Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Industrial

Augmented Reality (AR) is one of the disruptive technologies that are also emerging with Industry 4.0, combining the physical world with computer-generated visuals, offering an intuitive interaction experience. It provides real-time interaction between virtual and physical objects, improving work performance and efficiency in manufacturing environments, enabling the combination of digital knowledge into the user’s physical world in many other areas, such as healthcare, education, retail, Information Technology and entertainment.

- augmented reality

- human augmentation

- Industry 4.0

- Industry 5.0

- lean thinking

1. Lean Thinking

Lean Production is an organizational approach that resulted from the Toyota Production System (TPS), which main goal is “doing more with less”, where less means less human effort, fewer stocks, fewer resources, less space, and less product development time [14,19]. Additionally, it tries to enable greater production flexibility, while meeting quality standards and deadlines.

This organizational approach aims to increase productivity and reduce costs by eliminating waste [14], which are all the activities that do not add value to the products from a client’s point of view. Ohno [14] classified the wastes into seven categories: (1) overproduction; (2) over processing; (3) transportation; (4) defects; (5) motion; (6) inventory; and (7) waiting. Later on, Liker [20] identified an extra waste, i.e., untapped human potential.

However, successful implementation of Lean principles goes beyond process improvement, since any change in work practices or workstations has deep effects on workers and their performance, affecting their well-being, safety and security [21]. Hence, it can be said that Human Factors (HF) and ergonomics have an impact on a company’s business strategy and competitiveness [22]. Most of the industrial projects implementing lean principles do not always address the ergonomics factors [23], although ergonomics and HF should be included in the lean process from the outset, which is not seen in a lot of organizations that fail to understand the potential of combining and carrying out ergonomic concepts in parallel with lean techniques [24].

Most the organisation are focused on the gains of productivity and process improvement, instead of taking advantage of this field of study to advance organizational effectiveness, business performance and costs [21,25], however, the right combination with lean and ergonomic design concepts will reduce errors, improve productivity and simultaneously improve the working conditions while reducing risk factors that can lead to the development of injuries or MSD [25,26].

It is important to ensure that people develop their tasks without waste (muda, in Japanese) and symptoms of waste. Beyond muda, there are the mura and muri that are considered the symptoms of muda. For instance, within an ergonomic context, mura are the consequences of wastes that result in workplace unevenness or irregularities, such as applying a force that increases the risk of strains and injuries that causes higher fatigue, which leads to reduced work pace and productivity. Muri is the overburden or stress caused by repetitive tasks or weight lifting or, even, accidents that could occur in the workplace due to other symptoms of waste, such as unevenness or irregularity, i.e., mura. Together these three Japanese words are called 3M [20]. Ergonomic design focuses on the creation of efficient and appropriate body postures, reducing the amount of strength required to perform a task, avoiding incorrect postures, repetitive tasks and motions throughout the work shift [21].

After decades, enhancing Lean Production solutions represent a huge potential for the current industrial landscape and the cutting-edge technologies enabled by Industry 4.0 paradigm bring several opportunities under the smart factories context to improve organisations competitiveness and working conditions [15].

2. Industry 4.0 and Industry 5.0

In recent years, the industrial landscape has been dramatically altered due to technological advancements and new manufacturing processes. This has sparked conversations between academics and organisations around a new concept called Industry 4.0, also referred to as the Fourth Industrial Revolution. This has allowed companies to benefit from emerging technologies that integrate digital and physical systems and enable more efficient, automated, and interconnected production [4,27].

Industry 4.0 is being compared with the previous three industrial revolutions that occurred in the last centuries. After steam power, electricity and the advent of computers, the emerging fourth industrial revolution will bring together the digital and physical worlds, embracing successive innovations and disruptive developments, mostly regarding digital technology and manufacturing [2].

Industry 4.0 has been highly discussed and studied, with a considerable impact on the industrial landscape by introducing disruptive changes with the advent of smart and future factories. This concept is a broad term encompassing the future of industrial developments, such as Cyber-Physical Systems, the Internet of Things, the Internet of Systems, Robotics, Big Data, Cloud Manufacturing, and AR, which will revolutionize both products and processes. Companies that make use of these technologies will increase their efficiency and productivity, transforming the current work environment and workplaces and bringing new ways of operating [5].

