Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Polymer Science

Traditional metals and alloys are often used for electromagnetic interference (EMI) shielding due to their excellent electrical conductivity. However, they have drawbacks such as being heavy, expensive, and having low corrosion resistance, which limits their application in electromagnetic shielding. Therefore, it is crucial to develop novel EMI shielding materials. Polymers, being highly flexible, corrosion-resistant, and possessing high specific strength, are frequently employed in electromagnetic shielding materials.

- conductive polymer composites

- electromagnetic shielding

1. Introduction

With the rapid advancement of electronic communications and wearable technology in the 5G era [1,2,3], people’s daily lives and productivity have been greatly enhanced. However, this technological progress has also led to a new environmental challenge—electromagnetic radiation pollution, which has raised significant concerns [4,5,6]. Alongside air pollution, noise pollution, and water pollution, electromagnetic radiation pollution has emerged as another major environmental issue [7,8]. Numerous studies have demonstrated that electromagnetic radiation not only disrupts the normal functioning and reduces the longevity of electronic devices but also poses health risks, including the development of various diseases [9,10]. Therefore, whether it is to maintain the normal operation of electronic devices or to protect human health, the study of electromagnetic shielding materials has become a focus of research in recent years [11,12,13]. Metals were initially employed as electromagnetic shielding materials due to their exceptional electrical conductivity [14,15,16], but their disadvantages are also obvious. First of all, metal materials have high density, are not easy to process, and have poor corrosion resistance. Secondly, metal materials mainly shield electromagnetic waves through reflection, which will inevitably cause secondary pollution [17,18,19,20]. These shortcomings limit the application of metal materials in electromagnetic shielding. High-entropy alloys (HEAs) are expected to break the limitations of traditional alloys in the field of electromagnetic shielding. HEAs have excellent mechanical properties, corrosion resistance, and oxidation resistance. These characteristics make HEAs effective electromagnetic shielding materials in extreme environments. In addition, since HEAs are composed of multiple elements, their lattice distortion will lead to a decrease in electrical conductivity, which may change the electromagnetic shielding mechanism of the material from reflection to absorption, thereby reducing the secondary pollution caused by reflection [21,22,23,24,25]. Polymers have attracted extensive attention due to their light weight, good processability, corrosion resistance, and low cost. Researchers are gradually developing polymers as electromagnetic shielding materials [26,27,28]. According to their components and composition, conductive polymer-based EMI shielding materials can be further separated into intrinsic and composite groups.

ICPs (Intrinsically Conductive Polymers) are a class of polymer materials with conjugated π bonds. They include PA (polyacetylene), PANI (polyaniline), PT (polythiophene), and PPy (polypyrrole). After doping, carriers are generated between polymer chains, making them conductive. These materials possess high conductivity, as well as the advantages of light weight, corrosion resistance, and good flexibility of polymer materials [29,30]. However, achieving high conductivity often requires doping, which involves complex preparation processes and high costs. Consequently, they are primarily used in special situations, such as military applications [31]. In contrast, CPCs (Conductive Polymer Composites) offer more advantages. Although the polymers used in CPCs are not conductive, they can be blended with conductive fillers to prepare lightweight, corrosion-resistant, low-cost, and processable electromagnetic shielding materials, allowing for greater flexibility in design [32,33]. Nevertheless, the characteristics of CPCs also present challenges. Increasing the content of conductive filler is necessary to improve the electromagnetic interference shielding effectiveness (EMI SE) of CPCs. However, excessively high filler content can compromise the mechanical properties and processability, and increase production costs. [33,34,35]. To address these issues, researchers have focused on enhancing the structure of CPCs, including foam structures [36,37,38], separated structures [39,40], and layered structures [41,42,43]. These improved CPCs with enhanced structures exhibit superior electromagnetic shielding capabilities and have gained widespread application. Presently, research on CPCs has become a popular topic, especially with the rapid advancement of 5G communication technology and the potential future prospects of 6G technology. As a result, CPCs will play a significant role in the development of EMI shielding technology [44,45,46].

