The Collaborative Research Center 1153 is investigating a novel process chain for manufacturing high-performance hybrid components. The combination of aluminum and steel can reduce the weight of components and lead to lower fuel consumption. During the welding of aluminum and steel, a brittle intermetallic phase is formed that reduces the service life of the component. After welding, the workpiece is heated inhomogeneously and hot-formed in a cross-wedge rolling process. Since the intermetallic phase grows depending on the temperature during hot forming, temperature control is of great importance.

1. Introduction

The technical requirements for components are rising steadily while, at the same time, material shortages and rising costs, as well as CO

22 constraints, add to the difficulty of material selection

[1]. A promising solution to many of these new challenges is the use of hybrid materials with locally adapted properties. The Collaborative Research Center (CRC) 1153 researches a novel process chain called “Tailored Forming” for the manufacturing of hybrid components. Components produced by Tailored Forming have adapted material to the complex load profiles during operation

[2]. Thereby, the lifetime of a component can be increased whilst saving costs due to the usage of a more affordable material in areas of the component with lower stress during operation. For this purpose, hybrid workpieces are produced with the combination of high-alloy and low-alloy steel. Another material combination investigated in the CRC 1153 is aluminum and steel. This combination enables weight reduction, and thus, a reduction in fuel consumption

[3]. It can be applied when the weight of components made of steel is to be reduced and a component made of aluminum would not meet all technical requirements. The physical properties of aluminum and steel, such as melting temperature, electrical or thermal conductivity, and density, vary strongly

[4]. In the joining zone, an intermetallic phase is formed

[5][6]. The formation of this phase is dependent on the longitude of the welding process and the occurring temperatures

[7]. The resulting thickness of the intermetallic phase is unevenly distributed, and should be kept as thin as possible, as the phase is very brittle, and is the limiting factor of the strength and performance of a hybrid component

[4][7]. This poses challenges for temperature control during the subsequent forming processes. The requirements for the process control of materially bonded aluminum–steel combinations are extensive, since the forming processes and material-specific properties must be precisely matched to each other

[8]. Forming temperatures that are too high can lead to failure of the workpiece, as the aluminum is softened. Too-low temperatures lead to high forming forces and stress conditions in the joining zone, resulting in fracture. Behrens et al. found that the intermetallic phase grows during reheating and forming

[5]. Therefore, a low temperature in the suitable temperature range for forming the hybrid workpiece should be selected, as the intermetallic phase then exhibits less growth.

2. Research on Hybrid Materials and Inhomogeneous Heating

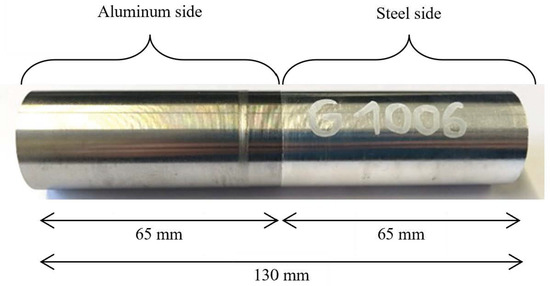

In the CRC 1153, different hybrid geometries are researched. One of them is the serially arranged combination of aluminum and steel (

Figure 1). These workpieces are manufactured by rotary friction welding. Friction welding is a process in which the heat required for the material joint is generated by friction between the joining partners

[7]. The workpieces are then formed using CWR or impact extrusion. In the case of CWR, the workpiece rotates around its own axis while the tools move transversely to it. The tools are wedge-shape profiled and create a mass distribution along the axis of rotation of the workpiece

[9]. Kruse et al. investigated the joining zone displacement in serially arranged hybrid parts

[10]. For this purpose, inhomogeneously heated billets made from steel and aluminum were cross-wedge rolled and examined. Behrens et al. developed a heating and forming strategy for hybrid components made from aluminum and steel using Finite Element Analysis (FEA) and experimental trials

[2].

Figure 1. Serially arranged aluminum–steel billet produced by friction welding.

