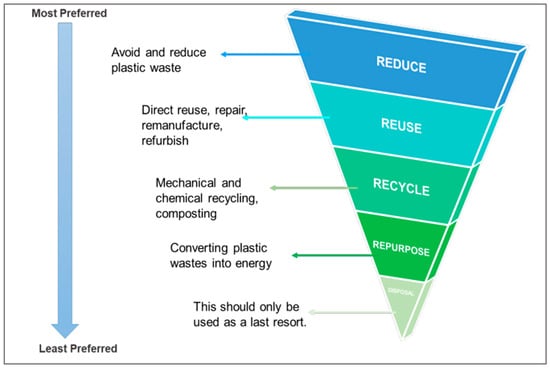

Plastic materials have gathered attention recently due to their omnipresence in the global economy. The transition towards a circular economy is the only way to prevent the environment from landfilling and incineration.

- mechanical recycling

- sorting technologies

- decontamination process

- polyolefins

- engineering (PET, PA6) and bio-sourced polymer (PLA and PHB)

1. Introduction

2. Sorting Technologies

|

Sorting Method |

Characteristics |

Drawbacks |

Reference |

|---|---|---|---|

|

Manual |

Hand based sorting |

Laborious, bad working environment |

[5] |

|

Tribo-electric |

Based on electrostatic charge |

Only for clean, dry, and non-surface-treated products. |

[6] |

|

Near-infrared Radiation (NIR) |

Fundamental vibration |

It is not adapted for dark plastics and is very expensive. |

[7] |

|

Flotation |

It is related to a specific gravity of material. |

It is not applied to High-density Polyethylene (HDPE) and Low-density Polyethylene (LDPE). |

[8] |

|

X-ray fluorescence (XRF) |

Uses X-rays as a source |

It is very expensive |

[9] |

3. Recycling Techniques: Overview

|

Type of Recycling |

Process |

Limits |

References |

|---|---|---|---|

|

Primary recycling (Re-extrusion) |

It is a process based on the extrusion of plastics. It does not require too much equipment and high investment. |

It is adapted for plastic scrap with less contamination |

|

|

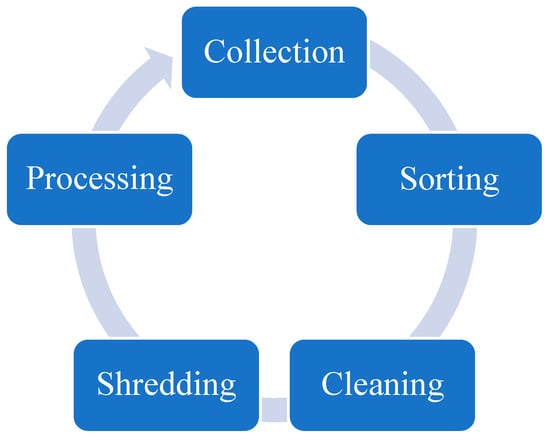

Secondary recycling (Mechanical recycling) |

The technique begins in the sorting center by separating, washing, and grinding plastics. After these steps, plastic materials are processed with extruders and pelletized. |

Degradation of thermomechanical properties of plastics |

|

|

Tertiary recycling (Chemical recycling) |

Chemical recycling consists of converting polymer into molecules or monomers that can be used to manufacture new polymers. |

It is an expensive process with a negative impact on the environment |

[26] |

|

Quaternary recycling (Energy recovery) |

Quaternary recycling aims to generate energy heat or electricity from plastic scraps [20]. |

The emission of toxic gases. |

[20] |

4. Sources of Contaminations

4.1. Structural Inhomogeneities

4.2. Impurities

5. Decontamination Techniques

5.1. Degassing System

5.1.1. Without Chemical Agent

5.1.2. With Chemical Agent

5.2. Filtration System

|

Filtration System |

Advantages/Disadvantages |

References |

|---|---|---|

|

Manual screen changers |

It helps minimize labor and downtime for screen changes during line shutdown. The compact design eliminates the need for line disassembly and uses a hand lever to manually index the slide plate for screen change. |

|

|

Hydraulic screen changer |

It’s used in industry due to its wide range of sizes. It can reach 450 mm. Single screen operation limits filtration area, and the use of seals add to maintenance and the probability of leakage. The mesh size can reach 100 µm in some applications. |

