Bacterial infections and antibiotic resistance remain significant contributors to morbidity and mortality worldwide. Despite recent advances in biomedical research, a substantial number of medical devices and implants continue to be plagued by bacterial colonisation, resulting in severe consequences, including fatalities. The development of nanostructured surfaces with mechano-bactericidal properties has emerged as a promising solution to this problem. These surfaces employ a mechanical rupturing mechanism to lyse bacterial cells, effectively halting subsequent biofilm formation on various materials and, ultimately, thwarting bacterial infections.

- antibacterial surfaces

- nanofabrication

- antimicrobial

- polymeric implants

1. Introduction

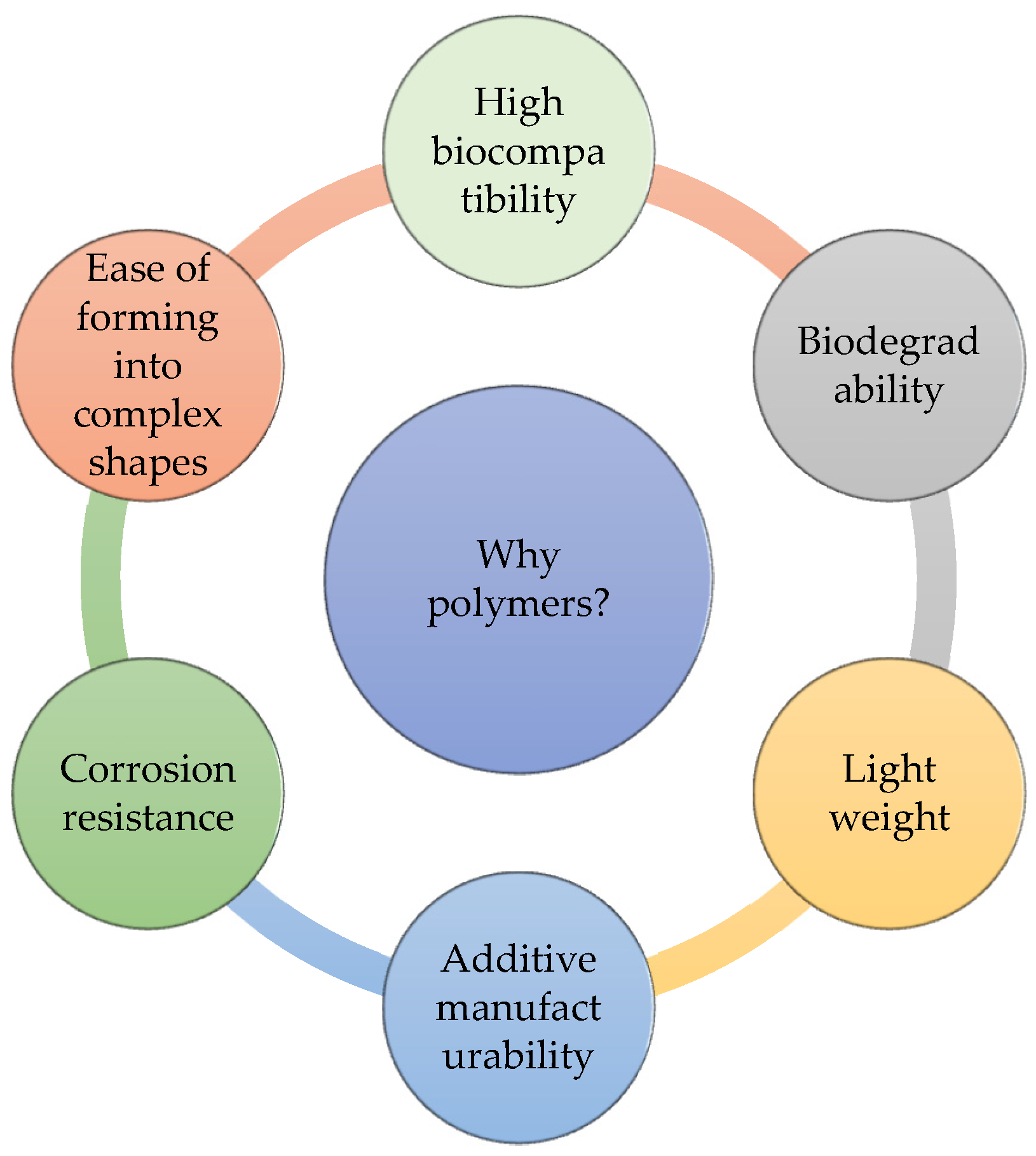

2. Polymers Used in Biomedical Applications

| Polymer | Characteristics, Physical, and Mechanical Properties | Biomedical Applications |