After a decade of discussion surrounding Industry 4.0, visionaries are now predicting the next revolution—Industry 5.0. During this time, Industry 4.0 has concentrated more on digitalisation and the use of disruptive technologies for greater efficiency and flexibility. In contrast, Industry 5.0 will emphasize the importance of a human-centric industry and its service to humanity. This will involve a renewed focus on social aspects, enabling companies to be more ethical and socially responsible in their practices [16,28,29].

Industry 5.0 complements and extends the Industry 4.0 paradigm. Merging between real and virtual worlds is crucial to gather and generate useful data to create solutions to face the challenges, enhancing the safety, security, and comfort conditions of people [30,31,32]. Thus, Industry 5.0 is a strategy that has resulted from a forward-looking exercise to help frame how industrial developments and emerging societal trends and needs can co-exist, driving the transition to human-centric, sustainable and resilient systems [16].

The human-centric approach puts people’s needs and goals at the forefront, leveraging technology implementation to suit human interests. Consequently, the primary focus is on humans and employees. Additionally, Industry 5.0 is directed towards building sustainable systems, creating circular processes and cutting down energy usage in order to protect the environment. Furthermore, resilience refers to the construction of systems endowed with exceptional robustness, flexible processes and adaptable production capacity to accommodate the changing market requirements [16].

In addition, the concept of Industry 5.0 is related to the one of Society 5.0. Both of them are focused on a shift of society, economy and industry towards a new paradigm aimed at creating a people-centric society [16,33,34]. Society 5.0 concept was presented in 2016 [35] and its aim is to stimulate economic growth while solving societal and environmental problems, enhancing the quality of life and creating a society that attends to the different needs of people, regardless of region, age, sex, language or disabilities [36].

Therefore, the paradigms of Industry 4.0 and 5.0 can create synergies to promote the elimination of wastes (3M) within the workplaces and foster healthy work environments.

3. Lean Thinking, Industry 4.0 and Industry 5.0

In the past few years, the relationship between Industry 4.0 technologies and lean practices has been studied, and the potential of combining the two areas and the benefits associated with this union. This integration of the two domains has been initially referred to as Lean Automation [15]. Enhancing Lean Production solutions using new technologies represents a huge potential for the current industrial landscape and brings several opportunities for the smart factories’ context [15,37].

The emerging technologies associated with Industry 4.0 can provide numerous benefits when integrated with Lean Thinking principles [38]. However, it is important to evaluate how effective each technology is in a particular context to make the most of this symbiosis. Many mistakes have been made over the years and emerging technologies should be implemented only after a thorough cost-benefit analysis determined by an issue that cannot be resolved in any other way. This is significant because these technologies require a considerable investment and skillset, which may not be accessible for companies [39].

The most frequent advantages that come from the fourth industrial revolution technologies employed in lean are often related to data collection, communication between different productive actors, data analysis capability, and data display. When these technologies are combined with lean principles and concepts, they can effectively reduce non-value-adding activities in businesses, improving employee satisfaction. Moreover, it was concluded that AR technology can effectively promote ongoing improvement and eliminate waste, as well as support problem-solving and decision-making, enhance HF, and facilitate communication and data sharing [38].

In fact, each Industry 4.0 technology has an important role in supporting the implementation of each one of the Lean Thinking principles. By applying the correct Industry 4.0 technologies, organizations will be more aware of the value for the client and will map properly value streams to eliminate wastes and to have flow. At the same time, production will be pulled by the client using Industry 4.0 technologies available and a continuous improvement process will be possible. Implications of these result in a sustainable, human-centric and resilient production system, as required by Industry 5.0 [18].

4. Ergonomics and Human Factors

The ability of humans to work is directly related to their well-being and health, being extremely important to provide people with favourable working conditions, maximizing their well-being and promoting their safety. Moreover, the technological developments enabled by Industry 4.0 could play a crucial role in creating waste-free workplaces that address Industry 5.0 pillars. According to Hancock and Diaz [40], technology is the most powerful shaping force on the planet and its individual impact is most evident in human factors. Therefore, ergonomics can mediate these synergies between operators and technology, enhancing the work environment and the design of healthy workplaces.

