1. Mechanism of Biodiesel Production from Fish Waste

Initially plant, algal, and animal oils and fats were used for biodiesel production [

29,

30,

31]. Later, fish and their wastes were identified as the best sources for biodiesel production because they are rich in fatty acid esters. The fat and oil contents of the fish and their waste completely depend on the fish’s age, sex, nutritional condition, health, and the time of year. Fish oil is found in several parts including the flesh, frames, head, fin, skin, guts, and tail of the fish in different quantities [

25]. Mainly fish oil contains triglycerides of fatty acids, with variable amounts of phospholipids, glycerol ethers, and wax esters. In addition, the lipid composition in fish is fairly different from land animal lipids and vegetable oils due to the presence of large quantity long-chain PUFAs including omega-3 [eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA)]. Hence, the global fish oil market size was valued at USD 1905.77 million in 2019 and is estimated to reach USD 2844.12 million by 2027 [

9].

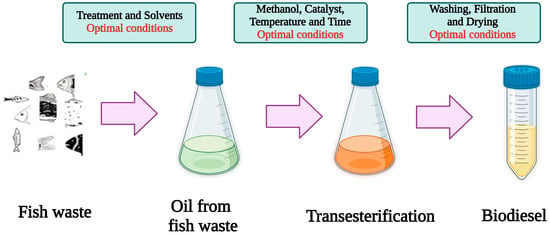

In this section, the mechanism of extraction of fats and oils from fish waste in biodiesel production was described.

Figure 1 explains the schematic representation of biodiesel production from fish waste. The identification of various fish wastes has been carried out using normal selection methods. Also, fish waste or discarded parts of fish were separated based on the type, organ, and size. Different types of discarded fish wastes, such as internal organs, bones, viscera, trimmings, tails, fins, skin, etc., were generally found on the sea shore and in the fish industry [

32]. Furthermore, fats and oil were extracted from specific discarded parts of the fish. Before this, it is mandatory to check the fat and oil contents in fish waste through chemical analysis. The extraction of fish oil was carried out using different procedures and pretreatments with various solvents.

Table 1 illustrates the different methods and solvents used for fish oil production from various fish wastes. At the initial stages, researchers preferred to use waste fish oil directly for biodiesel production [

19], which is always not economical. Distilled water was also used as a solvent at high temperatures to remove free fatty acids from fish waste to obtain better fish oil for biodiesel production [

33]. The incubated content was centrifuged and the supernatant with oil was withdrawn using a micropipette and stored in an amber flask at 4 °C. If there are more fatty acid esters, then the waste is useful for the production of biodiesel. Also, the fish waste was converted into crude oil by squeezing or grinding and it was later mixed with boiling water along with a catalyst [

34]. Yahyaee et al. [

15] designed a machine to separate oil from fish waste. In some experiments, fish waste was crushed with a solvent such as hexane or n-hexane to obtain the crude oil [

32,

35]. Furthermore, direct-waste fish oil or prepared crude oil will be pretreated to obtain refined oil. In certain experiments, the pyrolysis or fast pyrolysis will be applied to obtain bio-oil for biodiesel production [

36]. In the process of pyrolysis, water of a high temperature is required for bio-oil generation. Fish oil was extracted with the help of boiled water, mechanical expeller, and petroleum ether as the solvent [

24]. Waste fish oil was degummed with phosphoric acid and later with water and NaOH for efficient biodiesel production [

25]. Zhang et al. [

27] and Smaisim et al. [

28] used n-hexane and hexane as solvents for fat and oil extraction. Finally, the physico-chemical properties of extracted fish oils were analyzed, which is helpful for biodiesel production.

Figure 1. Schematic representation of biodiesel production from fish waste.

Table 1. Extraction of oil from fish waste.

