An analysis of the literature data on the electrical, thermal, mechanical, and electrochemical properties of the conventional perovskite-type cathode materials shows that lanthanum strontium manganite (La,Sr)MnO3 (LSM) fulfils all the requirements for its use in high-temperature SOFCs. However, as the temperature decreases, the use of LSM materials, which are predominantly electronic conductors with a low level of ionic conductivity, becomes unsatisfactory due to their low electrochemical activity for the oxygen reduction reaction (ORR). On the other hand, cobalt-based perovskite materials, including lanthanum strontium cobaltite ferrite (La,Sr)(Co,Fe)O3−δ (LSCF), are characterized by superior catalytic activity due to high values of both electronic and ionic conductivity.

- SOFC

- cathode

- air electrode

- LSM

- LSCF

- thermal expansion

- conductivity

- solid oxide fuel cell

1. Introduction

2. Key Functional Properties of LSM and LSCF Electrode Materials: Advantages and Drawbacks

This entry is adapted from the peer-reviewed paper 10.3390/ma16144967

References

- Erixno, O.; Rahim, N.A.; Ramadhani, F.; Adzman, N.N. Energy Management of Renewable Energy-Based Combined Heat and Power Systems: A Review. Sustain. Energy Technol. Assess. 2022, 51, 101944.

- Iliev, I.K.; Filimonova, A.A.; Chichirov, A.A.; Chichirova, N.D.; Pechenkin, A.V.; Vinogradov, A.S. Theoretical and Experimental Studies of Combined Heat and Power Systems with SOFCs. Energies 2023, 16, 1898.

- Lee, J.; Lin, K.-Y.A.; Jung, S.; Kwon, E.E. Hybrid Renewable Energy Systems Involving Thermochemical Conversion Process for Waste-to-Energy Strategy. Chem. Eng. J. 2023, 452, 139218.

- He, V.; Gaffuri, M.; Van Herle, J.; Schiffmann, J. Readiness Evaluation of SOFC-MGT Hybrid Systems with Carbon Capture for Distributed Combined Heat and Power. Energy Convers. Manag. 2023, 278, 116728.

- Wang, Y.; Cao, Q.; Liu, L.; Wu, Y.; Liu, H.; Gu, Z.; Zhu, C. A Review of Low and Zero Carbon Fuel Technologies: Achieving Ship Carbon Reduction Targets. Sustain. Energy Technol. Assess. 2022, 54, 102762.

- Maestre, V.M.; Ortiz, A.; Ortiz, I. Challenges and Prospects of Renewable Hydrogen-Based Strategies for Full Decarbonization of Stationary Power Applications. Renew. Sustain. Energy Rev. 2021, 152, 111628.

- Russo, M.A.; Carvalho, D.; Martins, N.; Monteiro, A. Forecasting the Inevitable: A Review on the Impacts of Climate Change on Renewable Energy Resources. Sustain. Energy Technol. Assess. 2022, 52, 102283.

- Shen, M. Solid Oxide Fuel Cell-Lithium Battery Hybrid Power Generation System Energy Management: A Review. Int. J. Hydrogen Energy 2021, 46, 32974–32994.

- Kumar, P.; Singh, O. A Review of Solid Oxide Fuel Cell Based Hybrid Cycles. Int. J. Energy Res. 2022, 46, 8560–8589.

- Feng, Y.; Qu, J.; Zhu, Y.; Wu, B.; Wu, Y.; Xiao, Z.; Liu, J. Progress and Prospect of the Novel Integrated SOFC-ICE Hybrid Power System: System Design, Mass and Heat Integration, System Optimization and Techno-Economic Analysis. Energy Convers. Manag. 2023, 18, 100350.

- Kasaeian, A.; Javidmehr, M.; Mirzaie, M.R.; Fereidooni, L. Integration of Solid Oxide Fuel Cells with Solar Energy Systems: A Review. Appl. Therm. Eng. 2023, 224, 120117.

- Singh, M.; Zappa, D.; Comini, E. Solid Oxide Fuel Cell: Decade of Progress, Future Perspectives and Challenges. Int. J. Hydrogen Energy 2021, 46, 27643–27674.

- Bilal Hanif, M.; Motola, M.; Qayyum, S.; Rauf, S.; Khalid, A.; Li, C.-J.; Li, C.-X. Recent Advancements, Doping Strategies and the Future Perspective of Perovskite-Based Solid Oxide Fuel Cells for Energy Conversion. Chem. Eng. J. 2022, 428, 132603.

- Hu, S.; Li, J.; Zeng, Y.; Pu, J.; Chi, B. A Mini Review of the Recent Progress of Electrode Materials for Low-Temperature Solid Oxide Fuel Cells. Phys. Chem. Chem. Phys. 2023, 25, 5926–5941.

- Tarutin, A.P.; Filonova, E.A.; Ricote, S.; Medvedev, D.A.; Shao, Z. Chemical Design of Oxygen Electrodes for Solid Oxide Electrochemical Cells: A Guide. Sustain. Energy Technol. Assess. 2023, 57, 103185.

- Md Harashid, M.A.; Chen, R.S.; Ahmad, S.H.; Ismail, A.F.; Baharuddin, N.A. Recent Advances in Electrode Material for Symmetrical Solid Oxide Fuel Cells and Way Forward Sustainability Based on Local Mineral Resources. Int. J. Energy Res. 2022, 46, 22188–22221.

- Tahir, N.N.M.; Baharuddin, N.A.; Samat, A.A.; Osman, N.; Somalu, M.R. A Review on Cathode Materials for Conventional and Proton-Conducting Solid Oxide Fuel Cells. J. Alloys Compd. 2022, 894, 162458.

- Zhang, M.; Du, Z.; Zhang, Y.; Zhao, H. Progress of Perovskites as Electrodes for Symmetrical Solid Oxide Fuel Cells. ACS Appl. Energy Mater. 2022, 5, 13081–13095.

- Pikalova, E.Y.; Kalinina, E.G.; Pikalova, N.S.; Filonova, E.A. High-Entropy Materials in SOFC Technology: Theoretical Foundations for Their Creation, Features of Synthesis, and Recent Achievements. Materials 2022, 15, 8783.

- Skutina, L.; Filonova, E.; Medvedev, D.; Maignan, A. Undoped Sr2MMoO6 Double Perovskite Molybdates (M = Ni, Mg, Fe) as Promising Anode Materials for Solid Oxide Fuel Cells. Materials 2021, 14, 1715.

- Curi, M.; da Silva, E.R.; de Furtado, J.G.M.; Ferraz, H.C.; Secchi, A.R. Anodes for SOFC: Review of Material Selection, Interface and Electrochemical Phenomena. Quim. Nova 2021, 44, 86–97.

- Filonova, E.; Medvedev, D. Recent Progress in the Design, Characterisation and Application of LaAlO3− and LaGaO3-Based Solid Oxide Fuel Cell Electrolytes. Nanomaterials 2022, 12, 1991.

- Kim, D.; Jeong, I.; Kim, K.J.; Bae, K.T.; Kim, D.; Koo, J.; Yu, H.; Lee, K.T. A Brief Review of Heterostructure Electrolytes for High-Performance Solid Oxide Fuel Cells at Reduced Temperatures. J. Korean Ceram. Soc. 2022, 59, 131–152.

- Hanif, M.B.; Rauf, S.; Motola, M.; Babar, Z.U.D.; Li, C.-J.; Li, C.-X. Recent Progress of Perovskite-Based Electrolyte Materials for Solid Oxide Fuel Cells and Performance Optimizing Strategies for Energy Storage Applications. Mater. Res. Bull. 2022, 146, 111612.

- Dey, S.; Chaudhary, S.; Parvatalu, D.; Mukhopadhyay, M.; Sharma, A.D.; Mukhopadhyay, J. Advancing Electrode Properties through Functionalization for Solid Oxide Cells Application: A Review. Chem. Asian J. 2023, 18, e202201222.

- Kaur, P.; Singh, K. Review of Perovskite-Structure Related Cathode Materials for Solid Oxide Fuel Cells. Ceram. Int. 2020, 46, 5521–5535.

