Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Environmental Sciences

Butanol fermentation, also known as acetone–butanol–ethanol (ABE) fermentation, refers to the synthesis of butanol by butanol-producing strains using starch crops or sugars as raw materials under strict anaerobic conditions while generating byproducts of acetone and ethanol.

- ABE fermentation

- butanol-producing strains

- low-cost raw materials

1. Introduction

As an important platform chemical, butanol is widely used in industries such as medicine and chemicals, mainly as a solvent or chemical synthesis raw material. At the same time, butanol can be used as a fuel instead of gasoline or as a fuel additive.

With the highlighting of global carbon emissions and environmental issues, butanol production via fermentation has received widespread attention [1,2]. Butanol fermentation, also known as acetone–butanol–ethanol (ABE) fermentation, refers to the synthesis of butanol by butanol-producing strains using starch crops or sugars as raw materials under strict anaerobic conditions while generating byproducts of acetone and ethanol. ABE fermentation began in the 1850s and has a history of 150 years.

In 1914, Weizmann isolated a strain of butanol-producing clostridia that can synthesize butanol from starch, named Clostridium acetobutylicum (C. acetobutylicum), and its butanol titer can exceed 10 g/L with stable heredity. To date, C. acetobutylicum remains an important species for industrial butanol production, and its discovery laid an important foundation for the industrial development of butanol fermentation.

In the late 1950s, with the rapid development of the petrochemical industry, the cost of synthesizing acetone and butanol using chemical methods became even cheaper, while the high costs of raw materials and subsequent purification of butanol from fermentation resulted in a huge impact on the ABE fermentation industry and many butanol fermentation plants were shut down, leading to a downturn in the butanol fermentation industry [3].

2. Butanol-Producing Strain

Clostridium is the main type of bacterium that is capable of producing butanol, including species such as Clostridium acetobutylicum, Clostridium beijerinckii, Clostridium saccharoperbutylacetonicum, Clostridium saccharobutylicum, Clostridium sporogenes, Clostridium pasteurianum, Clostridium carboxidivorus, Clostridium tetanomorphum, and Clostridium aurantibutyricum [3]. All these strains are strict anaerobic bacteria with rod-shaped cell morphology and are Gram-positive bacteria capable of forming endospores. Table 1 shows the butanol fermentation performance of different strains.

Table 1. Butanol fermentation performance of different strains.

| Strain | Raw Material | Main Product | Butanol Titer (g/L) | Reference |

|---|---|---|---|---|

| Clostridium acetobutylicum | Glucose | Butanol, acetone, ethanol | 10.4 | [4] |

| Clostridium beijerinckii | Glucose | Butanol, isopropyl alcohol | 15.2 | [5] |

| Clostridium saccharoperbutylacetonicum | Glucose | Butanol, acetone, ethanol | 16.2 | [6] |

| Clostridium saccharoperbutylicum | Glucose | Butanol, acetone, ethanol | 9.7 | [7] |

| Clostridium sporogenes | Glucose | Butanol, ethanol, propyl alcohol, isobutanol, methyl butanol | 0.12 | [8] |

| Clostridium perfrigens | Glucose | Butanol, ethanol, propyl alcohol, isobutanol, methyl butanol | 0.02 | [8] |

| Clostridium pasteurianum | Glycerinum | Butanol, 1, 3-propylene glycol | 6.5 | [9] |

| Clostridium carboxidivorus | CO | Butanol, ethanol | 0.37 | [10] |

Among the butanol-producing microorganisms, Clostridium acetobutylicum, Clostridium beijerinckii, Clostridium saccharoperbutylacetonicum, and Clostridium saccharobutylicum are commonly used in industry and research with relatively high butanol titers [11]. Common butanol-producing strains can be divided into two categories based on the characteristics of substrate utilization: starch-metabolizing strains and sugar-metabolizing strains. The main difference between these strains is that the former can secrete amylase to hydrolyze starch into monosaccharides for growth and fermentation, while the latter can only use monosaccharides as fermentation substrates. C. acetobutylicum ATCC 824 and C. acetobutylicum DSM 1731 are typical starch-metabolizing strains, while typical sugar-metabolizing strains include C. acetobutylicum NCIMB8052, C. acetobutylicum P 262, and C. beijerinckii BA101 [12].

Due to the cytotoxicity of butanol, when the butanol titer reaches a certain level, the bacteria gradually form spores, enter a dormant state, and fermentation stops. Therefore, the butanol produced by Clostridium is usually below 13 g/L. To solve this problem, researchers have conducted a lot of strain breeding works to improve the butanol tolerance and production of bacteria. Currently, there are many methods available for strain improvement, such as mutation breeding, genome design, evolutionary engineering, and synthetic biology.

