Growing concerns about the environmental impacts, healthiness, and ethical implications of eating animal-based products, such as meat, eggs, and milk, has led to an increase in demand for plant-based alternatives. Plant-based milk substitutes can be created using two main approaches. First, certain oil-rich plant tissues (such as almonds, cashews, coconut flesh, flaxseeds, or soy beans) can be converted into colloidal suspensions using size-reduction and isolation techniques (such as soaking, grinding, enzyme-treatment, filtration, and centrifugation). Second, plant-based oils (such as corn, flaxseed soybean, or sunflower oil) can be homogenized with water in the presence of plant-based proteins (such as pea, legume, or soy proteins), polysaccharides (gum arabic or beet pectin), phospholipids (such as soy or sunflower lecithin), or saponins (such as quillaja saponin) to create an oil-in-water emulsion with similar characteristics to bovine milk.

- Plant-based milk

- Emulsions

- Homogenization

- Milk substitutes

- Processing

The manufacturing processes utilized to fabricate plant-based milk substitutes should ideally produce a final product that has some similarities to cow’s milk in terms of their composition and structure [8]. In particular, the colloidal nature of cow’s milk plays a crucial role in producing its desirable quality attributes, since the fat globules and casein micelles contribute to its milky appearance and creamy texture [9]. The sugars and salts found in milk also play a key role in determining its flavor profile. Hence, plant-based products typically consist of colloidal fat and/or protein dispersed within an aqueous solution containing sugars and salts. In general, two main approaches have been developed to create this kind of product [8]: (i) Breaking down the natural structures of certain plant materials to release oil bodies or other colloidal matter [5], and (ii) the fabrication of simulated fat globules using plant-based ingredients using homogenization technologies [10].

Extracted Oil Bodies

Many edible plants develop specialized tissues (seeds) where lipids are stored as a source of energy and materials that can be utilized during biosynthesis [11]. The lipids are usually contained in oil bodies that are small colloidal particles (typically 0.2 to 2 μm) consisting of a triglyceride core coated by a phospholipid shell that has proteins embedded in it [12]. This kind of structure is similar to the fat globules in raw cow’s milk [13], and therefore would be expected to exhibit many of the same functional attributes, such as creating a creamy appearance and texture, in plant-based milk substitutes [8].

Plant seeds have different names depending on their biological origin. For instance, the seeds from legumes are referred to as beans, whereas those from trees are called nuts. Some common types of seeds used to create plant-based milk substitutes are almonds, cashews, coconuts, flaxseeds, and soybeans [5,14]. Pure oils (rather than oil bodies) can be extracted from these plant sources and used to form plant-based milk substitutes (see next section), but large quantities of organic solvents are often required for this purpose, which is costly and environmentally unfriendly. More environmentally friendly processing operations can be utilized to isolate intact oil bodies from plant seeds, such as soaking them in water to soften their structure, grinding them to release the oil bodies, fractionating them to remove undesirable plant debris, homogenizing them to reduce the size of the particles, and thermally processing them to deactivate enzymes and microbes [14–17]. Plant seeds naturally contain proteins, polysaccharides, sugars, and minerals that may be dissolved or dispersed in the water phase where they create a flavor profile and nutritional attributes that somewhat resemble those of cow’s milk. Some of the common processes used to create plant-based milks using this approach are highlighted in Figure 1a and discussed in more detail in a previous article [8]. This kind of product may be fortified with nutrients or nutraceuticals by blending them with the plant-based milk substitute during or after the manufacturing process, which is discussed in detail later.

Even though plant-based milk substitutes containing natural oil bodies have many compositional and structural similarities to cow’s milk, they cannot completely mimic its desirable physicochemical and sensory attributes. Cow’s milk has a relatively bland but distinctive flavor profile due to the unique combination of sugars, salts, and lipids it contains [18]. The aroma, taste, and mouthfeel of plant-based milk substitutes are different because they contain different kinds of molecules and structures. For instance, soy milks have been reported to have a characteristic beany flavor [5]. Many consumers find this undesirable because they do not like this kind of flavor profile or because it does not conform with their expectations of what milk should taste like.

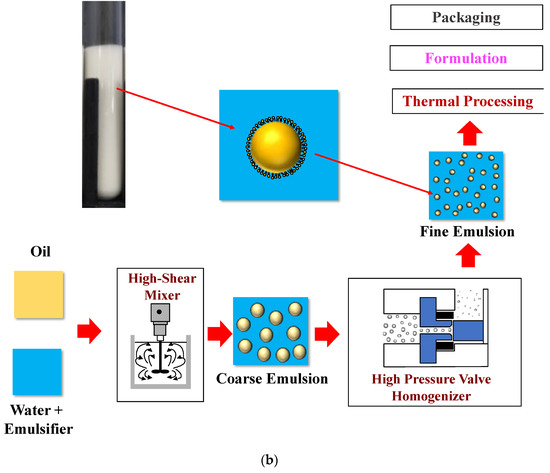

Figure 1a: Some commonly used processing operations that are utilized to produce plant-based milk substitutes. These processes need not be carried out in the order shown. Adapted from T. McHugh [17]. b: Plant-based milk substitutes can also be produced by homogenizing plant-based oil and emulsifiers with water. Typically, a coarse emulsion is formed first, which is then passed through a homogenizer.

Simulated Fat Globules

Plant-based milk substitutes with physical properties and sensory attributes fairly similar to cow’s milk can be produced from plant-based ingredients, such as plant-derived emulsifiers, oils, and others [10]. In this case, the plant-based ingredients are combined together to form an emulsion using a homogenization step (Figure 1b). The stability and properties of this type of colloidal dispersion depend strongly on the kind of ingredients and unit operations utilized during its production [19].