Advantages | Limitations | Ref. |

|---|---|---|---|---|---|

| PGA | Biodegradable, biocompatible, tensile stress: 890 MPa, density: 1.5 g/cm3, melting point: 225–230 °C, glass transition temperature: 35–40 °C | Tissue engineering applications in bone, tendon, cartilage, tooth, and spinal regeneration; nerve grafts; absorbable sutures | Stimulates cartilage regeneration; 3D-printability; high tensile strength | High friction coefficient and “binds and snags” when wet, high brittleness, high degradation causes inflammatory response | [26][27][58][59][60] |

| PLGA | Biodegradable, bioadsorbable, biocompatible, tensile stress: 3.4 MPa, density: 1.2 g/cm3, melting point: dependent on the percent composition (PLA, PGA), glass transition temperature: 40–60 °C | Therapeutic tools; drug delivery; tissue engineering | Stimulates osteoblasts; 3D-printability | Release of acidic byproducts leads to inflammation, degrade due to hydrolysis, poor strength | [26][28][29][30][61] |

| PCL | Biodegradable, bioadsorbable, biocompatible, tensile stress: 12.8 MPa, density: 1.15 g/cm3, melting point: 60 °C, glass transition temperature: −60 °C | Dental splints; drug delivery; tissue engineering | Stimulates osteoblasts; 3D printable; slow degradation rate; low cost in 3D printing due to low melting point; high biocompatibility | Poor mechanical properties; low cell adhesion | [26][31][62] |

| PU | Can be biodegradable or non-biodegradable based on chemical composition, non-bioabsorbable, biocompatible, tensile strength: 34.5–56 MPa, density: 1.23 g/cm3, melting point: 163 °C, glass transition temperature: −35 °C | Drug delivery; catheters, pacemaker leads insulation, vascular prostheses, heart valves, cardiac assist devices (cardiovascular applications) | High durability; high toughness; good biostability; low cost | Environmental stress cracking; material degradation in vivo; metal ion oxidation | [16][63][64][65] |

| PP | Non-biodegradable, non-bioabsorbable, biocompatible, tensile stress: 28 MPa, density: 0.9 g/cm3, melting point: 170 °C, glass transition temperature: −25 °C | Sutures; scaffolds (ligament or tendon repair); meshes for hernia and pelvic organ repair; heart valve structure, oxygenator and plasmapheresis membranes, finger joint prosthesis |

High melting point; less toxic; low cost | Limited biocompatibility; poor strength | [16][33][66][67][68] |

| PVA | Biodegradable, biocompatible, tensile stress: 40–90 MPa, density: 1.26 g/cm3, melting point: 228 °C, glass transition temperature: 85 °C | Wound dressings, drug delivery, targeted-tissue transportation systems; soft biomaterial implants. | High chemical and thermal stability; non-toxic | Weak hydrogel endurance in high temperature; relatively weak polymer; limited biocompatibility; degrades due to hydrolysis | [34][69][70][71][72] |

| Silicone or PDMS | Non-absorbable, non-biodegradable, biocompatible, hydrophobic, tensile stress: 2–10 MPa, density: 0.97 g/cm3, melting point: 228 °C glass transition temperature: ~120–123 °C |

Oxygenator membrane; tubing; shunts; prostheses; heart peacemaker leads; heart valve structures; burn dressing | Chemically inert; low toxicity; thermal stability; high biocompatibility | Prone to damage; non-durable; contamination of monomers; low mechanical strength | [16][47][63] |

| PLA | Biodegradable, bioabsorbable, biocompatible, tensile stress: 21–60 MPa, density: 1.21–1.25 g/cm3, melting point: 150–160 °C, glass transition temperature: 60–65 °C | Bone tissue engineering; drug delivery; plates, screws, pins, and wires in bone fixation; bio-absorbable implants; sutures in dermatology; drug-eluting stents | High biocompatibility; stimulates osteoblasts; less brittle; one of the highly used 3D-printable materials; degradation products are also non-toxic to humans and the environment. | Low mechanical strength | [26][33][39][40][66][67][73] |

| PMMA | Non-degradable, biocompatible, tensile stress: 48–76 MPa, density: 1.2 g/cm3, melting point: 130–180 °C, glass transition temperature: 80 °C | Dental implants; bone cement; lenses; drug delivery | One of the hardest thermoplastics with high scratch resistance; high mechanical strength | Less biocompatibility; high curing temperature; does not support osteointegration; causes necrosis effect | [16][74][75] |

| PEEK | Non-degradable, biocompatible, tensile stress: 84 MPa, density: 1.4 g/cm3, melting point: 343 °C, glass transition temperature: 143 °C | Dental implants; knee implants; spine implants; cranioplasticity; hip replacement; anterior plate fixation; heart valves; face reconstructions | High biocompatibility; 3D-printable; light weight; compatible with hydroxyapatite (natural bone tissue materials) hence substitute to metallic implants; stable at high temperatures; mechanical stability | Low thermoformability; bioinert (does not promote tissue integration); complex and costly manufacturing process | [76][77][78] |

