1. Introduction

As one of the most significant oil-producing crops worldwide, peanuts generate a multitude of by-products during the oil extraction process. Despite containing various nutrients such as protein, carbohydrates, and polyphenols, these peanut by-products in peanut meal have been primarily used in livestock feed for a long time with limited high-value applications. Fortunately, recent decades have witnessed an increasing focus on exploring the high-value utilization of peanut meal through methods like modification, (enzymatic) hydrolysis, and crosslinking, among others. Consequently, the by-products derived from peanut oil extraction possess versatile applications across different fields.

2. The Application of Peanut Meal and Its Hydrolysates in the Field of Food Processing

In order to enhance the utilization of peanut meal in the food industry, enzymatic hydrolysis and fermentation methods are commonly employed for texture, structure, and flavor modification. These treatments facilitate the conversion of peanut meal samples into food flavor agents. For instance, Zhang et al. [

78] used protease to hydrolyze protein from nonfat peanut meal and evaluated the physicochemical properties and sensory attributes of the resulting products. Various enzymes such as GA (Genencor Alkaline Protease), GN (Genencor Neutral Protease), and Protamex were used for hydrolyzing nonfat peanut meal protein. By assessing both the physicochemical properties and sensory attributes of the hydrolyzed products, it was observed that GA- and Protamex-treated products exhibited astringent and bitter taste profiles while GN-treated products possessed a pleasant umami flavor. This underscores their potential as food flavoring agents following enzymatic-hydrolysis-induced modifications in sensory properties. In terms of fermentation treatment, Zeng et al. [

79] developed a bacterial fermentation process using

Bacillus subtilis on peanut meal based on enzymatic hydrolysates to generate high-value-added products with desired flavors and an elevated nutritional content. Furthermore, the Maillard reaction enhanced both the flavor profile and antioxidant activity of peanut meal’s hydrolysates, rendering them suitable condiments capable of enhancing both the taste experience and beneficial antioxidant properties in various foods. Wang et al. [

80] used a flavor protease and trypsin to hydrolyze peanut meal. Through the electronic tongue test, the results revealed that hydrolysates exhibited a strong umami taste followed by saltiness then sourness, indicating its potential candidacy as a food condiment.

Additionally, peanut meal can undergo further processing to yield plant-based protein meat. Zhang et al. [

81] utilized a high-water extrusion method through an extruder to process peanut meal, resulting in the modification and unfolding of the molecular structure of peanut protein. Subsequently, through the influence of hydrogen bonds and disulfide bonds, the molecules were reorganized and gradually formed a fibrous meat-like structure, ultimately creating a form of “plant-based protein meat”.

Due to its high protein content of superior quality, peanut meal can be enzymatically hydrolyzed using Alcalase and other enzymes to extract bioactive peptides for the development of nutritious functional foods. The resulting peptides exhibit diverse tastes and bioactivities depending on the extent of hydrolysis [

82]. Ye et al. [

83] utilized Alcalase to hydrolyze peanut meal and obtain a mixture of peptides, which were subsequently combined with selenium nanoparticles (SeNPs) through electrostatic interaction, leading to the formation of composite colloidal particles comprising peanut meal peptides and selenium. These particles were further utilized in the development of nutritional functional food products. Zhang et al. [

85] employed papain-hydrolyzed peptides and microwave extraction techniques to break down peanut meal into small-molecule peptides that demonstrated multiple bioactivities, including antioxidant properties, free radical scavenging abilities, and angiotensin converting enzyme (ACE) inhibition. Consequently, these papain-hydrolyzed peanut peptides could be applied as ingredients in functional foods. In a different approach, Kahlon et al. [

86] did not subject peanut meal to hydrolysis but instead used it as a primary raw material ingredient along with okra and sorghum for the production of a snack called sorghum–peanut meal–okra.

In recent decades, a growing number of studies have focused on the fermentation of peanut meal by probiotics in order to enhance its economic value and unlock its multifunctional properties. For instance, Jiang et al. [

87] conducted a fermentation process using

Bacillus subtilis on peanut meal and observed that the fermented peanut meal improved the learning and memory abilities of mice with dysbiosis. Additionally, it helped to alleviate intestinal disorders without any adverse effects on mice growth. Similarly, Zhang et al. [

68] also utilized

Bacillus subtilis for fermenting peanut meal, resulting in the production of hydrolyzed peanut peptides. Interestingly, they found that a longer fermentation time led to an increased content of peanut peptides; moreover, highly hydrolyzed peanut peptide exhibited an enhanced antioxidant activity and higher levels of acidic amino acids. These studies demonstrate the potential of probiotic fermentation to enhance the nutritional and functional properties of peanut meal, leading to the development of value-added products with improved health benefits.