Various researchers are working on the subject of hybrid forging technology. The difference between Tailored Forming and hybrid forging lies in the structure of the respective process chains. In Tailored Forming, a joining process is followed by a forming process that thermomechanically influences the joining zone. In hybrid forging, the joining of two materials takes place during forming. The Leiber Group GmbH & Co. KG (Emmingen-Liptingen, Germany) developed a forging process for the production of hybrid connecting rods

[11]. The two materials are forged together and joints are produced, which results in a combination of form fit and cohesive bonding. Tomczak et al. investigated the skew rolling of bimetallic rods

[12]. A workpiece is produced by placing a sleeve made of material A on a core made of material B. The workpiece is then rolled to join the two materials together. The process has been evaluated for several material combinations. Graf et al. investigated a hybrid forging process for components made from a combination of aluminum and plastic to reduce the weight of the component

[13].

Other research deals with the issue of inhomogeneously heated parts. Jagodzinski et al. investigated inhomogeneous heating strategies for forging processes in order to adjust the flow properties of the material by means of different temperatures

[14]. It was found that the flash could be reduced by up to 11.8 %. This was achieved by using the varying yield stress due to the different temperatures to optimize the material flow. A process window was established that allows for the reduction in flash. Matzenmiller et al. investigated the forging process of a shaft with partial heating, and provided a parameter study for different properties of the workpiece

[15]. By means of simultaneously cold and hot forging, locally adapted material properties are set. Ennen et al. researched a tailored heating approach to realize adapted forming behavior that produces complex preforms

[16]. To this end, the limits of temperature profiles were determined simulatively and experimentally. Okman et al. investigated the usage of temperature gradients to facilitate material flow

[17]. It was found that more differentiated local forms can be formed when low thermal diffusivity and higher temperature sensitivity were present. Kayatürk investigated simultaneous hot and cold forging, in which areas with a high degree of forming are hot-forged and other areas remain cold, in order to attain the properties of cold forging, such as high surface quality and dimensional accuracy

[18]. Yoshikara et al. have explored another application of partial heating in manufacturing

[19]. The quality of deep-drawn components can be greatly increased if the formability in the forming area is increased by local heating, while cracks are avoided with simultaneous cooling in other areas

[19]. Kahrimanidi conducted research on Tailor Heat Treated Blanks, in which the plates are heated in areas of high formability, and other areas remain cool, so that the material’s strength is maintained

[20].

3. Cross-Wedge Rolling of Hybrid Components

During CWR of hybrid components, the flow properties of the different materials are critical for stable processing. Torsional and other stresses are transferred to the workpiece, and can cause failure of the joining zone, which is manifested by the separation of the joined sections of the workpiece. The joining zone is also subjected to tensile and compressive stresses during heating due to different coefficients of thermal expansion of the two materials, so special attention must be paid to the thermal processes in the area of the joining zone during heating

[2]. Temperature control for serial components made from aluminum and steel is complex because the properties of the two materials differ greatly (

Table 1)

[2].

Table 1. Comparison of the physical properties of aluminum and iron

[2].

| Property |

Iron |

Aluminum |

Unit |

| Density |

7.86 |

2.7 |

g/cm33 |

| Thermal expansion (0–100 °C) |

12 |

24 |

10−6−6·m/(m·K) |

| Melting temperature |

1536 |

660 |

°C |

With higher temperature, the shape-changing capacity of metal increases and the resulting strength decreases, since thermally activated processes in the crystal lattice, such as recrystallization and recovery, take place

[21]. Hot forming for steel starts at 1000 °C, within the scope of the CRC 1153 investigations, is normally performed at 1250 °C

[22]. The hot forming temperature for aluminum is between 350 and 450 °C

[22]. A homogeneous forming temperature for the hot forming of hybrid components made from aluminum and steel would therefore lead to excessive forces in the steel or to the melting of the aluminum. The influence of temperature on the forming processes can be shown, in part, by the material-specific yield curves: Yield stress is the stress required to cause plastic deformation in the material in a homogeneous uniaxial loading condition

[22]. It is thus directly related to the forming force that must be applied to form the workpiece. Therefore, Behrens et al. analyzed the flow curves of steel and aluminum for different temperatures

[8]. Each material was tested at room temperature as well as in specific temperature ranges. Steel was tested at 300 to 1200 °C and aluminum at 300 to 550 °C. The resulting flow curves were then compared to find individual temperature ranges for each material where the flow properties are similar. For steel (20MnCr5), a temperature of 900 to 1200 °C was selected, and for aluminum (EN AW-6082), a temperature of 300 to 550 °C was found to have similar yield curves. Kruse et al. developed an inhomogeneous temperature profile for CWR, where the flow properties of the two materials were adapted

[10]. The thermal influence on the joining zone was low enough to successfully perform CWR processes.