| PEKK | Non-degradable, biocompatible, tensile stress: 115 MPa, density: 1.3 g/cm3, melting point: 363–386 °C, glass transition temperature: 162 °C | Dental implants; crown and bridge in dentistry; endodontic post; removable denture framework; restorative and prosthetic applications | High biocompatibility; 3D-printable; light weight; high mechanical strength; excellent chemical resistance | Bioinert (does not promote tissue integration); more complex and costly manufacturing process than PEEK | [52][79] |

| PET | Non-degradable, high biocompatibility, tensile stress: 75–100 MPa, density:1.38 g/cm3, melting point: 255–265 °C, glass transition temperature: 85 °C | Sutures; heart valves; surgical meshes; scaffolds; urinary and bloodstream catheters; commercial vascular prosthesis | 3D-printable; cost effective; excellent chemical resistance | Bioinert (does not promote tissue integration) | [80][81][82] |

| PTFE | Non-degradable, biocompatible, tensile stress: 30.5 MPa, density: 2.175 g/cm3, melting point: 327 °C, glass transition temperature: 127 °C | Vascular graft prostheses; heart patches; stapes prosthesis | High mechanical strength; chemically inert | Difficult to 3D-print | [16][83] |

| Chitosan | Biodegradable, biocompatible, tensile stress: 32.2 MPa, density: 0.20–0.38 g/cm3, melting point:105 °C, glass transition temperature: 75 °C | Antitumor drug delivery; protein and peptide drug delivery; gene delivery; antibiotic delivery; polyphenol delivery; wound healing applications | Antimicrobial; anti-inflammatory; antifungal; nontoxicity; antitumor activity; antioxidant activity | Low mechanical strength; significant variations of properties based on the source of material | [84][85][86][87][88][89][90] |

3. Mechanism of Bacteria Adhesion on Surfaces

This entry is adapted from the peer-reviewed paper 10.3390/nano13202799

References

- Donlan, R.M. Biofilms: Microbial Life on Surfaces. Emerg. Infect. Dis. 2002, 8, 881–890.

- Davies, D. Understanding Biofilm Resistance to Antibacterial Agents. Nat. Rev. Drug Discov. 2003, 2, 114–122.

- Hernando-Amado, S.; Coque, T.M.; Baquero, F.; Martínez, J.L. Defining and Combating Antibiotic Resistance from One Health and Global Health Perspectives. Nat. Microbiol. 2019, 4, 1432–1442.

- Li, B.; Webster, T.J. Bacteria Antibiotic Resistance: New Challenges and Opportunities for Implant-Associated Orthopedic Infections. J. Orthop. Res. 2017, 36, 22–32.

- Varela, M.F.; Stephen, J.; Lekshmi, M.; Ojha, M.; Wenzel, N.; Sanford, L.M.; Hernandez, A.J.; Parvathi, A.; Kumar, S.H. Bacterial Resistance to Antimicrobial Agents. Antibiotics 2021, 10, 593.

- Ashtiani, R.E.; Alam, M.; Tavakolizadeh, S.; Abbasi, K. The Role of Biomaterials and Biocompatible Materials in Implant-Supported Dental Prosthesis. Complement. Alternat. Med. 2021, 2021, 3349433.

- Santos, G.A. The Importance of Metallic Materials as Biomaterials. Adv. Tissue Eng. Regen. Med. Open Access 2017, 3, 200–302.

- Klinke, T.; Daboul, A.; Maron, J.; Gredes, T.; Puls, R.; Jaghsi, A.; Biffar, R. Artifacts in Magnetic Resonance Imaging and Computed Tomography Caused by Dental Materials. PLoS ONE 2012, 7, e31766.

- Prakasam, M.; Locs, J.; Salma-Ancane, K.; Loca, D.; Largeteau, A.; Berzina-Cimdina, L. Biodegradable Materials and Metallic Implants-A Review. J. Funct. Biomater. 2017, 8, 44.

- Shekhawat, D.; Singh, A.; Bhardwaj, A.; Patnaik, A. A Short Review on Polymer, Metal and Ceramic Based Implant Materials. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1017, 012038.

- Mahanty, A.; Shikha, D. Changes in the Morphology, Mechanical Strength and Biocompatibility of Polymer and Metal/Polymer Fabricated Hydroxyapatite for Orthopaedic Implants: A Review. J. Polym. Eng. 2022, 42, 298–322.

- Peschke, E.; Ulloa, P.; Jansen, O.; Hoevener, J.-B. Metallic Implants in MRI—Hazards and Imaging Artifacts. Rofo 2021, 193, 1285–1293.

