The rheological behavior of cement paste displays several complexities such as non-linearity, yielding, time-dependence and chemical changes. The most common testing procedures allowing for the characterization of this behavior have been reported. For flow behavior, the most relevant protocol consists of the application of a ramp sweep (shear rate or shear stress) so that the flow curve (shear stress as a function of the shear rate) is at steady state flow. The structural build-up can be characterized by static yield stress measurements or the SAOS protocol for various resting times. The non-linearity of flow behavior corresponds to a shear-thinning/shear-thickening phenomenon that can be represented by the Herschel–Bulkley model. If the shear-thinning phenomenon can be related to the flocculation state, the origins of shear thickening are not clearly elucidated. Theories based on order–disorder transition, particle clustering, or viscous/inertial regime transition have been developed to explain the appearance of shear thickening.

1. Introduction

The development of modern cementitious materials, such as 3D-printable cementitious materials [

1,

2,

3], low-carbon cement [

4,

5], or self-compacting concrete [

6,

7], requires a deep understanding of the rheological behavior at the fresh state. Other types of concretes including recycled aggregates or plastic fiber pose challenges with respect to their fresh state behavior [

8,

9]. In addition, several processes, such as pumping or casting, are strongly conditioned by the rheological behavior. For instance, the development of 3D-printable concretes based on extrusion generates several challenges that directly concern the rheology of cementitious materials. Indeed, 3D concrete formulations must be pumpable but stable in shape once placed without formwork. In addition, the sequential layers put in place by extrusion must adhere and structure themselves quickly. Finally, the geometry of the printed parts must be controlled within the appropriate geometric tolerances [

3,

10].

At the fresh cement paste scale, the rheological behavior is dictated by the cement particles’ organization and the interparticle forces [

11]. Several methods and procedures were developed to characterize this behavior and to examine the effect of influencing factors such as superplasticizers [

12,

13,

14], supplementary cementitious materials (SCMs) [

15,

16], or formulation parameters [

17]. Moreover, the rheological behavior of cement paste exhibits different complexities such as non-linearity (shear thinning/shear thickening), viscoelasticity, yielding, structural build-up at rest, and chemical evolution. In general, the rheograms of cement paste are not linear and can present a shear-thinning phenomenon leading to the decrease in viscosity with an increasing shear rate. This behavior is characteristic of flocculated suspensions [

15,

18] and is attenuated with the incorporation of a dispersant (superplasticizer). In fact, the flow behavior becomes linear with viscosity independent from the shear rate due to the enhanced dispersion by the addition of the superplasticizer.

Furthermore, cementitious materials cannot be described as thixotropic materials [

19,

20,

21,

22,

23], since the evolution of rheological properties at rest is not fully reversible. At rest, a structural build-up due to flocculation and chemical evolution occurs and allows for evaluating the loss of workability during the dormant period of cement hydration. An irreversible part due to chemical hydration remains despite the application of a strong shearing which theoretically can erase the structural build-up [

20]. The addition of dispersants or retarders induces a decrease in the structural build-up, and the behavior of the cement paste tends towards a thixotropic behavior [

20].

2. Testing Procedures

2.1. Flow Tests

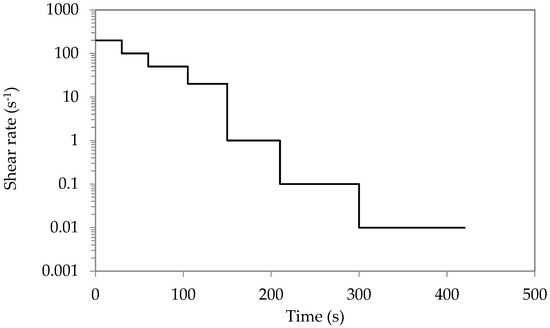

Flow tests are usually performed using rotational rheometers by applying an imposed shear rate or shear stress. The most relevant procedure for cement paste consists of the application of a strong preshear in order to induce a structural breakdown and ensure a same initial state for the tested samples, followed by a flow sweep (or stepped flow) with a decreasing shear rate, as shown in Figure 1. The applied time at each step must be greater than the characteristic time, which depends on the shear rate. In fact, the characteristic time is inversely proportional to the shear rate. So, for a high shear rate, the required time to reach the steady state flow is negligible, while for a very low shear rate, this time increases and is of the order of 10 to 50 s. It should be noted that most modern rheometers are equipped with steady state sensors that allow the equilibrium state to be detected at each applied shear rate.

