Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

The increasing global population and urbanization have led to a pressing need for effective solutions to manage the organic fraction of municipal solid waste (OFMSW). High-solids anaerobic digestion (HS-AD) has garnered attention as a sustainable technology that offers reduced water demand and energy consumption, and an increased biogas production rate.

- high-solids anaerobic digestion

- municipal solid wastes

- rheological characteristics

- mass transfer

1. Introduction

With the exponential population growth, economic development, and rapid urbanization, the increased generation of municipal solid wastes has become a pressing concern for waste management [1]. The inherent complexity and heterogeneity of organic solid wastes demand the fine-tuning of process design for optimal waste utilization and the minimization of environmental impact. High-solids anaerobic digestion (HS-AD) of the organic fraction of municipal solid waste (OFMSW) has garnered significant attention as a promising anaerobic digestion (AD) technology for sustainable waste treatment and resource recovery [2]. For HS-AD, the total solids (TS) concentration would reach ≥15% [3][4], and it exhibits advantages such as flexible feedstock types, low water demand, a small reactor volume, high organics loading, and less heat consumption compared to the traditional low-solids anaerobic digestion (LS-AD) [5][6]. Additionally, the digestate produced as a by-product of the HS-AD process serves as a nutrient-rich fertilizer, aligning with circular economy principles and promoting sustainable agricultural practices [7].

2. Overview of HS-AD and Process Design

2.1. Basics and Influencing Factors of HS-AD

HS-AD provides an efficient solution for the organic fraction of municipal solid wastes, encompassing food waste, agriculture waste, cow manure, sewage sludge, energy crops, municipal solid waste, garden waste, and industrial waste streams [8]. HS-AD is facilitated by distinct bacterial and archaeal communities under oxygen-depleted conditions, yielding nutrient-rich digestate along with around 60% methane (CH4) and around 40% carbon dioxide (CO2) as by-products [9]. The process of AD involves a series of interconnected biochemical and physicochemical reactions that occur both sequentially and simultaneously. These reactions can be classified into four stages: hydrolysis, acidogenesis, acetogenic, and methanogenesis [10]. Hydrolysis is the initial rate-limiting stage in AD. Hydrolysis bacteria break down complex organic compounds into simpler soluble substances, which are further metabolized during the fermentation step by microbes, leading to the production of VFAs. Acetic acid production, another critical step, is facilitated by genera such as Syntrophomonas and Syntrophobacter. Meanwhile, methanogens are divided into hydrogenotrophic and acetoclastic, which consume hydrogen and CO2 or utilize acetate as the primary substrate for methane production, respectively. Each phase is facilitated by specific microbial communities, and the interdependence and interconnectedness of the microbial communities between these stages is essential to maintain the balance of the microbial community and achieve optimal AD performance [11]. Disruptions or imbalances in the microbial community during these phases can result in the failure of AD systems [12].

Considering the influencing factors, such as organic loading rate (OLR), pH, the presence of inhibitory and harmful compounds, temperature, and solids retention time (SRT), is essential for maximizing HS-AD efficiency [13]. The OLR in HS-AD is approximately 10 VS/(m3·d), while the LS-AD exhibits an OLR of around 5–6 kgVS/(m3·d). Insufficient OLR leads to insufficient biogas production, and excessive OLR leads to organic overload and toxicity issues [14]. It is also essential to maintain the appropriate pH range (6.5–7.5) for the activity of acid-producing bacteria and methanogenic archaea [15]. Extreme pH values under 6.3 or over 7.8 could hinder the microbial species responsible for AD and negatively impact methane production [13]. The accumulation of VFAs during acidogenesis decreases the pH of AD systems and thus inhibits the methanogenic process of methanogens. Continuous monitoring and appropriate measures are necessary to manage toxic compounds such as ammonia, sulfides, heavy metals, and antibiotics that inhibit microbial activity and lead to process failure [4]. In addition, temperature is a crucial factor in AD, and it can be classified into three primary ranges: psychrophilic (10–30 °C), mesophilic (35–40 °C), and thermophilic (55–60 °C) [1]. The metabolic activity of microorganisms is temperature-dependent, with higher temperatures generally resulting in faster digestion. Additionally, SRT plays a significant role in preserving microbial balance and functional activity within the AD [16]. The longer SRT are often recommended to mitigate irregular organic loading and toxic compounds, but achieving optimal performance requires careful consideration of the interplay among SRT, organic loading, and specific system characteristics. Despite the challenges associated with maintaining the process stability of HS-AD, various strategies have been developed to address these difficulties. These strategies include substrate pretreatment, mixing optimization based on rheological properties, and the regulation of microbial populations involved in AD.