In the later stage, extracted and refined oils were used for biodiesel generation. In certain situations, fish oil can also be collected directly from canning industries to conduct biodiesel generation. Before that, it is required to know the nature of the fish oil, and the type of fatty acid, which determines the biodiesel purity [

37]. In general, transesterification is a widely used method for biodiesel production [

27]. In some experiments, both esterification and transesterification methods were applied to obtain biodiesel. Potent fish oil extraction was achieved from fish waste mixed with the optimum ratio of methanol (CH

3OH) and water. Furthermore, transesterification was carried out for the production of biodiesel from extracted fatty acids and oils.

In transesterification, alcohol (majorly methanol or ethanol) content, i.e., methanol to oil molar ratio, is one of the major concerns. A catalyst is a significant factor for transesterification which may be alkaline or acidic. If it is enzyme-based transesterification, then lipase is added to the mixture and kept at a constant temperature (30–50 °C) in an orbital shaker depending on the conditions. Temperature is another key controlling factor in this reaction, which dictates the yield [

25]. Reaction time is also a critical component for efficient biodiesel production. These factors are crucial in transesterification, which dictates the yield levels. Alkaline transesterification, enzyme-based transesterification, thermally-induced transesterification, etc., are some of the transesterification methods.

Table 2 illustrates the different transesterification methods and solvents used for biodiesel production. Finally, it is important to know the properties of biodiesel by determining the cetane number, flash point, cloud point, density, kinematic viscosity, etc. [

27]. It is also mandatory to know the chemical composition of biodiesel using a standard instrument such as gas chromatography. Finally, the capacity of the biodiesel is checked through the engine testing approach. Several other methods have also been implemented for biodiesel generation worldwide, aside from the conventional wet rendering and dry rendering processes.

Table 2. Extraction of biodiesel from fish waste via different transesterification methods.

Most of the popular fish possess oils and fatty acids which, however, depend on the species. Hence, an initial screening of fishes for oils and fatty acid composition through chemical analysis is mandatory [

37]. Among the wide variety of fish species, few are famous, such as ahi, albacore, anchovy, monkfish, bonito, bacalao, bass, big eye, black cod, bluefin tuna, Bombay duck, carp, catfish, cod, tilapia, and salmon. Besides strictly balancing food security, it is very important to focus on the waste of these fish for biodiesel production. For instance,

Sardinella longiceps (Indian oil sardine) waste is one of the best sources for biodiesel production [

41]. In addition,

Oreochromis aureus (tilapia),

Tenualosa ilisha (Ilish),

Stolephorus indicus (anchovy),

Eleutheronema tetradactylum (salmon), etc., are some of the examples of fish whose waste is often used for biodiesel production [

42,

43]. Choosing a potential candidate fish and their waste for exploring the possibility of improvement in biodiesel production at the industrial level is one of the main targets in the energy sector.

2. Biodiesel Production Using Various Fish Wastes

Biodiesel is one of the clean renewable fuels which causes less pollution when it is combusted. In recent times, increasing demand for renewable energy makes biodiesel an attractive alternative to depleting fossil fuels [

5]. The advantage of fish waste is its abundant availability in the seashore and aquaculture industry. In addition, the production of diesel through conventional and chemical methods is expensive and insufficient. So, the evolution of biodiesel from selected fish waste represents a sustainable and environmentally friendly process which is preferable in the present scenario [

7]. In the below paragraphs, fish waste used for biodiesel production was emphasized, which will be useful for large-scale generation.

For more than two decades, both the basic and applied science of biodiesel production with different species of fishes and their waste were noticed. In the initial stages, most of the researchers internationally studied fish oil contents in different fishes [

44]. Furthermore, few of them focused on fatty acid and oil contents in the fish waste. These works provide the basis for biodiesel production from the oils of fish and their waste. Adebanjo et al. [

45] worked on diesel production with animal fat using the method of pyrolysis, which gave the clue that fish oils are useful for diesel generation. Meher et al. [

46] illustrated the technical aspects of biodiesel production by transesterification, one of the common methods which is used widely by altering certain stages. Bechtel and Oliveira [

47] estimated the lipid contents in cold water fishes. In the same year, Sun et al. [

48] worked on the composition of fatty acids in various fishes for diesel production. Preto et al. [

