Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Green extraction techniques are more and more relevant due to major sustainable goals set by the United Nations. Greener extraction processes are being designed through the use of unconventional extraction techniques and green solvents, resulting in less hazardous processes which, consequently, reduces environmental impacts.

- antioxidant

- bioactive pigments

- bioeconomy

- green chemistry

1. Introduction

The 12 principles of green chemistry [1], as well as the rising academic and public interest in non-hazardous compounds [2], have been the main drivers of innovation in extraction techniques. A green extraction method or technique is based on the design of an extraction process that decreases energy consumption, permits the use of new-generation solvents, reduces waste by converting it into co-products, and assures a safe and high-quality final product [3][4].

The significance of greener extraction methods has become increasingly apparent due to the United Nations (UN) prioritizing a more sustainable future. As part of these efforts, studies focused on implementing environmentally friendly extraction processes that efficiently convert diverse biomass sources into valuable products such as bioactive compounds and biobased materials have been conducted in recent years. By doing so, waste generation is minimized, environmental impact is reduced, and the economic value of various biomass sources is enhanced. This holds particular importance for underdeveloped nations [5].

The aforementioned extraction methods produce vital bioactive compounds from different biomass sources (i.e., microalgae species, food waste, and lignocellulosic sources) that reportedly have multiple health-promoting properties [6][7]. Bioactive compounds like polyphenols, vitamins, and fatty acids have attracted great attention due to their role in the prevention of several chronic diseases [8]. Furthermore, bioactive pigments or phytochemicals such as chlorophylls, betalains, carotenoids, phycocyanin, and anthocyanins also have great antimicrobial, antioxidant, and immunologic properties that are of great interest in the pharmaceutical, food, and materials consumer sectors [9][10].

To provide some context, several reviews [11][12][13][14] have already covered different innovative extraction methods from different biomass sources, including mainly food waste and microalgae. The number of reviews focused on extraction techniques from food waste, microalgae, and lignocellulosic biomass is not surprising given the great potential of these sources. For instance, microalgae are autotrophic microorganisms that produce high-value compounds such as polysaccharides, polyunsaturated fatty acids (PUFAs), and bioactive pigments like carotenoids (mainly lutein, zeaxanthin, and astaxanthin) [15][16]. On the other hand, food waste has also gained interest in society due to the higher global population and the consequent rise in food waste generation [17]. Food wastage such as peels, seeds, rind, and pulp are generated and often discharged into landfills, thus causing a significant economic and ecological burden due to greenhouse gas emissions (GHGs) that can contribute to climate change [12][18][19]. To solve such issues, researchers have tried to develop innovative outlets for these wastes, mainly related to energy and the extraction of bioactive compounds [11][12].

Lignocellulosic biomass is another great biomass source since it is considered one of the most abundant sources of bioenergy and biobased products. Lignocellulosic biomass includes various agricultural residues such as bark, branches, logs, and leaves [20] from deciduous and coniferous trees and waste from the pulp and paper industry [21][22]. Lignin—a main component of lignocellulosic biomass—may undergo a reversed process of depolymerization, with the release of some important polyphenolic components classified as aromatic aldehydes (vanillin, syringaldehyde), hydroxybenzoic (vanillic, syringic) acids, and hydroxycinnamic (p-coumaric, ferulic) acids [7].

Up to this moment, the reported extraction studies have mainly focused on the use of non-conventional extraction techniques such as microwave-assisted extraction (MAE), ultrasound-assisted extraction (UAE), pressurized liquid extraction (PLE), pulsed electric fields (PEF), and supercritical fluid extraction (SC) in the extraction of rich bioactive compounds from different biomass sources (i.e., food waste, microalgae, and lignocellulosic sources) [14]. These techniques have been distinguished from conventional techniques such as maceration and Soxhlet due to the use of more sophisticated equipment and higher efficiency in the extraction of several compounds of interest in less time [23].

Solvents are usually employed in order to create a mass transfer of the targeted bioactive molecules [24]. These solvents may bring some issues due to their toxicity and flammability; therefore, it is important to choose the right solvent to be used in the extraction process. Factors such as cost, biocompatibility, and efficiency in extraction must be considered when designing an extraction process [25].

