Printed sensors fabricated on flexible platforms such as paper, plastic and textiles have been implemented for wearable applications in the biomedical, defense, food, and environmental industries.

- Printed and Flexible Sensors

- Flexible hybrid electronics

- Printing Processes

1. Introduction

Sensors, which represent the “ears”, “noses”, or “eyes” for information processing systems, are being widely used in numerous industrial applications as well as in our day-to-day lives. Sensors are typically employed to provide real-time information, which has helped in advancing the electronic industry by simplifying modern technical systems and making many technical applications more cost-effective, reliable, and safer. The need for sensing technologies has seen a dramatic increase in sensor R&D and applications over the past 25 years [1,2,3]. The remarkable advances in sensing technology, which have already been made possible and the potential range of applications that are yet to be developed, have placed sensors on the threshold of a revolution similar to that experienced by silicon technology in the computing industry during the 1980s [1,4]. An increasing demand for miniaturized, cost-effective, and reliable sensors capable of monitoring multiple environmental, physical, chemical, and biological parameters thus requires the development of novel sensing devices with advanced capabilities.

Flexible hybrid electronics (FHE) is a rapidly emerging field, with significant commercial potential that drives investments in research and development within the electronic manufacturing industry [5,6]. FHE draws upon two primary threads: printed electronics (PE) and other advanced deposition/assembly processes, and semiconductor devices and packaging technologies [7,8]. FHE devices are a natural bridge between the silicon driven IC industry and the PE industry. Printing is an additive process that has expanded into electronic applications where electronic materials are deposited selectively using electrically functional inks in combination with standard printing processes [9,10,11,12,13,14,15]. This eliminates the need for masking and etching, thus resulting in a cleaner process that produces less waste than traditional methods. Due to the universal application of FHE technology, FHE markets are expected to experience exponential growth over the next decade with a global market for consumer and industrial products manufactured using this technology of up to $3 billion USD by 2030 [16].

The last few years have seen a noticeable increase in the development of wearable technology devices that are often worn on the human body [17,18,19,20]. These devices provide the user with information about various physiological parameters and surroundings. Currently, some of the markets for wearable devices are in sports, fitness, and healthcare [21,22]. Examples of these applications include Nike’s Fitbit exercise tracking and monitoring device and google contact lenses for diabetics that will provide a continuous readout on blood glucose levels [23,24,25,26]. The wearable tech market is forecasted to reach $302.3 million by 2023 [27]. More recently, with the advent of FHE devices, wearable devices that integrate novel flexible, stretchable or even tattoo-like sensors, consisting of stretchable electrodes and interconnects, which enable conformal and intimate skin-device contact, have been a major focus of several research groups and companies [17,20,28,29,30]. The development of these devices includes the deposition of functional materials on conformal and/or non-curvy surfaces in various designs.

The two main approaches in developing printed electronic devices are contact and non-contact printing [31]. In the contact printing approach, ink is transferred from the surface of patterned structures to the substrate by physical contact. Gravure, screen, and flexography printing are examples of contact printing processes [31,32]. In a non-contact process, the ink is transferred to the substrate via nozzles or openings, with no physical contact with the substrate. Inkjet and aerosol printing are frequently used for non-contact printing [31,32]. The emergence of FHE based on PE has started to increasingly revolutionize the field of sensing; both in industrial and consumer settings [33,34]. Flexible sensors can be used for curved surfaces, complex geometries, and foldable applications. In contrast, rigid sensors fabricated by conventional microelectronics techniques cannot provide the expected/desired responses on non-flat surfaces similar to the flexible sensors. In recent years, the efforts to gain a better understanding of the dynamics of printing flexible sensors has increased, and this interdisciplinary approach addresses the challenges of fabricating miniaturized, low-cost, flexible sensors via high-throughput techniques, which are expected to be used for applications in aerospace, automotive, environmental, packaging, biomedical, and defense [35,36,37,38,39]. PE enables the fabrication of cost-effective sensors via large-area printing due to roll-to-roll manufacturing capability utilizing solution-process techniques, large-area substrates, multiple device printing per print batch, and fabricating in ambient conditions [36,37,38,39,40,41]. Modern fabrication technologies and the rapid maturation of application-based methodologies in PE have led to an increased understanding of semiconductor analyte interactions for use in chemical and biological detection. In addition, various types of physical sensors, such as strain sensors, optical sensors, temperature sensors, pressure sensors, and chemical sensors, including electrochemical sensors and gas sensors, have been realized using printing processes [42,43,44,45,46,47,48].

