Advanced composite materials have excellent performance and broad engineering application prospects, and have received widespread attention in recent years. Advanced composite materials can mainly be divided into fiber-reinforced composite materials, laminated composite materials, matrix composite materials, and other composite materials.

1. Introduction

With the development of science and technology and the diversification of social needs, industrial development has increasingly higher requirements for material properties. Many types of materials have received widespread attention in this field, from commonly used composite materials (such as glass fibers) to advanced composite materials (such as carbon fibers, magnetorheological elastomers, metal substrates, etc.). Advanced composite materials have excellent performance and broad engineering application prospects, and have received widespread attention in recent years. Therefore, increasingly more scholars are beginning to study structural strengthening and resilience improvement in advanced composite materials, which is crucial for improving the safety, reliability, and durability of composite equipment. Advanced composite materials can be mainly divided into four categories: fiber-reinforced composite materials, laminated composite materials, matrix composite materials, and other composite materials. The distinction among these four material categories can be outlined in the following manner: Firstly, fiber-reinforced composite materials are mainly characterized by embedding high-strength fiber materials as reinforcing materials in a continuous matrix. Fibers can be carbon fiber, glass fiber, aramid fiber, etc. Usually, fibers in fiber-reinforced composite materials are distributed in a continuous form in the matrix to provide reinforcement effects. Secondly, from a precise perspective, laminated composite materials are also categorized within the realm of fiber-reinforced composite materials. However, unlike traditional fiber-reinforced composite materials, they are alternately stacked with fiber layers, each with a different fiber direction, and then formed by pressing layer by layer. The arrangement of these laminated fibers in different directions provides excellent anisotropic properties, allowing the material to exhibit excellent mechanical properties in multiple directions. Thirdly, matrix composite materials refer to composite materials formed by the combination of two or more different materials, with at least one material serving as the matrix and the other materials serving as reinforcing or filling materials. The matrix material is usually metal or ceramic, while the reinforcing material can be fiber, particle, or sheet-like material. Lastly, other composite materials do not belong to any of these types, including composite materials with special applications in certain fields such as viscoelastic materials, magnetorheological fluids, cement mortar, etc. The continuous research and improvement in the performance of these four types of advanced composite materials from different research perspectives is still of great significance.

2. Fiber-Reinforced Composite Materials in Structural Reinforcement and Resilience Enhancement

2.1. Comparison of Common Fiber-Reinforced Composite Materials and Their Mixing Techniques

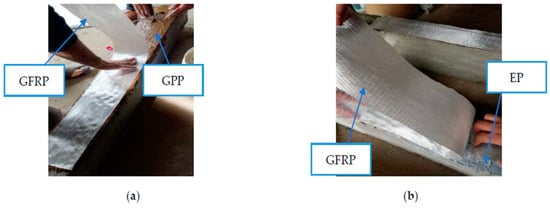

One of the biggest problems facing contemporary civil engineering is the strengthening, updating, and transformation of old structures. One of the most promising answers to these needs is the use of fiber-reinforced polymer (FRP). FRP is a composite material composed of synthetic fibers (such as carbon, glass, asbestos, beryllium, molybdenum, and aromatic polyamides) and synthetic polymer matrices (such as epoxy resin, polyester, and vinyl ester) [1]. Glass fiber-reinforced polymer (GFRP) and carbon fiber-reinforced polymer (CFRP) are the most suitable reinforcement materials for various civil engineering applications, as they have the highest temperature resistance, greatest strength, and lowest cost [2]. Bonding carbon fiber-reinforced polymer (CFRP) to the tensile surface of components can significantly improve structural strength. In addition, the type of adhesive material used is important to prevent debonding of the CFRP. Rageh has proposed two unique methods to enhance the adhesion between glass fiber-reinforced polymer (GFRP) and RC concrete surfaces, as shown in Figure 1 [3]. The purpose of Figure 1 is to demonstrate how CFRP is bonded to RC concrete beams through two different bonding materials, EP and GPP. The two adhesive materials are epoxy (EP) and geopolymer (GPP) with different proportions of short glass fiber (SGF). A more conventional method than the two proposed unique methods is to use epoxy resin to bond structural elements to steel plates. Through experiments and ABAQUS simulations, it has been proven that geopolymer slurries with and without short glass fibers in reinforced beams outperform epoxy resins in terms of performance and cost. At the same time, increasing the SGF ratio in GPP has a significant effect on improving the bearing capacity of the beam. GPP as an adhesive material enhances the maximum beam deflection and the beam ductility factor better than EP.

