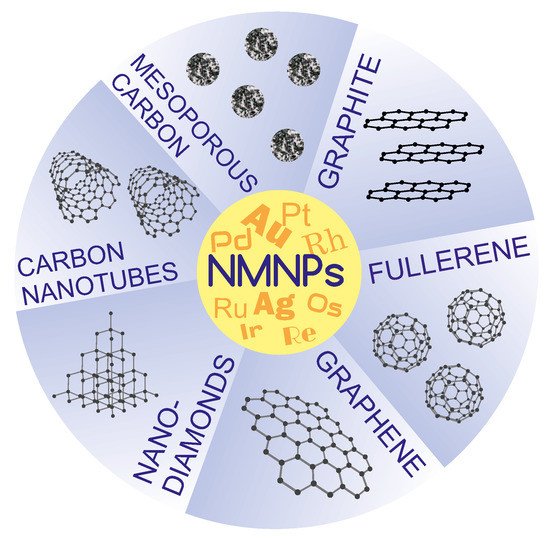

Noble-metal nanoparticles (NMNPs), with their outstanding properties, have been arousing the interest of scientists for centuries. Although our knowledge of them is much more significant today, and people can obtain NMNPs in various sizes, shapes, and compositions, our interest in them has not waned. When talking about noble metals, gold, silver, and platinum come to mind first. Still, people cannot forget about elements belonging to the so-called platinum group, such as ruthenium, rhodium, palladium, osmium, and iridium, whose physical and chemical properties are very similar to those of platinum. It makes them highly demanded and widely used in various applications. The current knowledge on the preparation of all noble metals is presented in the form of nanoparticles and their assembling with carbon supports.

- carbon-supported nanoparticles

- catalysts

- fuel cells

1. Introduction

2. Methods of Obtaining Noble-Metal Nanoparticles/Carbonaceous Materials Nanocomposites

| Synthesis Method | Precursors | Type of NMNPs | NM Particle Size [nm] | References |

|---|---|---|---|---|

| Surface functionalization | CNF, NaOH, H2SO4, H2PtCl6 | Pt | 6 | [29] |

| CNF/TiO2, EG, NaOH, H2PtCl6 | Pt | 3.8 | [30] | |

| Ketjen Black, HNO3, H2PtCl6 | Pt | 2.5 | [31] | |

| N-CNT, HCOOH, H2PtCl6 | Pt (nanorods) | 3–4 × 10 | [32] | |

| Vulcan XC72, HNO3, H2PtCl6 | Pt | 2.2 ± 0.4 | [33] | |

| rGO, HCOOH, H2PtCl6, PdCl2 | PtPd | 4 × 20–200 | [34] | |

| Pt nanowires | ||||

| Pd nanoparticles | 5 | |||

| Ni-N-CNTs, PDDA, PdCl2 | Pd | 2–5 | [35] | |

| MWCNTs, THF, H2PtCl6, SnCl4 | PtSn | ~4 | [36] | |

| CX, HNO3, H2PtCl6, RuCl3 | PtRu | 3.8–4.4 | [37] | |

| BDD, NaOH, SDBS, RuCl3, H2PtCl6 | PtRu | 2–5 | [38] | |

| rGO, KAuCl4, K2PtCl6 | Pt | 2.34 ± 0.52 | [39] | |

| Pt-Au | 2.86 ± 1.30 | |||

| rGO, Vulcan XC-72, H2PtCl6 | Pt | 0.5–2.5 | [40] | |

| G-CNTs, KOH, H2PtCl6 | Pt | 4.3–6.8 | [41] | |

| rGO, EG, HAuCl4, H2PtCl6 | Pt-Au | [42] | ||

| CQD, Vulcan XC-72, H2PtCl6, NaBH4 | Pt | [43] | ||

| N-GQD, Na2CO3, HCl, PdCl2 | Pd | [44] | ||

| N-GN, CoCl2, RuCl3 | RuCo | 6.2 | [45] | |

| C60, H2PtCl6, | Pt | <5 | [46] | |

| C60, NaOH, H2PtCl6 | Pt | 3.93–4.20 | [47] | |

| GO-PyrC60, PdCl2 | Pd | 10 | [48] | |

| CA, Vulcan XC-72R, H2PtCl6, NaBH4 | Pt | 3.24 | [49] | |

| MNC, CCA, NaOH, H2PtCl6, NaBH4 | Pt | 3.1 | [50] | |

| Vulcan XC-72R, NaOH, H2PtCl6, H2IrCl6 | PtIr | 3.6–3.9 | [51] | |

| CNT, H2SO4, IrCl3 | Ir | ~1 | [52] | |

| MWCNT, EG, HNO3, H2SO4, H2PtCl6, RuCl3, ReCl3 | Pt-Ru | 2.79 ± 0.58 | [53] | |

| Pt-Re | 3.53 ± 0.80 | |||

| Pt-Ru-Re | 2.88 ± 0.64 | |||

| Pt-Ru-Re | 2.68 ± 0.55 | |||

| Pt-Ru-Re | 3.19 ± 0.54 | |||

| Electrochemical deposition | CNT, EG, H2PtCl6, RuCl3 | Pt-Ru | 3.1–5.6 | [54] |

