You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Biolubricants are a kind of lubricant obtained from plants (mainly vegetable oils such as cardoon, corn, palm, safflower, or rapeseed oils), which makes them biodegradable and environmentally friendly (especially important if they are spilled in the environment). They mainly act as anti-friction media between contact surfaces.

- biolubricants

- transesterification

- vegetable oils

- oxidative stability

- fatty acids

1. Biolubricants: Definition and Raw Materials

Biolubricants are a kind of lubricant based on plants (mainly from vegetable oils such as palm, safflower, or rapeseed oils), which makes them biodegradable and environmentally friendly. They mainly act as anti-friction media. Thus, the main purposes of this kind of product, as in the case of petroleum-based lubricants, are wear reduction by decreasing friction coefficient between two contacting surfaces, rust and oxidation prevention, and sealing effect against dirt, dust, or water [1][2].

In that sense, it is interesting to point out the versatility of biolubricants, as they can present different states of matter (solid, liquid, or semi-solid) obtained from different sources (from natural to synthetic oils), which make them suitable for multiple purposes such as automotive (engine or gearbox oils, transmission or brake fluids, etc.) or industrial oils (machine, hydraulic or compressor oils, for instance).

These products usually present some advantages compared to traditional lubricants based on petrol, like the following [2]:

-

They are more sustainable and biodegradable, as raw materials are natural compared to oil. Also, there are no by-products with difficult management, as they can be used for other purposes or re-used in the same biolubricant production.

-

Biolubricants usually have higher lubricity and viscosity index values (clearly exceeding 140–150, compared to the low values found for lubricants, at 90–100), which is important as it means that their viscosity is less dependent on temperature.

-

They present, in general, higher flash and combustion points, which is a positive issue when it comes to safety during storage and shipping.

However, they also present some disadvantages or challenges, like the following:

-

Due to the presence of saturated fatty acids, biolubricants might present a poor performance at low temperatures, which limits their worldwide marketability.

-

Hydrolysis can take place in contact with moisture, increasing the possibility of corrosion in facilities by increasing free fatty acid levels.

-

They usually have a short oxidative stability, which could imply a change in their properties during storage or oxidation, which is undesirable.