- Jun, A.; Kim, J.; Shin, J.; Kim, G. Perovskite as a Cathode Material: A Review of Its Role in Solid-Oxide Fuel Cell Technology. ChemElectroChem 2016, 3, 511–530.

- Klyndyuk, A.I.; Chizhova, E.A.; Kharytonau, D.S.; Medvedev, D.A. Layered oxygen-deficient double perovskites as promising cathode materials for solid oxide fuel cells. Materials 2022, 15, 141.

- Vinoth Kumar, R.; Khandale, A.P. A Review on Recent Progress and Selection of Cobalt-Based Cathode Materials for Low Temperature-Solid Oxide Fuel Cells. Renew. Sustain. Energy Rev. 2022, 156, 111985.

- Jiang, S.P. Development of Lanthanum Strontium Manganite Perovskite Cathode Materials of Solid Oxide Fuel Cells: A Review. J. Mater. Sci. 2008, 43, 6799–6833.

- Carda, M.; Budáč, D.; Paidar, M.; Bouzek, K. Current Trends in the Description of Lanthanum Strontium Manganite Oxygen Electrode Reaction Mechanism in a High-Temperature Solid Oxide Cell. Curr. Opin. Electrochem. 2022, 31, 100852.

- Oliveira, L.C.; Venâncio, R.; de Azevedo, P.V.; Anchieta, C.G.; Nepel, T.C.; Rodella, C.B.; Zanin, H.; Doubek, G. Reviewing Perovskite Oxide Sites Influence on Electrocatalytic Reactions for High Energy Density Devices. J. Energy Chem. 2023, 81, 1–19.

- Jiang, S.P. Development of Lanthanum Strontium Cobalt Ferrite Perovskite Electrodes of Solid Oxide Fuel Cells—A Review. Int. J. Hydrogen Energy 2019, 44, 7448–7493.

- Ndubuisi, A.; Abouali, S.; Singh, K.; Thangadurai, V. Recent Advances, Practical Challenges, and Perspectives of Intermediate Temperature Solid Oxide Fuel Cell Cathodes. J. Mater. Chem. A 2022, 10, 2196–2227.

- Li, Z.; Li, M.; Zhu, Z. Perovskite Cathode Materials for Low-Temperature Solid Oxide Fuel Cells: Fundamentals to Optimization. Electrochem. Energy Rev. 2022, 5, 263–311.

- Safian, S.D.; Abd Malek, N.I.; Jamil, Z.; Lee, S.-W.; Tseng, C.-J.; Osman, N. Study on the Surface Segregation of Mixed Ionic-Electronic Conductor Lanthanum-Based Perovskite Oxide La1 − xSrxCo1 − yFeyO3 − δ Materials. Int. J. Energy Res. 2022, 46, 7101–7117.

- Zarabi Golkhatmi, S.; Asghar, M.I.; Lund, P.D. A Review on Solid Oxide Fuel Cell Durability: Latest Progress, Mechanisms, and Study Tools. Renew. Sustain. Energy Rev. 2022, 161, 112339.

- Connor, P.A.; Yue, X.; Savaniu, C.D.; Price, R.; Triantafyllou, G.; Cassidy, M.; Kerherve, G.; Payne, D.J.; Maher, R.C.; Cohen, L.F.; et al. Tailoring SOFC Electrode Microstructures for Improved Performance. Adv. Energy Mater. 2018, 8, 1800120.

- Celik, I.; Lee, S.; Abernathy, H.; Hackett, G. Performance Degradation Predictions Based on Microstructural Evolution Due to Grain Coarsening Effects in Solid Oxide Fuel Cell Electrodes. J. Electrochem. Soc. 2018, 165, F64–F74.

- Geofrey Sahini, M.; Daud Lupyana, S. Perspective and Control of Cation Interdiffusion and Interface Reactions in Solid Oxide Fuel Cells (SOFCs). Mater. Sci. Eng. B 2023, 292, 116415.

- Zhang, L.; Chen, G.; Dai, R.; Lv, X.; Yang, D.; Geng, S. A Review of the Chemical Compatibility between Oxide Electrodes and Electrolytes in Solid Oxide Fuel Cells. J. Power Sources 2021, 492, 229630.

- Khan, M.Z.; Song, R.-H.; Mehran, M.T.; Lee, S.-B.; Lim, T.-H. Controlling Cation Migration and Inter-Diffusion across Cathode/Interlayer/Electrolyte Interfaces of Solid Oxide Fuel Cells: A Review. Ceram. Int. 2021, 47, 5839–5869.

- Wang, F.; Kishimoto, H.; Ishiyama, T.; Develos-Bagarinao, K.; Yamaji, K.; Horita, T.; Yokokawa, H. A Review of Sulfur Poisoning of Solid Oxide Fuel Cell Cathode Materials for Solid Oxide Fuel Cells. J. Power Sources 2020, 478, 228763.

- Wang, C.C.; O’Donnell, K.; Jian, L.; Jiang, S.P. Co-Deposition and Poisoning of Chromium and Sulfur Contaminants on La0.6Sr0.4Co0.2Fe0.8O3 − δ Cathodes of Solid Oxide Fuel Cells. J. Electrochem. Soc. 2015, 162, F507–F512.

- Wang, R.; Parent, L.R.; Gopalan, S.; Zhong, Y. Experimental and Computational Investigations on the SO2 Poisoning of (La0.8Sr0.2)0.95MnO3 Cathode Materials. Adv. Powder Mater. 2023, 2, 100062.

- Horita, T. Chromium Poisoning for Prolonged Lifetime of Electrodes in Solid Oxide Fuel Cells—Review. Ceram. Int. 2021, 47, 7293–7306.

- Zhou, L.; Mason, J.H.; Li, W.; Liu, X. Comprehensive Review of Chromium Deposition and Poisoning of Solid Oxide Fuel Cells (SOFCs) Cathode Materials. Renew. Sustain. Energy Rev. 2020, 134, 110320.

- Wang, R.; Sun, Z.; Lu, Y.; Gopalan, S.; Basu, S.N.; Pal, U.B. Comparison of Chromium Poisoning between Lanthanum Strontium Manganite and Lanthanum Strontium Ferrite Composite Cathodes in Solid Oxide Fuel Cells. J. Power Sources 2020, 476, 228743.

- Jiang, S.P.; Chen, X. Chromium Deposition and Poisoning of Cathodes of Solid Oxide Fuel Cells—A Review. Int. J. Hydrogen Energy 2014, 39, 505–531.

- Li, Q.; Wang, X.; Jia, L.; Chi, B.; Pu, J.; Li, J. High Performance and Carbon-Deposition Resistance Metal-Supported Solid Oxide Fuel Cell with a Nickel–Manganese Spinel Modified Anode. Mater. Today Energy 2020, 17, 100473.

- Girona, K.; Laurencin, J.; Fouletier, J.; Lefebvre-Joud, F. Carbon Deposition in CH4/CO2 Operated SOFC: Simulation and Experimentation Studies. J. Power Sources 2012, 210, 381–391.

- Chen, K.; Jiang, S.P. Surface Segregation in Solid Oxide Cell Oxygen Electrodes: Phenomena, Mitigation Strategies and Electrochemical Properties. Electrochem. Energy Rev. 2020, 3, 730–765.