| GO, H2PtCl6, KH2PO4 | Pt | 10 | [55] | |

| GO, CNF, H2PtCl6, H2SO4 | Pt | 350–500 | [56] | |

| CP, H2PtCl6, RuCl3, HCl, KOH | Pt-Ru | 52.9 ± 9.2 | [57] | |

| GR, ZnO, K2PtCl6, H2SO4 | Pt | 250 | [58] | |

| BDD, NaBH4, NaOH, H2PtCl6 | Pt | 15 ± 5 | [59] | |

| BDD, Ni(NO3)2, HCl, PdCl2 | Pd | ~13 | [60] | |

| Vulcan XC-72, H2PtCl6, H2SO4 | Pt | 1–4 | [61] | |

| Electroless deposition | CNO, H2PtCl6 | Pt | 20 | [62] |

| CNT, CoCl2, H2PtCl6 | Pt | 30–40 | [63] | |

| CNT, SDS, EG, Na2PdCl4 | Pd | 2–5 | [64] | |

| MWCNT, HAuCl4 | Au | 10 | [65] | |

| PC, C6H5K3O7, RhCl3, RuCl3, IrCl3 | Ir | 0.96 ± 0.13 | [66] | |

| Rh | 1.11 ± 0.31 | |||

| Ru | 1.37 ± 0.39 | |||

| NiO/Ni/CNTs, K2PtCl6 | Pt | ~2 | [67] |

2.1. Noble-Metal Nanoparticles on Mesoporous Carbon Materials

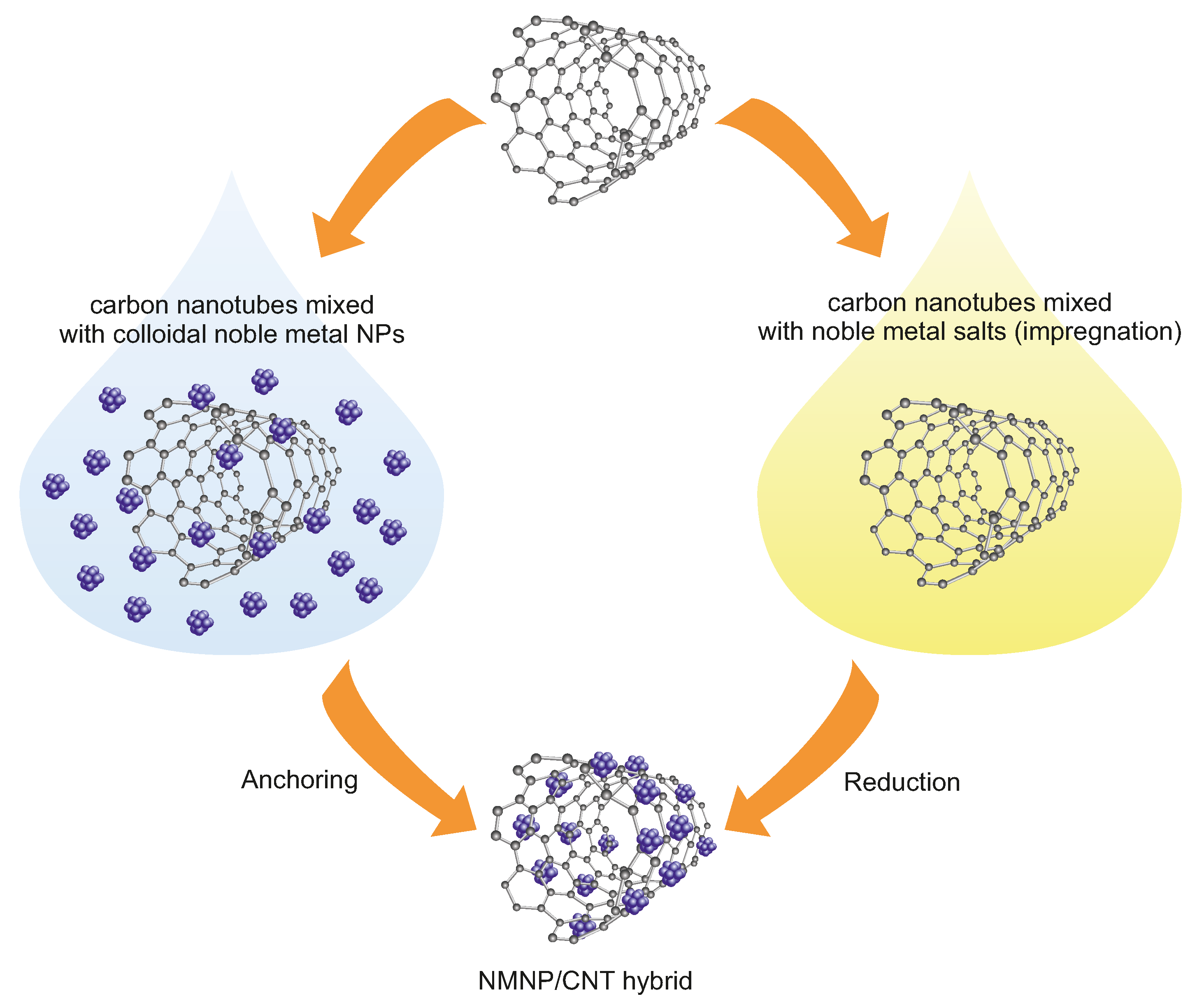

2.2. Noble-Metal Nanoparticles on Carbon Nanotubes

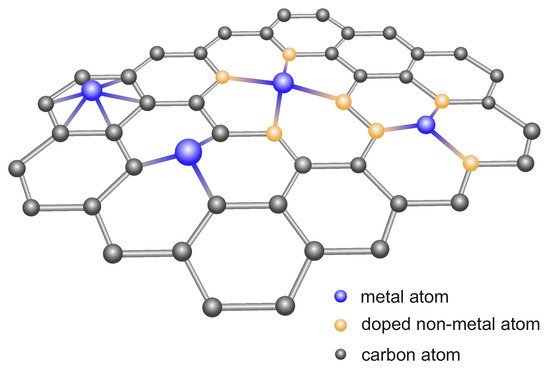

2.3. Noble-Metal Nanoparticles on Graphene

This entry is adapted from the peer-reviewed paper 10.3390/cryst12050584

References

- Richter, F.; Meng, Y.; Klasen, T.; Sahraoui, L.; Schüth, F. Structural mimicking of inorganic catalyst supports with polydivinylbenzene to improve performance in the selective aerobic oxidation of ethanol and glycerol in water. J. Catal. 2013, 308, 341–351.

- Martinuzzi, S.; Cozzula, D.; Centomo, P.; Zecca, M.; Müller, T.E. The distinct role of the flexible polymer matrix in catalytic conversions over immobilised nanoparticles. RSC Adv. 2015, 5, 56181–56188.

- Koga, H.; Tokunaga, E.; Hidaka, M.; Umemura, Y.; Saito, T.; Isogai, A.; Kitaoka, T. Topochemical synthesis and catalysis of metal nanoparticles exposed on crystalline cellulose nanofibers. Chem. Commun. 2010, 46, 8567–8569.

- Turner, M.; Golovko, V.; Vaughan, O.; Abdulkin, P.; Berenguer-Murcia, A.; Tikhov, M.; Johnson, B.; Lambert, R. Selective oxidation with dioxygen by gold nanoparticle catalysts derived from 55-atom clusters. Nature 2008, 454, 981–983.

- Yamada, Y.; Tsung, C.K.; Huang, W.; Huo, Z.; Habas, S.; Soejima, T.; Aliaga, C.; Somorjai, G.; Yang, P. Nanocrystal bilayer for tandem catalysis. Nat. Chem. 2011, 3, 372–376.

- An, K.; Alayoglu, S.; Musselwhite, N.; Na, K.; Somorjai, G.A. Designed Catalysts from Pt Nanoparticles Supported on Macroporous Oxides for Selective Isomerization of n-Hexane. J. Am. Chem. Soc. 2014, 136, 6830–6833.

- Kuo, C.H.; Tang, Y.; Chou, L.Y.; Sneed, B.T.; Brodsky, C.N.; Zhao, Z.; Tsung, C.K. Yolk–Shell Nanocrystal@ZIF-8 Nanostructures for Gas-Phase Heterogeneous Catalysis with Selectivity Control. J. Am. Chem. Soc. 2012, 134, 14345–14348.

- Joo, S.H.; Park, J.; Tsung, C.K.; Yamada, Y.; Yang, P.; Somorjai, G. Thermally Stable Pt/Mesoporous Silica Core-shell Nanocatalysts for High-Temperature Reactions. Nat. Mater. 2008, 8, 126–131.

- Wang, S.; Wang, J.; Zhao, Q.; Li, D.; Wang, J.Q.; Cho, M.; Cho, H.; Terasaki, O.; Chen, S.; Wan, Y. Highly Active Heterogeneous 3 nm Gold Nanoparticles on Mesoporous Carbon as Catalysts for Low-Temperature Selective Oxidation and Reduction in Water. ACS Catal. 2015, 5, 797–802.

- Lam, E.; Luong, J.H. Carbon Materials as Catalyst Supports and Catalysts in the Transformation of Biomass to Fuels and Chemicals. ACS Catal. 2014, 4, 3393–3410.

- Zhou, R.; Qiao, S. Silver/Nitrogen-Doped Graphene Interaction and Its Effect on Electrocatalytic Oxygen Reduction. Chem. Mater. 2014, 26, 5868–5873.

- Zheng, Y.; Luo, R.; Xu, Y.; Zhang, L.; Liu, P.; Chen, Q. Adsorbate-Mediated Deposition of Noble-Metal Nanoparticles on Carbon Substrates for Electrocatalysis. ACS Appl. Energy Mater. 2020, 3, 6460–6465.