3. The Application of Peanut Meal and Its Hydrolysates in the Field of Breeding

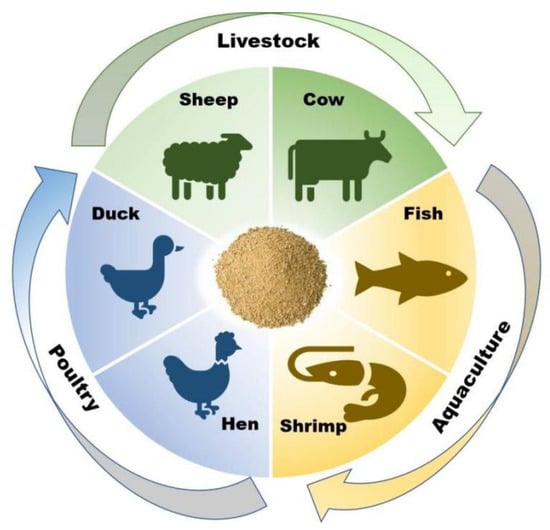

The by-products generated from oil extraction, namely peanut meal and soybean meal, exhibit similarities in terms of the abundant protein and dietary fiber contained. Typically, soybean meal surpasses peanut meal in terms of its higher vitamin and amino acid content. However, due to the coarser flavor profile of these by-products, peanut meal and soybean meal have primarily been utilized in livestock and poultry breeding for an extended period. It is worth noting that compared to soybean meal, peanut meal contains a higher oil content and is more susceptible to bacterial contamination. As a result, peanut meal is frequently employed in the field of livestock breeding as a partial substitute for the original feed (such as soybean meal). Conversely, in aquaculture, peanut meal is used partially as a replacement for fish meal (Figure 3).

Figure 3. The applications of peanut meal and its hydrolysates in the field of breeding.

3.1. The Application of Peanut Meal and Its Hydrolysates in the Aquaculture Field

Fish meal is consistently in high demand within the aquaculture industry. However, fish meal resources are constantly influenced by various factors, such as climate variability (e.g., El Niño events) and price fluctuations [

88,

102,

103,

104]. Consequently, an increasing number of individuals have opted to produce fish meal using plant-based proteins [

105,

106]. Amongst a plethora of plant proteins available, soybean meal and peanut meal have been identified as exceptional raw materials for fish meal production due to their elevated levels of crude protein and essential amino acids.

Ye et al. [

88] investigated the substitution of fish meal with peanut meal as a feed for the juvenile hybrid grouper (

Epinephelus fuscoguttatus ♀ ×

Epinephelus lanceolatus ♂) and assessed its effects on growth performance, immunity, and gut microbiota over a duration of 10 weeks. The findings revealed that the replacement of fish meal with peanut meal did not yield any significant effects on growth performance, feed utilization, somatic indices, or whole-body composition (

p > 0.05). Li et al. [

107] used peanut meal as a substitute for the original cottonseed protein or soybean protein in the diets of Channel Catfish. Following a 9-week investigation, the findings demonstrated that peanut meal can effectively replace up to 25 wt% of the original cottonseed meal or soybean meal without any detrimental impact on fish growth, feed efficiency, and the body composition of fish.

Vo et al. [

90] assessed the suitability of three types of processed peanut meals, namely untreated peanut meal (UPM), fermented peanut meal (FPM), and germinated peanut meal (GPM), as potential replacements for fish meal in barramundi (

Lates calcarifer) diets within a commercial aquaculture setting. The findings revealed that these peanut meals could partially substitute fish meal in the diet of juvenile barramundi, with a 60% replacement of GPM and UPM resulting in increased lipid droplet accumulation in the liver, reduced myodegeneration in muscle tissue, and reduced acidic mucin content in the distal gut.

3.2. The Application of Peanut Meal and Its Hydrolysates in the Poultry Breeding Field

In the field of poultry breeding, peanut meal can serve as a viable alternative to soybean meal in terms of protein and unsaturated fatty acid content, thereby effectively balancing the amino acid profile and enhancing unsaturated fatty acid levels [

101]. Xia et al. [

96] conducted a study to assess the impact of replacing soybean meal with peanut meal on egg production, egg quality, oxidative status, and yolk fatty acid profile in laying ducks. The findings revealed that up to 75% substitution of soybean meal with peanut meal had no detrimental effects on the egg-laying performance or egg quality in laying ducks. However, the complete replacement of soybean meals by peanut meal resulted in a reduced egg production and antioxidant capacity of eggs, along with an elevated ω-6 and ω-3 fatty acid ratio in the yolk. Saleh et al. [

95] incorporated peanut and linseed meal into broiler feed along with an enzyme mixture comprising xylanase, cellulase, β-mannanase, phytase, α-amylase, and protease. Following a 35-day feeding period, they found that the addition of exogenous protease and 50% peanut meal enhanced the peptide and amino acid absorption efficiency while also upregulating mRNA expression in the duodenum. Pesti et al. [