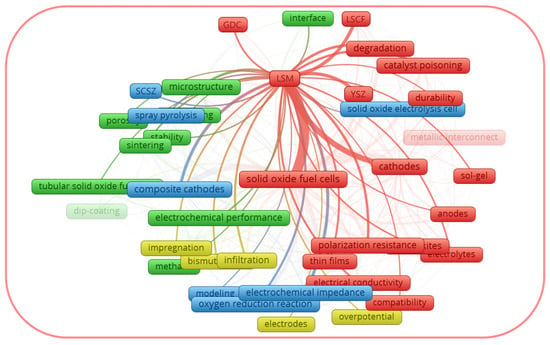

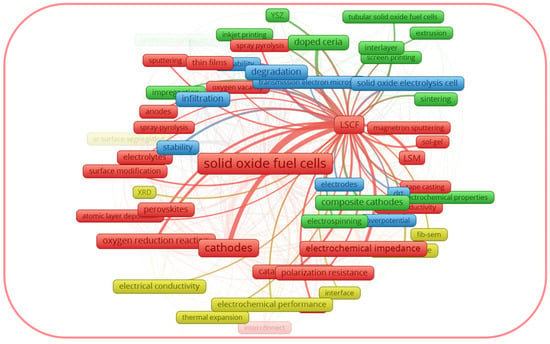

- van Eck, N.J.; Waltman, L. Software Survey: VOSviewer, a Computer Program for Bibliometric Mapping. Scientometrics 2010, 84, 523–538.

- Cherepanov, V.A.; Barkhatova, L.Y.; Voronin, V.I. Phase Equilibria in the La–Sr–Mn–O System. J. Solid State Chem. 1997, 134, 38–44.

- Cherepanov, V.A.; Filonova, E.A.; Voronin, V.I.; Berger, I.F.; Barkhatova, L.Y. Phase Equilibria in the LaCoO3–LaMnO3–SrCoO2.5–SrMnO3 System. Mater. Res. Bull. 1999, 34, 1481–1489.

- Filonova, E.A.; Demina, A.N.; Kleibaum, E.A.; Gavrilova, L.Y.; Petrov, A.N. Phase Equilibria in the System LaMnO3+δ-SrMnO3-LaFeO3-SrFeO3 − d. Inorg. Mater. 2006, 42, 443–447.

- Yusenko, M.V.; Belyaev, V.D.; Demin, A.K.; Bronin, D.I.; Sobyanin, V.A.; Snytnikov, P.V. A Study of the Electrochemical Characteristics of Single-Chamber Solid Oxide Fuel Cells Based on Platinum and Strontium-Doped Lanthanum Manganite Electrodes and Fed with a Methane–Air Mixture. Kinet. Catal. 2022, 63, 117–122.

- Mizusaki, J. Electronic Conductivity, Seebeck Coefficient, Defect and Electronic Structure of Nonstoichiometric La1 − xSrxMnO3. Solid State Ion. 2000, 132, 167–180.

- Mori, M.; Hiei, Y.; Sammes, N.M.; Tompsett, G.A. Thermal-Expansion Behaviors and Mechanisms for Ca- or Sr-Doped Lanthanum Manganite Perovskites under Oxidizing Atmospheres. J. Electrochem. Soc. 2000, 147, 1295.

- Demina, A.N.; Polovnikova, K.P.; Filonova, E.A.; Petrov, A.N.; Demin, A.K.; Pikalova, E.Y. Thermal Expansion and Electrical Conductivity of La0.7Sr0.3Mn1 − yCryO3. Inorg. Mater. 2007, 43, 430–435.

- Løken, A.; Ricote, S.; Wachowski, S. Thermal and Chemical Expansion in Proton Ceramic Electrolytes and Compatible Electrodes. Crystals 2018, 8, 365.

- Tsvetkov, D.S.; Sereda, V.V.; Malyshkin, D.A.; Ivanov, I.L.; Zuev, A.Y. Chemical Lattice Strain in Nonstoichiometric Oxides: An Overview. J. Mater. Chem. A 2022, 10, 6351–6375.

- Maiti, T.K.; Majhi, J.; Maiti, S.K.; Singh, J.; Dixit, P.; Rohilla, T.; Ghosh, S.; Bhushan, S.; Chattopadhyay, S. Zirconia- and Ceria-Based Electrolytes for Fuel Cell Applications: Critical Advancements toward Sustainable and Clean Energy Production. Environ. Sci. Pollut. Res. 2022, 29, 64489–64512.

- Sameshima, S.; Kawaminami, M.; Hirata, Y. Thermal Expansion of Rare-Earth-Doped Ceria Ceramics. J. Ceram. Soc. Jpn. 2002, 110, 597–600.

- Tsvinkinberg, V.A.; Tolkacheva, A.S.; Filonova, E.A.; Gyrdasova, O.I.; Pikalov, S.M.; Vorotnikov, V.A.; Vylkov, A.I.; Moskalenko, N.I.; Pikalova, E.Y. Structure, Thermal Expansion and Electrical Conductivity of La2 − xGdxNiO4+δ (0.0 ≤ x ≤ 0.6) Cathode Materials for SOFC Applications. J. Alloys Compd. 2021, 853, 156728.

- Lee, D.; Han, J.-H.; Chun, Y.; Song, R.-H.; Shin, D.R. Preparation and Characterization of Strontium and Magnesium Doped Lanthanum Gallates as the Electrolyte for IT-SOFC. J. Power Sources 2007, 166, 35–40.

- Tietz, F. Thermal Expansion of SOFC Materials. Ionics 1999, 5, 129–139.

- De Haart, L.G.J.; Vinke, I.C. Long-Term Operation of Planar Type SOFC Stacks. ECS Trans. 2011, 35, 187–194.

- Kim-Lohsoontorn, P.; Brett, D.J.L.; Laosiripojana, N.; Kim, Y.-M.; Bae, J.-M. Performance of Solid Oxide Electrolysis Cells Based on Composite La0.8Sr0.2MnO3 − δ—Yttria Stabilized Zirconia and Ba0.5Sr0.5Co0.8Fe0.2O3 − δ Oxygen Electrodes. Int. J. Hydrogen Energy 2010, 35, 3958–3966.

- De Souza, R.A.; Kilner, J.A.; Walker, J.F. A SIMS Study of Oxygen Tracer Diffusion and Surface Exchange in La0.8Sr0.2MnO3+δ. Mater. Lett. 2000, 43, 43–52.

- Tai, L. Structure and Electrical Properties of La1 − xSrxCo1 − yFeyO3. Part 2. The System La1 − xSrxCo0.2Fe0.8O3. Solid State Ion. 1995, 76, 273–283.

- Mineshige, A.; Izutsu, J.; Nakamura, M.; Nigaki, K.; Kobune, M.; Fujii, S.; Inaba, M.; Ogumi, Z.; Yao, T. Electrical Property, Crystal Structure and Oxygen Nonstoichiometry of La1 − xSrxCo0.2Fe0.8O3 − δ. Electrochemistry 2000, 68, 515–518.

- Teraoka, Y.; Zhang, H.M.; Okamoto, K.; Yamazoe, N. Mixed Ionic-Electronic Conductivity of La1 − xSrxCo1 − yFeyO3 − δ Perovskite-Type Oxides. Mater. Res. Bull. 1988, 23, 51–58.

- Petric, A. Evaluation of La–Sr–Co–Fe–O Perovskites for Solid Oxide Fuel Cells and Gas Separation Membranes. Solid State Ion. 2000, 135, 719–725.

- Carter, S. Oxygen Transport in Selected Nonstoichiometric Perovskite-Structure Oxides. Solid State Ion. 1992, 53–56, 597–605.

- Katsuki, M. High Temperature Properties of La0.6Sr0.4Co0.8Fe0.2O3 − δ Oxygen Nonstoichiometry and Chemical Diffusion Constant. Solid State Ion. 2003, 156, 453–461.

- Simner, S.P.; Anderson, M.D.; Engelhard, M.H.; Stevenson, J.W. Degradation Mechanisms of La–Sr–Co–Fe–O3 SOFC Cathodes. Electrochem. Solid-State Lett. 2006, 9, A478.

- Wang, H.; Barnett, S.A. Degradation Mechanisms of Porous La0.6Sr0.4Co0.2Fe0.8O3 − δ Solid Oxide Fuel Cell Cathodes. J. Electrochem. Soc. 2018, 165, F564–F570.

- Laurencin, J.; Hubert, M.; Sanchez, D.F.; Pylypko, S.; Morales, M.; Morata, A.; Morel, B.; Montinaro, D.; Lefebvre-Joud, F.; Siebert, E. Degradation Mechanism of La0.6Sr0.4Co0.2Fe0.8O3 − δ/Gd0.1Ce0.9O2 − δ Composite Electrode Operated under Solid Oxide Electrolysis and Fuel Cell Conditions. Electrochim. Acta 2017, 241, 459–476.