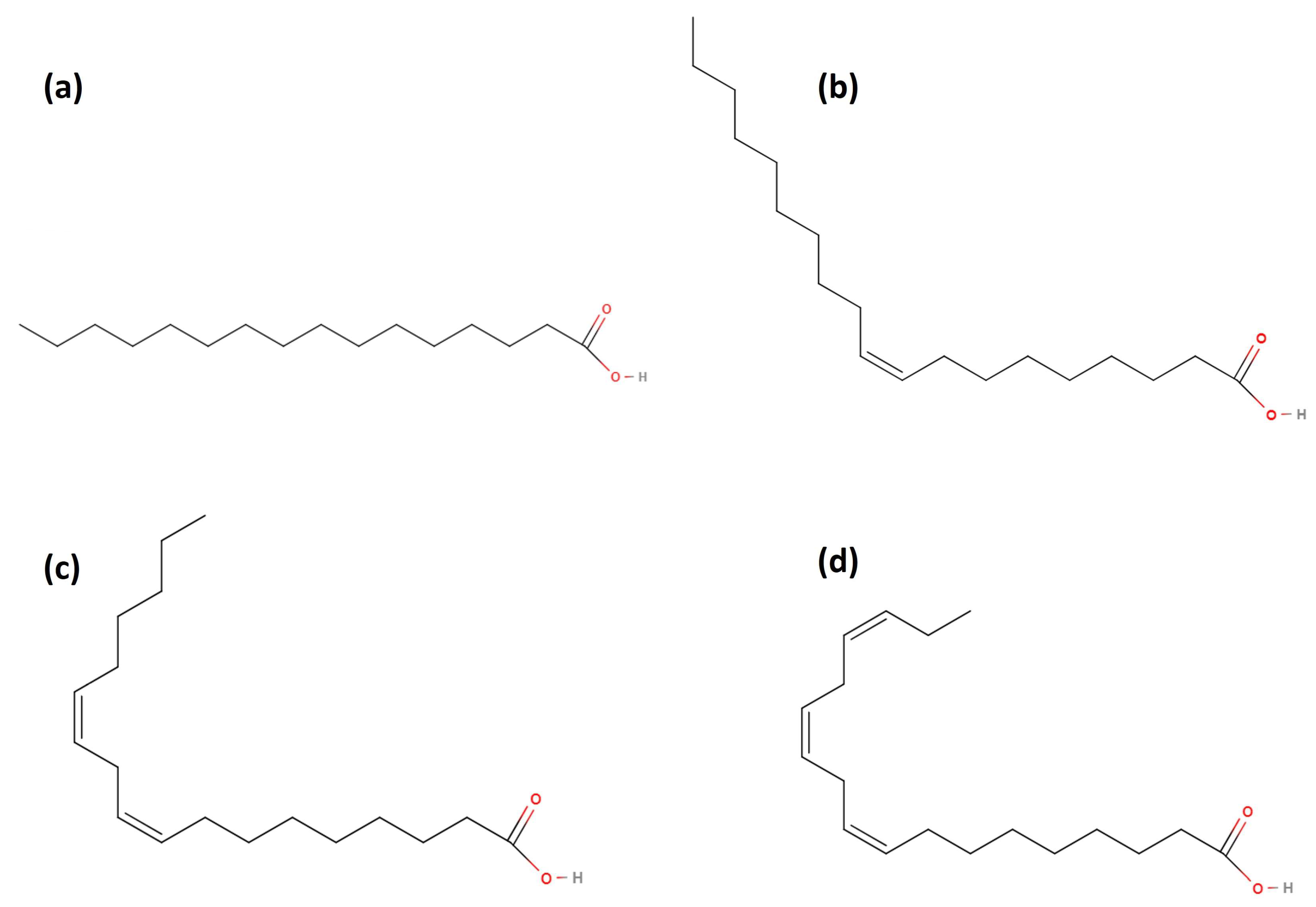

As mentioned above, there are plenty of oilseed crops that are easily adapted to extreme climate and soil conditions, and that can be suitable for biolubricant production, as the subsequent vegetable oil can be a perfect raw material for this purpose. These vegetable oils, along with the use of waste cooking oil, usually present homogeneous characteristics, although their fatty acid composition can present a considerable influence on the properties of these raw materials and, consequently, on the final biolubricant. Indeed, as many previous studies have pointed out, the role of fatty acids in some properties of biolubricants (for instance, viscosity or oxidative stability) is essential, as the presence of some functional groups such as hydroxyl groups (as in the case of ricinoleic acid) or even double bonds can alter these properties, as observed in Figure 1.

Figure 1. Molecular structure of some fatty acids: (a) palmitic acid, (b) oleic acid, (c) linoleic acid, (d) linolenic acid.

According to this figure, it can be observed how fatty acids basically differ from each other according to their molecular chain length and the presence of double bonds (which will be essential to understand the oxidative stability of biolubricants obtained through double transesterification). This way, a thorough knowledge of vegetable oils and their corresponding fatty acid composition is essential to assess, at least approximately, the main properties of the future biolubricant. It should be noted that the oil content in vegetable seeds might vary, according to the literature, from 20–36% for moringa to 45–70% for olive, with some representative crops such as rapeseed and palm presenting around 38–46% and 30–60%, respectively [1]. This fact should be considered in the final biolubricant yield as well as the agronomic performance of these crops.

Table 1 shows some examples of the main vegetable oils and their corresponding fatty acid composition. As observed, some oils present a homogeneous fatty acid profile, whereas other crops (especially genetically modified) have a wide range of specific fatty acids, as in the case of safflower, whose oleic acid content can vary from less than 30% to up to 70%. In that sense, it is not a matter of “names” or “species”, but a matter of fatty acid composition, as the fatty acid profile of some safflower oils could perfectly fit with the fatty acid profile of other vegetable oils like rapeseed.