- Frackowiak, E.; Beguin, F. Carbon materials for the electrochemical storage of energy in capacitors. Carbon 2001, 39, 937–950.

- Yang, T.; Ling, H.; Lamonier, J.F.; Jaroniec, M.; Huang, J.; Monteiro, M.J.; Liu, J. A synthetic strategy for carbon nanospheres impregnated with highly monodispersed metal nanoparticles. NPG Asia Mater. 2016, 8, e240.

- Dai, L.; Chang, D.W.; Baek, J.B.; Lu, W. Carbon nanomaterials: Carbon nanomaterials for advanced energy conversion and storage (small 8/2012). Small 2012, 8, 1122.

- Noor, T.; Yaqoob, L.; Iqbal, N. Recent Advances in Electrocatalysis of Oxygen Evolution Reaction using Noble-Metal, Transition-Metal, and Carbon-Based Materials. ChemElectroChem 2021, 8, 447–483.

- Dai, L.; Xue, Y.; Qu, L.; Choi, H.J.; Baek, J.B. Metal-free catalysts for oxygen reduction reaction. Chem. Rev. 2015, 115, 4823–4892.

- Liu, H.; Song, C.; Zhang, L.; Zhang, J.; Wang, H.; Wilkinson, D.P. A review of anode catalysis in the direct methanol fuel cell. J. Power Sources 2006, 155, 95–110.

- Uchida, M.; Aoyama, Y.; Tanabe, M.; Yanagihara, N.; Eda, N.; Ohta, A. Influences of both carbon supports and heat-treatment of supported catalyst on electrochemical oxidation of methanol. J. Electrochem. Soc. 1995, 142, 2572.

- Liu, Y.; Ji, C.; Gu, W.; Jorne, J.; Gasteiger, H.A. Effects of catalyst carbon support on proton conduction and cathode performance in PEM fuel cells. J. Electrochem. Soc. 2011, 158, B614.

- Qu, W.L.; Wang, Z.B.; Jiang, Z.Z.; Gu, D.M.; Yin, G.P. Investigation on performance of Pd/Al2O3-C catalyst synthesized by microwave assisted polyol process for electrooxidation of formic acid. Rsc Adv. 2012, 2, 344–350.

- Moore, A.D.; Holmes, S.M.; Roberts, E.P. Evaluation of porous carbon substrates as catalyst supports for the cathode of direct methanol fuel cells. RSC Adv. 2012, 2, 1669–1674.

- Vogel, W. Size contraction in Pt/C and PtRu/C commercial E-TEK electrocatalysts: An in situ X-ray diffraction study. J. Phys. Chem. C 2008, 112, 13475–13482.

- Chen, T.W.; Kalimuthu, P.; Veerakumar, P.; Lin, K.C.; Chen, S.M.; Ramachandran, R.; Mariyappan, V.; Chitra, S. Recent Developments in Carbon-Based Nanocomposites for Fuel Cell Applications: A Review. Molecules 2022, 27, 761.

- Li, J.; Stephanopoulos, M.F.; Xia, Y. Introduction: Heterogeneous single-atom catalysis. Chem. Rev. 2020, 120, 11699–11702.

- Wang, A.; Li, J.; Zhang, T. Heterogeneous single-atom catalysis. Nat. Rev. Chem. 2018, 2, 65–81.

- Wu, B.; Kuang, Y.; Zhang, X.; Chen, J. Noble metal nanoparticles/carbon nanotubes nanohybrids: Synthesis and applications. Nano Today 2011, 6, 75–90.

- Khalil, I.; Julkapli, N.M.; Yehye, W.A.; Basirun, W.J.; Bhargava, S.K. Graphene–gold nanoparticles hybrid—Synthesis, functionalization, and application in a electrochemical and surface-enhanced raman scattering biosensor. Materials 2016, 9, 406.

- Chung, S.; Ham, K.; Kang, S.; Ju, H.; Lee, J. Enhanced corrosion tolerance and highly durable ORR activity by low Pt electrocatalyst on unique pore structured CNF in PEM fuel cell. Electrochim. Acta 2020, 348, 136346.

- Jeon, Y.; Ji, Y.; Cho, Y.I.; Lee, C.; Park, D.H.; Shul, Y.G. Oxide–Carbon Nanofibrous Composite Support for a Highly Active and Stable Polymer Electrolyte Membrane Fuel-Cell Catalyst. ACS Nano 2018, 12, 6819–6829.

- Ott, S.; Orfanidi, A.; Schmies, H.; Anke, B.; Nong, H.N.; Hübner, J.; Gernert, U.; Gliech, M.; Lerch, M.; Strasser, P. Ionomer distribution control in porous carbon-supported catalyst layers for high-power and low Pt-loaded proton exchange membrane fuel cells. Nat. Mater. 2020, 19, 77–85.

- Mardle, P.; Ji, X.; Wu, J.; Guan, S.; Dong, H.; Du, S. Thin film electrodes from Pt nanorods supported on aligned N-CNTs for proton exchange membrane fuel cells. Appl. Catal. B Environ. 2020, 260, 118031.

- Orfanidi, A.; Madkikar, P.; El-Sayed, H.A.; Harzer, G.S.; Kratky, T.; Gasteiger, H.A. The Key to High Performance Low Pt Loaded Electrodes. J. Electrochem. Soc. 2017, 164, F418–F426.

- Du, S.; Lu, Y.; Steinberger-Wilckens, R. PtPd nanowire arrays supported on reduced graphene oxide as advanced electrocatalysts for methanol oxidation. Carbon 2014, 79, 346–353.

- Zhang, X.; Yang, P.; Jiang, S.P. Pd nanoparticles assembled on Ni- and N-doped carbon nanotubes towards superior electrochemical activity. Int. J. Hydrog. Energy 2021, 46, 2065–2074.

- Tetrahydrofuran-functionalized multi-walled carbon nanotubes as effective support for Pt and PtSn electrocatalysts of fuel cells. Electrochim. Acta 2010, 55, 2964–2971.

- Alegre, C.; Gálvez, M.E.; Baquedano, E.; Moliner, R.; Pastor, E.; Lázaro, M.J. Oxygen-Functionalized Highly Mesoporous Carbon Xerogel Based Catalysts for Direct Methanol Fuel Cell Anodes. J. Phys. Chem. C 2013, 117, 13045–13058.

- La-Torre-Riveros, L.; Guzman-Blas, R.; Méndez-Torres, A.E.; Prelas, M.; Tryk, D.A.; Cabrera, C.R. Diamond Nanoparticles as a Support for Pt and PtRu Catalysts for Direct Methanol Fuel Cells. ACS Appl. Mater. Interfaces 2012, 4, 1134–1147.

- Beltrán-Gastélum, M.; Salazar-Gastélum, M.; Flores-Hernández, J.; Botte, G.; Pérez-Sicairos, S.; Romero-Castañon, T.; Reynoso-Soto, E.; Félix-Navarro, R. Pt-Au nanoparticles on graphene for oxygen reduction reaction: Stability and performance on proton exchange membrane fuel cell. Energy 2019, 181, 1225–1234.

- Şanlı, L.I.; Yarar, B.; Bayram, V.; Gürsel, S.A. Electrosprayed catalyst layers based on graphene–carbon black hybrids for the next-generation fuel cell electrodes. J. Mater. Sci. 2017, 52, 2091–2102.