2. Electromagnetic Shielding Mechanism

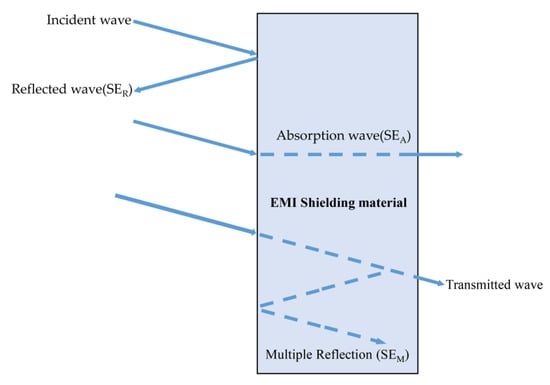

The principle of electromagnetic interference (EMI) shielding refers to the ability of EMI materials to absorb, reflect, or weaken electromagnetic waves [47]. There are several theoretical explanations for the electromagnetic shielding process, including the eddy current effect theory, the electromagnetic field theory, and the transmission line theory. The transmission line theory is widely recognized due to its simplicity in calculation, high precision, and ease of understanding. Figure 1 illustrates the specific mechanism [48]. When an electromagnetic wave travels through a material, a portion of the wave is reflected on the surface of the electromagnetic shielding material caused by a discontinuity in the interface impedance (i.e., reflection loss efficiency, SER). A part of the electromagnetic wave enters the material and is continuously attenuated due to loss (i.e., absorption loss efficiency, SEA). A portion of the electromagnetic wave will be dissipated by multiple reflections inside the material (i.e., multiple reflection efficiency, SEM), and the remaining electromagnetic waves will be transmitted in waves after passing through the shielding material. The shielding performance of a material is usually expressed by the shielding efficiency (SE), which can be expressed by Equation (1) [49,50,51,52].

SE = SER + SEA + SEM

Figure 1. Electromagnetic shielding mechanism diagram.

EMI SE is strongly associated with the charge, current, and polarization events occurring on the surface and inside the shielding enclosure [53,54]. When an electromagnetic wave is reflected and absorbed by the shielding surface, there is poor impedance matching between the shielding material surface and the free interface, resulting in induced charges in the magnetic field within the shielding material. Therefore, it is necessary for the shielding material to have good conductivity [55,56]. Conductivity is a crucial factor influencing the electromagnetic shielding ability of materials, since higher conductivity generates a larger number of free charges, leading to impedance mismatch and increased reflections. Increased reflection results in a higher SER of the material, subsequently increasing the SE of the material as well [57,58]. When an un-reflected electromagnetic wave enters the shielding material and is absorbed and attenuated, the material contains numerous dipoles that experience orientation polarization within the magnetic field. Hence, the shielding material must possess good magnetic conductivity, excellent electromagnetic loss, and an appropriate dielectric constant [59,60,61,62]; when the remaining electromagnetic wave reaches the transmission edge of the electromagnetic shielding enclosure, it undergoes multiple reflection attenuation. Shielding materials with a porous structure and a large number of interfaces can improve the frequency of multiple reflections and scatterings, thereby effectively enhancing the SE of the materials [63,64,65]. Consequently, an effective electromagnetic shielding material should exhibit both strong reflectivity and efficient electromagnetic wave absorption [66,67].

3. Research Progress of Polymer-Based Composites with Different Structures in the Field of Electromagnetic Shielding

Polymer-based EMI shielding materials have gained significant attention as a viable alternative to traditional metal materials. This is because conventional metals lack corrosion resistance and possess drawbacks such as difficult processing, heavy weight, poor air permeability, high price, and limited control over shielding effectiveness. Consequently, the use of traditional metals is restricted within certain applications [68,69]. Polymer-based materials offer several advantages, including lightweight properties, corrosion resistance, and ease of manufacturing. Moreover, for CPCs, an effective structure (conductive network) provides exceptional conductivity and ultra-high EMI shielding effectiveness. The prevailing polymer-based EMI shielding composites encompass uniform structure, isolation structure, porous structure, and layered structure [33,34,35].

