Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Vehicle models are grouped into numerous types based on the structural characteristics and working conditions, including wheeled tractors, tracked tractors, rice transplanters, high clearance sprays, agricultural robots, agricultural tractor–trailers, etc.

- autonomous navigation

- agricultural vehicle

- path tracking

1. Introduction

According to a report by the Population Division of the United Nations Department of Economic and Social Affairs in 2019, it is expected that the total world population will reach 9.7 billion by the middle of this century, and the demand for food will grow rapidly [1]. For a long time, intensive and extensive agriculture has been a priority solution to the imbalance between population growth and food shortages, but this approach is costly and labor-intensive [2]. On the one hand, many countries’ agricultural sectors are facing an aging agricultural workforce [3]. On the other hand, due to the development of urbanization, more and more young laborers are moving away from agricultural production activities and towards cities, which will lead to a difficult problem of food shortage in the future. To address food shortages and other issues in agriculture, agriculturally developed countries are researching autonomous agricultural vehicles, replacing the basic technique and labor force required by traditional farming with sensor technology and electro-hydraulic control technology [4]. The global population aging and labor shortage have promoted the demand for mechanization and automation in industries, agriculture, and other fields [5]. Benefiting from the development and improvement of satellite positioning technology, inertial navigation technology, and control theory, the agricultural vehicle automatic navigation technology is increasingly being applied in agricultural production activities such as plowing, sowing, fertilization, and harvesting, becoming a key technology for precision agriculture [6]. The agricultural vehicle automatic navigation technology enables vehicles to better adapt to the complex field, improves the accuracy and efficiency of agricultural machinery operations, and reduces repeated and missed operations. Not only that, but it can also reduce the prolonged fatigue and repetitive driving work of the driver, thereby obtaining sufficient time to monitor and control agricultural machinery [7].