- Zhou, Y.; Hu, X.; Guo, S.; Yu, C.; Zhong, S.; Liu, X. Multi-functional graphene/carbon nanotube aerogels for its applications in supercapacitor and direct methanol fuel cell. Electrochim. Acta 2018, 264, 12–19.

- Chen, D.J.; Zhang, Q.; Feng, J.X.; Ju, K.J.; Wang, A.J.; Wei, J.; Feng, J.J. One-pot wet-chemical co-reduction synthesis of bimetallic gold–platinum nanochains supported on reduced graphene oxide with enhanced electrocatalytic activity. J. Power Sources 2015, 287, 363–369.

- Pan, D.; Li, X.; Zhang, A. Platinum assisted by carbon quantum dots for methanol electro-oxidation. Appl. Surf. Sci. 2018, 427, 715–723.

- Deming, C.P.; Mercado, R.; Lu, J.E.; Gadiraju, V.; Khan, M.; Chen, S. Oxygen Electroreduction Catalyzed by Palladium Nanoparticles Supported on Nitrogen-Doped Graphene Quantum Dots: Impacts of Nitrogen Dopants. ACS Sustain. Chem. Eng. 2016, 4, 6580–6589.

- Zhang, M.; Li, H.; Chen, J.; Yi, L.; Shao, P.; Xu, C.Y.; Wen, Z. Nitrogen-doped graphite encapsulating RuCo nanoparticles toward high-activity catalysis of water oxidation and reduction. Chem. Eng. J. 2021, 422, 130077.

- Mondal, S.K. Synthesis of Mesoporous Fullerene and its Platinum Composite: A Catalyst for PEMFc. J. Electrochem. Soc. 2012, 159, K156–K160.

- McPherson, I.J.; Ash, P.A.; Jones, L.; Varambhia, A.; Jacobs, R.M.J.; Vincent, K.A. Electrochemical CO Oxidation at Platinum on Carbon Studied through Analysis of Anomalous in Situ IR Spectra. J. Phys. Chem. C 2017, 121, 17176–17187.

- Zhang, X.; Zhang, J.W.; Xiang, P.H.; Qiao, J. Fabrication of graphene-fullerene hybrid by self-assembly and its application as support material for methanol electrocatalytic oxidation reaction. Appl. Surf. Sci. 2018, 440, 477–483.

- Gu, K.; Kim, E.; Sharma, S.; Sharma, P.; Bliznakov, S.; Hsiao, B.; Rafailovich, M. Mesoporous carbon aerogel with tunable porosity as the catalyst support for enhanced proton-exchange membrane fuel cell performance. Mater. Today Energy 2021, 19, 100560.

- Kin, Y.; Saito, K.; Oda, H.; Ando, T.; Nakagawa, K. Development of Direct Methanol Fuel Cell Catalyst Using Marimo Nano Carbon. Catal. Lett. 2019, 149, 1–6.

- Bak, J.; Kim, H.; Lee, S.; Kim, M.; Kim, E.J.; Roh, J.; Shin, J.; Choi, C.H.; Cho, E. Boosting the Role of Ir in Mitigating Corrosion of Carbon Support by Alloying with Pt. ACS Catal. 2020, 10, 12300–12309.

- Luo, F.; Hu, H.; Zhao, X.; Yang, Z.; Zhang, Q.; Xu, J.; Kaneko, T.; Yoshida, Y.; Zhu, C.; Cai, W. Robust and Stable Acidic Overall Water Splitting on Ir Single Atoms. Nano Lett. 2020, 20, 2120–2128.

- Choudhary, A.K.; Pramanik, H. Addition of rhenium (Re) to Pt-Ru/f-MWCNT anode electrocatalysts for enhancement of ethanol electrooxidation in half cell and single direct ethanol fuel cell. Int. J. Hydrog. Energy 2020, 45, 13300–13321.

- Tsai, M.C.; Yeh, T.K.; Tsai, C.H. Electrodeposition of platinum-ruthenium nanoparticles on carbon nanotubes directly grown on carbon cloths for methanol oxidation. Mater. Chem. Phys. 2008, 109, 422–428.

- Zhou, Y.G.; Chen, J.J.; Wang, F.b.; Sheng, Z.H.; Xia, X.H. A facile approach to the synthesis of highly electroactive Pt nanoparticles on graphene as an anode catalyst for direct methanol fuel cells. Chem. Commun. 2010, 46, 5951–5953.

- Yao, Z.; Zhu, M.; Jiang, F.; Du, Y.; Wang, C.; Yang, P. Highly efficient electrocatalytic performance based on Pt nanoflowers modified reduced graphene oxide/carbon cloth electrode. J. Mater. Chem. 2012, 22, 13707–13713.

- Ahn, S.H.; Choi, I.; Kwon, O.J.; Kim, J. One-step co-electrodeposition of Pt-Ru electrocatalysts on carbon paper for direct methanol fuel. Chem. Eng. J. 2012, 181, 276–280.

- Gao, L.; Ding, L.; Fan, L. Pt nanoflower/graphene-layered composites by ZnO nanoparticle expansion of graphite and their enhanced electrocatalytic activity for methanol oxidation. Electrochim. Acta 2013, 106, 159–164.

- Gao, F.; Yang, N.; Smirnov, W.; Obloh, H.; Nebel, C. Size-controllable and homogeneous platinum nanoparticles on diamond using wet chemically assisted electrodeposition. Electrochim. Acta 2013, 90, 445–451.

- Mavrokefalos, C.; Hasan, M.; Rohan, J.; Foord, J. Enhanced Mass Activity and Stability of Bimetallic Pd-Ni Nanoparticles on Boron-Doped Diamond for Direct Ethanol Fuel Cell Applications. ChemElectroChem 2017, 5, 455–463.

- Dhanasekaran, P.; Lokesh, K.; Ojha, P.; Sahu, A.; Bhat, S.; Kalpana, D. Electrochemical deposition of three-dimensional platinum nanoflowers for high-performance polymer electrolyte fuel cells. J. Colloid Interface Sci. 2020, 572, 198–206.

- Goh, Y.A.; Chen, X.; Yasin, F.M.; Eggers, P.K.; Boulos, R.A.; Wang, X.; Chua, H.T.; Raston, C.L. Shear flow assisted decoration of carbon nano-onions with platinum nanoparticles. Chem. Commun. 2013, 49, 5171–5173.

- Wang, Q.; Geng, B.; Tao, B. A facile room temperature chemical route to Pt nanocube/carbon nanotube heterostructures with enhanced electrocatalysis. J. Power Sources 2011, 196, 191–195.

- Chen, X.; Hou, Y.; Wang, H.; Cao, Y.; He, J. Facile Deposition of Pd Nanoparticles on Carbon Nanotube Microparticles and Their Catalytic Activity for Suzuki Coupling Reactions. J. Phys. Chem. C 2008, 112, 8172–8176.

- Qu, L.; Dai, L. Substrate-Enhanced Electroless Deposition of Metal Nanoparticles on Carbon Nanotubes. J. Am. Chem. Soc. 2005, 127, 10806–10807.

- Ming, M.; Zhang, Y.; He, C.; Zhao, L.; Niu, S.; Fan, G.; Hu, J.S. Room-Temperature Sustainable Synthesis of Selected Platinum Group Metal (PGM = Ir, Rh, and Ru) Nanocatalysts Well-Dispersed on Porous Carbon for Efficient Hydrogen Evolution and Oxidation. Small 2019, 15, 1903057.