2.2. Classification and Commercial Systems of HS-AD

The design choice, implementation scale, and operation modes in digesters have a significant impact on the spatiotemporal hydrodynamics, biokinetics, as well as heat and mass transfer [1]. In the field of HS-AD, various reactor configurations have been developed to accommodate different operational requirements. These configurations include the flow orientation (horizontal and vertical), operating temperature (psychrophilic, mesophilic, and thermophilic), number of stages (single and multistage), and feeding mode (batch and continuous) [17]. The capacity of the HS-AD experienced a significant 50% growth between 2010 and 2015 in Europe, despite its utilization being limited to only treating 35% of the total waste processed by AD [18].

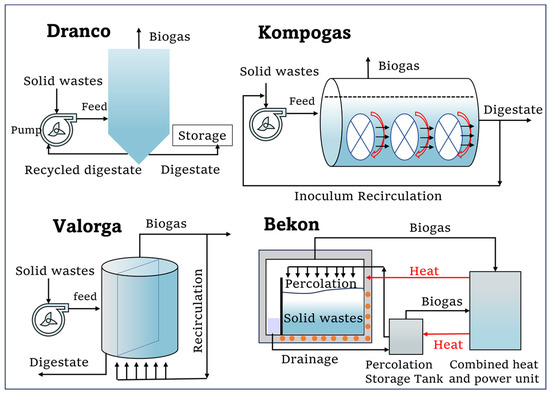

Common commercial systems utilized in the HS-AD field include Dranco [19], VALORGA [20], KOMPOGAS [21], BEKON, Biocel, and BIOFerm (Figure 1) [16]. The raw materials contain TS in the range of 30–40%. Around 60% of the overall capacity for municipal waste treatment in Europe is attributed to HS-AD systems [22]. The operational strategies adopted by each of these systems in designing digesters are evaluated next to overcome the major challenges (slow mass transfer) in HS-AD. The Dranco, VALORGA, and KOMPOGAS systems are all typical continuous and single-stage HS-AD systems, which can be operated continuously for solid contents of between 20 and 60% [7][23]. It is worth noting that some of these dry systems lack internal mixing, and therefore, substrate and digestate are mixed before feeding the digester [21]. The Dranco system (thermophilic or mesophilic) has no mixing apart from that occurring due to the downward plug flow of the feeding waste. A Dranco digester in Brecht, Belgium, treated biomass feedstock with TS = 35% (15% food waste, 75% garden waste, and 10% paper) for HRT = 14 days to produce 468 m3/t of biogas. The VALORGA system (thermophilic or mesophilic, vertical) uses pressurized biogas for mixing, but the process of pressurizing biogas necessitates a significant amount of energy, and there is a notable likelihood for organic materials to obstruct the nozzles [9]. The KOMPOGAS system (thermophilic, horizontal), which originated in Switzerland in the 1980s, can complete digestion in approximately 14–20 days by utilizing a horizontal push flow and internal stirring paddle for mixing. The operation of this digester falls within a range of 23% to 28% total solids, which resembles the methodology employed in the Dranco process [9]. Compared to the continuous HS-AD systems above, the batch HS-AD systems were developed relatively later. Batch HS-AD systems reduce system complexity and machinery maintenance requirements [24]. The BEKON system in Germany, Biocel system in Netherlands, and BIOFerm system (single-stage, mesophilic) were shown to be able to treat wastes with a feed TS of 25% to 35% at HRT = 28 days, but the process stability (incomplete mixing and accumulation of VFAs) of the batch-mode digesters remained [25]. More in-depth information can be found in previous studies [1][16][26].

Figure 1. The classification of the HS-AD process technology.

As well as the above standalone digesters, common multistage HS-AD has been leveraged to enhance the overall process efficiency. The initial phase involves the processes of hydrolysis and acidogenesis, whereas the subsequent stage is accountable for acetogenesis and methanogenesis. A novel biogas production method called Biopercolat was devised, employing a two-step anaerobic digestion process, including a hydrolysis chamber with axial mixing and a methanogenic chamber [27]. The Biotechnische Abfallverwertung (BTA) system utilizes a hydrocyclone for solid or liquid separation after which the solid fraction is mixed with pretreated leachate and then pumped into a hydrolysis tank [28]. The dual-stage digester configuration facilitates a faster attainment of stability compared to single-stage reactors [29]. Nonetheless, there are certain drawbacks associated with utilizing a two-stage system, including the accumulation of hydrogen that can impede the growth of acid-forming bacteria, reduced stability of biomass, technical complexity, and storage limitations, as well as increased operational expenses [30].