98] compared two types of diets at three protein levels (16, 18.5, and 21%) for 22-to-34-week-old commercial Leghorns, where one group was a corn–peanut meal-based diet and the other group was a corn–soybean meal-based diet. The results demonstrated that during the initial 6-week period, hens fed with peanut meal exhibited a slight reduction in egg size (

p < 0.05), while no significant difference in egg size was observed during the latter 6 weeks (

p > 0.14). In terms of egg quality, hens fed with peanut meal demonstrated a superior interior quality at both 26 and 30 weeks of age. Moreover, following a 2-week storage experiment, eggs from hens fed with peanut meal displayed higher Haugh units when refrigerated (4 °C,

p < 0.05) or stored at room temperature (20 °C,

p < 0.10) compared to those from soybean meal-fed hens. Additionally, the specific gravity of eggs from hens fed with peanut meal was marginally lower than that of soybean meal-fed hens. These finding suggests that incorporating peanut meal into laying hen diets can be advantageous.

3.3. The Application of Peanut Meal and Its Hydrolysates in the Livestock

Breeding Field

Peanut meal has been a primary component of livestock feed for an extended period, including cows, sheep, pigs, and horses. For example, dos Santos et al. [

99] conducted an experiment using peanut meal to replace soybean meal in the diet of 12 lactating cows for 60 days. The results exhibited that substituting soybean meal with peanut meal had no adverse effect on the dry matter and nutrient intake and digestibility in cows. Moreover, there was no significant difference observed in microbial protein synthesis and nitrogen balance, the microbial nitrogen synthesis and microbial protein synthesis efficiency presented no difference either. Additionally, the nitrogen balance and retention rates were also similar. Therefore, regions where peanut meal is more cost-effective can entirely replace soybean meal in dairy cow diets without affecting nitrogen balance or microbial protein synthesis.

In terms of sheep, de Lima Valença et al. [

101] conducted a study on 40 uncastrated male Ile de France lambs, wherein soybean meal was partially substituted with peanut meal to evaluated the microbiological and physicochemical characteristics of fresh and aged semimembranosus muscle in lambs. The results showed that peanut meal can be utilized as a partial replacement for soybean meal in lambs’ diets without compromising the quality of lamb meat.

4. Application of Peanut Meal and Its Hydrolysates in Industrial Field

As a by-product of oil extraction, peanut meal has limited industrial applications. However, considering its protein content, which contains numerous active groups, particularly globulin, it could serve as a valuable source for industrial processing. Currently, several plant proteins have been utilized in the industrial field, such as soybean protein, wheat, and zein, as well as some relatively lesser-known proteins such as sunflower proteins, pea proteins, and mung bean proteins. Therefore, the potential exists to apply peanut protein and its hydrolysates in the industrial field

4.1. The Utilization of Peanut Meal and Its Hydrolysates for Plant Protein-Based

Adhesives Preparation

The wood adhesive industry has long relied on petroleum-based chemicals for their exceptional performance and cost-effectiveness. However, these adhesives derived from petroleum have the potential to emit formaldehyde, thus giving rise to significant environmental concerns.

In recent years, plant-based adhesives have garnered significant attention due to their renewable and environmentally friendly properties. When it comes to plant-based adhesives, soybean meal, a by-product generated during the extraction of soybean oil, has long been the preferred choice for fabricating protein-based wood adhesive. However, challenges such as a low solid content, high viscosity, and limited water resistance have impeded the widespread application and development of soybean meal-based adhesives in various industries [

111,

118]. In order to enhance the adhesion performance of plant protein-based wood adhesives, peanut meal has been increasingly considered as a viable material for their preparation. Chen and colleagues [

114] used hot-pressed and cold-pressed peanut meal as raw materials to develop two distinct types of plant-based adhesive. Through a series of tests, they found that the treatment temperature and modifier quantity were not critical factors. However, incorporating hot-pressed peanut meal and adding SDS significantly enhanced the adhesive strength of the peanut meal-based adhesive, which could achieve an average value of 1.05 ± 0.07 MPa. The utilization of peanut meal by Li et al. [

115] in the preparation of wood adhesives through SDS and ethylene glycol diglycidyl ether (EGDE) modification resulted in a significant improvement (90%) in water resistance, meeting the requirements for interior wood use. This enhancement can be attributed to the disruption of the structure of peanut meal protein caused by added SDS, allowing for reaction with EDGE to form a dense network.

