. Superior low-cycle fatigue performance of iron-based SMA for seismic damping application. J. Constr. Steel Res. 2021, 184, 106817.

- Miller, D.J.; Fahnestock, L.A.; Eatherton, M.R. Development and experimental validation of a nickel-titanium shape memory alloy self-centering buckling-restrained brace. Eng. Struct. 2012, 40, 288–298.

- Shi, F.; Zhou, Y.; Ozbulut, O.E.; Ren, F.M. Hysteretic response and failure behavior of an SMA cable-based self-centering brace. Struct. Control Health Monit. 2022, 29, e2847.

- Ozbulut, O.E.; Roschke, P.N.; Lin, P.Y.; Loh, C.H. GA-based optimum design of a shape memory alloy device for seismic response mitigation. Smart Mater. Struct. 2010, 19, 065004.

- Cao, S.S.; Ozbulut, O.E. Long-stroke shape memory alloy restrainers for seismic protection of bridges. Smart Mater. Struct. 2020, 29, 115005.

This entry is offline, you can click here to edit this entry!