1. Introduction

Air filtration biomaterials have recently become a research hotspot on account of the increasing attention paid to the global air quality problem [

1]. Particulate matter (PM) is the pollution made up of particles (tiny pieces) of solids that are in the air that may include: dust, dirt, etc. [

2]. PM air pollutants result from both natural and anthropogenic sources. Increased concentration of PM in the surrounding atmospheric environment devastates human health [

3]. Particulate matter has been divided into three different groups: the first group is PM10, which includes coarse particles and relatively large particles. PM10 mostly describes inhalable particles, including those particles less than 10 micrometers in diameters [

4]. The second group is fine particle matter (PM2.5), which includes tiny particles that can cause haziness to the air upon their elevation. PM2.5 are able to travel deeply into the respiratory tract, reaching the lungs [

5]. Exposure to fine particles can cause short-term health effects such as eye, nose, throat, and lung irritation, coughing, sneezing, runny nose, and shortness of breath [

6]. The third group is ultrafine particles (PM0.1), which have an aerodynamic diameter of around 0.1 μm [

7]. All three groups of PM form a real danger to the human health since they have the ability to penetrate the human body through the respiratory system. Therefore, the removal, or at least the reduction, of PM has become a necessity for a safe environment.

Air filters have been used to capture different types of PM, including PM10 and PM2.5 [

8,

9]. The PM filter industry has had tremendous progression, even though some concerns and challenges still exist. First of all, the technology that has been used for existing PM filters is lacking ecofriendly characteristics since remarkable amounts of solvents and toxic materials are used for the electrospinning process that negatively influence human health and the surrounding environment [

10]. Moreover, the accumulating discarded filters with high volumes of trapped PM constitute a direct threat to the environment. Besides the toxicity, those PM filters were designed to capture PM at a small range of concentration which is 1000 mg within the size of a cubic centimeter. In this case, those filters are facing a great challenge to capture PM within highly polluted environments. The capture of particulate matter via conventional and common purification technologies basically focuses on size-dependent mechanisms, which in most cases is fairly difficult due to the extremely small particle size of particulate matter and its ultra-low mass [

11]. Conventional filters have been made of several materials such as fabrics, wool, cotton, etc., mostly without considering their pore size or removal efficiency. In the research of Liu et al. [

12], filters made of a polyamide-56 nanofiber/net had a high filtration effectiveness of 99.995% for most of air pollutants. Although the filter was able to remove almost all the particulate matter, the issue of using toxic and non-ecofriendly material is still present. Other scientists have used PLA/PMMA composite nanofibers to solve the fine particle matter issue and claim that they removed 99.5% of PM2.5 using synthetic stimulations [

13]. Liu et al. [

14] developed a superhydrophobic filter using a mix of synthetic polymers and they were able to remove up to 96% of the PM2.5. Bioaerogels have been proposed for PM filtration as ecofriendly and sustainable functional materials [

15]. Bioaerogels are known to have various advantages over synthetic-based materials such as regeneration, biocompatibility, biodegradability, low density, high porosity, and a large specific surface area [

16,

17]. They are three-dimensional nanoporous structures with high surface area and porosity, derived from biopolymers such as chitosan, cellulose, alginate, or proteins [

18,

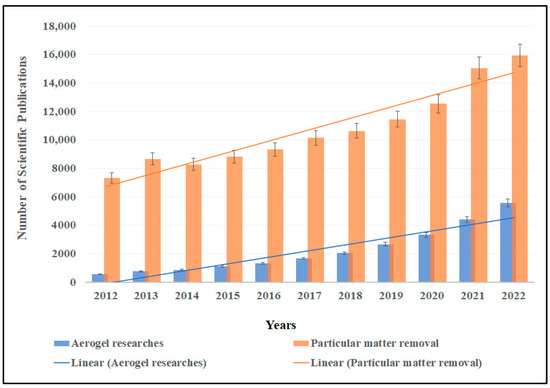

19]. These aerogels exhibit unique properties that make them attractive for various applications across multiple industries. Thus, extensive studies have been conducted regarding the fabrication, modification, and application of aerogels in the past few years, which can be observed from the increased number of scientific publications in the past ten years together with concerns about the adverse health effects of particulate matter pollution (

Figure 1).

Figure 1. Number of scientific studies in the last ten years about aerogel and particular matter removal. Search conducted through Science Direct database on 17 April 2023.

In the early periods of the air industrial revolution, filters were used to purify the atmosphere from particulate matter [

20]. Air filters were developed rapidly during that period of time using different precursor materials. However, currently, there is growing interest in finding inexpensive, abundant, and effective materials to use as effective air filtration with much focus on natural organic polymers, mainly from agriculture. Several researchers have prepared effective biopolymer-based aerogel filters for particulate matter removal [

21,

22].