- Zhao, L.; Drennan, J.; Kong, C.; Amarasinghe, S.; Jiang, S.P. Insight into Surface Segregation and Chromium Deposition on La0.6Sr0.4Co0.2Fe0.8O3 − δ Cathodes of Solid Oxide Fuel Cells. J. Mater. Chem. A 2014, 2, 11114–11123.

- Lee, W.; Han, J.W.; Chen, Y.; Cai, Z.; Yildiz, B. Cation Size Mismatch and Charge Interactions Drive Dopant Segregation at the Surfaces of Manganite Perovskites. J. Am. Chem. Soc. 2013, 135, 7909–7925.

- He, S.; Jiang, S.P. Electrode/Electrolyte Interface and Interface Reactions of Solid Oxide Cells: Recent Development and Advances. Prog. Nat. Sci. 2021, 31, 341–372.

- Stochniol, G.; Syskakis, E.; Naoumidis, A. Chemical Compatibility between Strontium-Doped Lanthanum Manganite and Yttria-Stabilized Zirconia. J. Am. Ceram. Soc. 1995, 78, 929–932.

- Yokokawa, H.; Tu, H.; Iwanschitz, B.; Mai, A. Fundamental Mechanisms Limiting Solid Oxide Fuel Cell Durability. J. Power Sources 2008, 182, 400–412.

- Kindermann, L. Chemical Compatibility of the LaFeO3 Base Perovskites (La0.6Sr0.4)ZFe0.8M0.2O3 − δ (z = 1, 0.9; M = Cr, Mn, Co, Ni) with Yttria Stabilized Zirconia. Solid State Ion. 1996, 89, 215–220.

- Hubert, M.; Laurencin, J.; Cloetens, P.; Mougin, J.; Ferreira Sanchez, D.; Pylypko, S.; Morales, M.; Morata, A.; Morel, B.; Montinaro, D.; et al. Solid Oxide Cell Degradation Operated in Fuel Cell and Electrolysis Modes: A Comparative Study on Ni Agglomeration and LSCF Destabilization. ECS Trans. 2017, 78, 3167–3177.

- Kostogloudis, G. Chemical Reactivity of Perovskite Oxide SOFC Cathodes and Yttria Stabilized Zirconia. Solid State Ion. 2000, 135, 529–535.

- Fan, B.; Yan, J.; Yan, X. The Ionic Conductivity, Thermal Expansion Behavior, and Chemical Compatibility of La0.54Sr0.44Co0.2Fe0.8O3 − δ as SOFC Cathode Material. Solid State Sci. 2011, 13, 1835–1839.

- Darvish, S.; Asadikiya, M.; Hu, B.; Singh, P.; Zhong, Y. Thermodynamic Prediction of the Effect of CO2 to the Stability of (La0.8Sr0.2)0.98MnO3±δ System. Int. J. Hydrogen Energy 2016, 41, 10239–10248.

- Hu, B.; Mahapatra, M.K.; Keane, M.; Zhang, H.; Singh, P. Effect of CO2 on the Stability of Strontium Doped Lanthanum Manganite Cathode. J. Power Sources 2014, 268, 404–413.

- Zhao, Z.; Liu, L.; Zhang, X.; Wu, W.; Tu, B.; Ou, D.; Cheng, M. A Comparison on Effects of CO2 on La0.8Sr0.2MnO3+δ and La0.6Sr0.4CoO3 − δ Cathodes. J. Power Sources 2013, 222, 542–553.

- Darvish, S.; Gopalan, S.; Zhong, Y. Thermodynamic Stability Maps for the La0.6Sr0.4Co0.2Fe0.8O3±δ–CO2–O2 System for Application in Solid Oxide Fuel Cells. J. Power Sources 2016, 336, 351–359.

- Zhao, Z.; Liu, L.; Zhang, X.; Wu, W.; Tu, B.; Cui, D.; Ou, D.; Cheng, M. High- and Low- Temperature Behaviors of La0.6Sr0.4Co0.2Fe0.8O3 − δ Cathode Operating under CO2/H2O-Containing Atmosphere. Int. J. Hydrogen Energy 2013, 38, 15361–15370.

- Lai, S.Y.; Ding, D.; Liu, M.; Liu, M.; Alamgir, F.M. Operando and in Situ X-ray Spectroscopies of Degradation in La0.6Sr0.4Co0.2Fe0.8O3 − δ Thin Film Cathodes in Fuel Cells. ChemSusChem 2014, 7, 3078–3087.

- Liu, Y.L.; Hagen, A.; Barfod, R.; Chen, M.; Wang, H.J.; Poulsen, F.W.; Hendriksen, P.V. Microstructural Studies on Degradation of Interface between LSM–YSZ Cathode and YSZ Electrolyte in SOFCs. Solid State Ion. 2009, 180, 1298–1304.

- Hu, B.; Mahapatra, M.K.; Singh, P. Performance Regeneration in Lanthanum Strontium Manganite Cathode during Exposure to H2O and CO2 Containing Ambient Air Atmospheres. J. Ceram. Soc. Jpn. 2015, 123, 199–204.

- Xia, Z.; Zhao, D.; Zhou, Y.; Deng, Z.; Kupecki, J.; Fu, X.; Li, X. Control-Oriented Performance Prediction of Solid Oxide Electrolysis Cell and Durability Improvement through Retard Oxygen Electrode Delamination with Reverse Operation. Energy Convers. Manag. 2023, 277, 116596.

- Wachsman, E.D.; Huang, Y.-L.; Pellegrinelli, C.; Taillon, J.A.; Salamanca-Riba, L.G. Towards a Fundamental Understanding of the Cathode Degradation Mechanisms. ECS Trans. 2014, 61, 47–56.

- Wei, B.; Chen, K.; Zhao, L.; Lü, Z.; Jiang, S.P. Chromium Deposition and Poisoning at La0.6Sr0.4Co0.2Fe0.8O3 − δ Oxygen Electrodes of Solid Oxide Electrolysis Cells. Phys. Chem. Chem. Phys. 2015, 17, 1601–1609.

- Subotić, V.; Futamura, S.; Harrington, G.F.; Matsuda, J.; Natsukoshi, K.; Sasaki, K. Towards Understanding of Oxygen Electrode Processes during Solid Oxide Electrolysis Operation to Improve Simultaneous Fuel and Oxygen Generation. J. Power Sources 2021, 492, 229600.

- He, S.; Saunders, M.; Chen, K.; Gao, H.; Suvorova, A.; Rickard, W.D.A.; Quadir, Z.; Cui, C.Q.; Jiang, S.P. A FIB-STEM Study of Strontium Segregation and Interface Formation of Directly Assembled La0.6Sr0.4Co0.2Fe0.8O3 − δ Cathode on Y2O3-ZrO2 Electrolyte of Solid Oxide Fuel Cells. J. Electrochem. Soc. 2018, 165, F417–F429.

- Pellegrinelli, C.; Huang, Y.-L.; Wachsman, E.D. Effect of H2O and CO2 on LSCF−GDC Composite Cathodes. ECS Trans. 2019, 91, 665–680.

- Xiong, C.; Qiu, P.; Zhang, W.; Pu, J. Influence of Practical Operating Temperature on the Cr Poisoning for LSCF-GDC Cathode. Ceram. Int. 2022, 48, 33999–34004.

- Minh, N.Q. Development of Reversible Solid Oxide Fuel Cells (RSOFCs)and Stacks. ECS Trans. 2011, 35, 2897–2904.

- Monaco, F.; Ferreira-Sanchez, D.; Hubert, M.; Morel, B.; Montinaro, D.; Grolimund, D.; Laurencin, J. Oxygen Electrode Degradation in Solid Oxide Cells Operating in Electrolysis and Fuel Cell Modes: LSCF Destabilization and Interdiffusion at the Electrode/Electrolyte Interface. Int. J. Hydrogen Energy 2021, 46, 31533–31549.