- Hargreaves, B.A.; Worters, P.W.; Pauly, K.B.; Pauly, J.M.; Koch, K.M.; Gold, G.E. Metal-Induced Artifacts in MRI. AJR Am. J. Roentgenol. 2011, 197, 547–555.

- Ramakrishna, S.; Mayer, J.; Wintermantel, E.; Leong, K.W. Biomedical Applications of Polymer-Composite Materials: A Review. Compos. Sci. Technol. 2001, 61, 1189–1224.

- Jaganathan, S.K.; Supriyanto, E.; Murugesan, S.; Balaji, A.; Asokan, M.K. Biomaterials in Cardiovascular Research: Applications and Clinical Implications. Biomed Res. Int. 2014, 2014, 459465.

- Teo, A.J.T.; Mishra, A.; Park, I.; Kim, Y.-J.; Park, W.-T.; Yoon, Y.-J. Polymeric Biomaterials for Medical Implants and Devices. ACS Biomater. Sci. Eng. 2016, 2, 454–472.

- Bozkurt, Y.; Karayel, E. 3D Printing Technology; Methods, Biomedical Applications, Future Opportunities and Trends. J. Mater. Res. Technol. 2021, 14, 1430–1450.

- Gonzalez, G.; Roppolo, I.; Pirri, C.F.; Chiappone, A. Current and Emerging Trends in Polymeric 3D Printed Microfluidic Devices. Addit. Manuf. 2022, 55, 102867.

- Kalirajan, C.; Dukle, A.; Nathanael, A.J.; Oh, T.-H.; Manivasagam, G. A Critical Review on Polymeric Biomaterials for Biomedical Applications. Polymers 2021, 13, 3015.

- Senevirathne, S.W.M.A.I.; Hasan, J.; Mathew, A.; Woodruff, M.; Yarlagadda, P.K.D.V. Bactericidal Efficiency of Micro- and Nanostructured Surfaces: A Critical Perspective. RSC Adv. 2021, 11, 1883–1900.

- Modaresifar, K.; Azizian, S.; Ganjian, M.; Fratila-Apachitei, L.E.; Zadpoor, A.A. Bactericidal Effects of Nanopatterns: A Systematic Review. Acta Biomater. 2019, 83, 29–36.

- Slepicka, P.; Kasalkova, N.S.; Siegel, J.; Kolska, Z.; Bacakova, L.; Svorcik, V. Nano-Structured and Functionalized Surfaces for Cytocompatibility Improvement and Bactericidal Action. Biotechnol. Adv. 2015, 33, 1120–1129.

- Patil, D.; Overland, M.; Stoller, M.; Chatterjee, K. Bioinspired Nanostructured Bactericidal Surfaces. Curr. Opin. Chem. Eng. 2021, 34, 100741.

- Tripathy, A.; Sen, P.; Su, B.; Briscoe, W.H. Natural and Bioinspired Nanostructured Bactericidal Surfaces. Adv. Colloid Interface Sci. 2017, 248, 85–104.

- Al-Shalawi, F.D.; Mohamed Ariff, A.H.; Jung, D.-W.; Mohd Ariffin, M.K.A.; Seng Kim, C.L.; Brabazon, D.; Al-Osaimi, M.O. Biomaterials as Implants in the Orthopedic Field for Regenerative Medicine: Metal versus Synthetic Polymers. Polymers 2023, 15, 2601.

- Asghari, F.; Samiei, M.; Adibkia, K.; Akbarzadeh, A.; Davaran, S. Biodegradable and Biocompatible Polymers for Tissue Engineering Application: A Review. Artif. Cells Nanomed. Biotechnol. 2017, 45, 185–192.

- Mi, H.-Y.; Salick, M.R.; Jing, X.; Jacques, B.R.; Crone, W.C.; Peng, X.-F.; Turng, L.-S. Characterization of Thermoplastic Polyurethane/Polylactic Acid (TPU/PLA) Tissue Engineering Scaffolds Fabricated by Microcellular Injection Molding. Mater. Sci. Eng. C Mater. Biol. Appl. 2013, 33, 4767–4776.

- Qian, J.; Xu, W.; Yong, X.; Jin, X.; Zhang, W. Fabrication and in Vitro Biocompatibility of Biomorphic PLGA/NHA Composite Scaffolds for Bone Tissue Engineering. Mater. Sci. Eng. C Mater. Biol. Appl. 2014, 36, 95–101.

- Badaraev, A.D.; Sidelev, D.V.; Yurjev, Y.N.; Bukal, V.R.; Tverdokhlebov, S.I. Modes Development of PLGA Scaffolds Modification by Magnetron Co-Sputtering of Cu and Ti Targets. J. Phys. Conf. Ser. 2021, 1799, 012001.