- Bian, Y.; Wang, H.; Gao, Z.; Hu, J.; Liu, D.; Dai, L. A facile approach to high-performance trifunctional electrocatalysts by substrate-enhanced electroless deposition of Pt/NiO/Ni on carbon nanotubes. Nanoscale 2020, 12, 14615–14625.

- Bahr, J.L.; Tour, J.M. Covalent chemistry of single-wall carbon nanotubes. J. Mater. Chem. 2002, 12, 1952–1958.

- Jiang, L.; Gao, L. Modified carbon nanotubes: An effective way to selective attachment of gold nanoparticles. Carbon 2003, 41, 2923–2929.

- Georgakilas, V.; Perman, J.A.; Tucek, J.; Zboril, R. Broad family of carbon nanoallotropes: Classification, chemistry, and applications of fullerenes, carbon dots, nanotubes, graphene, nanodiamonds, and combined superstructures. Chem. Rev. 2015, 115, 4744–4822.

- Labulo, A.H.; Martincigh, B.S.; Omondi, B.; Nyamori, V.O. Advances in carbon nanotubes as efficacious supports for palladium-catalysed carbon–carbon cross-coupling reactions. J. Mater. Sci. 2017, 52, 9225–9248.

- Zhang, R.Y.; Olin, H. Gold-carbon nanotube nanocomposites: Synthesis and applications. Int. J. Biomed. Nanosci. Nanotechnol. 2011, 2, 112–135.

- Huang, H.; Wang, X. Recent progress on carbon-based support materials for electrocatalysts of direct methanol fuel cells. J. Mater. Chem. A 2014, 2, 6266–6291.

- Li, H.; Chang, G.; Zhang, Y.; Tian, J.; Liu, S.; Luo, Y.; Asiri, A.M.; Al-Youbi, A.O.; Sun, X. Photocatalytic synthesis of highly dispersed Pd nanoparticles on reduced graphene oxide and their application in methanol electro-oxidation. Catal. Sci. Technol. 2012, 2, 1153–1156.

- Fan, J.J.; Fan, Y.J.; Wang, R.X.; Xiang, S.; Tang, H.G.; Sun, S.G. A novel strategy for the synthesis of sulfur-doped carbon nanotubes as a highly efficient Pt catalyst support toward the methanol oxidation reaction. J. Mater. Chem. A 2017, 5, 19467–19475.

- Lu, R.; Zang, J.; Wang, Y.; Zhao, Y. Microwave synthesis and properties of nanodiamond supported PtRu electrocatalyst for methanol oxidation. Electrochim. Acta 2012, 60, 329–333.

- Hsieh, C.T.; Hung, W.M.; Chen, W.Y.; Lin, J.Y. Microwave-assisted polyol synthesis of Pt–Zn electrocatalysts on carbon nanotube electrodes for methanol oxidation. Int. J. Hydrog. Energy 2011, 36, 2765–2772.

- Hsieh, C.T.; Wei, J.M.; Hsiao, H.T.; Chen, W.Y. Fabrication of flower-like platinum clusters onto graphene sheets by pulse electrochemical deposition. Electrochim. Acta 2012, 64, 177–182.

- He, Z.; Chen, J.; Liu, D.; Zhou, H.; Kuang, Y. Electrodeposition of Pt-Ru nanoparticles on carbon nanotubes and their electrocatalytic properties for methanol electrooxidation. Diam. Relat. Mater. 2004, 13, 1764–1770.

- Choi, H.C.; Shim, M.; Bangsaruntip, S.; Dai, H. Spontaneous Reduction of Metal Ions on the Sidewalls of Carbon Nanotubes. J. Am. Chem. Soc. 2002, 124, 9058–9059.

- Shen, X.; Xia, X.; Du, Y.; Wang, C. Electroless deposition of Au nanoparticles on reduced graphene oxide/polyimide film for electrochemical detection of hydroquinone and catechol. Front. Mater. Sci. 2017, 11, 262–270.

- Liu, X.W.; Mao, J.J.; Liu, P.D.; Wei, X.W. Fabrication of metal-graphene hybrid materials by electroless deposition. Carbon 2011, 49, 477–483.

- Qi, J.; Jiang, L.; Tang, Q.; Zhu, S.; Wang, S.; Yi, B.; Sun, G. Synthesis of graphitic mesoporous carbons with different surface areas and their use in direct methanol fuel cells. Carbon 2012, 50, 2824–2831.

- Calvillo, L.; Celorrio, V.; Moliner, R.; Garcia, A.; Caméan, I.; Lazaro, M. Comparative study of Pt catalysts supported on different high conductive carbon materials for methanol and ethanol oxidation. Electrochim. Acta 2013, 102, 19–27.

- Cao, J.; Chen, Z.; Xu, J.; Wang, W.; Chen, Z. Mesoporous carbon synthesized from dual colloidal silica/block copolymer template approach as the support of platinum nanoparticles for direct methanol fuel cells. Electrochim. Acta 2013, 88, 184–192.

- Yarlagadda, V.; Carpenter, M.K.; Moylan, T.E.; Kukreja, R.S.; Koestner, R.; Gu, W.; Thompson, L.; Kongkanand, A. Boosting fuel cell performance with accessible carbon mesopores. ACS Energy Lett. 2018, 3, 618–621.

- Maiyalagan, T.; Alaje, T.O.; Scott, K. Highly stable Pt–Ru nanoparticles supported on three-dimensional cubic ordered mesoporous carbon (Pt–Ru/CMK-8) as promising electrocatalysts for methanol oxidation. J. Phys. Chem. C 2012, 116, 2630–2638.

- Su, F.; Poh, C.K.; Tian, Z.; Xu, G.; Koh, G.; Wang, Z.; Liu, Z.; Lin, J. Electrochemical behavior of Pt nanoparticles supported on meso-and microporous carbons for fuel cells. Energy Fuels 2010, 24, 3727–3732.

- Yu, M.; Han, Y.; Li, J.; Wang, L. One-step synthesis of sodium carboxymethyl cellulose-derived carbon aerogel/nickel oxide composites for energy storage. Chem. Eng. J. 2017, 324, 287–295.

- Han, S.; Sun, Q.; Zheng, H.; Li, J.; Jin, C. Green and facile fabrication of carbon aerogels from cellulose-based waste newspaper for solving organic pollution. Carbohydr. Polym. 2016, 136, 95–100.

- Chen, Y.; Zhang, L.; Yang, Y.; Pang, B.; Xu, W.; Duan, G.; Jiang, S.; Zhang, K. Recent progress on nanocellulose aerogels: Preparation, modification, composite fabrication, applications. Adv. Mater. 2021, 33, 2005569.

- Antolini, E. Lignocellulose, cellulose and lignin as renewable alternative fuels for direct biomass fuel cells. ChemSusChem 2021, 14, 189–207.

- Cheng, S.; Rettew, R.E.; Sauerbrey, M.; Alamgir, F.M. Architecture-dependent surface chemistry for Pt monolayers on carbon-supported Au. ACS Appl. Mater. Interfaces 2011, 3, 3948–3956.

- Park, S.J.; Kim, B.J.; Lee, S.Y. Effect of surface modification of mesoporous carbon supports on the electrochemical activity of fuel cells. J. Colloid Interface Sci. 2013, 405, 150–156.