3.1. Uniform Structure

The uniform structure refers to the dispersion of conductive filler in the matrix in a uniform manner. Common methods for preparing EMI shielding materials with such a structure include solution and melt blending, as well as in situ polymerization. These methods are preferred due to their low cost and simplicity. However, this type of material has a significant drawback. To enhance the EMI shielding effectiveness (SE), it is necessary to increase the filler content in the matrix. This, in turn, leads to a high percolation value of the material, ultimately impacting its mechanical properties [70,71,72,73]. Acharya et al. [74] prepared PVDF(polyvinylidene fluoride)/RGO(reduced graphene oxide) electromagnetic shielding composite; when the concentration of the material was 21%, the EMI SE reached 60 dB. Li et al. [75] obtained a POM(polyformaldehyde)/MWCNT(multi-carbon nanotube) composite. The composite, with a concentration of 40%, had an EMI SE of 70 dB. They observed that the electromagnetic interference shielding effectiveness of the material was influenced by the filler content. As the filler content increased in the matrix, the EMI SE of the material improved; however, this enhancement was accompanied by a reduction in its mechanical performance [51,74]. Consequently, it was crucial to modify the filler and develop a novel process to reduce the filler content [76]. Researches on poly-based electromagnetic shielding composites with uniform structure are summarized in Table 1. It is worth mentioning that the frequency range of commonly used electromagnetic waves is 0 to 400 Ghz. Most of the studies on the electromagnetic shielding performance of the polymer matrix composites mentioned herein were carried out in the frequency range of 8 ∓ 12 Ghz (X-band). This preference is due to the X-band’s low atmospheric attenuation rate, where gas molecules and suspended particles in the atmosphere absorb and scatter electromagnetic waves, resulting in energy attenuation. As a result, the cost of transmitting electromagnetic waves in the X-band is relatively low while maintaining a high throughput. Consequently, the X-band is widely suitable for communication satellites, aviation and marine radars, and military applications [18,77,78].

Table 1. Summary of the research on poly-based electromagnetic shielding composites with uniform structure.

| Materials * | Filler Loading | EMI SE (dB) | Thickness (mm) | Frequency | Ref. |