Ingredients

Oil: The bulk oils used to prepare emulsions are isolated from a range of oil-rich plant materials, including coconut, corn, flaxseed, olive, palm, sesame, soybean, sunflower, and vegetable oils. These oils have different compositions, physical properties, chemical reactivities, flavor profiles, and nutritional attributes, which impact their application within plant-based milk substitutes. The fatty acid profile of oils, such as the ratio of saturated, monounsaturated, and polyunsaturated fats, impacts their nutritional profile. Liquid oils can be homogenized directly, whereas solid fats have to be melted first. The interfacial tension and viscosity of oils influence the sizes of the droplets generated inside a homogenizer, which affects the emulsion stability and quality [19]. Oil-soluble nutrients or nutraceuticals are typically dissolved within the oil phase prior to homogenization.

Emulsifier: Numerous plant-based emulsifiers are utilized by formulators to create emulsions, such as biosurfactants, phospholipids, proteins, and polysaccharides [20,21]. These are currently isolated from natural plant sources (such as soybeans, wheat, rice, oat, peas, flaxseed, or faba beans), but in the future, they may also be produced by cellular agriculture [22,23]. Plant-based emulsifiers differ appreciably in their capacity to form and stabilize emulsions. Typically, the smaller and more surface-active the emulsifier, the more effective it is at generating fine droplets inside a homogenizer. This is why smaller droplets can be produced using small biosurfactants (such as quillaja saponins) than large biopolymers (such as gum arabic) when the same homogenization conditions are used. Conversely, plant-based emulsifiers that produce thicker interfacial layers often provide better emulsion stability because they lead to intense steric repulsive forces that inhibit droplet aggregation. This is why emulsions that are more stable to environmental stresses can be produced from large biopolymers (such as gum arabic) than small biopolymers (such as pea protein). The advantages and disadvantages of different kinds of plant-based emulsifiers for forming and stabilizing the oil droplets in plant-based milk substitutes has been discussed recently [8].

Additives: A variety of other ingredients can be incorporated into plant-based milk substitutes to improve their functional properties [20,21]. Thickening agents can be used to create desirable textural or mouthfeel attributes, or to inhibit the creaming of lipid droplets or the sedimentation of insoluble matter. Numerous kinds of biopolymers can be employed as thickening agents, which vary in their molecular, physical, functional, and biological properties. For a fully plant-based milk, these biopolymers should be derived entirely from plants, e.g., starch, pectin, corn fiber, or locust bean gum. In some products, however, it may be acceptable to use other non-animal-based biopolymers, such as those isolated from seaweed (e.g., alginate and carrageenan) or obtained by microbial fermentation (e.g., xanthan gum). Anionic biopolymers, such as carrageenan or pectin, may also be used in milk-like products to inhibit the flocculation of protein-coated droplets. They do this by adsorbing to cationic patches on the surfaces of the oil droplets, thereby creating a thick coating that stops the droplets from coming close together [24].

A range of other additives may also be incorporated to enhance the quality attributes, nutritional profile, or safety of plant-based milk substitutes, including minerals, vitamins, nutraceuticals, colors, flavors, or preservatives. It is important that these ingredients are carefully selected so that they do not promote any undesirable changes in the quality attributes or stability of the end product. A number of nutrition scientists have criticized plant-based milk substitutes based on the fact that they do not contain all of the essential nutrients found in cow’s milk, such as high-quality proteins, minerals (such as calcium), and vitamins (such as vitamins A, D, E, and B12). For this reason, many manufacturers of plant-based milk substitutes are incorporating these ingredients into their products. Typically, non-polar nutritional components are added to the oil phase before homogenization, whereas polar ones are added to the water phase before or after homogenization. As an example, calcium carbonate and tricalcium phosphate are being added as a source of calcium. These colloidal forms of calcium are selected because they are insoluble and so do not promote aggregation of the anionic proteins in plant-based milk substitutes due to ion binding and electrostatic screening effects. The calcium is present in colloidal particles that can be dispersed throughout the product but shaking may still be required to avoid their sedimentation.

Manufacturing Operations

The manufacture of plant-based milk substitutes using this approach requires a homogenization step to transform the oil and water phases into an oil-in-water emulsion (Figure 1b) [25]. First, the oil-soluble ingredients are dissolved within the oil phase, while the water-soluble ingredients (including a hydrophilic emulsifier) are dissolved into the water phase. Second, an emulsion pre-mix is produced by blending the oil phase and water phase together. Third, a fine emulsion is produced by passing the emulsion pre-mix through a mechanical device (a “homogenizer”) that further breaks down the oil droplets. A number of homogenizers can be used for this purpose, including colloid mills, high-pressure valve homogenizers, microfluidizers, and sonicators. The same mechanical devices are typically used in the dairy industry to convert raw milk into homogenized milk. There are benefits and drawbacks to each type of homogenizer, which have been discussed in detail elsewhere [19]. In particular, they vary in their purchasing, running, and maintenance costs; their throughput; the viscosity of samples they can handle; their robustness; and the size of the droplets they can produce. After formation, plant-based milk substitutes typically undergo some form of heating step to extend their shelf-life and ensure they are safe to consume. This thermal processing step is designed to deactivate any enzymes or microbes that may cause spoilage or health problems, while still maintaining high product quality. The ability of plant-based milk substitutes to remain stable after thermal processing depends on the type of emulsifier used, with natural surfactants or polysaccharides giving better stability than proteins [20]. The impact of the emulsifier type on the thermal stability of plant-based milk substitutes has been discussed in more detail in a recent review article [8].

This entry is adapted from the peer-reviewed paper 10.3390/foods9040421