- Su, F.; Tian, Z.; Poh, C.K.; Wang, Z.; Lim, S.H.; Liu, Z.; Lin, J. Pt nanoparticles supported on nitrogen-doped porous carbon nanospheres as an electrocatalyst for fuel cells. Chem. Mater. 2010, 22, 832–839.

- Harzer, G.S.; Orfanidi, A.; El-Sayed, H.; Madkikar, P.; Gasteiger, H.A. Tailoring catalyst morphology towards high performance for low Pt loaded PEMFC cathodes. J. Electrochem. Soc. 2018, 165, F770.

- Saifuddin, N.; Raziah, A.; Junizah, A. Carbon Nanotubes: A Review on Structure and Their Interaction with Proteins. J. Chem. 2013, 2013, 676815.

- Planeix, J.; Coustel, N.; Coq, B.; Brotons, V.; Kumbhar, P.; Dutartre, R.; Geneste, P.; Bernier, P.; Ajayan, P. Application of carbon nanotubes as supports in heterogeneous catalysis. J. Am. Chem. Soc. 1994, 116, 7935–7936.

- Brandao, A.T.; Rosoiu, S.; Costa, R.; Lazar, O.A.; Silva, A.F.; Anicai, L.; Pereira, C.M.; Enachescu, M. Characterization and electrochemical studies of MWCNTs decorated with Ag nanoparticles through pulse reversed current electrodeposition using a deep eutectic solvent for energy storage applications. J. Mater. Res. Technol. 2021, 15, 342–359.

- Ohtaka, A.; Sansano, J.M.; Nájera, C.; Miguel-García, I.; Berenguer-Murcia, Á.; Cazorla-Amorós, D. Palladium and Bimetallic Palladium–Nickel Nanoparticles Supported on Multiwalled Carbon Nanotubes: Application to Carbon-Carbon Bond-Forming Reactions in Water. ChemCatChem 2015, 7, 1841–1847.

- Li, Y.; Fu, Y.; Lai, C.; Qin, L.; Li, B.; Liu, S.; Yi, H.; Xu, F.; Li, L.; Zhang, M.; et al. Porous materials confining noble metals for the catalytic reduction of nitroaromatics: Controllable synthesis and enhanced mechanism. Environ. Sci.-Nano 2021, 8, 3067–3097.

- Guo, D.J.; Cui, S.K. A composite strategy to prepare high active Pt-WO3/MWCNT catalysts for methanol electro-oxidation. J. Phys. Chem. Solids 2021, 159, 110293.

- Lee, K.M.; Li, L.; Dai, L. Asymmetric end-functionalization of multi-walled carbon nanotubes. J. Am. Chem. Soc. 2005, 127, 4122–4123.

- De Volder, M.F.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon nanotubes: Present and future commercial applications. Science 2013, 339, 535–539.

- Li, Y.; Hu, F.P.; Wang, X.; Shen, P.K. Anchoring metal nanoparticles on hydrofluoric acid treated multiwalled carbon nanotubes as stable electrocatalysts. Electrochem. Commun. 2008, 10, 1101–1104.

- Wang, Z.; Zhang, Q.; Kuehner, D.; Ivaska, A.; Niu, L. Green synthesis of 1–2 nm gold nanoparticles stabilized by amine-terminated ionic liquid and their electrocatalytic activity in oxygen reduction. Green Chem. 2008, 10, 907–909.

- Tunckol, M.; Fantini, S.; Malbosc, F.; Durand, J.; Serp, P. Effect of the synthetic strategy on the non-covalent functionalization of multi-walled carbon nanotubes with polymerized ionic liquids. Carbon 2013, 57, 209–216.

- Zheng, M.; Li, P.; Fu, G.; Chen, Y.; Zhou, Y.; Tang, Y.; Lu, T. Efficient anchorage of highly dispersed and ultrafine palladium nanoparticles on the water-soluble phosphonate functionalized multiwall carbon nanotubes. Appl. Catal. B Environ. 2013, 129, 394–402.

- Maya-Cornejo, J.; Garcia-Bernabé, A.; Compañ, V. Bimetallic Pt-M electrocatalysts supported on single-wall carbon nanotubes for hydrogen and methanol electrooxidation in fuel cells applications. Int. J. Hydrog. Energy 2018, 43, 872–884.

- Bhuvanendran, N.; Ravichandran, S.; Zhang, W.; Ma, Q.; Xu, Q.; Khotseng, L.; Su, H. Highly efficient methanol oxidation on durable PtxIr/MWCNT catalysts for direct methanol fuel cell applications. Int. J. Hydrog. Energy 2020, 45, 6447–6460.

- Yu, D.; Xue, Y.; Dai, L. Vertically aligned carbon nanotube arrays co-doped with phosphorus and nitrogen as efficient metal-free electrocatalysts for oxygen reduction. J. Phys. Chem. Lett. 2012, 3, 2863–2870.

- Jin, Z.; Nie, H.; Yang, Z.; Zhang, J.; Liu, Z.; Xu, X.; Huang, S. Metal-free selenium doped carbon nanotube/graphene networks as a synergistically improved cathode catalyst for oxygen reduction reaction. Nanoscale 2012, 4, 6455–6460.

- Sumpter, B.G.; Meunier, V.; Romo-Herrera, J.M.; Cruz-Silva, E.; Cullen, D.A.; Terrones, H.; Smith, D.J.; Terrones, M. Nitrogen-mediated carbon nanotube growth: Diameter reduction, metallicity, bundle dispersability, and bamboo-like structure formation. ACS Nano 2007, 1, 369–375.

- Chizari, K.; Janowska, I.; Houllé, M.; Florea, I.; Ersen, O.; Romero, T.; Bernhardt, P.; Ledoux, M.J.; Pham-Huu, C. Tuning of nitrogen-doped carbon nanotubes as catalyst support for liquid-phase reaction. Appl. Catal. A Gen. 2010, 380, 72–80.

- Chen, G.X.; Zhang, J.M.; Wang, D.D.; Xu, K.W. First-principles study of palladium atom adsorption on the boron- or nitrogen-doped carbon nanotubes. Phys. B Condens. Matter 2009, 404, 4173–4177.

- Rajala, T.; Kronberg, R.; Backhouse, R.; Buan, M.E.M.; Tripathi, M.; Zitolo, A.; Jiang, H.; Laasonen, K.; Susi, T.; Jaouen, F.; et al. A platinum nanowire electrocatalyst on single-walled carbon nanotubes to drive hydrogen evolution. Appl. Catal. B Environ. 2020, 265, 118582.

- Tsai, M.C.; Yeh, T.K.; Tsai, C.H. An improved electrodeposition technique for preparing platinum and platinum–ruthenium nanoparticles on carbon nanotubes directly grown on carbon cloth for methanol oxidation. Electrochem. Commun. 2006, 8, 1445–1452.

- Zhang, l.; Fang, Z.; Zhao, G.C.; Wei, X.W. Electrodeposited Platinum Nanoparticles on the Multi-Walled Carbon Nanotubes and its Electrocatalytic for Nitric Oxide. Int. J. Electrochem. Sci. 2008, 3, 746–754.

- Chen, X.; Li, N.; Eckhard, K.; Stoica, L.; Xia, W.; Assmann, J.; Muhler, M.; Schuhmann, W. Pulsed electrodeposition of Pt nanoclusters on carbon nanotubes modified carbon materials using diffusion restricting viscous electrolytes. Electrochem. Commun. 2007, 9, 1348–1354.