Table 1. Potential raw materials for biolubricant production and their fatty acid composition (indicated in numerical symbol C:D, where C is the number of carbon atoms and D is the number of double bonds in their molecular structure). n.d. = not determined.

| Vegetable Oil | 16:0 | 16:1 | 18:0 | 18:1 | 18:2 | 18:3 | Others | References |

|---|---|---|---|---|---|---|---|---|

| Castor | 0.5–1.3 | n.d. | 0.5–1.2 | 4–5 | 2–8.4 | 0.4–1 | 83–88 | [3][4][5][6][7][8] |

| Coconut | 8–11 | n.d. | 1–3 | 5–8 | 0–1 | n.d. | 57–71 | [3][4] |

| Corn | 10.3–13 | 0.3 | 2–3 | 25–31 | 54–60 | 1 | n.d. | [3][4][9] |

| Jatropha | 13–16 | n.d. | 5–10.5 | 24–45 | 32–63 | 0.3–0.7 | 0.8–1.4 | [3][4][10][11][12] |

| Olive | 11.5–13.7 | 1.8 | 2.5 | 71–74 | 9.5–10 | 1.5 | n.d. | [3][4][11] |

| Palm | 37–47.9 | 0.4 | 3–8 | 37–45 | 1.9–10 | 0.3–0.5 | 1 | [3][4][11][13] |

| Rapeseed | 4–5 | 0.1–0.2 | 1–2 | 56–69.8 | 20–26 | 6.2–10 | 9.1 | [3][4][6][14] |

| Safflower | 5–7 | 0.08 | 1–4 | 10–21 | 73–79 | n.d. | n.d. | [3][4][15] |

| Soybean | 9.3–12 | 0.2–1.7 | 3–4.7 | 21–27.3 | 48.5–56.3 | 5.6–8 | 2.3 | [3][4][8][10][11] |

| Sunflower | 4.9–7 | 0.1–0.3 | 1.9–5 | 18.7–68 | 21–68.6 | 0.1–1.9 | 2.2 | [3][4][7][10][16][17] |

| WCO | 6.6–36.8 | 0.21–1.9 | 3–18.4 | 17.9–37.5 | 11.8–72.1 | 0.02–2.02 | 3.3 | [10][18][19][20] |

Thus, some interesting points can be inferred from this table:

-

In general, palmitic, oleic, and linoleic acids are the majority of fatty acids found in most vegetable oils, which points out their vital role in some properties in the final biolubricant. In that sense, the presence of double bonds in their molecular structure (see Figure 1), which can be conserved in the molecular structure of the final biolubricant (especially in the case of double transesterification of fatty acids), could determine its oxidative stability. Thus, the knowledge of the ratio of some fatty acids (such as oleic/linoleic ratio) is usually interesting to understand oxidative stability in biodiesel or biolubricants.

-

Nevertheless, there are some specific oils, such as castor oil, whose main fatty acid presents some special properties, as in the case of ricinoleic acid, with a hydroxyl group that can influence the properties of the final biolubricant regarding viscosity (as it promotes intermolecular interactions like hydrogen bonds, implying an increase in viscosity). In any case, there are other oils that present high quantities of other fatty acids, such as lauric and myristic acid in the case of coconut oil or icosenoic acid for rapeseed, which could imply changes in the properties of the corresponding biolubricants.

-

The use of GM crops, as in the case of safflower, might vary the properties of the corresponding oil, with a considerable increase in oleic acid (exceeding 80%), improving some properties such as oxidative stability in the final biolubricant obtained [21]. Other studies point out the same aspect related to soybean oil, with a wide range of fatty acid contents depending on the gene technology used or the selection of soybean mutants [22]. Consequently, it is more interesting to consider FA profiles instead of kinds of vegetable oils, as it would give us a more exact idea about the raw material.

-

The nature of WCO (and its subsequent fatty acid composition) might vary depending on the eating habits of the area where the research study was carried out. That is the reason why there was a wide range of oleic and linoleic acids in this table. In general, the main oils used for cooking are rapeseed, sunflower, soy, and olive oil, which can vary in the diet of some regions or areas. In any case, the fatty acid composition of this waste is relatively equivalent to the rest of vegetable oils, which supports the idea that its use as biodiesel and biolubricant source is feasible if a proper pre-treatment is carried out.

2. Main Characteristics of Biolubricants

It is clear that a biolubricant should present a series of characteristics that are essential for its use in lubrication processes. In that sense, there are plenty of requirements that should be accomplished to be a real alternative for lubricants [9][23].