Figure 1. Strengthening RC beams with (

a) GFRP and (

b) EP (adapted from [

3]).

However, research has shown that there are various types of FRP debonding failures regardless the type of bonding material or bonding method used, including middle crack debonding, concrete cover separation, and plate end debonding. When FRP degumming fails, the effectiveness of the strengthening mechanism is greatly reduced [

6,

7,

8]. A solution to this problem may be to combine effective installation procedures with well-defined and controlled prestressing of CFRP materials. An anchor system is one of the commonly used installation procedures and strengthening technologies in construction engineering, which has a wide range of applications in strengthening and reinforcing concrete structures, steel structures, and other components. When FRP debonding fails, this anchoring system may significantly improve the debonding process and interface bonding between FRP and RC concrete surfaces [

9,

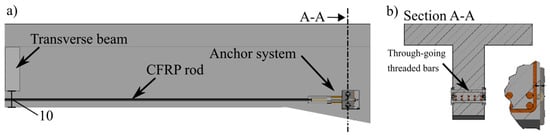

10]. Schmidt studied a new type of prestressed CFRP NSMR reinforcement anchorage system, as shown in

Figure 2 [

11]. The purpose of

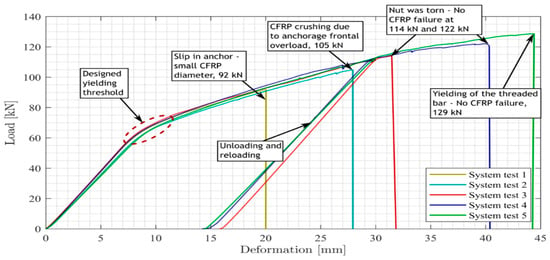

Figure 2 is to show the approximate appearance of the anchoring system. The system has undergone five laboratory tests and has been successfully used in pilot projects to reinforce cast-in-place concrete bridges. The study focuses on considering the system’s responsiveness to ensure that it can provide consistent load/deformation curves, yield thresholds, and yield mechanisms. All reinforcement systems have undergone in situ anticounterfeiting loading after installation and prestressing procedures have been carried out as required to eliminate any possible failure modes below the anticounterfeiting loading level, as is shown in

Figure 3. This study indicates that this new anchoring system has performed well in laboratory testing and pilot projects, and has great potential for application. The fatigue resistance of CFRP and GFRP materials is an important mechanical property. Engineering structures are often affected by cyclic loads, which can lead to material fatigue and adversely affect the service life and damage tolerance of components and connections. Alam detailed the effect of cyclic loading on the fatigue performance of carbon fiber composite materials [

12].

Figure 2. Side view (

a) and section view (

b) of the proposed strengthening method (adapted from [

11]).

Figure 3. Load deformation test curves (adapted from [

11]).

2.2. Methods for Improving the Performance of Fiber-Reinforced Composite Materials

Fiber-reinforced composite materials, as an important structural material, are influenced by various factors in their performance. In order to improve the performance of fiber-reinforced composite materials, many new improvement methods have emerged in recent years, such as surface modification, crosslinking, changing fiber orientation, additives, etc. Yang studied the analysis method of fiber fracture and orientation changes during the manufacturing process of short-fiber-reinforced composite materials [

14]. Using a simplified CFD model to study experimental phenomena, the results showed that nozzle diameter has a significant impact on fiber fracture and mechanical properties, with smaller nozzle diameters leading to higher shear rates and more fiber fracture. Fibers of different lengths have different fracture ratios at different printing stages. The direction of the fibers inside the bead is related to the height of the layer. A larger layer height leads to better alignment, but it will reduce mechanical performance. Song adopted a new fiber surface treatment method to improve interface compatibility, and the treated fibers are shown in

Figure 4.