2. Applications of Nanostructured Bioaerogel in Particulate Matter Removal

Nanostructured bioaerogel filtration was introduced as a new concept to purify the atmosphere that can overcome the limitations associated with conventional approaches. Nanostructured bioaerogels exhibit unique properties such as huge surface area, high porosity, and controlled pore size; biopolymer-based aerogels can be utilized in all types of PM air filtration [

25,

47]. Multilayered aerogel filters differ from conventional monolayered filters in that they can even eliminate ultrafine PM along with fine PM. For this reason, they were widely used in synthesizing aerogel-based filters [

109,

110].

2.1. Biomass-Based Nanostructured Aerogel

Biomass aerogel is a type of aerogel material that is derived from biomass, which refers to any organic material that is produced by living organisms or from their metabolic processes. Biomass can be derived from a wide range of sources, such as plant matter, agricultural waste, and industrial byproducts [

111]. Biomass aerogels have several advantages over traditional aerogels, including lower cost, increased sustainability, and reduced environmental impact [

112]. One of the key advantages of biomass aerogels is their potential to provide a sustainable alternative to traditional aerogel materials, which are often derived from non-renewable sources and can be expensive to produce. In a recent investigation, Wang et al. [

113] prepared a novel environmentally friendly nanostructured aerogel by using konjac glucomannan as a precursor material and enhanced it with wheat straw. The bioaerogel was prepared by using the conventional approach of sol–gel followed by a freeze-drying process. The authors reported that the addition of wheat straw biomass into the aerogel enhanced its porosity from 50% to more than 88%. The filtration capacity of the aerogel also improved to 90.38%. Furthermore, the addition of wheat straw significantly enhanced the mechanical properties of the aerogel, which reported compressive strength, compression modulus, and elasticity of 501.56 Pa, 2000.66 Pa, and 0.603, respectively. By utilizing biomass, which is often a waste product or byproduct of other processes, biomass aerogels can be produced at a lower cost and with reduced environmental impact.

Overall, biomass aerogels are a promising new material with a wide range of potential applications and are an example of how sustainable biomaterials can be utilized in advanced materials science. Biomass nanostructured aerogel have shown great potential in particulate matter removal due to their high surface area, porous structure, and ability to adsorb pollutants. Wang et al. [

114] fabricated another konjac glucomannan nanostructured aerogel for particulate matter removal using the conventional sol–gel and lyophilization methods. The authors reported that the addition of starch and gelatin into the aerogel could significantly enhance the filtration performance of the aerogel and increase its compressive strength. These polysaccharides increase the porosity of the aerogel, reduce the pore size, and thus enhance its filtration performance. The same authors also used wheat straw as a filler in the aerogel and reported that its addition decreased the filtration resistance and significantly enhanced the breathability of the aerogel. This could be attributed to the multi-cavities of wheat straw [

115]. Wheat-straw-enriched bioaerogel exhibited 93.5% filtration efficiency of fine particulate matter (≥0.3 μm) and an air permeability 271.4 L/s·m

2. Such nanostructured bioaerogel possessed a water contact angle of 105.4°, which shows its potential in resisting moisture and its workability even in humid conditions as an air filtration material. In a recent study, corn protein was used to fabricate nanostructured bioaerogels with controlled structures for particulate matter removal [

116]. The authors enhanced the filtration properties of the aerogel by adding polyvinyl alcohol to glue dispersed corn protein nanofibers and form the bioaerogel. The aerogel exhibited high capturing properties for particulate matter; up to 99.52% of PM2.5 and 98.80% of PM0.3. The authors also stated that their nanostructured bioaerogel was able to eliminate formaldehyde by 87.41% at a low pressure drop. Overall, biomass aerogels have shown great potential in particulate matter removal due to their unique properties and versatility. Further research is needed to optimize their use for different applications and to address any potential limitations.

2.2. Cellulose-Based Nanostructured Aerogel

Cellulose is the most abundant biopolymer on earth. Cellulose aerogels have been extensively studied and used in several applications including particulate matter removal [

117]. Cellulose is considered a great alternative for plastics and other fossil-oil-based materials that can alleviate environmental pollution [

29]. Cellulose aerogels are made by first extracting cellulose from plants and then dissolving it in a solvent. The cellulose solution is then subjected to a process called gelation, where it is transformed into a gel-like substance. The gel is then dried under controlled conditions to remove the solvent, resulting in a highly porous, low-density aerogel material [

118]. Cellulose aerogels are known for their unique properties, including high thermal insulation, high mechanical strength, and biodegradability. In the past few years, a huge number of functional cellulosed aerogels have been prepared, modified, and utilized in particulate matter removal. Xie et al. [

65] recently fabricated a carbonized cellulose-based aerogel using cotton wastes as precursor materials. The authors claimed that their aerogel was able to significantly filtrate the particulate matter due to the grown molybdenum disulfide. Owing to the high specific surface area and the high electrical conductivity of the prepared bioaerogel, it forms a strong electrostatic force between the particulate matter particles and the aerogel, with more than 99.91% and 99.95% removal efficiency for PM2.5 and PM10, respectively [

65].