49] emphasized the importance of fish oil in biodiesel production. Salmon oil (a by-product of salmon processing) was used as a feedstock for diesel generation by El-Mashad et al. [

19]. Both acid-catalyzed (H

2SO

4) esterification and alkaline-catalyzed (KOH) transesterification were followed in this process for biodiesel production and a maximum yield of 99% was attained. Alberta et al. [

50] estimated the free fatty acid composition using the FTIR technique for biodiesel production. The production of biodiesel was carried out with crude fish oil from the soapstock of marine fish using the transesterification method and by crosschecking the fuel properties [

34]. Sodium hydroxide was used as an alkaline catalyst along with methanol in the transesterification process. They noticed that generated biodiesel contains oleic acid (C18:1) and palmitic acid (C16:0) as major components and they also compared the biodiesel with diesel generated through waste cooking oil.

Lin and Li [

51] produced the biodiesel from discarded parts of marine fish using the transesterification process. The efficiency of biodiesel generated through discarded parts of marine fish was noticed by testing the engine performance and emission characteristics and also by comparing the biodiesel with biodiesel generated from waste cooking oil. The generation of bio-oil from waste fish oil through a fast pyrolysis method was achieved by Wiggers et al. [

36]. The experiment was conducted under steady-state conditions at a high temperature (525 °C) and a bio-oil yield of 72–73% was obtained, which, in turn, is useful as diesel. Wisniewski et al. [

52] also used the pyrolysis process at 525 °C for the conversion of fish oil into biofuels. The chemical composition of heavy bio-oil generated through conversion was similar to that of diesel. Andersen and Weinbach [

53] proved the potentiality of residues from the fish industry to generate biodiesel in Norway. Santos et al. [

20] produced diesel using the oil of

Oreochromis niloticus (Nile tilapia) through ultrasound-assisted esterification. Initially, the oil was converted into free fatty acids by alcoholic saponification with potassium hydroxide and later acid hydrolysis with sulfuric acid. Furthermore, esterification was carried out with methanol and H

2SO

4 (as catalyst) by applying ultrasound (40kHz) at a 60 W intensity which showed a positive effect. They also applied response surface methodology (RSM) to evaluate the influence of alcohol on oil molar ratio, catalyst concentration, and temperature, and noticed a 98.2% yield after 90 min of reaction. Chakraborty et al. [

54] synthesized the biodiesel from vegetable oil using a calcinated scale of

Labeo rohita as a low-cost heterogeneous catalyst. The response surface methodology was conducted to determine the optimal parameters and a maximum FAME yield of 97.73% was obtained. This work emphasized that different parts of the fish will be useful for biodiesel production. Huong et al. [

21] generated biodiesel from the fat of tra catfish through a heterogeneous basic-catalyzed transesterification method using ultrasonic mixing (20kHz). They used KOH/γ-Al

2O

3 as a catalyst in this process. The maximum diesel yield was observed in a short reaction time and high amplitude level or a long reaction time and low amplitude level. Additionally, Behcet [

43] synthesized the biodiesel from waste anchovy fish oil in the process of transesterification catalyzed by NaOH. Later, biodiesel was blended with diesel in different combinations and the engine capacity was tested. It was concluded that biodiesel is an effective alternative to conventional petroleum diesel.

Biodiesel was generated through the methanolysis of fish oil derived from fish waste using

Carica papaya lipase [

55]. Also, in this study, they tested the molar ratio of oil and methanol, lipase dose, the initial water activity of lipase, temperature, and the effect of various solvents on biodiesel production, and 20% lipase optimized the formation of methyl esters (biodiesel). Zahidah Nurulfitri [

56] produced biodiesel using the liquid waste by-products of fish canning industries. Jayasinghe and Hawboldt [

57] highlighted biodiesel and other fuel production from fish waste using different methods. The biodiesel production was achieved using fish oil (menhaden oil) through standardizing the optimal conditions [