Lee investigated how fiber orientation and distribution influenced the mechanical behavior of short-fiber-reinforced thermoplastic composites by using synchrotron X-ray imaging combined with in situ tensile testing and digital volume correlation analysis [

17]. This research found that fiber orientation is crucial for local compressive strain and anisotropic mechanical behavior, while load-direction strain is greatly affected by local volume fraction. The local volume fraction also determines the stiffness of the subvolumes that can be estimated from the analysis homogenization model. Batu studied the effects of different fiber volume fractions and fiber orientations on the mechanical properties of fake banana/glass fiber-reinforced hybrid composites [

18]. The composites were manufactured by hand-lay technology, and the tensile, flexural, and compressive properties were measured by ASTM standard test methods. The effects of volume fraction and fiber orientation on the properties of composite materials were analyzed, and the results showed that both significantly affect the mechanical properties of hybrid composite materials. Zhang prepared five types of paper based composite friction materials with different glass fiber contents through the papermaking process, and studied the effect of glass fiber on material properties [

19]. The results indicate that the sample with 10 wt.% glass fiber has the best mechanical properties and wear resistance. With the increase in glass fiber content, the shear strength first increases and then decreases, the compressibility increases, and the recovery rate decreases.

2.3. Model Algorithm for Optimizing Fiber-Reinforced Composite Materials

Establishing model optimization algorithms plays an important role in the development of fiber-reinforced composite materials. At present, the commonly used modeling methods include multiscale topology optimization, theoretical model, and so on. Optimization algorithms mainly include genetic algorithms, trial-and-error methods, etc. The application of these models and algorithms can better predict the mechanical properties of composite materials, thereby optimizing the ratio and preparation process of composite materials. Alhaddad uses artificial neural network modeling methods to predict the performance of composite materials, especially the ultimate tensile strength [

22]. At the same time, the artificial bee colony algorithm is used to optimize printing and material parameters to achieve maximum tensile strength. The research results indicate that fiber properties, fiber morphology, fiber orientation, and fiber volume fraction have the greatest impact on the tensile strength of composite materials. Duan introduced a novel multiscale and multimaterial anisotropic penalty (MMCAP) model [

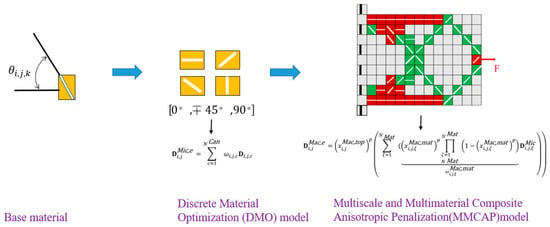

23]. This model is tailored for exploring the design optimization of composite structures with variable stiffness (VS), reinforced with fibers. The objective is to minimize structural compliance, as demonstrated in

Figure 5. This model utilizes improved solid isotropic material punishment (SIMP) and discrete material optimization (DMO) at the macro- and microscales, respectively, to achieve clear macromultimaterial structure topology and microspecific discrete fiber-laying angle selection. This method can effectively achieve multimaterial and multiscale design optimization of fiber-reinforced composite structures, achieving clear macroscopic topology of multimaterial structures and microscopic fiber-laying angles. This provides a new implementation strategy for lightweight, multimaterial, and multiscale design optimization of composite materials. Obid has proposed a new constitutive model that can describe the tensile and compressive responses of nonlinear anisotropic fiber materials under general stress states [

24]. Built upon the Ramberg–Osgood model, this framework is expanded by incorporating triaxial stress invariance as a marker for stress-state classification. This extension aims to account for tension–compression asymmetry within multiaxial stress conditions. Compared to other models, this model provides an elegant formula for describing all phenomena and implements a simple calibration program. Therefore, this method can describe the nonlinear behavior and tension compression asymmetry of fiber-reinforced composite materials, and has better advantages.

Figure 5. Schematic showing concurrent macroscale and multimaterial topology design optimization for composite laminates with minimum structural compliance.

2.4. Application of Fiber-Reinforced Composite Materials in Practical Projects

However, whether it is new technological methods or innovative modeling and simulation methods, their core goal is to improve practical applications. The mixed fiber technology in technical methods can significantly improve the strength and stiffness of materials, thereby producing lighter and higher strength materials for practical engineering, such as civil infrastructure reinforcement. The proposal for novel modeling and simulation methods, such as the MMCAP model, provides a new solution for lightweight application and multiscale optimization application of composite materials. Fiber-reinforced composite materials have been widely used in practical engineering and projects, mainly in fields such as aerospace, automotive, shipbuilding, architecture, electronics, etc. Lv used ultrasonic-assisted electroplating technology to evenly coat copper coatings on the surface of carbon fibers to improve their wettability with the aluminum substrate [

27]. This research found a linear relationship between the thickness of copper coatings and electroplating time. At the same time, copper coating can promote the infiltration of aluminum melt into carbon fiber bundles, thereby enhancing the mechanical properties of composite materials. The optimal coating thickness is 1.5 microns, and the tensile strength of the composite material is 169 MPa, the elastic modulus is 80 GPa, and the elongation is 4.2%. Therefore, ultrasonic-assisted electroplating technology can improve the performance of carbon fiber-reinforced aluminum matrix composites and enhance their application prospects in industrial and commercial applications. Kumar explored the preparation of carbon fiber powder-reinforced polymer composites and their application in pump impellers [

28].