Bacterial cellulose-based aerogels were prepared using a directional ice-templated approach and tested for PM removal [

22]. The authors modified bacterial cellulose to enhance the surface functional groups with reactive silane precursors. The aerogel exhibited excellent quantitative removal of PM (more than 95%). In a different study, Lyu et al. [

119] used waste hemp oil in the fabrication of aerogel via dissolution in a precooled NaOH/urea system. The aerogel was highly hydrophobic and highly porose and exhibited elastic behavior. The authors reported that their aerogel had a high removal capacity at 94% for both PM2.5 and PM10. Nanocellulose aerogels exhibit smooth fibers rich in surface functional groups. After the filtration, these fibers were found to be fully covered by particulate matter particles at the end of the filtering process, which proves the excellent PM capturing ability of nanocellulose aerogels.

2.3. Chitosan-Based Nanostructured Aerogel

Chitosan is another polysaccharide obtained from shrimp, shellfish, and other crustacean shells [

120]. It has been extensively used in different forms in air filtration due to its polarization ability, strong polarity, antimicrobial properties, biodegradability, and nontoxicity [

121]. These unique properties make chitosan highly attractive in air filtration applications. Chitosan aerogels are highly porous, lightweight materials that have a large surface area and can be easily modified to have specific chemical and physical properties [

122]. These properties make chitosan aerogels excellent candidates for air filtration applications. The air filtration process with chitosan-aerogel-based filters involves passing the contaminated air through the aerogel material, where particulate matters are trapped and removed. The highly porous nature of chitosan aerogels allows for a high airflow rate, resulting in efficient and effective air filtration [

56]. Chitosan-aerogel-based air filters have several advantages over conventional air filters, including high filtration efficiency, low energy consumption, and a long service life. They also have potential applications in various fields, such as indoor air purification, industrial air filtration, and medical air filtration. Desai et al. [

123] developed a chitosan-based nanofibrous filter through an electrospinning technique. The authors reported that the filtration efficiency of their fabrication was strongly associated with pore size and surface area. The authors claimed that their fabrication was able to eliminate heavy metals along with a 2–3 log reduction in air bacteria. In different study, Sun et al. [

124] fabricated a chitosan-dipped nanostructured air filter and claim its ability to eliminate most bacteria from the air. Chitosan was used with bacterial cellulose to fabricate a nanostructured aerogel integrated with Ti-based metal–organic frameworks [

125]. The bioaerogel had significantly high removal efficiencies of particulate matter even at low pressure drops. The authors stated that their fabrication had a filtration efficiency of more than 99.5% for PM2.5, with excellent stability even for a long time. Venkatesan et al. [

126] evaluated a chitosan–alginate-based aerogel membrane as an air conditioner filter using an air-conditioner-like model and found that the chitosan–alginate filter showed a better performance than conventional commercial filters. The authors incorporated silver nanoparticles into their filtration system and reported a 1.5 times enhancement in filtration efficiency. Overall, chitosan nanostructured aerogels have great potential in particulate matter removal, and further research and development could lead to their widespread use in air filtration systems.

2.4. Alginate-Based Nanostructured Aerogel

Alginate is a natural polysaccharide extracted from brown seaweed. It is a highly versatile biomaterial that has a wide range of applications in various fields, including air filtration and particulate matter removal [

127]. Alginate-based aerogels has been studied as potential materials for air filtration due to their unique properties, including their high porosity, biodegradability, and ability to capture particles [

128]. Alginate-based air filters work by using the electrostatic and adhesive properties of alginate to capture and trap airborne particles, such as fine dust, pollutants, and allergens. The alginate is often combined with other materials, such as activated carbon, to enhance its filtration efficiency and remove gases and odors. One of the advantages of alginate-based air filters is their low cost compared to other filter materials, making them a potentially affordable option for indoor air purification [

129]. Additionally, alginate is a natural, biodegradable material that is considered safe for human use, which is a desirable property for air filtration applications. Deng et al. [

130] fabricated a high-performance, ecofriendly, and biosafe PVA–sodium alginate–hydroxyapatite nanostructured composite using a green electrospinning technique. Owing to the nanopores in their fabrication, the authors were able to remove more than 99% of both types of fine particulate matter (PM0.3 and PM2.5). In order to improve its particulate matter capture efficiency, the authors created a unique wrinkled helical structure in their system, which promoted the physical interception of particulate pollutants. In a different study, Wu et al. [

131] developed self-supporting nanostructured aerogels for efficient particulate matter removal. The authors introduced both organic or choline cations and 1-butyl-3-methylimidazolium into the alginate due to the electrostatic interaction, and finally, freeze drying in liquid N

2 was used for the fabrication of the aerogel. The authors were able to remove up to 99.2%, 99.2%, and 93.4% of the PM10, PM2.5, and PM0.3 respectively. The aerogel performed this removal at low pressure drops of less than 10 Pa in a 15 h durability test. The use of alginate-based air filters is still in the early stages of research and development, and more studies are needed to fully understand their filtration efficiency and durability over time. Nonetheless, the potential of alginate in air filtration highlights the versatility of this biomaterial and its potential use in various applications.

This entry is adapted from the peer-reviewed paper 10.3390/gels9070575