- Lu, K.; Shen, F. Long Term Behaviors of La0.8Sr0.2MnO3 and La0.6Sr0.4Co0.2Fe0.8O3 as Cathodes for Solid Oxide Fuel Cells. Int. J. Hydrogen Energy 2014, 39, 7963–7971.

- Türk, H.; Götsch, T.; Schmidt, F.; Hammud, A.; Ivanov, D.; (Bert) de Haart, L.G.J.; Vinke, I.C.; Eichel, R.; Schlögl, R.; Reuter, K.; et al. Sr Surface Enrichment in Solid Oxide Cells—Approaching the Limits of EDX Analysis by Multivariate Statistical Analysis and Simulations. ChemCatChem 2022, 14, e202200300.

- Li, D.; Zhang, X.; Liang, C.; Jin, Y.; Fu, M.; Yuan, J.; Xiong, Y. Study on Durability of Novel Core-Shell-Structured La0.8Sr0.2Co0.2Fe0.8O3 − δ@Gd0.2Ce0.8O1.9 Composite Materials for Solid Oxide Fuel Cell Cathodes. Int. J. Hydrogen Energy 2021, 46, 28221–28231.

- Türk, H.; Schmidt, F.; Götsch, T.; Girgsdies, F.; Hammud, A.; Ivanov, D.; Vinke, I.C.; (Bert) de Haart, L.G.J.; Eichel, R.; Reuter, K.; et al. Complexions at the Electrolyte/Electrode Interface in Solid Oxide Cells. Adv. Mater. Interfaces 2021, 8, 2100967.

- Cheng, K.; Xu, H.; Zhang, L.; Du, Y.; Zhou, J.; Tang, S.; Chen, M. Numerical Simulation of the SrZrO3 Formation in Solid Oxide Fuel Cells. J. Electron. Mater. 2019, 48, 5510–5515.

- Jacobs, R.; Liu, J.; Na, B.T.; Guan, B.; Yang, T.; Lee, S.; Hackett, G.; Kalapos, T.; Abernathy, H.; Morgan, D. Unconventional Highly Active and Stable Oxygen Reduction Catalysts Informed by Computational Design Strategies. Adv. Energy Mater. 2022, 12, 2201203.

- Han, H.; Hu, X.; Zhang, B.; Zhang, S.; Zhang, Y.; Xia, C. Method to Determine the Oxygen Reduction Reaction Kinetics via Porous Dual-Phase Composites Based on Electrical Conductivity Relaxation. J. Mater. Chem. A 2023, 11, 2460–2471.

- Yan, Z.; He, A.; Hara, S.; Shikazono, N. Design and Optimization of Functionally Graded Electrodes for Solid Oxide Fuel Cells (SOFCs) by Mesoscale Modeling. Int. J. Hydrogen Energy 2022, 47, 16610–16625.

- Padinjarethil, A.K.; Bianchi, F.R.; Bosio, B.; Hagen, A. Electrochemical Characterization and Modelling of Anode and Electrolyte Supported Solid Oxide Fuel Cells. Front. Energy Res. 2021, 9, 668964.

- Bliem, R.; Kim, D.; Wang, J.; Crumlin, E.J.; Yildiz, B. Hf Deposition Stabilizes the Surface Chemistry of Perovskite Manganite Oxide. J. Phys. Chem. C 2021, 125, 3346–3354.

- Zeng, D.; Xu, K.; Zhu, F.; Chen, Y. Enhancing the Oxygen Reduction Reaction Activity and Durability of a Solid Oxide Fuel Cell Cathode by Surface Modification of a Hybrid Coating. Int. J. Hydrogen Energy 2023, 48, 23992–24001.

- Li, J.; Zhou, X.; Wu, C.; Zhao, L.; Dong, B.; Wang, S.; Chi, B. Self-Stabilized Hybrid Cathode for Solid Oxide Fuel Cell: A-Site Deficient Perovskite Coating as Solid Solution for Strontium Diffusion. Chem. Eng. J. 2022, 438, 135446.

- Zhang, X.; Jin, Y.; Jiang, Y.; Zong, X.; Li, Y.; Xiong, Y. Enhancing Chromium Poisoning Tolerance of La0.8Sr0.2Co0.2Fe0.8O3 − δ Cathode by Ce0.8Gd0.2O1.9 − δ Coating. J. Power Sources 2022, 547, 231996.

- Pei, K.; Zhou, Y.; Ding, Y.; Xu, K.; Zhang, H.; Yuan, W.; Sasaki, K.; Choi, Y.; Liu, M.; Chen, Y. An Improved Oxygen Reduction Reaction Activity and CO2-Tolerance of La0.6Sr0.4Co0.2Fe0.8O3 − δ Achieved by a Surface Modification with Barium Cobaltite Coatings. J. Power Sources 2021, 514, 230573.

- Pei, K.; Zhou, Y.; Xu, K.; He, Z.; Chen, Y.; Zhang, W.; Yoo, S.; Zhao, B.; Yuan, W.; Liu, M.; et al. Enhanced Cr-Tolerance of an SOFC Cathode by an Efficient Electro-Catalyst Coating. Nano Energy 2020, 72, 104704.

- Ishfaq, H.A.; Khan, M.Z.; Shirke, Y.M.; Qamar, S.; Hussain, A.; Mehran, M.T.; Song, R.-H.; Saleem, M. A Heuristic Approach to Boost the Performance and Cr Poisoning Tolerance of Solid Oxide Fuel Cell Cathode by Robust Multi-Doped Ceria Coating. Appl. Catal. B Environ. 2023, 323, 122178.

- Chen, Y.; Hinerman, A.; Liang, L.; Gerdes, K.; Navia, S.P.; Prucz, J.; Song, X. Conformal Coating of Cobalt Oxide on Solid Oxide Fuel Cell Cathode and Resultant Continuously Increased Oxygen Reduction Reaction Kinetics upon Operation. J. Power Sources 2018, 405, 45–50.

- Niu, Y.; Zhou, Y.; Zhang, W.; Zhang, Y.; Evans, C.; Luo, Z.; Kane, N.; Ding, Y.; Chen, Y.; Guo, X.; et al. Highly Active and Durable Air Electrodes for Reversible Protonic Ceramic Electrochemical Cells Enabled by an Efficient Bifunctional Catalyst. Adv. Energy Mater. 2022, 12, 2103783.

- Zhang, X.; Jin, Y.; Li, D.; Zong, X.; Xiong, Y. Effects of Gd0.8Ce0.2O1.9 − δ Coating with Different Thickness on Electrochemical Performance and Long-Term Stability of La0.8Sr0.2Co0.2Fe0.8O3 − δ Cathode in SOFCs. Int. J. Hydrogen Energy 2022, 47, 4100–4108.

- Chen, Y.; Paredes-Navia, S.A.; Romo-De-La-Cruz, C.-O.; Liang, L.; Fernandes, A.; Hinerman, A.; Prucz, J.; Williams, M.; Song, X. Coating Internal Surface of Porous Electrode for Decreasing the Ohmic Resistance and Shifting Oxygen Reduction Reaction Pathways in Solid Oxide Fuel Cells. J. Power Sources 2021, 499, 229854.

- Niu, Y.; Zhou, Y.; Lv, W.; Chen, Y.; Zhang, Y.; Zhang, W.; Luo, Z.; Kane, N.; Ding, Y.; Soule, L.; et al. Enhancing Oxygen Reduction Activity and Cr Tolerance of Solid Oxide Fuel Cell Cathodes by a Multiphase Catalyst Coating. Adv. Funct. Mater. 2021, 31, 2100034.

- Yokokawa, H.; Horita, T. Cathodes. In High Temperature and Solid Oxide Fuel Cells; Elsevier: Amsterdam, The Netherlands, 2003; pp. 119–147. ISBN 978-1-85617-387-2.

- Filonova, E.A.; Gilev, A.R.; Skutina, L.S.; Vylkov, A.I.; Kuznetsov, D.K.; Shur, V.Y. Double Sr2Ni1 − xMgxMoO6 Perovskites (x = 0, 0.25) as Perspective Anode Materials for LaGaO3-Based Solid Oxide Fuel Cells. Solid State Ion. 2018, 314, 112–118.