- Sun, F.; Sun, X.; Wang, H.; Li, C.; Zhao, Y.; Tian, J.; Lin, Y. Application of 3D-Printed, PLGA-Based Scaffolds in Bone Tissue Engineering. Int. J. Mol. Sci. 2022, 23, 5831.

- Maheshwari, U.; Samuel, S.; Nagiah, V.K. Fabrication and Evaluation of (PVA/HAp/PCL) Bilayer Composites as Potential Scaffolds for Bone Tissue Regeneration Application. Ceram Int. 2014, 40, 8469–8477.

- Hajiali, F.; Tajbakhsh, S.; Shojaei, A. Fabrication and Properties of Polycaprolactone Composites Containing Calcium Phosphate-Based Ceramics and Bioactive Glasses in Bone Tissue Engineering: A Review. Polym. Rev. 2018, 58, 164–207.

- Greene, J.P. Microstructures of Polymers. In Automotive Plastics and Composites; Elsevier: Amsterdam, The Netherlands, 2021; pp. 27–37.

- Gaaz, T.S.; Sulong, A.B.; Akhtar, M.N.; Kadhum, A.A.H.; Mohamad, A.B.; Al-Amiery, A.A. Properties and Applications of Polyvinyl Alcohol, Halloysite Nanotubes and Their Nanocomposites. Molecules 2015, 20, 22833–22847.

- Jiang, S.; Liu, S.; Feng, W. PVA Hydrogel Properties for Biomedical Application. J. Mech. Behav. Biomed. Mater. 2011, 4, 1228–1233.

- Nkhwa, S.; Lauriaga, K.F.; Kemal, E.; Deb, S. Poly(Vinyl Alcohol): Physical Approaches to Designing Biomaterials for Biomedical Applications. Conf. Pap. Sci. 2014, 2014, 403472.

- Zare, M.; Ghomi, E.R.; Venkatraman, P.D.; Ramakrishna, S. Silicone-based Biomaterials for Biomedical Applications: Antimicrobial Strategies and 3D Printing Technologies. J. Appl. Polym. Sci. 2021, 138, 50969.

- Ding, K.; Wang, Y.; Liu, S.; Wang, S.; Mi, J. Preparation of Medical Hydrophilic and Antibacterial Silicone Rubber via Surface Modification. RSC Adv. 2021, 11, 39950–39957.

- Carvalho, J.R.G.; Conde, G.; Antonioli, M.L.; Santana, C.H.; Littiere, T.O.; Dias, P.P.; Chinelatto, M.A.; Canola, P.A.; Zara, F.J.; Ferraz, G.C. Long-Term Evaluation of Poly (Lactic Acid) (PLA) Implants in a Horse: An Experimental Pilot Study. Molecules 2021, 26, 7224.

- Singhvi, M.S.; Zinjarde, S.S.; Gokhale, D.V. Polylactic Acid: Synthesis and Biomedical Applications. J. Appl. Microbiol. 2019, 127, 1612–1626.

- Casalini, T.; Rossi, F.; Castrovinci, A.; Perale, G. A Perspective on Polylactic Acid-Based Polymers Use for Nanoparticles Synthesis and Applications. Front. Bioeng. Biotechnol. 2019, 7, 259.

- Chen, T.; Zhao, X.; Weng, Y. Self-Assembled Polylactic Acid (PLA): Synthesis, Properties and Biomedical Applications. Front. Chem. 2022, 10, 1107620.

- Ebrahimi, F.; Ramezani Dana, H. Poly Lactic Acid (PLA) Polymers: From Properties to Biomedical Applications. Int. J. Polym. Mater. 2022, 71, 1117–1130.

- Pawar, R.P.; Tekale, S.U.; Shisodia, S.U.; Totre, J.T.; Domb, J.A. Biomedical Applications of Poly (Lactic Acid). Rec. Pat. Regen. Med. 2014, 4, 40–51.

- Ludwicka, K.; Kolodziejczyk, M.; Gendaszewska-Darmach, E.; Chrzanowski, M.; Jedrzejczak-Krzepkowska, M.; Rytczak, P.; Bielecki, S. Stable Composite of Bacterial Nanocellulose and Perforated Polypropylene Mesh for Biomedical Applications. J. Biomed. Mater. Res. B Appl. Biomater. 2019, 107, 978–987.

- Acik, G.; Altinkok, C.; Acik, B. Biodegradable and Antibacterial Chlorinated Polypropylene/Chitosan Based Composite Films for Biomedical Applications. Polym. Bull. 2022, 79, 9997–10011.

- Ali, U.; Karim, K.J.B.A.; Buang, N.A. A Review of the Properties and Applications of Poly (Methyl methacrylate) (PMMA). Polym. Rev. 2015, 55, 678–705.