Peanut meal with soybean meal was blended by Li and colleagues [

111] to prepare a plant-based wood adhesive using different weight ratios of materials. After characterizing the physicochemical properties, including the amino acid composition, molecular weight distribution, solid content, viscosity, hydrolytic stability, morphological properties, and functional groups, it was observed that the resulting adhesives from the blended mixture exhibited a decreased viscosity and a higher solid content compared to those made solely from soybean meal. Furthermore, when 20% peanut meal was added as an optimum ratio, the wet and dry shear strength of the plywood bonded with this adhesive increased by 50% (1.02 ± 0.02 MPa) and 31% (1.55 ± 0.03 MPa), respectively. This improvement in bonding performance can be attributed to the optimized protein structure and side chains promoting cross-linking reactions.

Chen et al. [

113] also advocated for the utilization of peanut meal protein-based wood adhesives in the plywood industry. They used urea (U) and epichlorohydrin (ECH) to augment the adhesive properties, while investigating the underlying modification mechanism. The results revealed that incorporating U and ECH into peanut meal-based wood adhesives resulted in an enhanced water resistance, increased the apparent viscosity, and provided a higher solid content compared to those without U and ECH addition. This improvement can be attributed to the denaturation of peanut meal protein by U, which exposed more reactive groups, facilitating accelerated reactions with ECH-treated peanut meal protein, ultimately leading to the formation of a dense and cross-linked network. Furthermore, it is noteworthy that employing U and ECH in adhesives yielded a remarkably smooth protein surface that effectively impeded moisture penetration and improved the water-resistance capacity.

Qu et al. [

112] employed sodium dodecyl sulfate (SDS) denaturation, nano-silica (nSiO

2) reinforcement, and polyamide polyamine epichlorohydrin resin (PAE) to facilitate the hot-pressed peanut meal protein (HPMP) adhesive with enhanced bonding strength achieved through a three-step cross-linking process. It was observed that the boiling water strength of the HPMP adhesive exceeded the bonding strength requirement specified by the China National Standards for Class I plywood, measuring at 0.85 MPa compared to the required 0.7 MPa. Additionally, the HPMP adhesive exhibited an extended mildew resistance for at least 12 days while experiencing a significant increase in the solids content by 45.4% and viscosity by 274.6%.

4.2. The Utilization of Peanut Meal and Its Hydrolysates for Biosurfactant Preparation

Biosurfactants are amphiphilic compounds produced by microorganisms such as bacteria, yeasts, and fungi under specific culture conditions. They exhibit a high activity, excellent emulsification performance, intricate spatial structure, low surface tension (typically below 30 mN/m), remarkable chemical stability, and thermal stability. Moreover, owing to their environmental friendliness and a wide availability of raw material sources, they can be extracted from industrial waste or agricultural products. As the by-products generated from peanut oil extraction, peanut meal can be enzymatically converted into a glycolipid anionic biosurfactant called rhamnolipid by

Pseudomonas aeruginosa [

108]. In comparison to chemical surfactants, rhamnolipid is more environmentally friendly and more easily degraded, exhibiting a high activity and non-toxicity. It finds applications in the field of oil exploitation for reducing the interfacial tension between oil and water, thereby enhancing the displacement efficiency of crude oil and reducing costs. Moreover, in agriculture, rhamnolipid can stimulate growth in crops, vegetables, fruits, and flowers while aiding nutrient absorption and improving the efficacy of pesticides and fertilizers. Additionally, rhamnolipids can serve as bulking agents to increase the baking volume and flavoring agents in food processing. Kane and colleagues [

109] employed three different enzymes (Alcalase, Flavourzyme, and pepsin) to hydrolyze peanut meal resulting in highly antioxidant hydrolysates with enhanced emulsifying properties and foaming ability. This suggests that hydrolyzed peanut meal proteins can act as a surfactant at air/water or oil/water interfaces for foams or emulsions, respectively.

4.3. The Utilization of Peanut Meal and Its Hydrolysates for Films Preparation

Due to its non-toxic biodegradable nature and excellent water vapor permeability, peanut meal has gained popularity in the production of films [

69]. However, the inherent hydrophilicity of plant proteins often leads to a decrease in mechanical properties (such as strength and elongation) and water resistance [

119], necessitating the addition of plasticizers to enhance these shortcomings. Reddy et al. [

117] utilized citric acid as a cross-linking agent to form crosslinked films with peanut meal protein, which exhibited an unaffected water vapor permeability while significantly improving in dry and wet tensile strengths compared to pure peanut protein films. Another experiment involving glycerol as a plasticizer demonstrated that by incorporating glycerin into peanut meal followed by drying under high pressure and temperature conditions, the resulting fabricated peanut protein film achieved an impressive elongation of up to 63%, surpassing films made from peanuts or other commonly used plant proteins. These findings indicate the immense potential of peanut meal in thermoplastic product processing.

This entry is adapted from the peer-reviewed paper 10.3390/molecules28196862