2. Printing Processes and Applications

2.1. Screen Printing

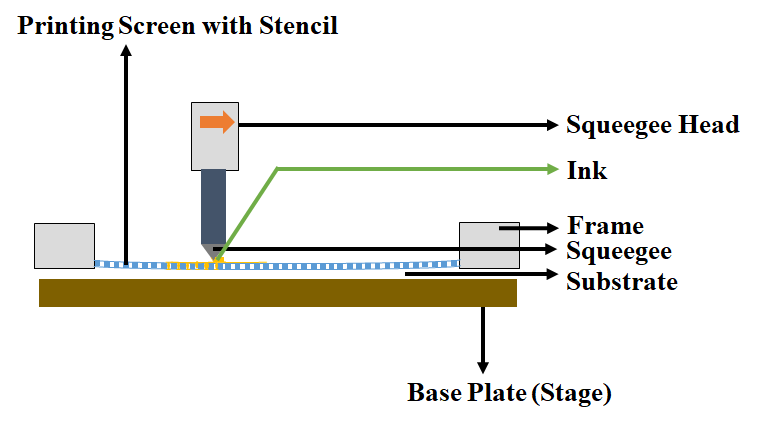

Screen printing is a technique in which a paste-like material (ink) is transferred onto the substrate. Screen printing is typically done either by hand or using a semi or fully automated system. The screen printer consists of a squeegee, stencil, and a screen with the design on it (Figure 1) [59,90]. Typically, screen fibers are made of plastic, natural silk, or metal fibers, and the squeeze is made of rubber. A section in the screen will be imposed by the design of the desired print and the ink is allowed to pass through it, and the desired design is created on the substrate being used. The ink is transferred either by pushing or forcing the ink by squeezing through the screen, and thus, this printing process is also referred as a push-through process. The print quality mainly depends on the mesh count, wire diameter, emulsion thickness, off-set height, and deflection angle of the screen. The screen-printing technique has the capability to print electronic devices at a low cost, with very little or no material wastage and provides an end product that can be extremely flexible [91,92]. With screen printing capabilities including R2R manufacturing and processing at ambient conditions, it is possible to fabricate a large number of printed devices in a relatively short period of time.

Figure 1. Schematic of the screen printing process.

2.2. Inkjet Printing

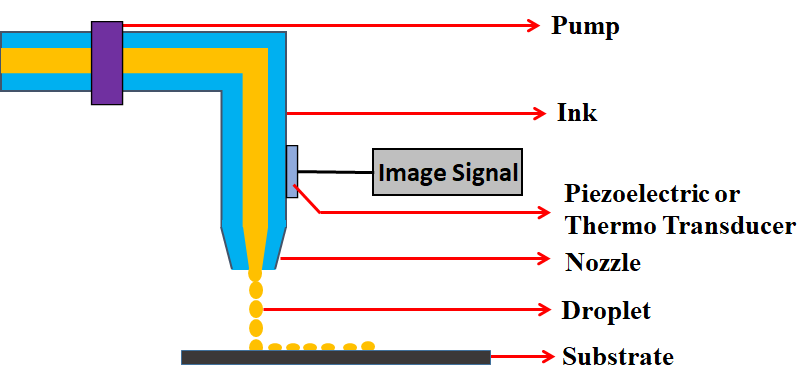

Inkjet printing is a non-impact printing method (NIP), and it uses a digital image signal to print the design by propelling ink droplets onto the substrate instead of any physical image carriers [59,90]. Typically, in inkjet printing, the inks will be in a liquid state with low viscosities and can be directly printed onto the substrate. Inkjet printing is classified into continuous inkjet printing and drop-on-demand (DOD) inkjet printing. In continuous Inkjet printing, a continuous flow of ink droplets is controlled electronically by a voltage source. Some of the ink droplets are subjected to electrostatic charge and are deflected to get a negative print by electrostatic deflectors while the uncharged drops are used to print the desired image onto the substrate. Thermal inkjet printers are very popular in the graphic printing and packaging industries. In a DOD-based inkjet printing, the ink droplets are created only if it is required by the image signal to get the desired print [59,90]. The droplets are formed either by using thermal or piezoelectric techniques as shown in Figure 2. In thermal inkjet printers, the ink droplets are forced or impelled out of the cartridge nozzle by a vapor bubble formed because of the vaporization of ink liquid. In piezoelectric inkjet printers, the volume of the cartridge nozzle is mechanically deformed based on the image signal and the ink droplets are released from the nozzle. DOD-based inkjet printing is very popular in FHE and has several advantages including as mask-less fabrication, high print resolution, cost efficiency, and scalability from table-top devices to big press units [90,110,111,112].

Figure 2. Schematic of the inkjet printing process.