- Frazer, R.Q.; Byron, R.T.; Osborne, P.B.; West, K.P. PMMA: An Essential Material in Medicine and Dentistry. J. Long Term Eff. Med. Implants 2005, 15, 629–639.

- Díez-Pascual, A.M. PMMA-Based Nanocomposites for Odontology Applications: A State-of-the-Art. Int. J. Mol. Sci. 2022, 23, 10288.

- Leigh, J.A. Use of PMMA in Expansion Dental Implants. J. Biomed. Mater. Res. 1975, 9, 233–242.

- Wang, H.; Lu, T.; Meng, F.; Zhu, H.; Liu, X. Enhanced Osteoblast Responses to Poly Ether Ether Ketone Surface Modified by Water Plasma Immersion Ion Implantation. Colloids Surf. B Biointerfaces 2014, 117, 89–97.

- Alqurashi, H.; Khurshid, Z.; Syed, A.U.Y.; Rashid Habib, S.; Rokaya, D.; Zafar, M.S. Polyetherketoneketone (PEKK): An Emerging Biomaterial for Oral Implants and Dental Prostheses. J. Adv. Res. 2021, 28, 87–95.

- Pietrocola, G.; Campoccia, D.; Motta, C.; Montanaro, L.; Arciola, C.R.; Speziale, P. Colonization and Infection of Indwelling Medical Devices by Staphylococcus Aureus with an Emphasis on Orthopedic Implants. Int. J. Mol. Sci. 2022, 23, 5958.

- Ardila, C.M.; Vivares-Builes, A.M. Antibiotic Resistance in Patients with Peri-Implantitis: A Systematic Scoping Review. Int. J. Environ. Res. Public Health 2022, 19, 15609.

- Momand, P.; Becktor, J.P.; Naimi-Akbar, A.; Tobin, G.; Götrick, B. Effect of Antibiotic Prophylaxis in Dental Implant Surgery: A Multicenter Placebo-controlled Double-blinded Randomized Clinical Trial. Clin. Implant Dent. Relat. Res. 2022, 24, 116–124.

- Rezić, I.; Majdak, M.; Ljoljić Bilić, V.; Pokrovac, I.; Martinaga, L.; Somogyi Škoc, M.; Kosalec, I. Development of Antibacterial Protective Coatings Active against MSSA and MRSA on Biodegradable Polymers. Polymers 2021, 13, 659.

- Dickson, M.N.; Liang, E.I.; Rodriguez, L.A.; Vollereaux, N.; Yee, A.F. Nanopatterned Polymer Surfaces with Bactericidal Properties. Biointerphases 2015, 10, 021010.

- Trott, A.T. Instruments, Suture Materials, and Closure Choices. In Wounds and Lacerations; Elsevier: Amsterdam, The Netherlands, 2012; pp. 82–94.

- Palispis, W.A.; Gupta, R. Biologic Augmentation in Peripheral Nerve Repair. In Biologics in Orthopaedic Surgery; Elsevier: Amsterdam, The Netherlands, 2019; pp. 141–163.

- Manoukian, O.S.; Sardashti, N.; Stedman, T.; Gailiunas, K.; Ojha, A.; Penalosa, A.; Mancuso, C.; Hobert, M.; Kumbar, S.G. Biomaterials for Tissue Engineering and Regenerative Medicine. In Encyclopedia of Biomedical Engineering; Elsevier: Amsterdam, The Netherlands, 2019; pp. 462–482.

- Houchin, M.L.; Topp, E.M. Physical Properties of PLGA Films during Polymer Degradation. J. Appl. Polym. Sci. 2009, 114, 2848–2854.

- Vignali, A.; Iannace, S.; Falcone, G.; Utzeri, R.; Stagnaro, P.; Bertini, F. Lightweight Poly(ε-Caprolactone) Composites with Surface Modified Hollow Glass Microspheres for Use in Rotational Molding: Thermal, Rheological and Mechanical Properties. Polymers 2019, 11, 624.

- Zhou, Z.-M.; Wang, K.; Lin, K.-W.; Wang, Y.-H.; Li, J.-Z. Influence of Characteristics of Thermoplastic Polyurethane on Graphene-Thermoplastic Polyurethane Composite Film. Micromachines 2021, 12, 129.

- Wang, W.; Wang, C. Polyurethane for Biomedical Applications: A Review of Recent Developments. In The Design and Manufacture of Medical Devices; Elsevier: Amsterdam, The Netherlands, 2012; pp. 115–151.

- Vermette, P.; Griesser, H.J.; Laroche, G.; Guidoin, R. Biomedical Applications of Polyurethanes. In Tissue Engineering Intelligence Unit 6 Landes Bioscience; Landes Bioscience: Georgetown, TX, USA, 2001.