[40] |

|

Rotary Disc type filtration system |

This system offers high pressure with a lower residence time. System size can reach 250 mm and offer constant pressure operation but relatively high-pressure drops, with a lower residence time. It is a highly automated system with sophisticated controls and a backflush option. Leakage and disc lockup concerns are related to the clamping force of housing plates. It may require attention and to adapt system setup. |

[40] |

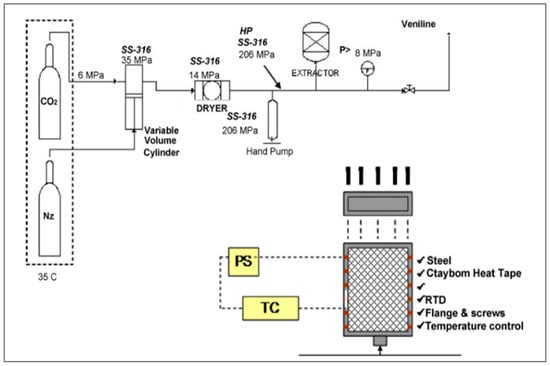

5.3. Supercritical Fluid

6. Identification and Quantification of Contamination Rate

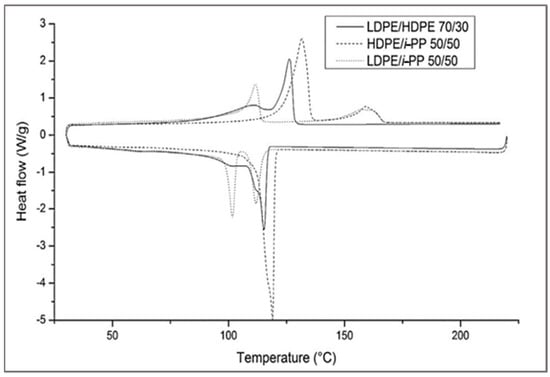

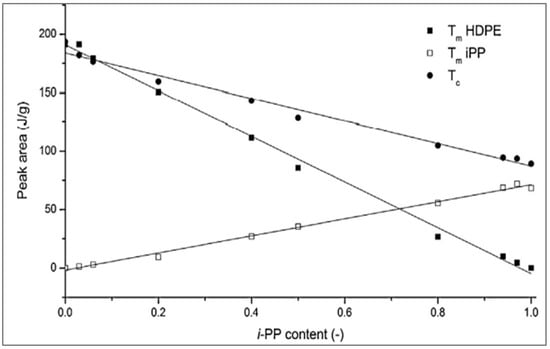

6.1. Differential Scanning Calorimetry (DSC)

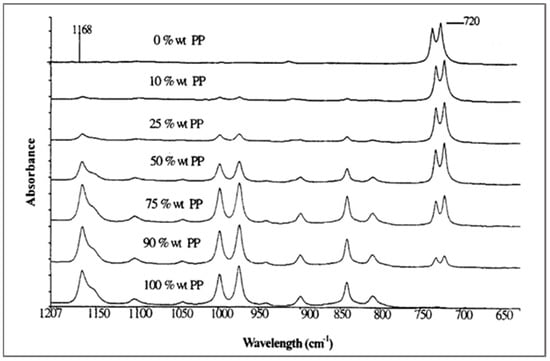

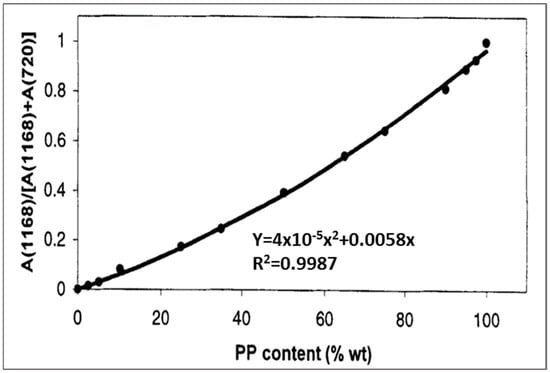

6.2. Fourier Transform Infrared Spectroscopy (FTIR)

6.3. Chromatography Analysis

This entry is adapted from the peer-reviewed paper 10.3390/waste1040050