2. Green Solvents

In recent years, environmental directives and legislation have sought to reduce solvent emissions or regulate the usage of potentially harmful or environmentally damaging chemical substances [26]. However, many existing chemical processes still depend heavily on harmful and toxic solvents. This paradigm is worse in developing countries because of the attractive prices of toxic solvents and their availability. This is a clear case of neglect whereby economic factors are favored above sustainability.

Nonetheless, in recent years, there have been more and more studies focused on the use of green solvents in chemical processes, with publications rising beyond the 10,000 mark from 2010 onwards in ScienceDirect when the term “green solvents” was searched.

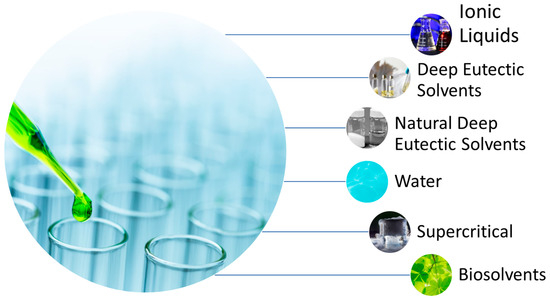

Green solvents (Figure 1) can be defined as chemicals that minimize the environmental impact resulting from their use in chemical processes and production [27]. This concept is part of green chemistry, which can be defined as the design of chemical processes that can reduce to eliminate the use and generation of hazardous substances [3]. To provide the readers with a better understanding, a green solvent can be defined as a solvent that possesses one or more of the following properties: low or non-volatility, nonflammable, no inhalation hazards (non-toxic, non-carcinogenic), able to be recycled, and biodegradability [28]. Furthermore, they possess an array of different physical and chemical characteristics that make them suitable for different types of extraction techniques.

Figure 1. Types of green solvents.

For instance, supercritical solvents are substances that are readily accessible at their critical points. Supercritical carbon dioxide is one of the most used supercritical solvents due to its safety and renewability [26]. Typically, supercritical solvents exhibit high diffusivities similar to the gas state. However, co-solvents such as ethanol are usually required to increase the solubility of solid reagents and products as the polarity of pure supercritical carbon dioxide is very low [26].

Ionic liquids (ILs) are pure compounds composed of ions [29], which present desirable thermodynamic properties such as thermal stability, adjustable viscosity, miscibility, solubility, and extraction capacity for an array of different compounds with distinct polarities [4].

As an alternative to ILs, deep eutectic solvents (DESs) have emerged since they present similar thermodynamic properties to ILs but are more easily synthesized, less detrimental to the environment, and present lower toxicity. DESs are formed by a hydrogen bond acceptor (HBA), such as quaternary ammonium, with a hydrogen bond donator (HBD), such as urea, carboxylic acids, or ammine [14]. When natural components are used for DES synthesis, usually for plant primary metabolites (e.g., sugars), they are called natural deep eutectic solvents (NADESs). Since these solvents are synthesized from natural components, which are inexpensive, abundant, and recyclable materials, they are seen as non-toxic solvents, making them highly compatible with food, pharmaceutical, and cosmetic formulations and use.

Water is considered the most natural of solvents and many researchers have considered water as the greenest solvent in chemistry both from an experimental and an industrial perspective. In recent decades, a new concept has also surfaced, which is switchable water. Switchable water is obtained by adding a base soluble (e.g., N,N,N′,N′-tetramethylbutane-1,4-diamine) to water [30]. This enables “the switch”, which consists of the addition or depletion of CO2 to monitor the ionic strength of an aqueous solution. At the end of the extraction process, it is possible to remove the base from the water solution to make it clean and safe once again [30], making it a great solvent option for the extraction of some polar compounds.

Biosolvents are solvents based on natural ingredients that have been developed to offer an alternative to fossil resources [31]. The major classes of biosolvents are (1) esters of natural organic acids (e.g., ethyl acetate and ethyl lactate), (2) fatty acid esters, (3) bioethanol, (4) terpenes compounds (e.g., eucalyptol, limonene, and others), (5) isosorbide, and (6) glycerol derivatives. These solvents are also considered green solvents since they are environmentally friendly and not harmful to humans [32][33][34].

This entry is adapted from the peer-reviewed paper 10.3390/pr11082255

References

- ACS—American Chemical Society Green Chemistry. Available online: https://www.acs.org/greenchemistry/principles/12-principles-of-green-chemistry.html (accessed on 12 June 2023).