- Hoque, M.B.; Solaiman; Alam, A.B.M.H.; Mahmud, H.; Nobi, A. Mechanical, Degradation and Water Uptake Properties of Fabric Reinforced Polypropylene Based Composites: Effect of Alkali on Composites. Fibers 2018, 6, 94.

- Islam, N.M.; Othman, N.; Ahmad, Z.; Ismail, H. Effect of Pro-Degradant Additives Concentration on Aging Properties of Polypropylene Films. Polym. Plast. Technol. Eng. 2010, 49, 272–278.

- Premkumar, J.; SonicaSree, K.; Sudhakar, T. Polymers in Biomedical Use. In Handbook of Polymer and Ceramic Nanotechnology; Springer International Publishing: Cham, Switzerland, 2021; pp. 1–28.

- Paradossi, G.; Cavalieri, F.; Chiessi, E.; Spagnoli, C.; Cowman, M.K.J. Poly(vinyl alcohol) as versatile biomaterial for potential biomedical applications. Mater. Sci. Mater. Med. 2003, 14, 687–691.

- Peng, C.; Chen, G. Preparation and Assessment of Heat-Treated α-Chitin Nanowhiskers Reinforced Poly(Viny alcohol) Film for Packaging Application. Materials 2018, 11, 1883.

- Hashim, H.; El-Mekawey, F.; El-Kashef, H.; Ghazy, R. Determination of Scattering Parameters of Polyvinyl Alcohol by Static Laser Scattering. Beni-Suef Univ. J. Basic Appl. Sci. 2014, 3, 203–208.

- Tubbs, R.K. Melting Point and Heat of Fusion of Poly(Vinyl Alcohol). J. Polym. Sci. A 1965, 3, 4181–4189.

- Gundapaneni, D.; Goswami, T. Thermal Isotherms in PMMA and Cell Necrosis during Total Hip Arthroplasty. J. Appl. Biomater. Funct. Mater. 2014, 12, 193–202.

- Clet, J.A.G.; Liou, N.-S.; Weng, C.-H.; Lin, Y.-S. A Parametric Study for Tensile Properties of Silicone Rubber Specimen Using the Bowden-Type Silicone Printer. Materials 2022, 15, 1729.

- Zhao, J.; Jiang, N.; Zhang, D.; He, B.; Chen, X. Study on Optimization of Damping Performance and Damping Temperature Range of Silicone Rubber by Polyborosiloxane Gel. Polymers 2020, 12, 1196.

- Verma, S.; Sharma, N.; Kango, S.; Sharma, S. Developments of PEEK (Polyetheretherketone) as a Biomedical Material: A Focused Review. Eur. Polym. J. 2021, 147, 110295.

- Senra, M.R.; de Marques, M.F.V.; Monteiro, S.N. Poly (Ether-Ether-Ketone) for Biomedical Applications: From Enhancing Bioactivity to Reinforced-Bioactive Composites—An Overview. Polymers 2023, 15, 373.

- Mbogori, M.; Vaish, A.; Vaishya, R.; Haleem, A.; Javaid, M. Poly-Ether-Ether-Ketone (PEEK) in Orthopaedic Practice- A Current Concept Review. J. Orthop. Rep. 2022, 1, 3–7.

- Sakihara, M.; Taira, Y.; Sawase, T. Effects of Sulfuric and Vinyl Sulfonic Acid Etchants on Bond Strength of Resin Composite to Polyetherketoneketone. Odontology 2019, 107, 158–164.

- Çaykara, T.; Sande, M.G.; Azoia, N.; Rodrigues, L.R.; Silva, C.J. Exploring the Potential of Polyethylene Terephthalate in the Design of Antibacterial Surfaces. Med. Microbiol. Immunol. 2020, 209, 363–372.

- Panowicz, R.; Konarzewski, M.; Durejko, T.; Szala, M.; Łazińska, M.; Czerwińska, M.; Prasuła, P. Properties of Polyethylene Terephthalate (PET) after Thermo-Oxidative Aging. Materials 2021, 14, 3833.

- Dhaka, V.; Singh, S.; Anil, A.G.; Sunil Kumar Naik, T.S.; Garg, S.; Samuel, J.; Kumar, M.; Ramamurthy, P.C.; Singh, J. Occurrence, Toxicity and Remediation of Polyethylene Terephthalate Plastics. A Review. Environ. Chem. Lett. 2022, 20, 1777–1800.

- Aumsuwan, N.; Heinhorst, S.; Urban, M.W. Antibacterial Surfaces on Expanded Polytetrafluoroethylene; Penicillin Attachment. Biomacromolecules 2007, 8, 713–718.