Figure 1. Flow sweep test with a decreasing shear rate.

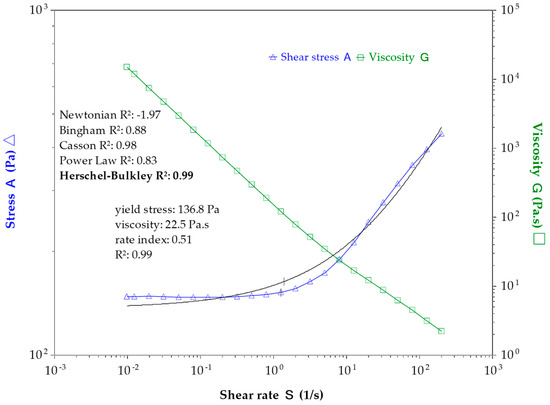

The response given by such flow test in terms of shear stress and viscosity is presented in Figure 2. The flow curve is non-linear and displays shear-thinning behavior. In fact, the viscosity decreases with an increasing shear rate, which characterizes the breakdown of agglomerated particles. For a low shear rate, the shear stress remains almost constant, which describes the flow stoppage of freshly mixed cement paste. This shear stress is defined as the dynamic yield stress and corresponds to the minimum stress required to initiate the flow onset.

Figure 2. Shear stress and viscosity as a function of the shear rate for cement paste with a w/c ratio of 0.4 after 20 min of hydration (test performed with Rheometer AR2000Ex from TA Instruments equipped with Vane geometry).

2.2. Oscillation Metods

Dynamic rheology consists of small-amplitude oscillation shear (SAOS) [

17,

21,

25] and large-amplitude oscillation shear (LAOS) [

26]. These procedures seem to be more appropriate for examining the microstructure of cement paste. The LAOS procedure appears to be relevant to investigating the evolution of non-linear viscoelastic properties at different frequencies and amplitudes represented by the Pipkin diagram [

26]. The SAOS procedure is more appropriate for examining the structural build-up during the dormant period of cement hydration [

21,

22,

27,

28,

29].

Oscillation procedures include strain sweep, frequency sweep, and time sweep tests. They consist of the measurement of the viscoelastic properties such as the storage (or elastic) modulus G′, the loss (viscous) modulus G″, critical strains, and other parameters (phase angle, oscillation stress …). The frequency sweep mode is generally performed to investigate the cement paste stability [

30]. The time sweep procedure is appropriate for examining the structural build-up and thixotropy [

19,

21,

22]. Strain (or stress) sweep tests can be carried out to probe the microstructure of cement paste and can give information concerning the network of cement particles and the forces acting inside this network.The amplitude sweep can be performed by applying an increasing stress (or strain) at a frequency of 1 Hz [

17,

19,

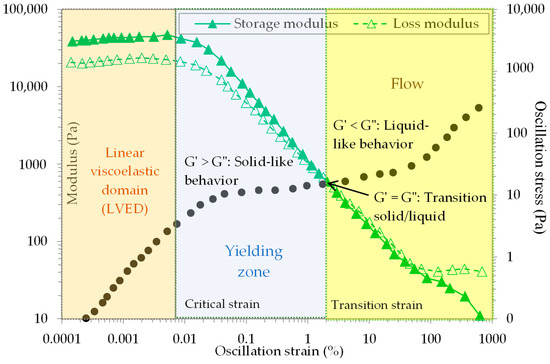

23]. The typical response of amplitude sweep is presented in

Figure 3. It is worth noting that this kind of non-destructive test allows the microstructure of fresh cement paste to be probed [

17,

27,

31]. As shown in

Figure 3, the evolution of storage and loss moduli during an amplitude sweep follows three phases. The first phase in which the moduli remain almost constant is defined as the linear viscoelastic domain (LVED). In this domain, the microstructure of cement paste is maintained [

27].

Figure 3. Example of an amplitude (strain or stress) oscillation test (test performed with Rheometer AR2000Ex from TA Instruments equipped with Vane geometry).