Saintane prepared two composite samples using carbon-based materials and powder metallurgy methods to manufacture carbon fiber-reinforced polymer composites to improve friction performance [

30]. By conducting shore hardness testing and compression testing on the sample, it was proven that Sample 2 had higher hardness and compression strength. The results of this study indicate that the carbon-based polymer friction composite material manufactured has excellent mechanical properties and can be used as a candidate material for commercial brake pads and other application fields.

3. Laminated Composite Materials in Structural Reinforcement and Resilience Enhancement

3.1. Effect of Changing the Deposition Order on the Properties of Laminated Composite Materials

Laminated composite materials are composite materials composed of two or more layers of different materials combined in a specific way, with good mechanical properties and various application fields. In order to further improve the strength and resilience of laminated composite materials, various new methods have been proposed, for example, changing the deposition sequence, adding synthetic fibers, interlayer reinforcement technology, design optimization, explosion-proof welding methods, etc. The deposition sequence and deposition materials are important factors affecting laminated composite materials. In recent years, many researchers have conducted experiments on material manufacturing and deposition sequence.

Bhaburi et al. estimated the surface/interface quality, microstructure, and mechanical properties of hybrid aluminum parts, and improved their microhardness and joint strength through heat treatment [

37]. In the field of laminated composite materials, SS316L and Inconel 718 alloy laminated composite materials are manufactured through mixed additives and subtraction to obtain materials with good mechanical and high-temperature properties.

3.2. Methods for Improving the Performance of Laminated Composite Materials

In addition to the main method of changing the sedimentary sequence, many other new methods have been proposed in recent years. Kumar studied the preparation process for titanium alloy laminates for multilayer composite material input [

39]. This study used a single stage process instead of rolling to prepare laminated plates, and investigated the sliding wear behavior of Ti-6Al-4V laminated plates. The research results indicate that composite materials have better wear resistance and lower wear rate than matrix materials, and the hardness value of composite materials is increased by about 25% compared to matrix materials. Biswas used the finite element method to study the effect of fiber orientation on the tensile, bending, and fatigue properties of bidirectional glass and carbon fiber-reinforced composite laminates [

40]. The experimental results show that laminates with a laminate angle of (0°/90°) exhibit the maximum tensile strength, bending strength, and fatigue life. The tensile strength, bending strength, and fatigue life decrease with the increase in layer angle, and the layer angle reaches the minimum value (±45°). Therefore, the fiber orientation of composite materials can affect the quality of laminated materials.

3.3. Modeling and Simulation for Optimization of Laminated Composite Materials

At present, models and software simulations have been widely established and applied toward laminated composite materials. Among them, finite element analysis and the genetic algorithm are the most commonly used methods, which can simulate the mechanical behavior of composite materials. In addition, multiscale simulation methods based on microstructure are gradually receiving attention, which can more realistically reflect the microstructure and mechanical properties of composite materials. Coelho described a computational model for designing bimaterial composite laminates using a multiscale topology optimization model to optimize the design of structures and materials [

48]. The model is based on a hierarchical optimization strategy, taking into account the manufacturing process and basic characteristics, and using a mixed set of micro- and macrodesign variables to characterize the distribution of the two materials. This method has yielded better design results, which helps to provide a deeper understanding of the effectiveness of the microstructure characteristics of composite laminates. Shi employed the LS-DYNA software to simulate the dynamic and progressive failure process in laminated composite materials [