-

Viscosity: This is an essential parameter for a biolubricant, as it will determine its use for specific purposes. Thus, the resistance to the flow of a specific fluid (normally expressed in cSt) will influence many factors, such as the film thickness between the surfaces in contact or its permanence during lubrication (the higher the viscosity is, the thicker the film will be). Viscosity is influenced by factors such as temperature or pressure. It can be measured by dynamic or kinematic methods (by using Cannon-Fenske or Ostwald viscosimeters) at a specific temperature (normally 40 or 100 °C, which will be useful to determine VI) [24].

-

Viscosity index (VI): This index indicates the changes in viscosity with temperature. Thus, a high viscosity index will imply a lower decrease in viscosity when temperature increases, which is a desirable effect as changes in temperature would not present a considerable influence on biolubricants [25][26]. High VI values will be obtained when the molecular structure of the final biolubricant is longer, and it will decrease with branching. That is the reason why the selection of a chemical route or specific reagents (like complex alcohols in double transesterification) will be vital to determine this parameter. It is calculated by measuring viscosity at 40 and 100 °C.

-

Oxidative stability (OS): This parameter is related to the stability of biolubricants during oxidation processes, including storage. It is expressed in hours and determined through the induction point (IP) according to the Rancimat method [27][28]. This way, free radical generation (mainly due to the presence of double bonds in biolubricants) could start a chain reaction, where the propagation of free radicals could end up generating undesirable products such as free fatty acids (FFA) or polymers, among other decomposition compounds. The former could be related to the increase in acidity, which is an undesirable effect, especially when it comes to the maintenance of equipment and facilities. The latter is especially related to an increase in viscosity, as the polymerization of esters generates more complex molecules, which could imply an increase in molecular interactions such as Van der Waals or hydrogen bonds and, therefore, a higher resistance to the flow of biolubricants (that is, an increase in viscosity).

-

Other parameters: the abovementioned properties are the most important ones to define the performance of a biolubricant, but there is a wide range of characteristics that should be considered, like pour point (the lowest temperature at which a biolubricant pours or flows, which is desirable to be as low as possible to be useful in cold climates), lubricity (that is, the reduction of friction between two surfaces in contact when the biolubricant is used), flash and combustion points (usually higher compared to traditional lubricants, which is a great advantage when it comes to safety during storage or shipping), hydrolytic stability (resistance of esters to hydrolyze, that is, to degrade in contact with water at high temperature) or biodegradability (which is considerably higher compared to petrol-based lubricants), among others.

Apart from the abovementioned properties, there are many other aspects that should be considered for the marketability of a biolubricant. For instance, acidity should be taken into account, as recently explained, whereas there are other parameters included in standards that should be considered. The changes in these parameters will be determined by different factors (such as raw materials used, the kind of chemical route selected for biolubricant production, or the chemical conditions that are chosen, including temperature, reaction time, reagents, etc.).

Thus, molecular factors such as functional groups and polarity (usually increase viscosity and tribofilm adhesion), numbers of branching (with a decrease in pour point and an improvement in oxidative stability), degree of unsaturation (with lower thermal and oxidative stabilities), or carbon chain length (improving viscosity and VI but with lower oxidative stability values) will determine the properties of a biolubricant, which are directly influenced by the abovementioned factors [29]

By way of example, Table 2 shows the most important characteristics of biolubricants mainly obtained through double transesterification (with methanol and the complex alcohol commented on in this table) from different sources.

Table 2. Some characteristics of biolubricants are obtained through double transesterification.

| Biolubricant | Viscosity 1, cSt | VI | Pour Point, °C | Flash Point, °C | IP, h | References |

|---|---|---|---|---|---|---|

| Rapeseed-based 2-ethyl-1-hexyl-esters | 7.97 | n.d. 2 | n.d. | 196 | <6 | [18] |

| Seed-based 2-ethyl-1-hexyl-esters | 7.47 | n.d. | n.d. | 195 | >3 | [18] |

| WCO-based 2-ethyl-1-hexyl-ester | 7.40 | n.d. | n.d. | 193 | >3 | [18][20] |

| WCO-based 2-ethyl-1-hexyl-ester | 34.91 | 122 | −1 | 216 | n.d. | [20] |

| Mustard seed oil-based 2-ethyl-1-hexyl ester | 8.6 | n.d. | n.d. | n.d. | n.d. | [30] |

