Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Agricultural Engineering

HydroLab is a module designed to implement different fertigation strategies in two independent samples of plants.

- hydroponics

- fertigation

- test bench

- test bed

1. Introduction

The agriculture industry currently faces a significant and unprecedented challenge: the efficient and timely production of food to meet the needs of a rapidly growing global population. According to the Food and Agriculture Organization (FAO) of the United Nations, the year 2050 is projected to be a pivotal year with profound global implications since the human population is anticipated to reach 9.73 billion individuals, with approximately 75% residing in urban areas [1]. Meeting the nutritional demands of this growing population will require significant increases in food production, estimated at approximately 70% compared to 2007 levels [2]. These challenges are compounded by a variety of factors, including resource constraints, environmental concerns, and supply chain inefficiencies.

The Green Revolution is one of the most significant events in agriculture history, marked by a series of research, development, and technology transfer initiatives aimed at bolstering industrialized agricultural production [3]. These initiatives focused on cultivating high-yield crop varieties, expanding fertigation infrastructure, and disseminating hybrid seeds that exhibited enhanced productivity. However, intensified soil utilization and increased reliance on fertigation were crucial factors that posed some of the most pressing challenges to agriculture during this time [3]. While the initiatives addressed the immediate needs, they had adverse repercussions, such as soil degradation, salinization of irrigated areas, overexploitation of groundwater resources, deforestation, greenhouse gas emissions, the exacerbation of the greenhouse effect, and contamination of water bodies with nitrates [4]. The long-term consequences of these actions have become increasingly apparent in previous years and different approaches must be investigated toward food security.

Hydroponics has gained popularity as it represents an environmentally friendly option that offers higher crop yields and improved quality [5]. Studies have indicated that the global hydroponic market is projected to experience significant growth, with an anticipated annual growth rate of 20.7% from 2021 to 2028, reaching a value of 9.8 billion [6]. This agricultural practice eliminates the need for soil and holds promise as a viable solution to the challenges facing traditional agriculture [2]. In hydroponics, plants are cultivated in natural or artificial substrates that facilitate the efficient uptake of nutrients from a carefully prepared nutrient solution. This method can address issues related to substandard crop quality and quantity, soil contamination, and the limited availability of arable land and water resources in traditional agriculture [7]. Despite these benefits, hydroponics still faces significant challenges, such as the optimization of fertigation strategies [8], particularly when considering different crops, varieties, and growing conditions [9,10].

Fertigation involves the injection of fertilizers into an irrigation system and it is the most critical activity in hydroponics. For instance, a high salt content in the nutrient solution generates osmotic pressure values that prevent the absorption of nutrients, while low content affects plant growth and productivity [11]. In some cases, frequent fertigation may be necessary due to the restricted root volume of the plants [12], but too frequent fertigation increases the moisture content in the root zone, reducing the oxygen availability to plants [13]. Moreover, fertigation requirements vary based on numerous factors such as plant species, cultivar, growth stage, utilized substrate, season, and climate conditions. Due to the lack of standard knowledge and the complexity of the problem, test benches are fundamental for investigating effective fertigation strategies.

2. HydroLab Framework

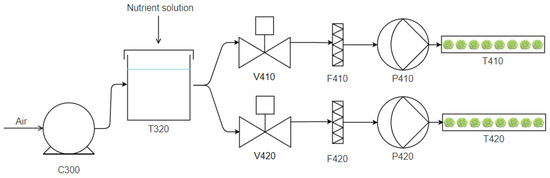

HydroLab is a module designed to implement different fertigation strategies in two independent samples of plants. The module is illustrated in Figure 1.

Figure 1. P&ID diagram of HydroLab: T320 denotes the nutrient solution tank, C300 denotes the air compressor, V410 and V420 denote the solenoid valves, P410 and P420 denote the diaphragm pumps, F410 and F420 denote the mesh filters, and T410 and T420 denote the two crop samples.

The user manually prepares a nutrient solution with a predefined level of pH and electrical conductivity (EC). Prior to fertigation, an air compressor is activated to mix the solution, ensuring that concentrated salts do not deposit. Subsequently, the solenoid valve and pump are activated to initiate fertigation of the crop sample. The nutrient solution passes through a mesh filter to remove solid particles that could potentially damage the pump. Two sets of solenoid valves, pumps, and mesh filters are implemented to independently manage the two crop samples.

3. HydroLab Architecture

In this section, the framework previously illustrated is instantiated through implementation technologies. Furthermore, its sensors and control architecture are presented.