22]. They used the transesterification method by taking methanol and an alkaline catalyst for biodiesel production with standard quality. Generally, the length of the carbon chain in fish oil is greater than in the plant oils, and this larger cetane number improves the diesel engine’s performance. Biodiesel production was achieved using oil from fish canning industry wastes [

58]. The experiment was performed using the acid esterification pre-treatment method with sulfuric acid as a catalyst and alkaline transesterification. The results showed that 1wt.% H

2SO

4 proved as optimal concentration for a better yield. Yahyaee et al. [

15] emphasized biodiesel production using waste fish oil through transesterification method in Iran. Almost 53% of fish waste was in the liquid phase in certain areas in this region. A special machine was designed to separate oil from fish waste and for 1L of fish oil, 0.9 L of biodiesel was produced. Patil et al. [

38] synthesized biodiesel through methanolysis using discarded marine fish waste and transesterification methods. Mild and strong acid-catalyzed transesterifications were conducted with phosphoric acid and sulfuric acid along with methanol. They highlighted that the ratio of oil to methanol, catalyst concentration, reaction time, and temperature were crucial for biodiesel production, and obtained the yield as per the ASTM standards. In addition, Ramakrishnan et al. [

59] studied the importance and performance of biofuels such as biodiesel through direct engine trials. Garcia-Moreno et al. [

39] achieved biodiesel production using fish waste by setting the optimal conditions. They followed a two-step method, including acid-catalyzed pre-treatment, to esterify the FFA and alkali-catalyzed (NaOH) transesterification with methanol and then finally analyzed the fuel properties. High-quality biodiesel was synthesized by Sharma et al. [

35] using the single-step transesterification method with methanol.

Biodiesel was produced by the synthesis of ethyl esters from fish oil waste through an alkaline transesterification method [

67]. In the transesterification process, ethanol and NaOH catalyst were used for maximum yield. Jung et al. [

2] applied a thermally-induced transesterification method, using clay as a porous material, for biodiesel production from fish waste. Al Azad et al. [

10] identified certain fish wastes as potential biodiesel sources which contain high suitable fatty acids. The methylation of the extracted crude fish oil was carried out to obtain FAME, and further transesterification was applied for biodiesel production. Keshri et al. [

16] characterized the properties of biodiesel generated from fish waste. Water is used as a solvent for the extraction of fats and later saponified with sodium hydroxide to reduce free fatty acid contents. Transesterification was carried out using potassium hydroxide as a catalyst for biodiesel production. Enzymatic transesterification was carried out for biodiesel production from the oil of viscera fish waste. Lipase from

Thermomyces lanuginosus was used and finally a 75.3% biodiesel yield was noticed after 24 h of reaction time [

18]. Zhang et al. [

27] produced biodiesel from fish waste (grass carp, catfish, and sea bass waste) using the transesterification method. Biodiesel with 100% purity was reached with sea bass wastes. In addition, a high protein content was generated from the fish waste, which may be useful as a high-protein feed. Alfio et al. [

14] emphasized the usage of biological waste for biodiesel generation, including fish waste. Biodiesel synthesis was carried out via fish waste oil obtained through supercritical methanol and thermodynamic optimization [

68]. Smaisim et al. [

28] synthesized the biodiesel using a nanomagnetic catalyst via thermodynamic analysis. Biodiesel yield (95 wt%) was high at a 55 °C reaction temperature along with catalyst assistance. Jaiswal et al. [

7] highlighted the lipid extraction from fish processing residues for sustainable biodiesel production. Recently, Adhithan and Sachdeva [

69] generated biodiesel from freshwater

Labeo catla waste and blended it with pure diesel using various percentages. Also, they cross-checked the emissions and found HC, CO, and smoke for the FBD-powered CI engine were lesser than those of the diesel-powered engine. Several other workers described the biochemical and molecular basis or reasons for variations in fatty acid contents in fish oil, and ultimately learned more about the various mechanisms. Overall, this information will be useful for the augmentation of biodiesel production using different fish wastes.

This entry is adapted from the peer-reviewed paper 10.3390/fermentation9090861