| Cardoon-based NPGE | 18.85 | 184 | n.d. | n.d. | <3 | [31] |

| WCO-based NPGE |

44.9 | 457 | −1 | 238 | n.d. | [20] |

| Palm-based PEE | 68.4 | 188 | −20 | 302 | n.d. | [32] |

| High-oleic safflower-based PEE | 77.7 | 155 | n.d. | 260 | 2.86 | [21] |

| WCO-based PEE | 68.5 | 144 | n.d. | 253 | 2.07 | [33] |

| Palm-based TMPE | 49.7 | 188 | −1 | n.d. | n.d. | [34] |

| High-oleic safflower-based TMPE | 73.39 | 103 | n.d. | 216 | 6.7 | [21] |

| High-oleic safflower-based TMPE | 89.11 | 131 | n.d. | 220 | >7 | [35] |

| Rapeseed-based TMPE | 75.5 | 128 | n.d. | 210 | 4.9 | [36] |

| Jatropha-based TMPE | 51.89 | 140 | −3 | n.d. | n.d. | [37] |

| Palm-based TMPE | 38.25 | 171 | 5 | 240 | n.d. | [37] |

| Sesame-based TMPE | 35.55 | 193 | −21 | 196 | n.d. | [38] |

| WCO-based TMPE |

30 | 179 | n.d. | n.d. | n.d. | [39] |

| Palm kernel-based isoamyl ester | 3-6 | 149 | n.d. | n.d. | 0.3 | [40] |

1 at 40 °C. 2 not determined.

As inferred from this table, several factors should be pointed out, like the following:

-

Viscosity values are mainly influenced by the alcohol used in the second transesterification, as it is the determining factor for the final molecular structure of the biolubricant. There are some exceptions where the raw material plays an important role, as in the case of castor oil, whose majority compound (ricinoleic acid) promotes a considerable increase in viscosity by itself. Thus, biolubricants obtained with complex alcohols usually present an increasing viscosity in that order: 2-ethyl-1-hexanol < NPG < TMP < PE.

-

Another important factor is the conversion of the process. Thus, low conversions will imply a mixture with biodiesel (with a viscosity range between 3 and 6, in most cases). That is the reason why the role of catalysts is so important in order to obtain high conversion rates at mild reaction conditions.

-

As previously explained, some properties of biolubricants are quite interesting, like high VI and flash points, which encourage the production of these compounds.

This entry is adapted from the peer-reviewed paper 10.3390/catal13091299

References

- Mobarak, H.M.; Niza Mohamad, E.; Masjuki, H.H.; Kalam, M.A.; Al Mahmud, K.A.H.; Habibullah, M.; Ashraful, A.M. The Prospects of Biolubricants as Alternatives in Automotive Applications. Renew. Sustain. Energy Rev. 2014, 33, 34–43.

- Salimon, J.; Salih, N.; Yousif, E. Biolubricants: Raw Materials, Chemical Modifications and Environmental Benefits. Eur. J. Lipid Sci. Technol. 2010, 112, 519–530.

- Karmakar, G.; Ghosh, P.; Sharma, B.K. Chemically Modifying Vegetable Oils to Prepare Green Lubricants. Lubricants 2017, 5, 44.

- Cecilia, J.A.; Plata, D.B.; Saboya, R.M.A.; de Luna, F.M.T.; Cavalcante, C.L.; Rodríguez-Castellón, E. An Overview of the Biolubricant Production Process: Challenges and Future Perspectives. Processes 2020, 8, 257.

- Encinar, J.M.; González, J.F.; Pardal, A. Transesterification of Castor Oil under Ultrasonic Irradiation Conditions. Preliminary Results. Fuel Process. Technol. 2012, 103, 9–15.

- Encinar, J.M.; Nogales-Delgado, S.; Sánchez, N.; González, J.F. Biolubricants from Rapeseed and Castor Oil Transesterification by Using Titanium Isopropoxide as a Catalyst: Production and Characterization. Catalysts 2020, 10, 366.

- Sánchez, N.; Encinar, J.M.; Nogales, S.; González, J.F. Biodiesel Production from Castor Oil by Two-Step Catalytic Transesterification: Optimization of the Process and Economic Assessment. Catalysts 2019, 9, 864.