- Picot-Allain, C.; Mahomoodally, M.F.; Ak, G.; Zengin, G. Conventional versus green extraction techniques—A comparative perspective. Curr. Opin. Food Sci. 2021, 40, 144–156.

- Chemat, F.; Vian, M.A.; Cravotto, G. Green Extraction of Natural Products: Concept and Principles. Int. J. Mol. Sci. 2012, 13, 8615–8627.

- Benvenutti, L.; Zielinski, A.A.F.; Ferreira, S.R.S. Which is the best food emerging solvent: IL, DES or NADES? Trends Food Sci. Technol. 2019, 90, 133–146.

- United Nation. Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations: New York, NY, USA, 2015.

- Santos, D.I.; Saraiva, J.M.A.; Vicente, A.A.; Moldão-Martins, M. 2—Methods for Determining Bioavailability and Bioaccessibility of Bioactive Compounds and Nutrients. In Innovative Thermal and Non-Thermal Processing, Bioaccessibility and Bioavailability of Nutrients and Bioactive Compounds; Barba, F.J., Saraiva, J.M.A., Cravotto, G., Lorenzo, J.M., Eds.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Cambridge, UK, 2019; pp. 23–54. ISBN 978-0-12-814174-8.

- Korga-Plewko, A.; Zgórka, G.; Józefczyk, A.; Grzegorczyk, A.; Biernasiuk, A.; Boguszewska, A.; Rajtar, B.; Świątek, Ł.; Polz-Dacewicz, M.; Kołodziej, P.; et al. Phytochemical profiling and biological activity of the extracts obtained from green biomass of three Miscanthus L. species using supercritical carbon dioxide extraction. Ind. Crops Prod. 2022, 189, 115641.

- Kamiloglu, S.; Tomas, M.; Ozdal, T.; Yolci-Omeroglu, P.; Capanoglu, E. Chapter 2—Bioactive Component Analysis. In Innovative Food Analysis; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2021; pp. 41–65. ISBN 978-0-12-819493-5.

- Sánchez-Muñoz, S.; Mariano-Silva, G.; Leite, M.O.; Mura, F.B.; Verma, M.L.; Da Silva, S.S.; Chandel, A.K. Production of Fungal and Bacterial Pigments and Their Applications. In Biotechnological Production of Bioactive Compounds; Elsevier: Amsterdam, The Netherlands, 2019; pp. 327–361. ISBN 9780444643230.

- Ravindran, R.; Jaiswal, A.K. Exploitation of Food Industry Waste for High-Value Products. Trends Biotechnol. 2016, 34, 58–69.

- Majid, I.; Khan, S.; Aladel, A.; Dar, A.H.; Adnan, M.; Khan, M.I.; Mahgoub Awadelkareem, A.; Ashraf, S.A. Recent insights into green extraction techniques as efficient methods for the extraction of bioactive components and essential oils from foods. CyTA-J. Food 2023, 21, 101–114.

- Rodríguez García, S.L.; Raghavan, V. Green extraction techniques from fruit and vegetable waste to obtain bioactive compounds—A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 6446–6466.

- Sharma, M.; Usmani, Z.; Gupta, V.K.; Bhat, R. Valorization of fruits and vegetable wastes and by-products to produce natural pigments. Crit. Rev. Biotechnol. 2021, 41, 535–563.

- Martins, R.; Sales, H.; Pontes, R.; Nunes, J.; Gouveia, I. Food Wastes and Microalgae as Sources of Bioactive Compounds and Pigments in a Modern Biorefinery: A Review. Antioxidants 2023, 12, 328.

- Saadaoui, I.; Rasheed, R.; Abdulrahman, N.; Bounnit, T.; Cherif, M.; Al Jabri, H.; Mraiche, F. Algae-Derived Bioactive Compounds with Anti-Lung Cancer Potential. Mar. Drugs 2020, 18, 197.

- Martins, R.; Mouro, C.; Pontes, R.; Nunes, J.; Gouveia, I. NADES Extraction of Bioactive Pigments from Spirulina platensis and Electrospinning Ability Evaluation. Polymers 2023, 15, 1574.

- Ben-Othman, S.; Jõudu, I.; Bhat, R. Bioactives from Agri-Food Wastes: Present Insights and Future Challenges. Molecules 2020, 25, 510.