- Wu, Y.; Sang, J.; Liu, Z.; Fan, H.; Cao, B.; Wang, Q.; Yang, J.; Guan, W.; Liu, X.; Wang, J. Enhancing the Performance and Stability of Solid Oxide Fuel Cells by Adopting Samarium-Doped Ceria Buffer Layer. Ceram. Int. 2023, 49, 20290–20297.

- Yang, Q.; Wang, Y.; Tian, D.; Wu, H.; Ding, Y.; Lu, X.; Chen, Y.; Lin, B. Enhancing Performance and Stability of Symmetrical Solid Oxide Fuel Cells via Quasi-Symmetrical Ceria-Based Buffer Layers. Ceram. Int. 2022, 48, 27509–27515.

- Zhang, Y.; Niu, B.; Hao, X.; Wang, Y.; Liu, J.; Jiang, P.; He, T. Layered Oxygen-Deficient Double Perovskite GdBaFe2O5+δ as Electrode Material for Symmetrical Solid-Oxide Fuel Cells. Electrochim. Acta 2021, 370, 137807.

- Niemczyk, A.; Zheng, K.; Cichy, K.; Berent, K.; Küster, K.; Starke, U.; Poudel, B.; Dabrowski, B.; Świerczek, K. High Cu Content LaNi1-xCuxO3 − δ Perovskites as Candidate Air Electrode Materials for Reversible Solid Oxide Cells. Int. J. Hydrogen Energy 2020, 45, 29449–29464.

- Yang, X.; Li, R.; Yang, Y.; Wen, G.; Tian, D.; Lu, X.; Ding, Y.; Chen, Y.; Lin, B. Improving Stability and Electrochemical Performance of Ba0.5Sr0.5Co0.2Fe0.8O3 − δ Electrode for Symmetrical Solid Oxide Fuel Cells by Mo Doping. J. Alloys Compd. 2020, 831, 154711.

- Huang, K.; Wan, J.; Goodenough, J.B. Oxide-Ion Conducting Ceramics for Solid Oxide Fuel Cells. J. Mater. Sci. 2001, 36, 1093–1098.

- Yun, J.W.; Yoon, S.P.; Park, S.; Han, J.; Nam, S.W.; Lim, T.-H.; Kim, J.-S. Modifying the Cathodes of Intermediate-Temperature Solid Oxide Fuel Cells with a Ce0.8Sm0.2O2 Sol–Gel Coating. Int. J. Hydrogen Energy 2009, 34, 9213–9219.

- Hanifi, A.R.; Paulson, S.; Torabi, A.; Shinbine, A.; Tucker, M.C.; Birss, V.; Etsell, T.H.; Sarkar, P. Slip-Cast and Hot-Solution Infiltrated Porous Yttria Stabilized Zirconia (YSZ) Supported Tubular Fuel Cells. J. Power Sources 2014, 266, 121–131.

- Hwang, S.; Lee, J.; Kang, G.; Choi, M.; Kim, S.J.; Lee, W.; Byun, D. A Hydrogel-Assisted GDC Chemical Diffusion Barrier for Durable Solid Oxide Fuel Cells. J. Mater. Chem. A 2021, 9, 11683–11690.

- Liu, Y.; Tian, Y.; Wang, Y.; Li, Y.; Pu, J.; Ciucci, F.; Chi, B. Nano Film Pr2Ni0.8Cu0.2O4+δ Decorated La0.6Sr0.4Co0.2Fe0.8O3 − δ Oxygen Electrode for Highly Efficient and Stable Reversible Solid Oxide Cells. Electrochim. Acta 2022, 430, 141032.

- Wang, Y.; Xu, N.; Dogdibegovic, E.; Su, T.; Brocato, A.D.; Zhou, X.-D. Role of Mixed Conducting Pr0.1Gd0.1Ce0.8O1.9 − δ Barrier Layer on the Promotion of SOFC Performance. Int. J. Hydrogen Energy 2022, 47, 1917–1924.

- Park, J.H.; Jung, C.H.; Kim, K.J.; Kim, D.; Shin, H.R.; Hong, J.-E.; Lee, K.T. Enhancing Bifunctional Electrocatalytic Activities of Oxygen Electrodes via Incorporating Highly Conductive Sm3+ and Nd3+ Double-Doped Ceria for Reversible Solid Oxide Cells. ACS Appl. Mater. Interfaces 2021, 13, 2496–2506.

- Park, J.H.; Han, S.M.; Kim, B.-K.; Lee, J.-H.; Yoon, K.J.; Kim, H.; Ji, H.-I.; Son, J.-W. Sintered Powder-Base Cathode over Vacuum-Deposited Thin-Film Electrolyte of Low-Temperature Solid Oxide Fuel Cell: Performance and Stability. Electrochim. Acta 2019, 296, 1055–1063.

- Choi, H.-J.; Na, Y.-H.; Kwak, M.; Kim, T.W.; Seo, D.-W.; Woo, S.-K.; Kim, S.-D. Development of Solid Oxide Cells by Co-Sintering of GDC Diffusion Barriers with LSCF Air Electrode. Ceram. Int. 2017, 43, 13653–13660.

- Yoo, Y.-S.; Jeon, S.-Y.; Park, M.-A.; Lee, J.; Lee, Y. Electrochemical Performance of Solid Oxide Electrolysis Cells with LSCF6428–SDC/SDC Electrode for H2O/CO2 High Temperature Co-Electrolysis. ECS Trans. 2017, 78, 3123–3128.

- Zhang, G.; Zheng, G.; Huang, Z.; Bao, X.; Shi, C.; Yang, X.; Zhou, J.; Chen, T.; Wang, S. The Effect of Fe2O3 Sintering Aid on Gd0.1Ce0.9O1.95 Diffusion Barrier Layer and Solid Oxide Fuel Cell Performance. Int. J. Hydrogen Energy 2023, 48, 21908–21919.

- Budiman, R.A.; Yamaguchi, T.; Ishiyama, T.; Develos-Bagarinao, K.; Yamaji, K.; Kishimoto, H. Interlayer Modification for High-Performance and Stable Solid Oxide Electrolysis Cell. Mater. Lett. 2022, 309, 131419.

- Wu, P.; Tian, Y.; Lü, Z.; Zhang, X.; Ding, L. Electrochemical Performance of La0.65Sr0.35MnO3 Oxygen Electrode with Alternately Infiltrated Sm0.5Sr0.5CoO3 − δ and Sm0.2Ce0.8O1.9 Nanoparticles for Reversible Solid Oxide Cells. Int. J. Hydrogen Energy 2022, 47, 747–760.

- Yaroslavtsev, I.Y.; Kuzin, B.L.; Bronin, D.I.; Bogdanovich, N.M. Polarization Characteristics of Composite Electrodes in Electrochemical Cells with Solid Electrolytes Based on CeO2 and LaGaO3. Russ. J. Electrochem. 2005, 41, 527–531.

- Mosiałek, M.; Zimowska, M.; Kharytonau, D.; Komenda, A.; Górski, M.; Krzan, M. Improvement of La0.8Sr0.2MnO3 − δ Cathode Material for Solid Oxide Fuel Cells by Addition of YFe0.5Co0.5O3. Materials 2022, 15, 642.

- Bogdanovich, N.M.; Bronin, D.I.; Vdovin, G.K.; Yaroslavtsev, I.Y.; Kuzin, B.L. Effect of Bi0.75Y0.25O1.5 Electrolyte Additive in Collector Layer to Properties of Bilayer Composite Cathodes of Solid Oxide Fuel Cells Based on La(Sr)MnO3 and La(Sr)Fe(Co)O3 Compounds. Russ. J. Electrochem. 2009, 45, 456–464.

- Perry Murray, E. (La,Sr)MnO3–(Ce,Gd)O2 − x Composite Cathodes for Solid Oxide Fuel Cells. Solid State Ion. 2001, 143, 265–273.