|---|---|---|---|---|---|

| PVA/GN/Fe3O4 | 0.1 wt% | 40.7 | 0.2 | 8–12 Ghz | [79] |

| EP/PES/MWCNT | 2.9 wt% | 23 | 2.2 | 8–12 Ghz | [80] |

| GN/CFN | 20 wt% | 73 | 2 | 8–12 Ghz | [72] |

| VGCNF/PVDF | 5 wt% | 16.4 | 0.82 | 30 Khz–1.5 Ghz | [81] |

| PEDOT/GNP | 15 wt% | 18 | - | 8–12 Ghz | [82] |

| RGO/PdNi/EVA | 1 wt% | 30 | - | 8–12 Ghz | [83] |

| POM/MWCNT | 40 wt% | 45.7 | 0.15 | 8–12 Ghz | [75] |

| PE/PVDF/Fe3O4/CNT | 10 wt% | 26 | 2.6 | 18–26 Ghz | [84] |

| PLLA/MWCNT | 10 vol% | 23 | 2.5 | 8–12 Ghz | [85] |

| PVDF/RGO | 21 wt% | 60 | 1.5 | 8–12 Ghz | [74] |

| PLA/PEO/GNP | 6 wt% | 10.5 | - | 8–12 Ghz | [86] |

| PMMA/GNP-MWCNT | 8 wt% | 36 | 2 | 8–12 Ghz | [87] |

| PDMS/GA | 12.5 wt% | 52 | 3 | 4–16 Ghz | [88] |

| PVDF/Ba4CO2Fe36O60 | 20 wt% | 83 | 0.12 | 8–18 Ghz | [89] |

| CF/PAA/Fe3O4 | 10 wt% | 40.6 | 3.5 | 2–18 Ghz | [90] |

| PVDF/PANI | 30 wt% | 65 | 1 | 8–12 Ghz | [73] |

| ABS/CB/CNT | 3 wt% | 29 | 2 | 8–12 Ghz | [91] |

| PP/MWCNT | 20 wt% | 47 | 2 | 8–12 Ghz | [92] |

| BF/PANI | 7 wt% | 35.73 | - | 8–12 Ghz | [93] |

| PS/PANI | 40 wt% | 45 | 0.25 | 8–12 Ghz | [71] |

| CB/EMA/TPO | 30 wt% | 29 | 1 | 14–20 Ghz | [94] |

| PLA/CNT | 5.6 wt% | 31.1 | - | 8–12 Ghz | [95] |

| SWCNT/PANI | 3 wt% | 32.8 | 0.5 | 8–12 Ghz | [96] |

| TPU/SiAPP/SCF/Ti3C2Tx MXene | 20 wt% | 50.5 | 1 | 8–12 Ghz | [97] |

* GN—graphene; PVA—polyvinyl alcohol; CFN—carbon fiber network; VGCNF—vapor-grown carbon nanofiber; PE—polyethylene; PLLA—poly (l-lactic acid); PLA—polylactic acid; PEO—poly(ethylene oxide); GA—graphene aerogel; CF—carbon fiber; PAA—polyacrylic acid; PP—polypropylene; BF—Bagasse Fiber.

3.2. Foam Structure

Shielding materials with foam structures offer numerous advantages, including anti-aging, corrosion resistance, light weight, and low cost. These materials find applications in various fields, such as aerospace, communication electronics, and military engineering [110,111,112,113]. Compared to other materials, foam-structured EMI shielding composites excel in using a small amount of conductive filler to achieve higher electromagnetic shielding performance, resulting in lower permeability values. Moreover, the hole walls on the surface provide multiple interfaces, allowing for multiple reflections and absorptions of electromagnetic radiation within the material. This property enhances the material’s EMI SE and reduces pollution caused by surface reflection to some extent. There are three primary processes used to create foam structures: physical foaming, chemical foaming, and freeze-drying [114,115,116]. Table 2 shows the recent research progress of foam-structured electromagnetic shielding materials.

Table 2. Summary of the research on poly-based electromagnetic shielding composites with foam structure.

| Materials * | Filler Loading | EMI SE (dB) | Thickness (mm) | Frequency | Ref. |