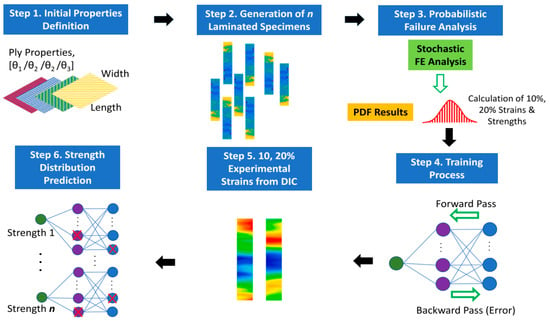

49]. This simulation utilized the MAT_162 material models, encompassing factors such as strain rate, damage evolution, and anisotropy effects. To determine the model parameters, traditional standard and nonstandard testing methods were used, including double shear and Brazilian testing. Through experiments and numerical simulation, the fidelity of the developed material model parameters was verified, including the modulus and strength in plane and full thickness directions, fiber matrix splitting and shear fracture, and other failure modes. Nastos introduced a strength prediction method for composite laminates based on a combination of numerical and nondestructive testing, aiming to predict strength through nondestructive testing, as shown in

Figure 10 [

50].

Figure 10. The concept of the nondestructive methodology for predicting strength in composite laminates (adapted from [

50]).

Yashiro conducted a mode II interlaminar fracture resilience test (DENT) and examined it through elastic–plastic finite element analysis [

51]. The aim was to explore the effect of material nonlinearity on the assessment of interlaminar fracture resilience within composite materials. The study revealed that the plastic zone size in the DENT test remains unaffected by the crack length. Furthermore, the disparity between the estimated energy release rate and the integration within the plastic zone size is relatively minor when compared to other quasi-static mode II interlaminar fracture resilience tests. The CC method is an effective way to evaluate the resilience of adhesives, and even significant plastic deformation does not affect the test results. These findings can be useful in evaluating the fracture resilience of laminated composite materials. Torabi described conducting experimental and theoretical crack investigations on laminated glass/epoxy composites to evaluate their load-bearing capacity [

52]. By using a new concept called virtual isotropic material (VIMC) and combining predictions from two brittle fracture models, namely maximum tangential stress (MTS) and average stress (MS), the fracture behavior of laminated materials can be predicted. This prediction is necessary because laminated materials have complex structures and predicting their load-bearing capacity is difficult. The research results indicate that using VIMC and LENFM filters to predict the load-bearing capacity of laminated materials can be directly, quickly, and conveniently predicted without the need for complex analysis.

3.4. Application of Laminated Composite Materials in Practical Engineering Projects

Changing the deposition sequence in technical methods can produce laminates with different resilience and tensile strength, and laminates manufactured using nanotechnology can be applied to very precise electrical components. The combination of new numerical values and nondestructive testing for strength prediction methods is of great significance for testing the performance of laminates, which is of great significance for practical applications. In recent years, there have been many new technological breakthroughs and practical applications in laminated composite materials. Among them, nanotechnology has been widely developed. One of the most effective uses of nanofibers or nanoparticles is as a staggered reinforcement for composite laminates, which can be embedded between two layers of laminates to study their effect on the overall performance of composite laminates. Bodduru studied the performance changes when E-glass fiber and sisal fiber were mixed together to manufacture laminates reinforced with epoxy polymer composites [

55]. Researchers treated sisal fibers with alkali (NaOH) and made laminated samples using the manual lamination method.

Palazzetti et al. reviewed the latest composite laminate technology, which interweaves electrospun nanofibers to enhance the material. The research in this literature adopts mechanical methods and focuses on the main load types. Researchers conducted in-depth research on the role and working mechanism of nanofibers and summarized the main results. The research results indicate that the nanofiber interlayer between the layers of the laminate can bring significant benefits from a structural and load-bearing perspective, while its impact on the weight and size of the laminate is minimal and even negligible. Compared with basic materials, the interlaced laminated sheets of nanofibers can significantly improve the mechanical properties of the material [

62,

63].

4. Matrix Composite Materials in Structural Reinforcement and Resilience Enhancement

4.1. Methods for Improving the Properties of Metal Matrix Composite

The strength and resilience improvement in metal matrix composite is one of the current research hotspots. Its new methods mainly focus on the stirring–casting method, material microstructure design, processing technology optimization, surface modification, and addition of appropriate second equalities. Rajaram studied the effect of particle weight fraction on the mechanical properties of metal matrix composite (MMC) by stirring–casting [

66]. Metal matrix was prepared using aluminum (Al7075) and quarry rock dust powder, with 0%, 5%, and 7.5% rock powder and Al7075 added. Hardness, bending, and wear tests were conducted, and machining was carried out according to ASTM standards. This research found that the quarry stone powder of Al7075 has a higher hardness and lower wear rate, and the metal matrix containing 7.5 wt.% has the highest bending degree. Therefore, sample 2 has higher hardness and wear resistance.