- Chen, G.; Gao, Y.; Luo, Y.; Guo, R. Effect of A Site Deficiency of LSM Cathode on the Electrochemical Performance of SOFCs with Stabilized Zirconia Electrolyte. Ceram. Int. 2017, 43, 1304–1309.

- Sun, K.; Yu, Z.; Ni, Q.; Li, Y.; Xu, D.; Gu, Y.; Zheng, Y.; Chen, H.; Ge, L.; Guo, L. Highly Durable Sr-Doped LaMnO3-Based Cathode Modified with Pr6O11 Nano-Catalyst for Protonic Ceramic Fuel Cells Based on Y-Doped BaZrO3 Electrolyte. J. Eur. Ceram. Soc. 2022, 42, 4266–4274.

- Cao, X.G.; Jiang, S.P. Identification of Oxygen Reduction Processes at (La,Sr)MnO3 Electrode/La9.5Si6O26.25 Apatite Electrolyte Interface of Solid Oxide Fuel Cells. Int. J. Hydrogen Energy 2013, 38, 2421–2431.

- Strandbakke, R.; Dyrlie, O.; Hage, F.S.; Norby, T. Reaction Kinetics of Protons and Oxide Ions in LSM/Lanthanum Tungstate Cathodes with Pt Nanoparticle Activation. J. Electrochem. Soc. 2016, 163, F507–F515.

- Shen, F.; Wang, R.; Tucker, M.C. Long Term Durability Test and Post Mortem for Metal-Supported Solid Oxide Electrolysis Cells. J. Power Sources 2020, 474, 228618.

- Mater, A.; Othmani, A.; Boukhachem, A.; Madani, A. Cathode Performance Study of La0.6Sr0.4Co0.8Fe0.2O3 − δ with Various Electrolyte-Doped Ceria Ce0.8Sm0.17Ln0.03O1.9 for IT-Solid Oxide Fuel Cell. J. Electron. Mater. 2020, 49, 4123–4133.

- Yang, C.; Cheng, J.G.; He, H.G.; Gao, J.F. Ni/SDC Materials for Solid Oxide Fuel Cell Anode Applications by the Glycine-Nitrate Method. Key Eng. Mater. 2010, 434–435, 731–734.

- Ahuja, A.; Gautam, M.; Sinha, A.; Sharma, J.; Patro, P.K.; Venkatasubramanian, A. Effect of Processing Route on the Properties of LSCF-Based Composite Cathode for IT-SOFC. Bull. Mater. Sci. 2020, 43, 129.

- He, A.; Onishi, J.; Shikazono, N. Optimization of Electrode-Electrolyte Interface Structure for Solid Oxide Fuel Cell Cathode. J. Power Sources 2020, 449, 227565.

- Loureiro, F.J.A.; Macedo, D.A.; Nascimento, R.M.; Cesário, M.R.; Grilo, J.P.F.; Yaremchenko, A.A.; Fagg, D.P. Cathodic Polarisation of Composite LSCF-SDC IT-SOFC Electrode Synthesised by One-Step Microwave Self-Assisted Combustion. J. Eur. Ceram. Soc. 2019, 39, 1846–1853.

- Wei, F.; Wang, L.; Luo, L.; Cheng, L.; Xu, X. One-Pot Impregnation to Construct Nanoparticles Loaded Scaffold Cathode with Enhanced Oxygen Reduction Performance for LT-SOFCs. J. Alloys Compd. 2023, 941, 168981.

- Sun, Y.; He, S.; Saunders, M.; Chen, K.; Shao, Z.; Jiang, S.P. A Comparative Study of Surface Segregation and Interface of La0.6Sr0.4Co0.2Fe0.8O3 − δ Electrode on GDC and YSZ Electrolytes of Solid Oxide Fuel Cells. Int. J. Hydrogen Energy 2021, 46, 2606–2616.

- Abarzua, G.; Udayabhaskar, R.; Mangalaraja, R.V.; Durango-Petro, J.; Usuba, J.; Flies, H. A Feasible Strategy for Tailoring Stable Spray-Coated Electrolyte Layer in Micro-Tubular Solid Oxide Fuel Cells. Int. J. Appl. Ceram. Technol. 2022, 19, 1389–1396.

- Samreen, A.; Galvez-Sanchez, M.; Steinberger-Wilckens, R.; Arifin, N.A.; Saher, S.; Ali, S.; Qamar, A. Electrochemical Performance of Novel NGCO−LSCF Composite Cathode for Intermediate Temperature Solid Oxide Fuel Cells. Int. J. Hydrogen Energy 2020, 45, 21714–21721.

- Hong, T.; Lee, S.; Ohodnicki, P.; Brinkman, K. A Highly Scalable Spray Coating Technique for Electrode Infiltration: Barium Carbonate Infiltrated La0.6Sr0.4Co0.2Fe0.8O3 − δ Perovskite Structured Electrocatalyst with Demonstrated Long Term Durability. Int. J. Hydrogen Energy 2017, 42, 24978–24988.

- Tsuji, Y.; Amezawa, K.; Nakao, T.; Ina, T.; Kawada, T.; Yamamoto, K.; Uchimoto, Y.; Orikasa, Y. Investigation of Cathodic Reaction Mechanism in Solid Oxide Fuel Cells by Operando X-ray Absorption Spectroscopy. Electrochemistry 2020, 88, 560–565.

- Chen, X.; Sun, X.; Zhou, J.; Zhou, D.; Zhu, X.; Meng, J. Effects of CoO and Bi2O3 Single/Dual Sintering Aids Doping on Structure and Properties of Ce0.8Nd0.2O1.9. Ceram. Int. 2020, 46, 22727–22732.

- Wang, Y.-P.; Liu, S.-H.; Zhang, H.-Y.; Li, C.-X.; Zhang, S.-L.; Yang, G.-J.; Li, C.-J. Structured La0.6Sr0.4Co0.2Fe0.8O3 − δ Cathode with Large-Scale Vertical Cracks by Atmospheric Laminar Plasma Spraying for IT-SOFCs. J. Alloys Compd. 2020, 825, 153865.

- Wang, J.; Yang, Z.; Yang, K.; Peng, S. Kinetics of Oxygen Reaction in Porous La0.6Sr0.4Co0.2Fe0.8O3 − δ-Ce0.8Gd0.2O1.9 Composite Electrodes for Solid Oxide Cells. Int. J. Hydrogen Energy 2021, 46, 25608–25619.

- Khaerudini, D.S.; Guan, G.; Zhang, P.; Hao, X.; Wang, Z.; Xue, C.; Kasai, Y.; Abudula, A. Performance Assessment of Bi0.3Sr0.7Co0.3Fe0.7O3 − δ–LSCF Composite as Cathode for Intermediate-Temperature Solid Oxide Fuel Cells with La0.8Sr0.2Ga0.8Mg0.2O3 − δ Electrolyte. J. Power Sources 2015, 298, 269–279.

- Zhang, S.-L.; Shang, Y.-B.; Li, C.-X.; Li, C.-J. Vacuum Cold Sprayed Nanostructured La0.6Sr0.4Co0.2Fe0.8O3 − δ as a High-Performance Cathode for Porous Metal-Supported Solid Oxide Fuel Cells Operating below 600 °C. Mater. Today Energy 2021, 21, 100815.

- Wang, S.-F.; Lu, H.-C.; Hsu, Y.-F.; Jasinski, P. High-Performance Anode-Supported Solid Oxide Fuel Cells with Co-Fired Sm0.2Ce0.8O2 − δ/La0.8Sr0.2Ga0.8Mg0.2O3 − δ/Sm0.2Ce0.8O2 − δ Sandwiched Electrolyte. Int. J. Hydrogen Energy 2022, 47, 5429–5438.

- Lei, L.; Tao, Z.; Hong, T.; Wang, X.; Chen, F. A Highly Active Hybrid Catalyst Modified (La0.60Sr0.40)0.95Co0.20Fe0.80O3 − δ Cathode for Proton Conducting Solid Oxide Fuel Cells. J. Power Sources 2018, 389, 1–7.