- Kalaycıoğlu, Z.; Torlak, E.; Akın-Evingür, G.; Özen, İ.; Erim, F.B. Antimicrobial and Physical Properties of Chitosan Films Incorporated with Turmeric Extract. Int. J. Biol. Macromol. 2017, 101, 882–888.

- Shahidi, F.; Arachchi, J.K.V.; Jeon, Y.-J. Food Applications of Chitin and Chitosans. Trends Food Sci. Technol. 1999, 10, 37–51.

- Shih, P.-Y.; Liao, Y.-T.; Tseng, Y.-K.; Deng, F.-S.; Lin, C.-H. A Potential Antifungal Effect of Chitosan against Candida Albicans Is Mediated via the Inhibition of SAGA Complex Component Expression and the Subsequent Alteration of Cell Surface Integrity. Front. Microbiol. 2019, 10, 602.

- Azuma, K.; Osaki, T.; Minami, S.; Okamoto, Y. Anticancer and Anti-Inflammatory Properties of Chitin and Chitosan Oligosaccharides. J. Funct. Biomater. 2015, 6, 33–49.

- Cho, Y.I.; No, H.K.; Meyers, S.P. Physicochemical Characteristics and Functional Properties of Various Commercial Chitin and Chitosan Products. J. Agric. Food Chem. 1998, 46, 3839–3843.

- Dong, Y.; Ruan, Y.; Wang, H.; Zhao, Y.; Bi, D. Studies on Glass Transition Temperature of Chitosan with Four Techniques. J. Appl. Polym. Sci. 2004, 93, 1553–1558.

- Jiang, S.; Qiao, C.; Wang, X.; Li, Z.; Yang, G. Structure and Properties of Chitosan/Sodium Dodecyl Sulfate Composite Films. RSC Adv. 2022, 12, 3969–3978.

- Cabral, J.P.S. Water Microbiology. Bacterial Pathogens and Water. Int. J. Environ. Res. Public Health 2010, 7, 3657–3703.

- Kreve, S.; Reis, A.C.D. Bacterial Adhesion to Biomaterials: What Regulates This Attachment? A Review. Jpn. Dent. Sci. Rev. 2021, 57, 85–96.

- Renner, L.D.; Weibel, D.B. Physicochemical Regulation of Biofilm Formation. MRS Bull. 2011, 36, 347–355.

- Zheng, S.; Bawazir, M.; Dhall, A.; Kim, H.-E.; He, L.; Heo, J.; Hwang, G. Implication of Surface Properties, Bacterial Motility, and Hydrodynamic Conditions on Bacterial Surface Sensing and Their Initial Adhesion. Front. Bioeng. Biotechnol. 2021, 9, 643722.

- Dunne, W.M., Jr. Bacterial Adhesion: Seen Any Good Biofilms Lately? Clin. Microbiol. Rev. 2002, 15, 155–166.

- Boks, N.P.; Busscher, H.J.; van der Mei, H.C.; Norde, W. Bond-Strengthening in Staphylococcal Adhesion to Hydrophilic and Hydrophobic Surfaces Using Atomic Force Microscopy. Langmuir 2008, 24, 12990–12994.

- Wilson, W.W.; Wade, M.M.; Holman, S.C.; Champlin, F.R. Status of Methods for Assessing Bacterial Cell Surface Charge Properties Based on Zeta Potential Measurements. J. Microbiol. Methods 2001, 43, 153–164.

- Hayashi, H.; Seiki, H.; Tsuneda, S.; Hirata, A.; Sasaki, H. Influence of Growth Phase on Bacterial Cell Electrokinetic Characteristics Examined by Soft Particle Electrophoresis Theory. J. Colloid Interface Sci. 2003, 264, 565–568.

- Tuson, H.H.; Weibel, D.B. Bacteria–Surface Interactions. Soft Matter 2013, 9, 4368.

- Limoli, D.H.; Jones, C.J.; Wozniak, D.J. Bacterial Extracellular Polysaccharides in Biofilm Formation and Function. Microbiol. Spectr. 2015, 3, 223–247.

- Kelleher, S.M.; Habimana, O.; Lawler, J.; O’ Reilly, B.; Daniels, S.; Casey, E.; Cowley, A. Cicada Wing Surface Topography: An Investigation into the Bactericidal Properties of Nanostructural Features. ACS Appl. Mater. Interfaces 2016, 8, 14966–14974.

- Watson, G.S.; Green, D.W.; Schwarzkopf, L.; Li, X.; Cribb, B.W.; Myhra, S.; Watson, J.A. A Gecko Skin Micro/Nano Structure—A Low Adhesion, Superhydrophobic, Anti-Wetting, Self-Cleaning, Biocompatible, Antibacterial Surface. Acta Biomater. 2015, 21, 109–122.