4.2. Methods for Improving the Properties of Ceramic Matrix Composite

The strength and resilience improvement in ceramic matrix composite is one of the research focuses in the field of composites. Among them, using new methods to enhance strength and resilience is one of the main directions of current research, and common methods include nanoparticle reinforcement, adding new elements, microstructure regulation, and powder metallurgy, among others. Li found that the Nb content and sintering temperature significantly affect the phase formation and microstructure of the sample, while the width of the Ti2

AlC layered structure increases with the increase in sintering temperature [

80]. The optimal compressive strength of

Ti2AlC MAX phase ceramic matrix composites was obtained under optimized Nb content (1 wt.%) and sintering temperature (1300 °C). This work demonstrates that LPBF and sintering methods can be used to design composite materials, and explores the properties of

Ti2AlC MAX phase ceramics from the perspective of microalloying. Xi investigated the effect of mixed ceramic reinforcement content on the mechanical properties of aluminum matrix composites [

81]. They used laser powder bed fusion to prepare composites reinforced with different contents of (ZrC TiC) ceramic fractions. The results showed that with the increase in mixed ceramic content, the laser absorption behavior of the composite material is enhanced, and the fraction of nanoparticles increases. The composites containing 20 wt.% ceramics exhibited high micro- and nanohardness, and the elastic modulus and tensile strength of 15 wt.% (ZrC + TiC)/Al composite material were significantly higher than the unreinforced Al matrix, due to the formation of nanoprecipitates and coherent binding at the reinforcement/matrix interface.

4.3. Application of Matrix Composite Materials in Practical Engineering Projects

Matrix composite materials have a wide range of applications due to their special properties, and have been applied in recent years in biomedical, biodegradable, brake pads, radiation shielding, and other related fields. Manso studied how to improve the wear resistance of metal bone implants by adding hard reinforcements [

91]. Studying the use of nontoxic and nonallergenic β, two different in situ composite materials were prepared by adding NbC powder to Ti-Nb alloy as the matrix material. This strategy can achieve the synthesis of reinforcing phases during the manufacturing process and achieve strong interface bonding through high chemical compatibility. The results showed that the friction and corrosion properties of both composite materials were improved, and the wear amount was less than 50%. These results indicate that the matrix composite material is a potential bone implant material that can improve its wear resistance and degradation process. Kabir’s study introduced a zinc-based composite material for biodegradable implant materials, which added graphene nanosheets to improve its mechanical properties and corrosion behavior [

92]. The research results show that the composite material has high mechanical properties and good biocompatibility, making it a potential biodegradable implant material. In the past few years, carbon ceramic brakes have been favored for their light weight, high-temperature resistance, and long lifespan.

5. Other Composite Materials in Structural Reinforcement and Resilience Enhancement

5.1. Theoretical Research and Practical Application of Viscoelastic Materials

Viscoelastic materials have characteristics such as elastic behavior, noninstantaneous deformation, and viscosity, making them the main materials for manufacturing viscoelastic dampers. Xu developed viscoelastic materials based on different matrix rubbers and conducted experiments [

96]. The results indicate that the viscoelastic damper based on a nitrile rubber matrix has high energy dissipation capacity, while the viscoelastic damper based on a silicone rubber matrix has stable performance under different working conditions. To elucidate its mechanical properties, an equivalent high-order fractional derivative model considering temperature and frequency effects was proposed, and numerical results consistent with experimental results were obtained. Xu introduced the application of viscoelastic dampers in seismic reduction [

97]. Firstly, the mathematical model of VE dampers and the dynamic analysis of structures with VE dampers were introduced. Then, an equivalent standard solid model is used to describe the effect of temperature on the energy absorption characteristics of VE dampers. Finally, the response of a three-story reinforced-concrete frame structure with and without VE dampers was studied through elastic–plastic time field analysis, frequency field analysis, and shaking table tests. The results showed that VE dampers can be modeled using an equivalent standard solid model, and are effective in reducing structural seismic response. Xu introduced the preparation and performance testing of acrylic viscoelastic dampers [

98].