|---|---|---|---|---|---|

| TEG/PU | 3 wt% | 20.4 | - | 8–12 Ghz | [117] |

| EVA/PPy/AgNPs | 52 wt% | 107.45 | 2.4 | 8–12 Ghz | [118] |

| PEN/GN/CNT/Fe4O3 | 3.5 wt% | 38 | 0.6 | 8–12 Ghz | [37] |

| TPU/Ti3C2Tx MXene | 0.66 vol% | 72.2 | 2 | 8–12 Ghz | [119] |

| CO3O4/CNT/MF | - | 25.6 | 3 | 8–12 Ghz | [120] |

| PET/BAHT/SWCNT | 2 wt% | 45.7 | - | 8–12 Ghz | [121] |

| RGO/PU | 5 wt% | 23 | - | 8–12 Ghz | [122] |

| CMF/SiO2/CNT | 30 wt% | 61.34 | 2 | 8–12 Ghz | [38] |

| TPU/MWCNT | 2.5 wt% | 44.86 | - | 10–14 Ghz | [123] |

| PVDF/CNT | 8 wt% | 41 | 1 | 8–12 Ghz | [124] |

| PS/PMMA/MWCNT | 2 vol% | 25.3 | 2 | 8–12 Ghz | [125] |

| ABS/CB:CNT | 15 wt% | 81.3 | 5 | 8–12 Ghz | [126] |

| PBS/CNT | 4 wt% | 24 | - | 8–12 Ghz | [127] |

| PA6/CF | 22 wt% | 36.6 | 1 | 18–26 Ghz | [36] |

| MXene/APU | 22 wt% | 76.2 | 5 | 8–12 Ghz | [128] |

| MWCNT/WPU/PVA/MCHM | 40 wt% | 23 | 2.5 | 8–12 Ghz | [129] |

| PDCPD-CNT/GN | 3.5 wt% | 43 | 3 | 8–12 Ghz | [130] |

| PEI/Ti3C2Tx MXene/AG | 1 wt% | 28 | - | 8–12 Ghz | [131] |

| PVDF/GNPs/CNT/Ni | 16 wt% | 19.4 | 1 | 8–12 Ghz | [132] |

| ABS/CNT | 7 wt% | 26.6 | 2 | 8–12 Ghz | [133] |

* TEG—thermally exfoliated graphene; PU—polyurethane; AgNPs—Ag nanoparticles; PEN—Poly(arylene ether nitrile); MF—melamine-formaldehyde; PET—poly(ethylene terephthalate); BAHT—bis(6-aminohexyl) terephthalamide; CMF—carbonated melamine foam; PBS—poly (butylene succinate); PDCPD—polydicyclopentadiene.

3.3. Segregated Structure

The polymer itself has low electrical conductivity, necessitating the continuous addition of conductive fillers to the polymer matrix to impart conductivity. However, excessively high filler content increases costs and processing difficulty, and damages the material’s mechanical properties [140,141,142]. These challenges are effectively addressed by creating polymer-based EMI shielding materials with segregated structures. The isolation structure of these materials ensures that conductive fillers are distributed only between the polymer particle interfaces, preventing them from dispersing freely throughout the matrix. This restricted distribution increases the probability of filler overlap at the interfaces and significantly reduces the percolation threshold. Consequently, even at low filler content, the composite material exhibits strong electrical conductivity and EMI shielding capability [143,144,145]. Research by numerous investigators has demonstrated that the generation of a segregated structure is advantageous for reducing the percolation threshold of the composite, while synergistic filler interactions enhance the material’s shielding ability and mechanical properties [39,40,146,147,148,149]. The recent studies of segregated-structured electromagnetic shielding materials are summarized in Table 3. Zhang et al. [150] prepared PVDF/Fe3O4-RGC composite using layered electrostatic assembly and hot pressing. Wu et al. [151] obtained Fe3O4@PA6/MWCNT composite with layer-adding manufacturing and molding. They found that establishing a separation structure could form a complete conductive network, and adjusting the content of magnetic fillers could effectively improve the EMI SE of the composite. Yang et al. [152] obtained TPU/EG(expanded graphite)/AG(silver) composite material. The inclusion of the Ag component at just 0.58 vol% led to remarkable improvements in the syntactic foam’s conductivity and EMI SE, reaching 171.2 S/m and 56.3 dB, respectively—well exceeding the minimum requirements for commercial EMI shielding. The introduction of a porous structure effectively mitigates the impedance mismatch between the surrounding air and the composite material, facilitating more incident electromagnetic waves and reducing reflectivity. The material’s reflection efficiency in the X-band decreased from 99% to 31%, successfully mitigating secondary electromagnetic wave emission pollution. Additionally, the strong interfacial bonding between the filler and matrix ensures excellent compressibility recovery and shielding stability, even after 50 compression cycles. Wang et al. [153].prepared BPEI(multiblock polyetherimide)/MLG(multilayer graphene) composites. Due to the existence of two blocks with large TG differences in BPEI, the polymer has a high chain mobility, which allows it to inter-diffuse between the BPEI particle interfaces below TK-N, forming a good isolated conductive network. The findings demonstrated that the BPEI/MLG composite loaded with 5.0 wt% MLG generated an isolation structure at a temperature of 270 °C, thereby giving it an electrical conductivity of 313.5 S/m and an EMI shielding performance of 62.2 dB. Ma et al. [154] prepared a CNT/PDMS(polydimethylsiloxane) composite by establishing chemical bonds between them. The cross-linked network of PDMS microspheres prevents the penetration of CNTs into the polymer microcells, resulting in the formation of segregated structures. The results showed that even with only 2.2 vol% of CNT, this composite exhibited exceptional shielding performance at 47.0 dB. Notably, the tensile strength and elongation at break of the composite material reached 3.6 MPa and 87.0%, respectively, marking a substantial increase of 35.0 and 7.0 times compared to traditional isolation composite materials. Additionally, the material exhibited excellent reliability, retaining a high EMI SE of 80% even after undergoing 1000 strain-release cycles at 30% ultimate elongation.