The adoption of HS-AD technologies incurs capital and operational costs, which vary depending on the technology chosen. For example, companies implementing Dranco technology in Saffenburg (Austria) and Brecht (Belgium) with large capacities require significant investments in digester capacity, maintenance, and heat energy to maintain thermophilic temperatures [16]. BEKON technology, with its advantages of not requiring pumps and agitators, and no need for pretreatment of bulk waste, proves to be more cost-effective in terms of machinery and operational costs, but it has limited digestion efficiency and a large reactor volume [24]. Detailed economic analyses are necessary to evaluate the cost-effectiveness of adopting these technologies, and cost estimations can be obtained from simulation models. Furthermore, technological advancements to increase the methane content in biogas may potentially reduce the overall cost of the HS-AD process, enhancing its economic viability.

Several case studies provided practical data on anaerobic digestion processes. For instance, Fernández et al. [31] observed that a TS content at 20% in the reactor yielded significantly better methane production compared to a TS content at 30%. Rodriguez et al. [32] identified the optimum solids retention time of 20 days for dry mesophilic anaerobic digestion of OFMSW. The data of HS-AD technologies offer promising solutions for efficiently treating high solid wastes. The prevalence of single-stage and continuous digesters is higher; however, the successful implementation of HS-AD processes in industrial settings relies on factors such as substrate properties, site choice, and size, as well as efficient automation for controlling process parameters.

This entry is adapted from the peer-reviewed paper 10.3390/bioengineering10091084

References

- Li, W.L.; Gupta, R.; Zhang, Z.K.; Cao, L.X.; Li, Y.Q.; Show, P.L.; Kumar, S.; Gupta, V.K.; Lin, K.Y.A.; Varjani, S.; et al. A review of high-solid anaerobic digestion (HSAD): From transport phenomena to process design. Renew. Sustain. Energy Rev. 2023, 180, 113305.

- Xu, Y.; Gong, H.; Dai, X. High-solid anaerobic digestion of sewage sludge: Achievements and perspectives. Front. Environ. Sci. Eng. 2020, 15, 71.

- Li, L.L.; Gao, Q.W.; Liu, X.P.; Zhao, Q.L.; Wang, W.Y.; Wang, K.; Zhou, H.M.; Jiang, J.Q. Insights into high-solids anaerobic digestion of food waste enhanced by activated carbon via promoting direct interspecies electron transfer. Bioresour. Technol. 2022, 351, 127008.

- Gao, Q.W.; Li, L.L.; Zhao, Q.L.; Wang, K.; Zhou, H.M.; Wang, W.Y.; Ding, J. Insights into high-solids anaerobic digestion of food waste concomitant with sorbate: Performance and mechanisms. Bioresour. Technol. 2023, 381, 129159.

- Li, L.L.; Wang, K.; Sun, Z.J.; Zhao, Q.L.; Zhou, H.M.; Gao, Q.W.; Jiang, J.Q.; Mei, W.Y. Effect of optimized intermittent mixing during high-solids anaerobic co-digestion of food waste and sewage sludge: Simulation, performance, and mechanisms. Sci. Total Environ. 2022, 842, 156882.

- Di Capua, F.; Spasiano, D.; Giordano, A.; Adani, F.; Fratino, U.; Pirozzi, F.; Esposito, G. High-solid anaerobic digestion of sewage sludge: Challenges and opportunities. Appl. Energy 2020, 278, 115608.

- Andre, L.; Pauss, A.; Ribeiro, T. Solid anaerobic digestion: State-of-art, scientific and technological hurdles. Bioresour. Technol. 2018, 247, 1027–1037.

- Kumar, M.; Dutta, S.; You, S.M.; Luo, G.; Zhang, S.C.; Show, P.L.; Sawarkar, A.D.; Singh, L.; Tsang, D.C.W. A critical review on biochar for enhancing biogas production from anaerobic digestion of food waste and sludge. J. Clean. Prod. 2021, 305, 127143.

- Li, Y.B.; Park, S.Y.; Zhu, J.Y. Solid-state anaerobic digestion for methane production from organic waste. Renew. Sustain. Energy Rev. 2011, 15, 821–826.

- Ren, Y.Y.; Yu, M.; Wu, C.F.; Wang, Q.H.; Gao, M.; Huang, Q.Q.; Liu, Y. A comprehensive review on food waste anaerobic digestion: Research updates and tendencies. Bioresour. Technol. 2018, 247, 1069–1076.

- Gerardi, M.H. The Microbiology of Anaerobic Digesters; John Wiley & Sons: Hoboken, NJ, USA, 2003.

- Tchobanoglus, G.; Burton, F.; Stensel, H.D. Wastewater engineering: Treatment and reuse. Am. Water Work. Assoc. J. 2003, 95, 201.