Early strain modification mainly involved mutagenesis and domestication, including physical and chemical mutagenesis methods. Annous et al. used chemical mutagenesis with nitrosoguanidine as the mutagen on C. acetobutylicum ATCC 824 to obtain a butanol high-yield strain, C. acetobutylicum BA105, with a titer of 18 g/L, 1.8 times that of the original strain. The amylase activity of the mutant strain was also significantly improved [13]. Syed et al. combined ultraviolet mutagenesis, methyl methanesulfonate mutagenesis, and nitrosoguanidine mutagenesis to induce mutation in C.acetobutylicum PTCC 23, screening for a butanol high-yield strain, C. acetobutylicum MEMS7, which produced 18.0 g/L butanol when using molasses as the substrate, a 20% increase over the original strain [14]. Li et al. used low-energy ion beam injection mutagenesis and nitrosoguanidine mutagenesis to induce mutation in C. beijerinckii L175 and obtained a butanol high-yield strain, C. beijerinckii MUT3, which produced 15.8 g/L butanol, a 46% increase over the original strain [15]. In 2001, Qureshi et al. used nitrosoguanidine as the mutagen to induce mutation in C. beijerinckii, screening for a butanol high-yield strain, C. beijerinckii BA101, which produced 19 g/L butanol, a 122.2% increase over the original strain. C. beijerinckii BA101 is still an important butanol high-yield strain to date, with stable genetic characteristics [16]. Currently, the highest butanol-producing strain in batch fermentation conditions is C. acetobutylicum JB200, which was domesticated under a long-term intermittent addition of butanol, and its butanol titer can reach 20 g/L [17].

In 2001, with the successful sequencing of the complete genomes of ethanol, acetone, and butanol synthetic pathways and metabolic pathways in the C. acetobutylicum TCC824 and C. beijerinckii NCIMB8052 strains, researchers aimed to obtain excellent strains with a high yield and high butanol tolerance by studying key genes, key enzymes, and metabolic networks. Jiang et al. knocked out the key enzyme gene acetyl-coenzyme A decarboxylase (adc) in the acetone synthesis process of C. acetobutylicum EA2018 to reduce the production of the fermentation byproduct acetone, thereby increasing the proportion of butanol in the total solvent. The results showed that acetone production decreased to 0.2 g/L, and the proportion of butanol increased from 70% to 80%, but the butanol titer also decreased from 13.6 g/L to 7.4 g/L, mainly because the acetone generation pathway is coupled with the acid reabsorption pathway, which is associated with the butanol production pathway [18]. Jang et al. selected key enzyme genes in the organic acid synthesis and butanol synthesis metabolic pathways for combined regulation. By knocking out the acetyl phosphate transferase gene (pta) and butyrate kinase gene (buk) and overexpressing the butanol dehydrogenase gene (adhE), the butanol titer increased by 60% to 18.9 g/L [19]. Mann et al. showed that enhancing the expression of the stress protein genes groESL, grpE, and htpG significantly improved butanol tolerance in Clostridium acetobutylicum. When the culture medium contained 2% (v/v) butanol, the original strain died within 2 h, whereas the survival rates of the genetically engineered strains groESL, grpE, and htpG were 45%, 25%, and 56%, respectively. However, the butanol titers of the genetically engineered strains grpE and htpG were only 52% and 68%, respectively, compared to the original strain [20]. Scotcher et al. reported that sporulation formation can affect ABE production. By inhibiting the expression of the SpoIIE gene, which controls sporulation formation, the formation of spores was delayed, and the titers of butanol, acetone, and ethanol increased by 110%, 43%, and 225%, respectively [21]. Cong et al. used metabolic engineering technology and gene editing technology to overexpress, knock out, or inhibit the transcription of key genes in the xylose transport pathway, xylose metabolism pathway, and butanol synthesis pathway and optimized and combined these genes to construct a strain that can efficiently produce butanol from xylose. The highest yield of recombined strain CC101 (ptb-Xyl T) ABE was 0.41 g/g, and when the xylose titer was increased to 55 g/L, the ABE titer increased to 14.6 g/L [22].

Some researchers have attempted to clone the key enzyme genes of the butanol synthesis pathway into nonbutanol-producing bacterial cells such as E. coli or yeast through synthetic biology to artificially construct the butanol synthesis pathway. However, studies have shown that although genetically engineered bacteria can synthesize butanol, their titers are low [23,24]. Atsumi et al. expressed six key enzyme genes in the butanol synthesis metabolic pathway in E. coli and knocked out several enzyme genes related to byproduct formation in E. coli. Butanol titer of 0.35 g/L was observed [25]. Eric et al. constructed a similar butanol synthesis metabolic pathway in S. cerevisiae and conducted fermentation using galactose as a substrate. The butanol titer was only 2.5 mg/L [26]. Schadeweg et al. integrated the butanol synthesis metabolic pathway into S. cerevisiae, overexpressed key butanol synthesis genes, deactivated competitive pathways, and supplemented pantothenate in a timely manner during the cultivation process, resulting in a butanol titer of 13 g/L [27].