- More, P.R.; Jambrak, A.R.; Arya, S.S. Green, environment-friendly and sustainable techniques for extraction of food bioactive compounds and waste valorization. Trends Food Sci. Technol. 2022, 128, 296–315.

- Socas-Rodríguez, B.; Álvarez-Rivera, G.; Valdés, A.; Ibáñez, E.; Cifuentes, A. Food By-Products and Food Wastes: Are They Safe Enough for Their Valorization? Trends Food Sci. Technol. 2021, 114, 133–147.

- Nogueira, G.P.; McManus, M.C.; Leak, D.J.; Franco, T.T.; Oliveira de Souza Dias, M.; Nakao Cavaliero, C.K. Are eucalyptus harvest residues a truly burden-free biomass source for bioenergy? A deeper look into biorefinery process design and Life Cycle Assessment. J. Clean. Prod. 2021, 299, 126956.

- Wei, H.; Yan, Y.; Gu, J.; Yi, W.; Tang, J. Lignocellulosic Biomass Valorization: Production of Ethanol. In Encyclopedia of Sustainable Technologies; Abraham, M.A., Ed.; Elsevier: Oxford, UK, 2017; pp. 601–604. ISBN 978-0-12-804792-7.

- Malolan, R.; Gopinath, K.P.; Vo, D.V.N.; Jayaraman, R.S.; Adithya, S.; Ajay, P.S.; Arun, J. Green ionic liquids and deep eutectic solvents for desulphurization, denitrification, biomass, biodiesel, bioethanol and hydrogen fuels: A review. Environ. Chem. Lett. 2021, 19, 1001–1023.

- Bitwell, C.; Indra, S.S.; Luke, C.; Kakoma, M.K. A review of modern and conventional extraction techniques and their applications for extracting phytochemicals from plants. Sci. Afr. 2023, 19, e01585.

- Dardavila, M.M.; Pappou, S.; Savvidou, M.G.; Louli, V.; Katapodis, P.; Stamatis, H.; Magoulas, K.; Voutsas, E. Extraction of Bioactive Compounds from C. vulgaris Biomass Using Deep Eutectic Solvents. Molecules 2023, 28, 415.

- Yilmaz, E.; Soylak, M. Type of Green Solvents Used in Separation and Preconcentration Methods. In New Generation Green Solvents for Separation and Preconcentration of Organic and Inorganic Species; Elsevier: Amsterdam, The Netherlands, 2020; pp. 207–266. ISBN 9780128185698.

- Clarke, C.J.; Tu, W.-C.; Levers, O.; Bröhl, A.; Hallett, J.P. Green and Sustainable Solvents in Chemical Processes. Chem. Rev. 2018, 118, 747–800.

- Capello, C.; Fischer, U.; Hungerbühler, K. What is a green solvent? A comprehensive framework for the environmental assessment of solvents. Green Chem. 2007, 9, 927–934.

- Winterton, N. The green solvent: A critical perspective. Clean Technol. Environ. Policy 2021, 23, 2499–2522.

- Lei, Z.; Chen, B.; Koo, Y.-M.; MacFarlane, D.R. Introduction: Ionic Liquids. Chem. Rev. 2017, 117, 6633–6635.

- Lajoie, L.; Fabiano-Tixier, A.S.; Chemat, F. Water as Green Solvent: Methods of Solubilisation and Extraction of Natural Products—Past, Present and Future Solutions. Pharmaceuticals 2022, 15, 1507.

- Bandres, M.; De Caro, P.; Thiebaud-Roux, S.; Borredon, M.-E. Green syntheses of biobased solvents. C. R. Chim. 2011, 14, 636–646.

- Popescu, M.; Iancu, P.; Plesu, V.; Todasca, M.C.; Isopencu, G.O.; Bildea, C.S. Valuable Natural Antioxidant Products Recovered from Tomatoes by Green Extraction. Molecules 2022, 27, 4191.

- Prasad, W.; Wani, A.D.; Khamrui, K.; Hussain, S.A.; Khetra, Y. Green solvents, potential alternatives for petroleum based products in food processing industries. Clean. Chem. Eng. 2022, 3, 100052.

- Viñas-Ospino, A.; López-Malo, D.; Esteve, M.J.; Frígola, A.; Blesa, J. Green Solvents: Emerging Alternatives for Carotenoid Extraction from Fruit and Vegetable By-Products. Foods 2023, 12, 863.

This entry is offline, you can click here to edit this entry!