Inhomogeneous temperature profiles can be generated using an induction heating furnace. Induction heating is a direct electrothermal process in which the temperature distribution in electrically conductive workpieces can be adjusted

[23]. The heat is directly produced inside the steel part of the workpiece. The aluminum part on the other side is heated by the heat transmission from steel to aluminum.

4. Methods of Thermal Monitoring during Cross-Wedge Rolling

Different methods of process control and, especially, of temperature measurements during CWR exist. Direct measurements, such as thermocouple outputs, can be used, as well as optical measurements. Pyrometry measurements, or measurements taken with a thermal imaging camera, of aluminum are associated with challenges such as the variable emissivity of aluminum surfaces and the influence of reflective surfaces on the workpiece

[24]. Additionally, the oxidation on the surface of a heated workpiece during CWR causes variation in the emissivity. As a result, both methods are not adequate for obtaining temperature measurements of aluminum during CWR

[24].

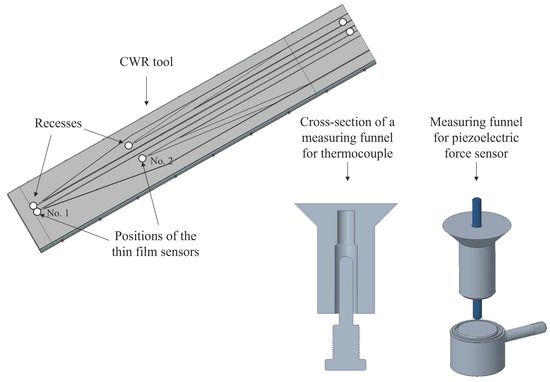

Since the hot forming of hybrid components creates complex requirements for the forming process, a special CWR tool has been developed that features tool-integrated process monitoring. The tool has milled recesses for so-called measuring funnels.

Figure 2 shows the tool and two types of measuring funnel. The measurement concept was developed following Yoneyama et al.

[25][26]. The first type is used for measuring the pressure of the workpiece applied onto the tool during the rolling process, with a pin transmitting the force to a piezo sensor positioned underneath the tool. The second type of measuring funnel is used for the indirect measurement of temperature. Type K thermocouples are inserted into the measuring funnel, and measure the transmitted heat right underneath the surface. The short contact duration between the measuring funnel and workpiece during CWR and the high latency of the thermocouples cause only small spikes in the measurement curves. The method is an indirect measurement that only measures transmitted heat and not the actual temperature of the workpiece. Additionally, the transmission of heat is greatly influenced by the contact conditions between the workpiece and tool.

Figure 2. Tool-integrated process monitoring during CWR.

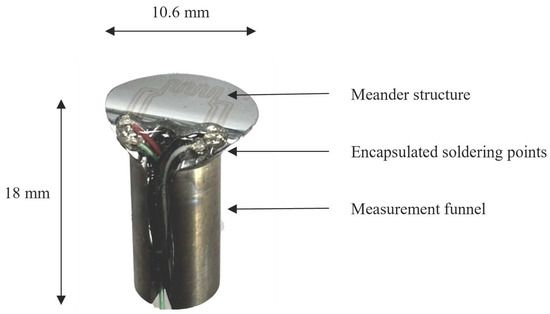

Thin-film sensors are a novel way to measure the surface temperature of workpieces in mixed-friction contact. The sensors were developed and produced at the Fraunhofer Institute for Surface Engineering and Thin Films (IST) in Braunschweig, Germany. The design of the measuring funnel was adapted to fit the meander structure and the brazing points (

Figure 3). The surface is build up of different layers. First, an Al

22O

33 isolation layer is deposited onto a polished steel surface with a roughness value of R

𝑧 < 0.1

μm. A homogeneous chromium layer is then applied and patterned employing a sequence of photolithography and wet chemical etching. A second layer of Al

22O

33 is deposited to protect the meander structure from physical wear. Wires are then soldered to the sensor, and the soldering points are encapsulated with a heat-resistant sealing paste. Each sensor has to be pre-characterized to explore the individual resistance changes of the meander structure. Thereby, a course of the thermoresistive characteristics of all sensors is established. The sensors used for the experiments were calibrated for temperatures up to 600 °C

[27].

Figure 3. Thin-film sensor on the measuring funnel.

This entry is adapted from the peer-reviewed paper 10.3390/jmmp7040130