2.3. Gravure Printing

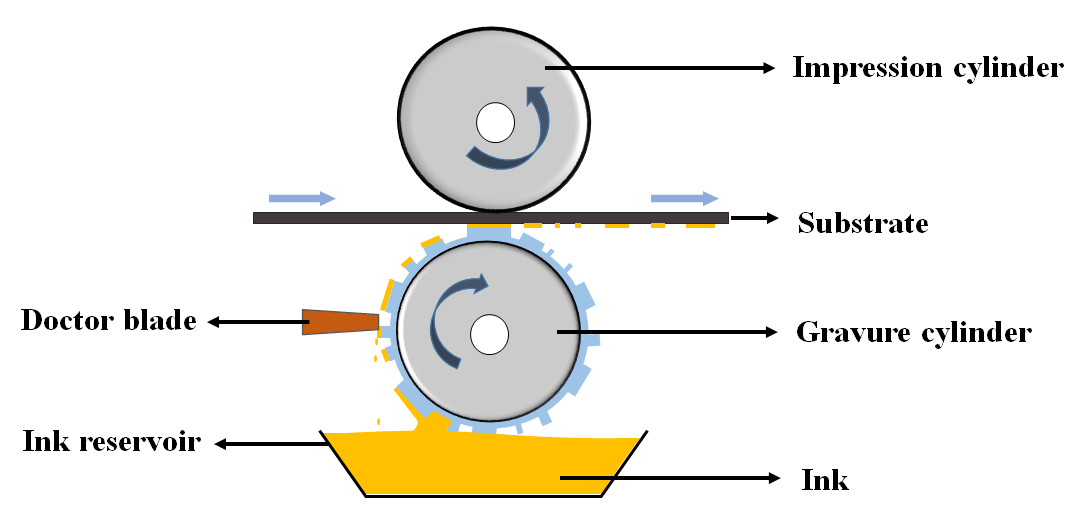

Gravure printing is an impact-based printing technique that provides economical production with fast outputs along with high-quality printing. It uses low viscosity inks and is known for its robustness. The image carrier cylinder (gravure cylinder), doctor blade, ink reservoir, and the impression cylinder are some of the main components of the gravure printer as shown in Figure 3 [59,90]. Typically, the impression cylinder is made of rubber, the gravure cylinder is made of copper-coated steel, and the doctor blade is manufactured with steel. In gravure printing, the image of the desired design is engraved on the surface of the gravure cylinder. The entire gravure cylinder is flooded by ink from the ink reservoir, and the extra ink is wiped off from the cylinder with the doctor blade prior to printing. The ink is transferred onto the substrate from the gravure cylinder with high pressures, and the substrate movement is controlled by the impression cylinder.

Figure 3. Schematic of the gravure printing process.

2.4. Flexographic Printing

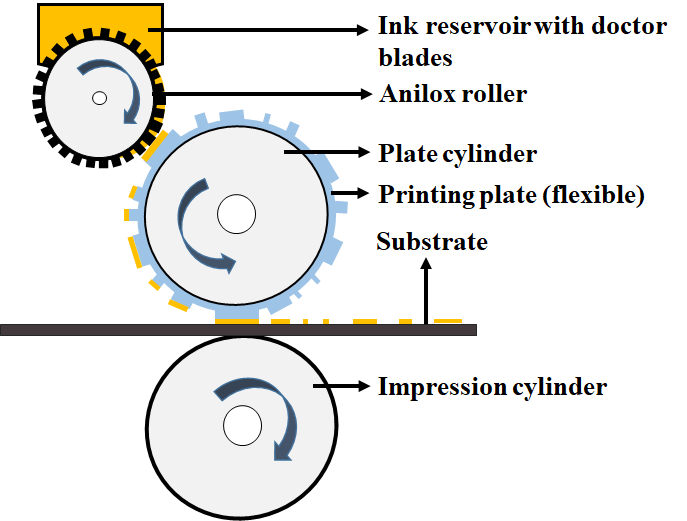

Flexographic printing is a well-established R2R high throughput rotational printing method. It is an indirect impact-based printing technique that can provide a wide range of ink thicknesses with the same resolution. The main parts of the flexographic printer are anilox roller, an impression cylinder, doctor blade, and the ink reservoir (Figure 4) [59,90]. Anilox roller (a steel cylinder), which has finely engraved cells on its surface made of chromium or ceramics, collects the specific amount of ink from the ink reservoir. Then, the collected ink is transferred onto the elevated structures of the printing plate. With the help of the plate cylinder, the ink on the printing plate is transferred onto the substrate. It is capable of addressing problems such as contact finger geometry as well as production line output. In addition, flexography has high-speed R2R printing capability (up to 100 m per minute) when compared to inkjet and screen printing [138,139]. Flexography printing is a well-matured printing technique in the graphic printing and packaging industries. However, the implementation of flexographic printing in FHE is not yet explored enough due to the limitations in research and commercial availability of functional inks compatible to flexographic printing. Therefore, there is only limited literature available on the development of flexography-based FHE devices [140,141,142].

Figure 4. Schematic of the flexography printing process.

This entry is adapted from the peer-reviewed paper 10.3390/bios10120199