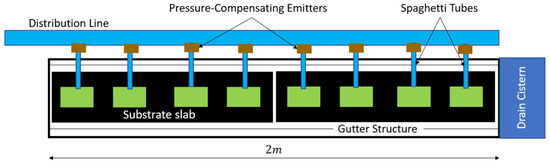

The objective of HydroLab is to develop fertigation strategies for hydroponics. In order to facilitate statistical analysis, the same strategy is applied to groups of crops. The module consists of two rows of plants, with each row containing eight plants (Figure 2). However, it may be scaled up to accommodate larger crop groups. On each row, two slabs with substrates are positioned on an inverted gutter structure equipped with lateral drain channels, as illustrated in Figure 3. The slope of the gutter is adjusted using suspensions to facilitate the drainage flow into a cistern located at the end of the structure. Each slab accommodates four plants, which are supplied with nutrients through spaghetti tubes connected to the main distribution line. Pressure compensating (PCJ CNL of 4 L/h) (https://www.netafim.com/en/products-and-solutions/product-offering/drip-irrigation-products/PCJ-online/ (accessed on 18 July 2023)) emitters are utilized to ensure precise and uniform irrigation for the plants [24]. These emitters include anti-draining features to prevent fluid leakage after pump shutdown, as well as self-compensating capabilities to maintain a consistent solution flow despite changes in line pressure. An SFDP1-011-070-21 (http://www.seaflo.com/en-us/product/detail/1070.html (accessed on 18 July 2023)) diaphragm pump is used to deliver the nutrient solution to the emitters in conjunction with a solenoid valve. This pump is chosen for its ability to handle chemical solutions within the acceptable pH range of 5 to 10. Drops are injected into the substrate using vertical stakes connected to the spaghetti tubes. Lastly, the EcoPlus HGC728459 (https://www.hawthornegc.com/shop/product/ecoplus-commercial-air-pumps (accessed on 18 July 2023)) compressor is employed to mix the solution before fertigation.

Figure 2. Configuration of each distribution line of HydroLab.

Figure 3. Gutter structure with lateral drain channels, adjustable suspensions, drip emitters, spaghetti tubes, and stakes.

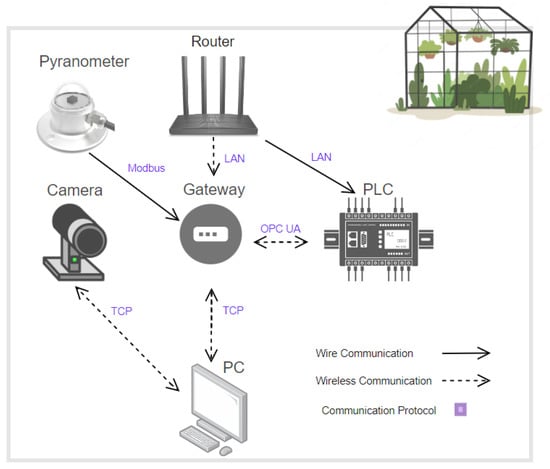

The sensors and control architecture of HydroLab are depicted in Figure 4. These components support the decision-making process concerning fertigation and are integrated with Internet of Things (IoT) technologies to facilitate remote monitoring and control of the system. Various sensors can be strategically placed based on specific experimental requirements. In particular, a pyranometer is utilized, as the case study described in Section 4 involves a comparison between a time-based strategy and solar radiation-based fertigation strategy. However, further sensors can be installed in the future (such as capacitance probes) to test fertirrigation based on the VWC [25,26]. Next, the different elements are illustrated.

Figure 4. HydroLab sensors and control architecture.

-

Pyranometer: A Hukseflux SR05-D1A3 (https://www.hukseflux.com/products/pyranometers-solar-radiation-sensors/pyranometers/sr05-d1a3-pyranometer (accessed on 18 July 2023)) pyranometer is utilized to measures solar radiation and temperature. The acquired values are transmitted to the Raspberry Pi using the Modbus protocol;

-

Programmable logic controller (PLC): The Beckhoff CX7000 (https://www.beckhoff.com/en-en/products/ipc/embedded-pcs/cx7000-arm-cortex-m7/cx7000.html (accessed on 18 July 2023)) PLC controls the HydroLab sensors and actuators. It transmits the acquired sensor data to the gateway through the OPC UA protocol;

-

Router: The ADSL2+ HG5316 (https://etb.com/mejorainternet/info/docs/HG531V1.pdf (accessed on 18 July 2023)) router facilitates the establishment of a closed communication network between the gateway and the PLC. It also generates a wireless network with internet access, enabling remote control of the system;

-

Gateway: As the utilized PLC does not have wireless communication capabilities, a Raspberry Pi is used as the gateway. The Raspberry Pi utilizes the Node-RED (https://nodered.org/ (accessed on 18 July 2023)) programming tool to facilitate communication with the PLC and the HMI (Human-Machine Interface). Additionally, the Raspberry Pi processes the solar radiation and temperature data and initiates fertigation when a specified threshold is reached. The fertigation command is sent to the PLC, which is responsible for its implementation;

-

Camera: The camera model Tapo C200 (https://www.tp-link.com/co/home-networking/cloud-camera/tapo-c200/ (accessed on 18 July 2023)) enables remote audiovisual monitoring of the crops. The camera can be operated through its dedicated smartphone application. It can also be adapted for viewing on any computer using emulators. Researchers and practitioners can monitor the development of their crops without the need for physical presence on-site;

-

HMI: The system’s control panel is implemented using the Node-RED interface, enabling the reading and writing of the system’s state from a personal computer.

Finally, a breakdown decomposition of the cost for implementing the module is represented in Table 2.

Table 2. Cost breakdown analysis of HydroLab.

| Component | Units | Cost [USD] |

|---|---|---|

| Gutter structure | 2 | 636 |

| Solenoid valve | 2 | 14 |

| Compressor | 1 | 241 |

| Router | 1 | 33 |

| Video camera | 1 | 48 |

| Mesh Filter | 2 | 34 |

| Diaphragm pump | 2 | 80 |

| Raspberry Pi | 1 | 34 |

| Pyranometer | 1 | 950 |

| PLC | 1 | 493 |

| Total cost | 2563 |

This entry is adapted from the peer-reviewed paper 10.3390/app13158867

This entry is offline, you can click here to edit this entry!