- Quinchia, L.A.; Delgado, M.A.; Reddyhoff, T.; Gallegos, C.; Spikes, H.A. Tribological Studies of Potential Vegetable Oil-Based Lubricants Containing Environmentally Friendly Viscosity Modifiers. Tribol. Int. 2014, 69, 110–117.

- Kania, D.; Yunus, R.; Omar, R.; Abdul Rashid, S.; Mohamad Jan, B. A Review of Biolubricants in Drilling Fluids: Recent Research, Performance, and Applications. J. Pet. Sci. Eng. 2015, 135, 177–184.

- Attia, N.K.; El-Mekkawi, S.A.; Elardy, O.A.; Abdelkader, E.A. Chemical and Rheological Assessment of Produced Biolubricants from Different Vegetable Oils. Fuel 2020, 271, 117578.

- Hájek, M.; Vávra, A.; De Paz Carmona, H.; Kocík, J. The Catalysed Transformation of Vegetable Oils or Animal Fats to Biofuels and Bio-Lubricants: A Review. Catalyst 2021, 11, 1118.

- Arianti, A.N.; Widayat, W. A Review of Bio-Lubricant Production from Vegetable Oils Using Esterification Transesterification Process. MATEC Web Conf. 2018, 156, 6007.

- Durango-Giraldo, G.; Zapata-Hernandez, C.; Santa, J.F.; Buitrago-Sierra, R. Palm Oil as a Biolubricant: Literature Review of Processing Parameters and Tribological Performance. J. Ind. Eng. Chem. 2022, 107, 31–44.

- Encinar, J.M.; Pardal, A.; Martínez, G. Transesterification of Rapeseed Oil in Subcritical Methanol Conditions. Fuel Process. Technol. 2012, 94, 40–46.

- Nogales-Delgado, S.; Encinar, J.M.; González, J.F. Safflower Biodiesel: Improvement of Its Oxidative Stability by Using BHA and TBHQ. Energy 2019, 12, 1940.

- Nogales-Delgado, S.; Encinar, J.M.; Guiberteau, A.; Márquez, S. The Effect of Antioxidants on Corn and Sunflower Biodiesel Properties under Extreme Oxidation Conditions. JAOCS J. Am. Oil Chem. Soc. 2019, 97, 201–212.

- Encinar, J.M.; González, J.F.; Sánchez, N.; Nogales-Delgado, S. Sunflower Oil Transesterification with Methanol Using Immobilized Lipase Enzymes. Bioprocess Biosyst. Eng. 2019, 42, 157–166.

- Encinar, J.M.; Nogales, S.; González, J.F. Biodiesel and Biolubricant Production from Different Vegetable Oils through Transesterification. Eng. Rep. 2020, 2, e12190.

- Bashiri, S.; Ghobadian, B.; Dehghani Soufi, M.; Gorjian, S. Chemical Modification of Sunflower Waste Cooking Oil for Biolubricant Production through Epoxidation Reaction. Mater. Sci. Energy Technol. 2021, 4, 119–127.

- Joshi, J.R.; Bhanderi, K.K.; Patel, J.V.; Karve, M. Chemical Modification of Waste Cooking Oil for the Biolubricant Production through Transesterification Process. J. Indian Chem. Soc. 2023, 100, 100909.

- Encinar, J.M.; Nogales-Delgado, S.; Álvez-Medina, C.M. High Oleic Safflower Biolubricant through Double Transesterification with Methanol and Pentaerythritol: Production, Characterization, and Antioxidant Addition. Arab. J. Chem. 2022, 15, 103796.

- Milazzo, M.F.; Spina, F.; Cavallaro, S.; Bart, J.C.J. Sustainable Soy Biodiesel. Renew. Sustain. Energy Rev. 2013, 27, 806–852.

- Kurre, S.K.; Yadav, J. A Review on Bio-Based Feedstock, Synthesis, and Chemical Modification to Enhance Tribological Properties of Biolubricants. Ind. Crop. Prod 2023, 193, 116122.

- ISO 3104:1994; UNE-EN ISO 3104/AC:1999 Petroleum Products. Transparent and Opaque Liquids. Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity. ISO: Geneva, Switzerland, 1999.