2.3. Transient Mode

The stress growth procedure consists of the application of a very low shear rate in the range of 10

−3 s

−1–10

−2 s

−1, depending on the rheometer sensitivity. In fact, the yield stress corresponds to the minimum stress required to initiate flow. Theoretically, it corresponds to the shear stress at rest, i.e., for a shear rate equal to 0. Since rheometers cannot apply a shear rate of zero, this shear rate must be as low as possible. The correct measurement of the yield stress consists of the application of a strong pre-shearing phase, followed by a sufficient resting time to allow the structure to be rebuilt [

23,

33,

34,

35,

36]. Then, a very low shear rate in the range of 10

−3 s

−1–10

−2 s

−1 is applied to the cement paste during a sufficient time to reach the steady state flow. This time has to be greater than the characteristic time of flocculation, which is of the order of 10 s [

23]. Vane geometry appears to be the most suitable for such a test.

3. Rheological Behavior of Cement Paste

3.1. Flow Behavior

The cementitious suspensions generally display a shear-thinning behavior with a continuous decrease in viscosity with the shear rate. This behavior, characteristic of flocculated suspensions, describes the deflocculation under shearing. For simplification, the rheological behavior of cement paste is often assimilated to a Binghamian behavior under certain conditions. In addition, cement pastes (without dispersant) exhibit a yield stress that has to be overcome to initiate flow. Viscoplastic models such as the Herschel–Bulkley model or Bingham model seem to be relevant and are widely used to describe the flow behavior of cement pastes. The flow curve obtained by a stress (or shear rate) sweep is fitted with such models to determine the dynamic yield stress at a very low shear rate.

The effect of several parameters such as the properties of cement, water-to-cement ratio (w/c), admixtures, and supplementary cementitious materials (SCMs) on the flow behavior has been widely studied [

15,

23,

32,

39,

40,

41,

42,

43,

44,

45]. The effect of w/c on rheological parameters can be described by the dependence on the solid volume fraction through the Krieger–Dougherty law for viscosity [

46] or yield stress [

47] or by the yield stress model (YODEL) developed by Flatt and Bowen [

48]. The effect of admixtures (especially superplasticizers) and SCMs has been the subject of a large number of publications.

Although it is often assumed, by simplification, that cement pastes behave like a Bingham fluid, it turns out that many experimental results reveal behaviors marked by nonlinear flow curves, especially with shear-thinning behavior. However, cement pastes can also display a shear-thickening behavior, particularly in the presence of superplasticizers and/or certain mineral additions [

15,

49,

50]. The shear-thickening behavior refers to the abrupt or continuous increase in viscosity with the shear rate.

By carrying out dynamic simulations, Bossis and Brady [

51] proposed a mechanism based on particle clustering to explain the shear thickening. The cluster formation results from the lubrication forces. In a suspension with short-range repulsive interparticle forces (electro-steric effect; Brownian motion) such as cement paste with a superplasticizer, the cluster formation could be avoided, especially at low or moderate shear rates. With an increasing shear rate, the hydrodynamic forces increase until their intensity exceeds that of the repulsive forces, thus inducing the formation of particle clusters.

Another mechanism based on the order–disorder transition has been proposed to explain the shear thickening [

15,

52,

53,

54]. According to this theory, the shear-thickening behavior would be the consequence of the transition from a layered flow, where the particles are ordered in successive layers, to a locally disordered state, where the particles are dislodged from the layer structure. In fact, the hydrodynamic forces cause this instability, which breaks up the layered flow. This local instability induces particle jamming, which probably involves cluster formation, leading to an increase in viscosity.

3.2. Linear Visco-Elastic Domain

The linear visco-elastic domain (LVED) can be determined by oscillation rheology. In this domain, the storage and loss moduli remain constant. Generally, fresh cement pastes (without a superplasticizer) exhibit a solid-like behavior in this domain with a storage modulus greater than the loss modulus (G′ > G″). The end of this domain is associated with a shear strain of the order of 10

−2%. This shear strain can be attributed to the breakage of the links between particles due to early hydrates nucleation [

23] and/or the attractive colloidal forces [

29,

32]. It has to be kept in mind that this critical strain remains identical from fresh cement paste to hardened cement paste [

29].

The effect of several factors (w/c ratio, SP dosage, SCMs …) on the LVED of fresh cement paste has been investigated, but the number of studies remains relatively limited [

17,

19,

27,

29,

55,

56]. Recently, an interesting study dealing with the effect of the w/c ratio and superplasticizer (SP) on the viscoelastic properties of fresh cement pastes has been carried out [

17].