- Di Bartolomeo, E.; Zunic, M.; Chevallier, L.; D’Epifanio, A.; Licoccia, S.; Traversa, E. Fabrication of Proton Conducting Solid Oxide Fuel Cells by Using Electrophoretic Deposition. ECS Trans. 2009, 25, 577–584.

- Watanabe, K.; Yamaguchi, Y.; Nomura, K.; Sumi, H.; Mori, M.; Mizutani, Y.; Shimada, H. Effect of Cobalt Content on Electrochemical Performance for La0.6Sr0.4CoxFe1 − xO3 − δ and BaZr0.8Yb0.2O3 − δ Composite Cathodes in Protonic Ceramic Fuel Cells. Ceram. Int. 2023, 49, 21085–21090.

- Vafaeenezhad, S.; Sandhu, N.K.; Hanifi, A.R.; Etsell, T.H.; Sarkar, P. Development of Proton Conducting Fuel Cells Using Nickel Metal Support. J. Power Sources 2019, 435, 226763.

- Zhang, Q.; Hou, Y.; Chen, L.; Wang, L.; Chou, K. Enhancement of Electrochemical Performance for Proton Conductive Solid Oxide Fuel Cell by 30%GDC−LSCF Cathode. Ceram. Int. 2022, 48, 17816–17827.

- Chen, X.; Zhang, H.; Li, Y.; Xing, J.; Zhang, Z.; Ding, X.; Zhang, B.; Zhou, J.; Wang, S. Fabrication and Performance of Anode-Supported Proton Conducting Solid Oxide Fuel Cells Based on BaZr0.1Ce0.7Y0.1Yb0.1O3 − δ Electrolyte by Multi-Layer Aqueous-Based Co-Tape Casting. J. Power Sources 2021, 506, 229922.

- Shimada, H.; Yamaguchi, Y.; Sumi, H.; Mizutani, Y. Performance Comparison of Perovskite Composite Cathodes with BaZr0.1Ce0.7Y0.1Yb0.1O3 − δ in Anode-Supported Protonic Ceramic Fuel Cells. J. Electrochem. Soc. 2020, 167, 124506.

- Gao, J.; Meng, Y.; Lee, S.; Tong, J.; Brinkman, K.S. Effect of Infiltration of Barium Carbonate Nanoparticles on the Electrochemical Performance of La0.6Sr0.4Co0.2Fe0.8O3 − δ Cathodes for Protonic Ceramic Fuel Cells. JOM 2019, 71, 90–95.

- Lai, Y.-W.; Lee, K.-R.; Yang, S.-Y.; Tseng, C.-J.; Jang, S.-C.; Tsao, I.-Y.; Chen, S.; Lee, S.-W. Production of La0.6Sr0.4Co0.2Fe0.8O3 − δ Cathode with Graded Porosity for Improving Proton-Conducting Solid Oxide Fuel Cells. Ceram. Int. 2019, 45, 22479–22485.

- Fan, Y.; Xi, X.; Li, J.; Wang, Q.; Xiang, K.; Medvedev, D.; Luo, J.-L.; Fu, X.-Z. Barium-Doped Sr2Fe1.5Mo0.5O6 − δ Perovskite Anode Materials for Protonic Ceramic Fuel Cells for Ethane Conversion. J. Am. Ceram. Soc. 2022, 105, 3613–3624.

- Gao, Y.; Yang, Y.; Lin, X.; Fu, M.; Hu, W.; Tong, H.; Tao, Z. Investigation and Study of Three Different Composite Cathodes for Proton-Conducting Solid Oxide Fuel Cells. Sep. Purif. Technol. 2022, 300, 121890.

- Lee, H.; Lee, S.; Lee, T.; Park, S.; Shin, D. Long Term Stability of Porosity Gradient Composite Cathode Controlled by Electro-Static Slurry Spray Deposition. Int. J. Hydrogen Energy 2017, 42, 3748–3752.

- Hanif, M.B.; Rauf, S.; Abadeen, Z.U.; Khan, K.; Tayyab, Z.; Qayyum, S.; Mosiałek, M.; Shao, Z.; Li, C.-X.; Motola, M. Proton-Conducting Solid Oxide Electrolysis Cells: Relationship of Composition-Structure-Property, Their Challenges, and Prospects. Matter 2023, 6, 1782–1830.

- Zayas-Rey, M.J.; Dos Santos-Gómez, L.; Porras-Vázquez, J.M.; Losilla, E.R.; Marrero-López, D. Evaluation of Lanthanum Tungstates as Electrolytes for Proton Conductors Solid Oxide Fuel Cells. J. Power Sources 2015, 294, 483–493.

- Marrero-López, D.; Martín-Sedeño, M.C.; Peña-Martínez, J.; Ruiz-Morales, J.C.; Núñez, P.; Aranda, M.A.G.; Ramos-Barrado, J.R. Evaluation of Apatite Silicates as Solid Oxide Fuel Cell Electrolytes. J. Power Sources 2010, 195, 2496–2506.

- Nesaraj, A.S.; Kumar, M.; Arul Raj, I.; Radhakrishna, I.; Pattabiraman, R. Investigations on Chemical Interactions between Alternate Cathodes and Lanthanum Gallate Electrolyte for Intermediate Temperature Solid Oxide Fuel Cell (ITSOFC). J. Iran. Chem. Soc. 2007, 4, 89–106.

- Giannici, F.; Chiara, A.; Canu, G.; Longo, A.; Martorana, A. Interface Solid-State Reactions in La0.8Sr0.2MnO3/Ce0.8Sm0.2O2 and La0.8Sr0.2MnO3/BaCe0.9Y0.1O3 Disclosed by X-ray Microspectroscopy. ACS Appl. Energy Mater. 2019, 2, 3204–3210.

- Lyagaeva, J.; Medvedev, D.; Pikalova, E.; Plaksin, S.; Brouzgou, A.; Demin, A.; Tsiakaras, P. A Detailed Analysis of Thermal and Chemical Compatibility of Cathode Materials Suitable for BaCe0.8Y0.2O3 − δ and BaZr0.8Y0.2O3 − δ Proton Electrolytes for Solid Oxide Fuel Cell Application. Int. J. Hydrogen Energy 2017, 42, 1715–1723.

- Pikalova, E.; Bogdanovich, N.; Kolchugin, A.; Brouzgou, A.; Bronin, D.; Plaksin, S.V.; Khasanov, A.; Tsiakaras, P. Effect of Nature of the Ceramic Component of the Composite Electrodes Based on La1.7Ca(Sr)0.3NiO4+δ on Their Electrochemical Performance. ECS Trans. 2015, 68, 809–815.

- Antonova, E.P.; Kolchugin, A.A.; Pikalova, E.Y.; Medvedev, D.A.; Bogdanovich, N.M. Development of Electrochemically Active Electrodes for BaCe0.89Gd0.1Cu0.01O3 − δ Proton Conducting Electrolyte. Solid State Ion. 2017, 306, 55–61.

- Pikalova, E.Y.; Kolchugin, A.A. The Influence of the Substituting Element (M = Ca, Sr, Ba) in La1.7M0.3NiO4+δ on the Electrochemical Performance of the Composite Electrodes. Eur. Chem. Technol. J. 2016, 18, 3.

- Pikalova, E.; Kolchugin, A.; Koroleva, M.; Vdovin, G.; Farlenkov, A.; Medvedev, D. Functionality of an Oxygen Ca3Co4O9+δ Electrode for Reversible Solid Oxide Electrochemical Cells Based on Proton-Conducting Electrolytes. J. Power Sources 2019, 438, 226996.

- Filonova, E.A.; Tokareva, E.S.; Pikalova, N.S.; Vylkov, A.I.; Bogdanovich, N.M.; Pikalova, E.Y. Assessment of Prospective Cathodes Based on (1 − x)Ca3Co4O9+δ–xBaCe0.5Zr0.3Y0.1Yb0.1O3 − δ Composites for Protonic Ceramic Electrochemical Cells. J. Solid State Electrochem. 2020, 24, 1509–1521.