5.2. Theoretical Research and Practical Application of Magnetorheological Materials

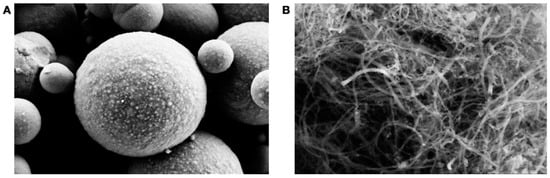

Magnetorheological fluid has the characteristics of adjustability, fast response speed, small size, and light weight, making it the main material for manufacturing magnetorheological dampers. Xu conducted research on magnetorheological fluids and their composite materials [

101]. Magnetorheological fluid is an intelligent material widely used for structural vibration reduction, consisting of iron particles, carrier fluid, and additives. One of the research hotspots is the expectation that ferromagnetic particles have low density and high magnetic properties. This article uses ultrasonic and mechanical stirring–grafting techniques to coat multiwalled carbon nanotubes (MWNT) onto carbonyl iron (CI) particles; an electron microscope image is shown in

Figure 17. In addition, shear yield stress tests were conducted on self-made composite materials, and the test results were compared with the theoretical values of the single- and double-chain micromechanical model to verify the effectiveness and accuracy of the proposed model. Xu discussed how to control the vibration response in aerospace or precision instrument platforms in the frequency range of 0 to 500 Hz [

102].

Figure 17. The electron micrographs of (

A) original CI particles and (

B) MWNTs (adapted from [

101]).

5.3. Performance Improvement and Practical Application of Concrete Mortar Composite Materials

Concrete and mortar composite materials are widely used in the construction industry, and their strength and resilience are key factors affecting their performance. In recent years, researchers have proposed various new methods to improve the strength and resilience of concrete and mortar composite materials, for example, the addition of nanomaterials, the use of additives, and microstructure regulation. Malakopoulos and Salifoglou studied the properties of mortars composed of Portland limestone cement, calcium carbonate, butyl stearate, and oleic acid [

107]. The results indicate that compared to ordinary Portland limestone cement mortar, adding calcium carbonate, butyl stearate, and oleic acid to the mortar mixture can improve durability. The use of alkaline activators to chemically polymerize aluminosilicate materials for the production of alkaline-activated materials can effectively reduce greenhouse gas emissions from ordinary Portland cement (OPC) (approximately 73%).

Dobiszewska studied the effect of concrete production on the environment and used waste byproducts as substitutes for clinker [

111]. Rock dust is considered a potential alternative material for the production of cement composite materials. However, there are conflicting findings in the literature regarding the effect of partial substitution of cement on the physical and mechanical properties and durability of cement composite materials. The effect of using rock dust instead of cement is mainly related to the filler effect. The higher the amount of replacement cement, the lower the mechanical properties and durability of cement composite materials. However, replacing cement with up to 10–15% rock powder will not affect the performance of cement composite materials. Sara uses construction and demolition (C&D) waste instead of natural sand, and uses ground and granulated blast furnace slag (GGBFS) instead of cement to manufacture self-compacting mortar [

112]. The research results indicate that using recycled concrete sand (RCS) instead of natural sand can produce self-compacting mortar, with an optimal yield of 50%. Replacing cement with GGBFS can offset the negative effects of mortar porosity and capillary water absorption, and improve long-term compressive strength.

6. Conclusions

Advanced composite materials, such as fiber-reinforced composites, laminated composites, matrix composites, and other advanced variants, possess distinct advantages in enhancing structural reinforcement and improving resilience. The main representatives of fiber-reinforced composite materials, CFRP and GFRP, are characterized by their light weight and high strength, and are widely used in civil engineering, aerospace, and automotive industries. Laminated composite materials can exhibit excellent crack resistance and resilience by changing the deposition sequence and optimization modeling, and are widely used in fields such as electrical components and piezoelectric sensors. The addition of nanoparticles or fiber-reinforced materials to the matrix enhances the performance of the matrix itself. It has good structural reinforcement effect, while also providing a certain degree of resilience and durability, and is widely used in fields such as construction and shipbuilding. Other advanced composite materials, such as viscoelastic materials and magnetorheological fluids, are very good energy dissipation materials with good resilience, and are widely used in the production of dampers and applied in other engineering fields. They are of great significance for seismic reduction and reinforcement of buildings.

This entry is adapted from the peer-reviewed paper 10.3390/buildings13102406