- Xiao, F.; Mo, Z.; Zhao, F.; Zeng, B. Ultrasonic-electrodeposition of gold–platinum alloy nanoparticles on multi-walled carbon nanotubes–ionic liquid composite film and their electrocatalysis towards the oxidation of nitrite. Electrochem. Commun. 2008, 10, 1740–1743.

- Huang, J.; Xie, Q.; Tan, Y.; Fu, Y.; Su, Z.; Huang, Y.; Yao, S. Preparation of Pt/multiwalled carbon nanotubes modified Au electrodes via Pt–Cu co-electrodeposition/Cu stripping protocol for high-performance electrocatalytic oxidation of methanol. Mater. Chem. Phys. 2009, 118, 371–378.

- Lorençon, E.; Ferlauto, A.S.; de Oliveira, S.; Miquita, D.R.; Resende, R.R.; Lacerda, R.G.; Ladeira, L.O. Direct production of carbon nanotubes/metal nanoparticles hybrids from a redox reaction between metal ions and reduced carbon nanotubes. ACS Appl. Mater. Interfaces 2009, 1, 2104–2106.

- Huang, J.Y.; Ding, F.; Yakobson, B.I.; Lu, P.; Qi, L.; Li, J. In situ observation of graphene sublimation and multi-layer edge reconstructions. Proc. Natl. Acad. Sci. USA 2009, 106, 10103–10108.

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Correction: Graphene and Graphene Oxide: Synthesis, Properties, and Applications. Adv. Mater. 2010, 22, 5226.

- Liu, M.; Hof, F.; Moro, M.; Valenti, G.; Paolucci, F.; Pénicaud, A. Carbon supported noble metal nanoparticles as efficient catalysts for electrochemical water splitting. Nanoscale 2020, 12, 20165–20170.

- Yang, N.; Swain, G.M.; Jiang, X. Nanocarbon electrochemistry and electroanalysis: Current status and future perspectives. Electroanalysis 2016, 28, 27–34.

- Huang, X.; Yin, Z.; Wu, S.; Qi, X.; He, Q.; Zhang, Q.; Yan, Q.; Boey, F.; Zhang, H. Graphene-based materials: Synthesis, characterization, properties, and applications. Small 2011, 7, 1876–1902.

- Huang, X.; Qi, X.; Boey, F.; Zhang, H. Graphene-based composites. Chem. Soc. Rev. 2012, 41, 666–686.

- Li, X.; Cai, W.; An, J.; Kim, S.; Nah, J.; Yang, D.; Piner, R.; Velamakanni, A.; Jung, I.; Tutuc, E.; et al. Large-Area Synthesis of High-Quality and Uniform Graphene Films on Copper Foils. Science 2009, 324, 1312–1314.

- Lotya, M.; Hernandez, Y.; King, P.J.; Smith, R.J.; Nicolosi, V.; Karlsson, L.S.; Blighe, F.M.; De, S.; Wang, Z.; McGovern, I.T.; et al. Liquid Phase Production of Graphene by Exfoliation of Graphite in Surfactant/Water Solutions. J. Am. Chem. Soc. 2009, 131, 3611–3620.

- Farooqui, U.; Ahmad, A.; Hamid, N. Graphene oxide: A promising membrane material for fuel cells. Renew. Sustain. Energy Rev. 2018, 82, 714–733.

- Arukula, R.; Vinothkannan, M.; Kim, A.R.; Yoo, D.J. Cumulative effect of bimetallic alloy, conductive polymer and graphene toward electrooxidation of methanol: An efficient anode catalyst for direct methanol fuel cells. J. Alloy. Compd. 2019, 771, 477–488.

- Su, C.; Loh, K.P. Carbocatalysts: Graphene Oxide and Its Derivatives. Acc. Chem. Res. 2013, 46, 2275–2285.

- Zhao, H.; Yang, J.; Wang, L.; Tian, C.; Jiang, B.; Fu, H. Fabrication of a palladium nanoparticle/graphene nanosheet hybrid via sacrifice of a copper template and its application in catalytic oxidation of formic acid. Chem. Commun. 2011, 47, 2014–2016.

- Chen, X.; Wu, G.; Chen, J.; Chen, X.; Xie, Z.; Wang, X. Synthesis of “clean” and well-dispersive Pd nanoparticles with excellent electrocatalytic property on graphene oxide. J. Am. Chem. Soc. 2011, 133, 3693–3695.

- Chen, Y.; Yang, X.; Kitta, M.; Xu, Q. Monodispersed Pt nanoparticles on reduced graphene oxide by a non-noble metal sacrificial approach for hydrolytic dehydrogenation of ammonia borane. Nano Res. 2017, 10, 3811–3816.

- Jeong, D.W.; Park, S.; Choi, W.J.; Bae, G.; Chung, Y.J.; Yang, C.S.; Lee, Y.K.; Kim, J.J.; Park, N.; Lee, J.O. Electron-transfer transparency of graphene: Fast reduction of metal ions on graphene-covered donor surfaces. Phys. Status Solidi RRL 2015, 9, 180–186.

- Iqbal, M.; Li, C.; Jiang, B.; Hossain, M.S.A.; Islam, M.T.; Henzie, J.; Yamauchi, Y. Tethering mesoporous Pd nanoparticles to reduced graphene oxide sheets forms highly efficient electrooxidation catalysts. J. Mater. Chem. A 2017, 5, 21249–21256.

- Li, S.S.; Zheng, J.N.; Ma, X.; Hu, Y.Y.; Wang, A.J.; Chen, J.R.; Feng, J.J. Facile synthesis of hierarchical dendritic PtPd nanogarlands supported on reduced graphene oxide with enhanced electrocatalytic properties. Nanoscale 2014, 6, 5708–5713.

- Vilian, A.E.; Hwang, S.K.; Kwak, C.H.; Oh, S.Y.; Kim, C.Y.; Lee, G.w.; Lee, J.B.; Huh, Y.S.; Han, Y.K. Pt-Au bimetallic nanoparticles decorated on reduced graphene oxide as an excellent electrocatalysts for methanol oxidation. Synth. Met. 2016, 219, 52–59.

- Hassan, H.M.; Abdelsayed, V.; Abd El Rahman, S.K.; AbouZeid, K.M.; Terner, J.; El-Shall, M.S.; Al-Resayes, S.I.; El-Azhary, A.A. Microwave synthesis of graphene sheets supporting metal nanocrystals in aqueous and organic media. J. Mater. Chem. 2009, 19, 3832–3837.

- Bai, R.G.; Muthoosamy, K.; Zhou, M.; Ashokkumar, M.; Huang, N.M.; Manickam, S. Sonochemical and sustainable synthesis of graphene-gold (G-Au) nanocomposites for enzymeless and selective electrochemical detection of nitric oxide. Biosens. Bioelectron. 2017, 87, 622–629.

- Huang, Y.X.; Xie, J.F.; Zhang, X.; Xiong, L.; Yu, H.Q. Reduced graphene oxide supported palladium nanoparticles via photoassisted citrate reduction for enhanced electrocatalytic activities. ACS Appl. Mater. Interfaces 2014, 6, 15795–15801.

- Zhou, X.; Huang, X.; Qi, X.; Wu, S.; Xue, C.; Boey, F.Y.C.; Yan, Q.; Chen, P.; Zhang, H. In Situ Synthesis of Metal Nanoparticles on Single-Layer Graphene Oxide and Reduced Graphene Oxide Surfaces. J. Phys. Chem. C 2009, 113, 10842–10846.