Materials with a segregated structure have garnered considerable interest due to their outstanding EMI shielding performance and remarkably low percolation threshold. However, the distribution of conductive fillers at the polymer particle interface poses challenges, hindering molecular chain diffusion and affecting interface compatibility. Additionally, agglomerated conductive fillers generate micropores along the direction of the conductive path. These adverse circumstances will impact the mechanical characteristics of the polymer-based EMI shielding material with a segregated structure [155,156,157,158]. Yang et al. [159] added SiO2 particles to PDMS, and the EMI SE of the composite was improved due to the volume exclusion effect and multi-interface. However, nanoparticles disrupt conductive networks.

Table 3. Summary of the research on poly-based electromagnetic shielding composites with segregated structure.

| Materials * | Filler Loading | EMI SE (dB) | Thickness (mm) | Frequency | Ref. |

|---|---|---|---|---|---|

| Starch/CNT | 3 vol% | 33.12 | 1.6 | 8–12 Ghz | [146] |

| PEBA/CNS composites | 0.2 wt% | 33 | 3.4 | 8–12 Ghz | [39] |

| PS/CNT/PEDOT:PSS | 6 wt% | 33.4 | 0.6 | 8–12 Ghz | [147] |

| PVDF/Fe3O4-RGC | 2.02 vol% | 44.5 | - | 8–12 Ghz | [150] |

| Fe3O4@PA6/MWCNT | 9 wt% | 24.8 | 0.5 | 8–12 Ghz | [151] |

| BPEI/MLG | 5 wt% | 62.2 | 2.3 | 8–12 Ghz | [153] |

| PP/RGO/MWCNT | 5 wt% | 16 | - | 8–12 Ghz | [145] |

| PLA/PBS/MWCNT | 2 wt% | 27.56 | 2 | 8–12 Ghz | [148] |

| PA12/CNT | 5.66 wt% | 23.9 | 2 | 8–12 Ghz | [149] |

| POM/CNT | 4 wt% | 21.5 | 2 | 8–12 Ghz | [40] |

| BN/GNP/PPS | 40 wt% | 70 | 3 | 8–12 Ghz | [157] |

| SiO2/CNT/PDMS | 35.4 vol% | 52.2 | 2 | 8–12 Ghz | [159] |

| NR/CNT | 7 wt% | 44.2 | 2 | 8–12 Ghz | [158] |

| PBS/CNT | 2 wt% | 24 | 2 | 8–12 Ghz | [142] |

| CNT/PDMS | 2.2 vol% | 47 | 2 | 8–12 Ghz | [154] |

| TPU/EG/AG | 0.58 vol% | 56.3 | - | 8–12 Ghz | [152] |

* PEBA—polyether block amide; CNS—carbon nanostructures; PSS—polystyrene sulfonate; RGC—reduced graphene oxide/single-wall carbon nanotube; PP—polypropylene; BN—boron nitride nanosheet; PPS—polyphenylene sulfide; NR—natural rubber; EG—expanded graphite.