Unfavourable work environments and conditions, as well as the exposure of workers to risk factors, can lead to the emergence of physical disabilities. Once the disability restricts the worker’s physical aptitude to undertake the tasks as usual, preventing them from lifting weights or moving, it is said that the worker is enduring a work-related MSD [41].

Work-related MSDs that are caused by repetitive tasks and high demanding working conditions remain to be one of the most significant problems in industrialized countries and one of the biggest concerns of corporations [42]. It has a massive effect on the labour market and significantly influences the health and well-being of the work force, escalating the number of health-related absences and decreasing productivity in organisations [43].

Logistics activities in warehouses and supermarkets, where the ergonomic conditions are, most of the time, not suitable for workers and the manual tasks, such as loading and unloading, represent a high risk of developing MSD [44,45]. Manual material handling highly increases the rate of MSD in workers, being one of the most difficult and physically demanding tasks due to repetitive movements, awkward postures of limbs or forceful exertion [46].

However, logistics plays a vital role in supply chain management, ensuring the delivery of products at the right time, in a safe and effective way. Despite the emergence of the new and essential concept of Logistic 4.0, which comprises the implementation of Industry 4.0 technologies in logistic activities, the primary discussion is mostly regarding efficiency, enhanced tracking and delivery to the customer [47]. Less importance has been given to HF in logistics and operator overload, overburden, stress and safety in the logistics field and how industry 4.0 technologies, AR in particular, can overcome these issues [48].

5. Augmented Reality and Human Augmentation

AR is one of the disruptive technologies that are emerging with Industry 4.0 and intends to combine the physical word with computer generated texts and images or animations, providing an intuitive interaction experience to the users [49]. AR can be defined as a real-time direct or indirect view of an enhanced or augmented real-world environment, combining real and virtual objects that interact in real-time, which allows the improvement of work performance and efficiency in a manufacturing environment [6,7]. In other words, AR is used to supplement and enhance the physical environment, overlaying digital computer-generated information such as images, sound, video and graphics [50].

Nevertheless, AR applications should take into account all human senses [51] and aspects such as touch and haptic sensations can be employed to enhance the perception of the actual environment [52]. The goal is to enable organizations to join together processes and visualizations [50], which simplifies the user’s experience by incorporating virtual de-tails and reinforcing their understanding and involvement with the real world, augmenting the sense of reality in real-time [6].

In the last years, the way of providing information to operators has been changing [49,53,54,55]. AR technology offers a range of chances for the manufacturing sector [56], since it can give operators access to data that cannot be obtained with their regular senses. What is more, this data is supplied in the pertinent context and when it is necessary [57].

AR has traditionally been primarily visual, enhancing sight sense. However, human perceptual capabilities are frequently shared by every sense, thus auditory and tactile senses are often enhanced as well within this context. In addition, AR can be used to enhance physical capabilities in order to reduce physical workload and improve ergonomic conditions and mitigate risks through the use of systems such as exoskeletons [58]. In sum, AR can be used to augment human senses, cognitive abilities and physical capabilities.

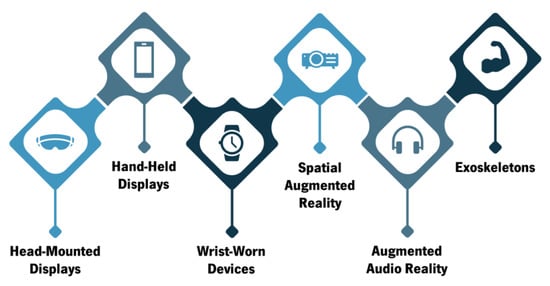

The hardware used by AR technology can be divided into several categories: Head-Mounted Displays (HMD); Hand-Held Displays (HHD), Wrist-Worn Displays (WWD) and Spatial Augmented Reality (SAR) [59]. Moreover, Augmented Audio Reality (AAR) allows the augmentation of hearing sense, in order to perceive virtual sounds as an extension to the natural ones, creating a hybrid augmented environment [60], while the creation of super-strong humans in an industrial environment can be enabled by the use of wearable, lightweight, flexible and mobile exoskeletons [61]. Figure 1 shows the different types of AR, categorized into six different applications.

Figure 1. Types of AR [59].