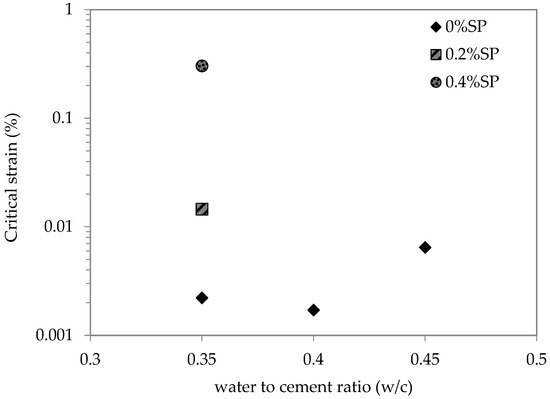

Furthermore, it appears that the critical strain at the end of the LVED is strongly affected by the superplasticizer dosage, while the effect of the w/c ratio is less significant. Only a high w/c ratio leads to an increase in this critical strain [

17]. The effect of the SP dosage thus appears to be more significant than that of the w/c ratio (

Figure 6). The interpretation of this phenomenon remains complex, and some ambiguities remain in the literature. First, the critical strain at the end of the LVED is attributed to the breakage of C-S-H bridges between cement particles [

17,

23].

Figure 6. Effect of water-to-cement ratio (w/c) and superplasticizer dosage on the critical strain (data from [

17]).

Concerning the effect of w/c on the critical strain, Jiao and De Schutter [

17] explain it by the increase in the dissolution rate, leading to the increase in early hydrates formation. In addition, these early hydrates could be more fragile when w/c increases. The effect of the superplasticizer on the critical strain is explained by the entanglement of superplasticizer molecules with each other and the possible enhancement of the C-S-H bridges.

3.3. Structural Build-Up

The term thixotropy reflects the fact that the rheological properties (viscosity) are time-dependent. Thixotropic materials thus become more fluid with an increasing shear time (at a constant shear rate) or more viscous when kept at rest. Therefore, the viscosity of thixotropic material gradually increases with the resting time (build-up), and when it is sheared, it must recover its initial state (break-down). Thixotropy therefore assumes that the evolution of rheological properties over time is reversible. Thus, the application of a shear makes it possible to erase the history of the structuration at rest. This reversible phenomenon is often attributed to reversible physico-chemical phenomena such as flocculation/deflocculation in colloidal suspensions [

23].

The term “thixotropy” is often used for cementitious materials to describe the reversible evolution at the macroscopic scale, e.g., the maintenance of workability [

35,

44,

63,

64]. However, due to cement hydration, the initial state cannot be completely recovered. This is referred to as workability loss (or slump loss). In fact, during the low-activity period of cement hydration, also called the dormant period, chemical changes occur in the cementitious material, leading to the formation of hydrates bridges between cement particles [

23].

Various testing procedures and approaches have been reported in the literature. The first procedure, called the hysteresis loop, consists of applying an increasing and decreasing shear rate. The area between the ascending and descending curve is an indicator of the thixotropy. This method can be used as a preliminary attempt to assess the thixotropy [

65,

66]. In fact, the hysteresis area depends not only on time but also on shear history (shear rate, test condition, step duration). The most common test consists of the measurement of the static yield stress (using the stress growth procedure) after different resting periods [

20,

21,

67,

68].

4. Conclusions

The non-linearity of flow behavior corresponds to a shear-thinning/shear-thickening phenomenon that can be represented by the Herschel–Bulkley model. If the shear-thinning phenomenon can be related to the flocculation state, the origins of shear thickening are not clearly elucidated. Theories based on order–disorder transition, particle clustering, or viscous/inertial regime transition have been developed to explain the appearance of shear thickening.

Furthermore, oscillation rheology allows for determining the linear viscoelastic domain (LVED) in which both storage and loss moduli remain constant. The end of this linear domain is associated with a critical strain of the order of 10−2%. This critical strain could be the signature of the breakage of interparticle bonds formed by early hydrates (C-S-H) and/or attractive colloidal forces, especially for cements with supplementary cementitious materials (SCMs) and alternative cements such as calcium sulfoaluminates cements or belite ye’elimite ferrite (BYF) cements.

This entry is adapted from the peer-reviewed paper 10.3390/eng4030107