3.4. Layered Structure

The polymer-based EMI shielding composite material with a layered structure contains multiple interfaces, allowing for repeated reflection of electromagnetic radiation, leading to polarization loss and electromagnetic wave absorption loss [160,161]. This layered structure of EMI shielding material can achieve high electromagnetic shielding performance even with a low content of conductive filler, while offering design flexibility. Typically, polymer-based electromagnetic shielding composites with a layered structure exhibit sandwich and gradient configurations, which can be easily prepared using methods like vacuum filtration and deposition [162,163,164]. Due to their strong absorbing ability, these layered materials find extensive applications in critical fields such as military technology and precision instruments, significantly reducing secondary pollution caused by electromagnetic wave reflection [165,166,167,168]. Yu et al. [169] prepared PI(polyimide)/Ti3C2Tx Mxene/AgNW(silver nanowire) composite through electrostatic spinning and a hot-press approach. Wu et al. [170] obtained PPA6@NiM(magnetic PA6 microspheres)/PDMS composite using the solvent coprecipitation method. Chu et al. [171] prepared h-PANI/CNF/Mxene composite films with the alternating vacuum-assisted filtration method. Guo et al. [172] obtained ANF(aramid nanofiber)/AgNW/GN composite films through a vacuum filtration and hot-press approach. They found that the electromagnetic shielding material with a layered structure exhibited a strong absorbing ability, primarily attributed to the formation of a dense conductive network in the core layer of the material and excellent adhesion between the layers [42,169,170,171,172]. Table 4 shows the recent research of layered-structured electromagnetic shielding materials. Song et al. [173] obtained TPU/MWCNT electromagnetic shielding material with a sandwich structure through the CO2 foaming method.

Polymer-based electromagnetic shielding composite materials with a layered structure offer significant design freedom, low cost, and strong microwave absorption ability. However, they encounter challenges in actual production [41,176,177]. The bonding of the layers in the layered structure material using physical methods can degrade the compatibility between the layers and may also lead to cracks forming during the bonding process. Consequently, these drawbacks have the potential to restrict the application of multilayer polymer-based electromagnetic shielding materials [43,178].

Table 4. Summary of the research on poly-based electromagnetic shielding composites with layered structure.

| Materials * | Filler Loading | EMI SE (dB) | Thickness (mm) | Frequency | Ref. |

|---|---|---|---|---|---|

| PI/Ti3C2Tx Mxene/AgNW | 20 wt% | 79.54 | 0.15 | 8–12 Ghz | [169] |

| PLA/MWCNT | 5 vol% | 26 | 1.5 | 24–40 Ghz | [41] |

| PPA6@NiM/PDMS | 54.9 wt% | 39.9 | 1 | 8–12 Ghz | [170] |

| PLLA/GNP/Fe3O4 | 10wt% | 41.7 | 0.4 | 8–12 Ghz | [176] |

| CF@(CNT/Fe3O4/EP) | 0.045 wt% | 30.5 | 2 | 8–12 Ghz | [177] |

| h-PANI/CNF/Mxene | 8 wt% | 35.3 | - | 8–12 Ghz | [171] |

| PVDF/SiBi58/Co-C | 30 vol% | 50 | 2 | 8–12 Ghz | [166] |

| EP/LMPA | 20 vol% | 20 | - | 8–12 Ghz | [161] |

| SR/Mxene/Fe3O4 | 21.2 wt% | 55.5 | 2 | 8–12 Ghz | [165] |

| CF/GF/PDMS | 1 wt% | 30 | 1 | 8–18 Ghz | [167] |

| ANF/AgNW/GN | 2 vol% | 68.3 | 0.04 | 8–12 Ghz | [172] |

| NR/MXene/CNT | 50 wt% | 49.9 | 0.2 | 8–12 Ghz | [43] |

| PEEK/MWCNT | 20 wt% | 44.5 | 0.56 | 8–12 Ghz | [42] |

| TPU/MWCNT | 5 wt% | 53.3 | 2.4 | 8–12 Ghz | [173] |

| NiFe2O4/AgNW/EPM | 10 wt% | 66.5 | 2 | 8–12 Ghz | [174] |

| MXene/AgNW/MoS2 | 10 wt% | 86.3 | 0.03 | 8–12 Ghz | [175] |

* LMPA—low-melting-point alloy; SR—silicone rubber; GF—graphene fiber; PEEK—polyether-ether-ketone.

This entry is adapted from the peer-reviewed paper 10.3390/molecules28155628

This entry is offline, you can click here to edit this entry!