3. ABE Synthetic Metabolic Pathway of Clostridium

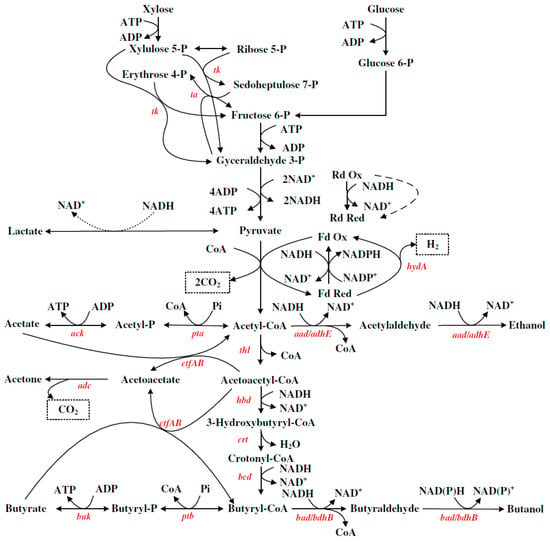

The ABE synthetic metabolic pathway of Clostridium acetobutylicum for the production of butanol is shown in Figure 1 [28]. The major metabolites produced during ABE fermentation include butanol, acetone, and ethanol, accompanied by the generation of CO2 and H2. The entire fermentation process is divided into two stages: the acidogenic phase and the solventogenic phase.

Figure 1. ABE synthesis pathway of Clostridium acetobutylicum [28]. (tk: transketolase; ta: transaldolase; hydA: hydrogenase; aad: acetaldehyde dehydrogenase; adhE: ethanol dehydrogenase; bad: butryraldehyde dehydrogenase; bdhB: butryraldehyde dehydrogenase; buk: butyrate kinase; pta: phosphotransacetylase; ack: acetate kinase; ctfAB: acetate/butyrate:CoA-transferase; hbd: 3-hydroxybutyryl-CoA dehydrogenase; crt: crotonase; bcd: butyryl-CoA dehydrogenase; adc: acetoacetate decarboxylase; ptb: phosphotransbutyrylase).

Clostridium acetobutylicum generates pyruvate through the Embden–Meyerhof–Parnas (EMP) pathway and then produces acetyl-CoA under the action of ferredoxin oxidoreductase, accompanied by the generation of CO2 and H2. The process of generating ABE from acetyl-CoA is divided into the acidogenic phase and the solventogenic phase.

The acidogenic phase is coupled with the logarithmic growth phase of the cell, and ATP is produced during the acidogenic phase, providing energy for cell growth. Phosphate acetyltransferase (pta) and acetate kinase (ack) control the synthesis of acetic acid, while butyrate kinase (buk) and phosphate butyryl transferase (ptb) control the synthesis of butyric acid. As acetic acid and butyric acid gradually accumulate, the pH of the fermentation broth gradually decreases. When the pH drops to a certain value (approximately 4.5), bacterial metabolism shifts to the solventogenic phase, and the transition phase between the acidogenic and solventogenic phases is called the transition phase. The metabolic shift of the cells is mainly due to the change in pH in the fermentation broth. The intracellular pH of Clostridium acetobutylicum is influenced by the environmental pH, and in general, the intracellular pH is one unit higher than the environmental pH. When the pH of the fermentation broth drops to approximately 4.5, some undissociated acetic acid and butyric acid enter the cytoplasm and dissociate, disrupting the original proton gradient inside and outside the cell membrane. To resist this adverse environment, the cells convert organic acids into acetyl-CoA and butyryl-CoA while continuing to consume substrates for the synthesis of butanol, acetone, and ethanol [29]. Grimmler et al. found that at least 245 genes showed differential expressions during the transition phase from the acidogenic to the solventogenic phase [30]. Bacterial stress responses, metabolic regulation, and fermentation culture conditions are all factors influencing the transition from the acidogenic to the solventogenic phase [31].

In the solventogenic phase, acetyl-CoA, butyryl-CoA, and acetoacetyl-CoA are the precursors for the synthesis of ethanol, butanol, and acetone, respectively, and are three key intermediate metabolites in the ABE synthesis pathway. Both butanol and ethanol are generated under the catalysis of aldehyde/alcohol dehydrogenases (aad, adhE), accompanied by the consumption of NAD(P)H, while acetone is produced under the catalysis of acetoacetyl-CoA transferase (ctfAB) and acetoacetyl-CoA decarboxylase (adc), accompanied by the release of CO2. The generation of acetone is coupled with the reabsorption of acid, where acetoacetyl-CoA transferase (ctfAB) uses acetate or butyrate as CoA acceptors to form acetyl-CoA or butyryl-CoA, which are used for the synthesis of ethanol and butanol. Therefore, inhibiting the synthesis pathway of acetone will also affect the generation of alcohols. As the fermentation enters the late solventogenic phase and the titer of products in the fermentation broth increases, the cells gradually decline, forming spores due to the toxicity of metabolic products (especially butanol) and nutrient depletion. At this point, the fermentation ends [32].

This entry is adapted from the peer-reviewed paper 10.3390/fermentation9090847

This entry is offline, you can click here to edit this entry!