AR technology has the potential to augment all human senses, providing virtual data to workers and extending, for example, their sight or hearing functions. Nevertheless, the prospects with regard to the utilization of this technology in industrial surroundings are not just restricted to sensory improvement, it is also possible to augment human beings in terms of their intellectual or cognitive abilities [62], as well as enhance their physical capabilities using exoskeletons in order to improve ergonomic conditions [63], allowing new forms of human actions [64].

AR application in the industrial environment holds a huge potential to augment human capabilities, specifically within the logistics area, allowing the improved of performance and efficiency, enhancing cognitive capabilities and reducing inequalities within workplaces [59].

Superimposing computer-generated information in the real world, in order to give relevant data that is not accessible within the real world, such as work instructions, directions or safety instructions, is one of the most promising possibilities of AR technology in a human-based environment [62]. This emerging technology has enabled the move from traditional paper-instructions to the utilization of 3D visualization procedures in recent years, which carries a significant potential regarding the elimination of waste caused by delays and human errors [65,66], as well as the reduction in training and operating times and the fostering of working conditions, quality, productivity and efficiency [67,68].

A recent review of the literature on this topic [69] summarizes 36 cases of AR technology applications in in-house logistics that are using superimposed virtual information in order to provide information to workers and enhance their sight sense, mostly using HMD and HHD. Furthermore, WWD equipped with barcode and QR code scanning technology are commonly used for order- picking and can reduce the operation times and the amount of equipment needed to perform these tasks, freeing the workers’ hands and speeding package scanning and inventory control, when compared with HHD [70]. Additionally, when it comes to AR wearable devices, it’s important to consider the ergonomic conditions and understand if it is comfortable and safe for workers that will use it during the working day [71]. WWD and AAR enable a hands-free operation that allows the employee to relieve the physical workload and manipulate the packages with both hands [72].

The implementation of new techniques and the instruction of workers on the necessary skills can be time-consuming and may impede the effectiveness of logistics operations. However, the use of AR technology during the training period can result in employees with the necessary knowledge to complete complex and challenging tasks, and this can boost productivity and shorten their learning curve [73].

Moreover, AR has the potential to enhance workers’ cognitive capabilities, provide feedback and data for safety measures, or even alert the operators regarding an immediate hazardous situation or danger in real-time [74].

AR solutions can also improve the quality of life for individuals with disabilities and the elderly, making the workforce more inclusive and sustainable., These solutions help to reduce disparities in the workplace [64], holding a set of benefits to assist workers with disabilities [75] In addition, they enhance physical capabilities, through the usage of exoskeletons to improve working conditions and allow operators to perform their tasks longer and lift heavier weights, while reducing the physical workload, injuries, accidents and risk factors [58].

Human augmentation techniques rely on the use of technologies that are able to augment human actions, senses, capabilities and cognition, allowing humans to perceive the real environment in a new and enhanced way. Based on augmenting technologies, relevant information is provided to operators, in order to enhance human life and allow new Human-Machine Interface solutions [64]. This approach is centred on the AR users and based on a human-centered real world merged with an information world [62].

Operator 4.0 is a concept that has emerged in Industry 4.0 context and can be understood as an Augmented Operator that performs collaborative work with machines and robots, being enabled by CPS and advanced technologies [76]. AR is a critical enabling technology for improving information transfer between the digital world and smart operators in the physical world [77]. The term Operator 4.0 refers to smart and skilled operators, assisted and augmented by systems that enable a reduced physical and cognitive workload during task performance, allowing them to be more creative and innovative, fostering continuous improvement without compromising productivity [76]. Therefore, the Augmented Operator paradigm is enabling the engagement and empowerment of workers [78], giving people more time to learn, think and innovate.

To take advantage of what Industry 4.0 has to offer and successfully utilize emerging technologies such as AR, businesses must develop human-centred production systems that put the needs of workers first. This technology will have a direct impact on operators and their work areas, creating a new interaction between humans and machines. This connection between the real and digital worlds will merge digital and physical worlds, resulting in a socio-technical transformation in smart factories and a novel Human-Machine Interface approach, resulting in the elimination of wastes in the workplace, non-value-added activities and hazards. Additionally, it will reduce the amount of effort required of workers during task performance, promoting good health within the organizations and providing equality for all, no matter their capabilities or disabilities, and creating a safe and secure working environment.

This entry is adapted from the peer-reviewed paper 10.3390/app13169120

This entry is offline, you can click here to edit this entry!