- Qin, X.; Li, Q.; Asiri, A.M.; Al-Youbi, A.O.; Sun, X. One-pot synthesis of Au nanoparticles/reduced graphene oxide nanocomposites and their application for electrochemical H2O2, glucose, and hydrazine sensing. Gold Bull. 2014, 47, 3–8.

- Yang, M.Q.; Pan, X.; Zhang, N.; Xu, Y.J. A facile one-step way to anchor noble metal (Au, Ag, Pd) nanoparticles on a reduced graphene oxide mat with catalytic activity for selective reduction of nitroaromatic compounds. CrystEngComm 2013, 15, 6819–6828.

- Zou, C.; Yang, B.; Bin, D.; Wang, J.; Li, S.; Yang, P.; Wang, C.; Shiraishi, Y.; Du, Y. Electrochemical synthesis of gold nanoparticles decorated flower-like graphene for high sensitivity detection of nitrite. J. Colloid Interface Sci. 2017, 488, 135–141.

- Liu, S.; Tian, N.; Xie, A.Y.; Du, J.H.; Xiao, J.; Liu, L.; Sun, H.Y.; Cheng, Z.Y.; Zhou, Z.Y.; Sun, S.G. Electrochemically seed-mediated synthesis of sub-10 nm tetrahexahedral Pt nanocrystals supported on graphene with improved catalytic performance. J. Am. Chem. Soc. 2016, 138, 5753–5756.

- Sheng, H.; Wei, M.; D’Aloia, A.; Wu, G. Heteroatom polymer-derived 3D high-surface-area and mesoporous graphene sheet-like carbon for supercapacitors. ACS Appl. Mater. Interfaces 2016, 8, 30212–30224.

- Luo, L.; Fu, C.; Yang, F.; Li, X.; Jiang, F.; Guo, Y.; Zhu, F.; Yang, L.; Shen, S.; Zhang, J. Composition-graded Cu–Pd nanospheres with Ir-doped surfaces on N-doped porous graphene for highly efficient ethanol electro-oxidation in alkaline media. ACS Catal. 2019, 10, 1171–1184.

- Qiu, X.; Yan, X.; Cen, K.; Sun, D.; Xu, L.; Tang, Y. Achieving highly electrocatalytic performance by constructing holey reduced graphene oxide hollow nanospheres sandwiched by interior and exterior platinum nanoparticles. ACS Appl. Energy Mater. 2018, 1, 2341–2349.

- Kumar, R.; Oh, J.H.; Kim, H.J.; Jung, J.H.; Jung, C.H.; Hong, W.G.; Kim, H.J.; Park, J.Y.; Oh, I.K. Nanohole-structured and palladium-embedded 3D porous graphene for ultrahigh hydrogen storage and CO oxidation multifunctionalities. ACS Nano 2015, 9, 7343–7351.

- Kumar, R.; Singh, R.K.; Vaz, A.R.; Savu, R.; Moshkalev, S.A. Self-assembled and one-step synthesis of interconnected 3D network of Fe3O4/reduced graphene oxide nanosheets hybrid for high-performance supercapacitor electrode. ACS Appl. Mater. Interfaces 2017, 9, 8880–8890.

- Qiu, X.; Li, T.; Deng, S.; Cen, K.; Xu, L.; Tang, Y. A General Strategy for the Synthesis of PtM (M= Fe, Co, Ni) Decorated Three-Dimensional Hollow Graphene Nanospheres for Efficient Methanol Electrooxidation. Chem.–A Eur. J. 2018, 24, 1246–1252.

- Yao, C.; Zhang, Q.; Su, Y.; Xu, L.; Wang, H.; Liu, J.; Hou, S. Palladium nanoparticles encapsulated into hollow N-doped graphene microspheres as electrocatalyst for ethanol oxidation reaction. ACS Appl. Nano Mater. 2019, 2, 1898–1908.

- Yu, K.; Lin, Y.; Fan, J.; Li, Q.; Shi, P.; Xu, Q.; Min, Y. Ternary N, S, and P-doped hollow carbon spheres derived from polyphosphazene as Pd supports for ethanol oxidation reaction. Catalysts 2019, 9, 114.

- Zhang, H.; Liu, G.; Shi, L.; Ye, J. Single-atom catalysts: Emerging multifunctional materials in heterogeneous catalysis. Adv. Energy Mater. 2018, 8, 1701343.

- Liu, J.; Ma, Q.; Huang, Z.; Liu, G.; Zhang, H. Recent progress in graphene-based noble-metal nanocomposites for electrocatalytic applications. Adv. Mater. 2019, 31, 1800696.

- Stambula, S.; Gauquelin, N.; Bugnet, M.; Gorantla, S.; Turner, S.; Sun, S.; Liu, J.; Zhang, G.; Sun, X.; Botton, G.A. Chemical structure of nitrogen-doped graphene with single platinum atoms and atomic clusters as a platform for the PEMFC electrode. J. Phys. Chem. C 2014, 118, 3890–3900.

- Yan, H.; Cheng, H.; Yi, H.; Lin, Y.; Yao, T.; Wang, C.; Li, J.; Wei, S.; Lu, J. Single-atom Pd1/graphene catalyst achieved by atomic layer deposition: Remarkable performance in selective hydrogenation of 1, 3-butadiene. J. Am. Chem. Soc. 2015, 137, 10484–10487.

- Detavernier, C.; Dendooven, J.; Sree, S.P.; Ludwig, K.F.; Martens, J.A. Tailoring nanoporous materials by atomic layer deposition. Chem. Soc. Rev. 2011, 40, 5242–5253.

- Sun, S.; Zhang, G.; Gauquelin, N.; Chen, N.; Zhou, J.; Yang, S.; Chen, W.; Meng, X.; Geng, D.; Banis, M.N.; et al. Single-atom catalysis using Pt/graphene achieved through atomic layer deposition. Sci. Rep. 2013, 3, 1–9.

- Yan, H.; Lin, Y.; Wu, H.; Zhang, W.; Sun, Z.; Cheng, H.; Liu, W.; Wang, C.; Li, J.; Huang, X.; et al. Bottom-up precise synthesis of stable platinum dimers on graphene. Nat. Commun. 2017, 8, 1070.

- Bulushev, D.A.; Zacharska, M.; Lisitsyn, A.S.; Podyacheva, O.Y.; Hage, F.S.; Ramasse, Q.M.; Bangert, U.; Bulusheva, L.G. Single atoms of Pt-group metals stabilized by N-doped carbon nanofibers for efficient hydrogen production from formic acid. ACS Catal. 2016, 6, 3442–3451.

- Zhang, C.; Sha, J.; Fei, H.; Liu, M.; Yazdi, S.; Zhang, J.; Zhong, Q.; Zou, X.; Zhao, N.; Yu, H.; et al. Single-atomic ruthenium catalytic sites on nitrogen-doped graphene for oxygen reduction reaction in acidic medium. ACS Nano 2017, 11, 6930–6941.

- Choi, C.H.; Kim, M.; Kwon, H.C.; Cho, S.J.; Yun, S.; Kim, H.T.; Mayrhofer, K.J.; Kim, H.; Choi, M. Tuning selectivity of electrochemical reactions by atomically dispersed platinum catalyst. Nat. Commun. 2016, 7, 10922.