- Verdier, S.; Coutinho, J.A.P.; Silva, A.M.S.; Alkilde, O.F.; Hansen, J.A. A Critical Approach to Viscosity Index. Fuel 2009, 88, 2199–2206.

- ASTM-D2270-10; Standard Practice for Calculating Viscosity Index from Kinematic Viscosity at 40 °C and 100 °C. ASTM: West Conshohocken, PA, USA, 2016.

- Focke, W.W.; Van Der Westhuizen, I.; Oosthuysen, X. Biodiesel Oxidative Stability from Rancimat Data. Thermochim. Acta 2016, 633, 116–121.

- UNE-EN 14112; Fat and Oil Derivatives—Fatty Acid Methyl Esters (FAME)—Determination of Oxidation Stability (Accelerated Oxidation Test). European Committee for Standardization: Brussels, Belgium, 2017.

- Chan, C.H.; Tang, S.W.; Mohd, N.K.; Lim, W.H.; Yeong, S.K.; Idris, Z. Tribological Behavior of Biolubricant Base Stocks and Additives. Renew. Sustain. Energy Rev. 2018, 93, 145–157.

- Chen, J.; Bian, X.; Rapp, G.; Lang, J.; Montoya, A.; Trethowan, R.; Bouyssiere, B.; Portha, J.F.; Jaubert, J.N.; Pratt, P.; et al. From Ethyl Biodiesel to Biolubricants: Options for an Indian Mustard Integrated Biorefinery toward a Green and Circular Economy. Ind. Crop. Prod 2019, 137, 597–614.

- Nogales-Delgado, S.; Encinar Martín, J.M. Cardoon Biolubricant through Double Transesterification: Assessment of Its Oxidative, Thermal and Storage Stability. Mater. Lett. 2021, 302, 130454.

- Aziz, N.A.M.; Yunus, R.; Rashid, U.; Syam, A.M. Application of Response Surface Methodology (RSM) for Optimizing the Palm-Based Pentaerythritol Ester Synthesis. Ind. Crop. Prod. 2014, 62, 305–312.

- Nogales-Delgado, S.; Cabanillas, A.G.; Romero, Á.G.; Encinar Martín, J.M. Monitoring Tert-Butylhydroquinone Content and Its Effect on a Biolubricant during Oxidation. Molecules 2022, 27, 8931.

- Yunus, R.; Fakhru’l-Razi, A.; Ooi, T.L.; Omar, R.; Idris, A. Synthesis of Palm Oil Based Trimethylolpropane Esters with Improved Pour Points. Ind. Eng. Chem. Res. 2005, 44, 8178–8183.

- Nogales-Delgado, S.; Encinar Martín, J.M.; Sánchez Ocaña, M. Use of Mild Reaction Conditions to Improve Quality Parameters and Sustainability during Biolubricant Production. Biomass Bioenergy 2022, 161, 106456.

- Encinar, J.M.; Nogales-Delgado, S.; Pinilla, A. Biolubricant Production through Double Transesterification: Reactor Design for the Implementation of a Biorefinery Based on Rapeseed. Processes 2021, 9, 1224.

- Heikal, E.K.; Elmelawy, M.S.; Khalil, S.A.; Elbasuny, N.M. Manufacturing of Environment Friendly Biolubricants from Vegetable Oils. Egypt. J. Pet. 2017, 26, 53–59.

- Ocholi, O.; Menkiti, M.; Auta, M.; Ezemagu, I. Optimization of the Operating Parameters for the Extractive Synthesis of Biolubricant from Sesame Seed Oil via Response Surface Methodology. Egypt. J. Pet. 2018, 27, 265–275.

- Ghafar, F.; Sapawe, N.; Dzazita Jemain, E.; Safwan Alikasturi, A.; Masripan, N. Study on the Potential of Waste Cockle Shell Derived Calcium Oxide for Biolubricant Production. Mater. Today Proc. 2019, 19, 1346–1353.

- Cerón, A.A.; Vilas Boas, R.N.; Biaggio, F.C.; de Castro, H.F. Synthesis of Biolubricant by Transesterification of Palm Kernel Oil with Simulated Fusel Oil: Batch and Continuous Processes. Biomass Bioenergy 2018, 119, 166–172.

This entry is offline, you can click here to edit this entry!