- Sarker, S.; Lamb, J.J.; Hjelme, D.R.; Lien, K.M. A Review of the Role of Critical Parameters in the Design and Operation of Biogas Production Plants. Appl. Sci. 2019, 9, 1915.

- Nkuna, R.; Roopnarain, A.; Rashama, C.; Adeleke, R. Insights into organic loading rates of anaerobic digestion for biogas production: A review. Crit. Rev. Biotechnol. 2022, 42, 487–507.

- Wang, Z.Z.; Hu, Y.S.; Wang, S.; Wu, G.X.; Zhan, X.M. A critical review on dry anaerobic digestion of organic waste: Characteristics, operational conditions, and improvement strategies. Renew. Sustain. Energy Rev. 2023, 176, 113208.

- Akinbomi, J.G.; Patinvoh, R.J.; Taherzadeh, M.J. Current challenges of high-solid anaerobic digestion and possible measures for its effective applications: A review. Biotechnol. Biofuels 2022, 15, 52.

- Nizami, A.-S.; Saville, B.A.; MacLean, H.L. Anaerobic digesters: Perspectives and challenges. In Bioenergy Production by Anaerobic Digestion; Routledge: London, UK, 2013; pp. 139–151.

- Charlottenburg, A.; Rosenheim, H. Anaerobic Digestion; European Bioplastics eV: Berlin, Germany, 2015; Volume 8.

- De Baere, L. The Dranco Technology: A Unique Digestion Technology for Solid Organic Waste; Organic Waste Systems Pub.: Brussels, Beligium, 2010; pp. 1–8.

- Alvarez, C.; Colon, J.; Lopes, A.C.; Fernandez-Polanco, M.; Benbelkacem, H.; Buffiere, P. Hydrodynamics of high solids anaerobic reactor: Characterization of solid segregation and liquid mixing pattern in a pilot plant VALORGA facility under different reactor geometry. Waste Manag. 2018, 76, 306–314.

- Wellinger, A.; Wyder, K.; Metzler, A.E. Kompogas—A New System for the Anaerobic Treatment of Source Separated Waste. Water Sci. Technol. 1993, 27, 153–158.

- De Baere, L.; Mattheeuws, B.; Velghe, F. State of the art of anaerobic digestion in Europe. In Proceedings of the 12th World Congress on Anaerobic Digestion (AD12), Guadalajara, Mexico, 31 October–4 November 2010; pp. 3–6.

- Fagbohungbe, M.O.; Dodd, I.C.; Herbert, B.M.J.; Li, H.; Ricketts, L.; Semple, K.T. High solid anaerobic digestion: Operational challenges and possibilities. Environ. Technol. Innov. 2015, 4, 268–284.

- Lutz, P. New BEKON Biogas technology for dry fermentation in batch process. In Description of BEKON Dry Fermentation Processing; BEKON: Unterföhring, Germany, 2010.

- Ten Brummeler, E.; Aarnink, M.; Koster, I. Dry anaerobic digestion of solid organic waste in a biocel reactor at pilot-plant scale. Water Sci. Technol. 1992, 25, 301–310.

- Elsharkawy, K.; Elsamadony, M.; Afify, H. Comparative analysis of common full scale reactors for dry anaerobic digestion process. E3s Web Conf. 2019, 83, 01011.

- Nkemka, V.N.; Murto, M. Two-stage anaerobic dry digestion of blue mussel and reed. Renew. Energy 2013, 50, 359–364.

- Chavez-Vazquez, M.; Bagley, D.M. Evaluation of the performance of different anaerobic digestion technologies for solid waste treatment. In Proceedings of the Joint CSCE/EWRI of ASCE International Conference on Environmental Engineering, Niagara Falls, ON, Canada, 21–24 July 2002.

- Liu, X.-Y.; Ding, H.-B.; Wang, J.-Y. Food waste to bioenergy. In Bioenergy and Biofuel from Biowastes and Biomass; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2010; pp. 43–70.

- Srisowmeya, G.; Chakravarthy, M.; Devi, G.N. Critical considerations in two-stage anaerobic digestion of food waste—A review. Renew. Sustain. Energy Rev. 2020, 119, 109587.

- Fernández, J.; Pérez, M.; Romero, L.I. Effect of substrate concentration on dry mesophilic anaerobic digestion of organic fraction of municipal solid waste (OFMSW). Bioresour. Technol. 2008, 99, 6075–6080.

- Rodríguez, J.F.; Pérez, M.; Romero, L.I. Mesophilic anaerobic digestion of the organic fraction of municipal solid waste: Optimisation of the semicontinuous process. Chem. Eng. J. 2012, 193, 10–15.

This entry is offline, you can click here to edit this entry!