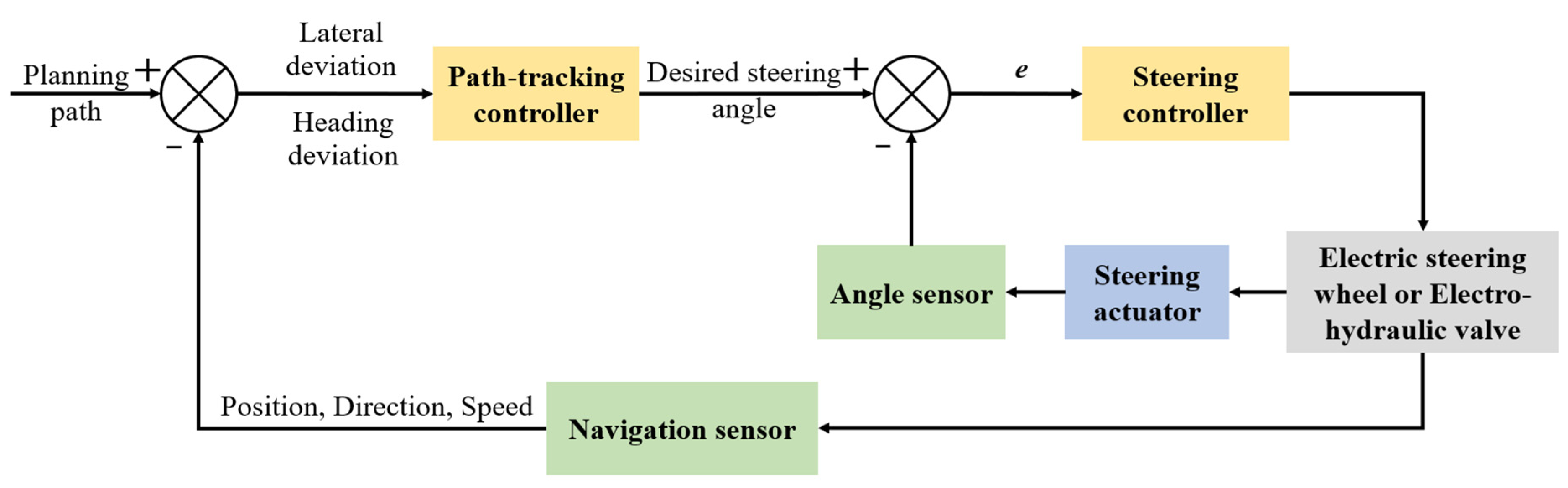

The key technologies of agricultural machinery automatic navigation mainly include positioning and attitude measurement, path planning, and path tracking control [8]. Figure 1 shows the composition of the agricultural machinery’s automatic navigation system. In order to achieve automatic navigation driving, it is necessary to install sensors on the vehicle that can provide a location, heading information, and environment information. The most frequently used positioning and attitude measurement technologies in the research of agricultural machinery automatic navigation driving include global navigation satellite system (GNSS), inertial navigation system (INS), machine vision (MV) navigation system, and light detection and ranging (LiDAR). GNSS can provide accurate navigation information, such as location, orientation, and speed, in an unobstructed environment, and is widely used in vehicles’ automatic driving. Alonso-García et al. [9] used low-cost GPS receivers as positioning sensors for agricultural tractors and evaluated the performance of tractor automatic navigation systems through tracking straight-line trajectory tests. The inertial navigation system (INS) collects acceleration and angular velocity information through the inertial measurement unit (IMU) and is not subject to external interference. However, as time goes by, the accumulation of sensor errors will lead to a decline in accuracy. LiDAR has the advantages of high precision, and strong anti-interference ability, and is widely used in orchard environment perception and navigation. Li et al. [10] used LiDAR to obtain the measurement data of the orchard tree, and finally fitted the straight line of the fruit tree, using the center of the tree row as the navigation path. A single sensor inevitably has certain limitations, which are not conducive to improving navigation and positioning accuracy and reliability. Therefore, positioning technology that combines the advantages of GNSS and INS is becoming increasingly popular in agricultural machinery automatic navigation driving. Yin et al. [11] developed autonomous rice transplanters using RTK-GNSS and IMU. The experimental results showed that the lateral error and heading error of linear path tracking were less than 10 cm and 5°, respectively.

Figure 1. Composition of agricultural machinery automatic navigation system.

The path-tracking control technology is the key to achieving automatic navigation for agricultural machinery [12]. In the case of accurate agricultural machinery location and attitude information, the path tracking control model and method are important to improving the precision and robustness of agricultural machinery automatic navigation system. Many researchers have conducted extensive research on path-tracking control methods for agricultural vehicles. Common methods include PID control, fuzzy control, model predictive control, pure pursuit model control, Stanley model control, etc. Luo et al. [13] used the RTK-DGPS receiver to obtain positioning information, combined the tractor kinematic model with the hydraulic steering control model, and designed a PID-based straight-line tracking controller. When the forward speed is 0.8 m/s, the maximum tracking deviation is less than 15 cm, and the average tracking deviation is less than 3 cm.

2. Control Methods Used in Agricultural Vehicle Path Tracking Control

Path tracking control technology is to calculate and obtain vehicle motion parameters, such as vehicle speed, steering wheel angle, etc., based on vehicle kinematic or dynamic modeling according to the algorithm, so that the vehicle can reach and track the predefined work path. The basic principle is depicted in Figure 2. The operating accuracy of agricultural machinery in autonomous driving depends on the control algorithms so that high-precision algorithms can improve the quality and efficiency of agricultural machinery operations. The environmental conditions of different fields are different, and the types of agricultural machinery used are also different.

Figure 2. Block diagram of the path tracking control system.

2.1. Dry Field Agricultural Machinery

The essence of path tracking is that under the developed control algorithm, the target vehicle can track the planned path within a certain accuracy range so that the vehicle can work along the planned path. Tractors can form different operating units with other agricultural machinery to complete tasks such as plowing, sowing, fertilization, and cultivation. The operating environment of tractors is complex and changeable, and the driving skills of drivers vary from person to person, resulting in problems such as low efficiency, decreased operation quality, and waste of land resources in field operation. In order to address these issues, many experts have conducted research on the path-tracking control technology for autonomous tractors. Backman et al. [14] developed a 4 WS tractor path tracking algorithm, which uses the tractor’s kinematic and dynamic model and the linear control law to control the steering of the tractor. Winter wheat sowing test results showed that the lateral tracking deviation of straight sowing is less than 0.05 m, and the heading angle tracking deviation is less than 1 degree. To improve the tractor’s ability to track variable curvature paths, Wu et al. [12] designed a variable curvature path tracking method based on the front wheel angle feedforward compensation strategy, which comprehensively considers the driving speed and target path curvature to adjust the look-ahead distance dynamically.

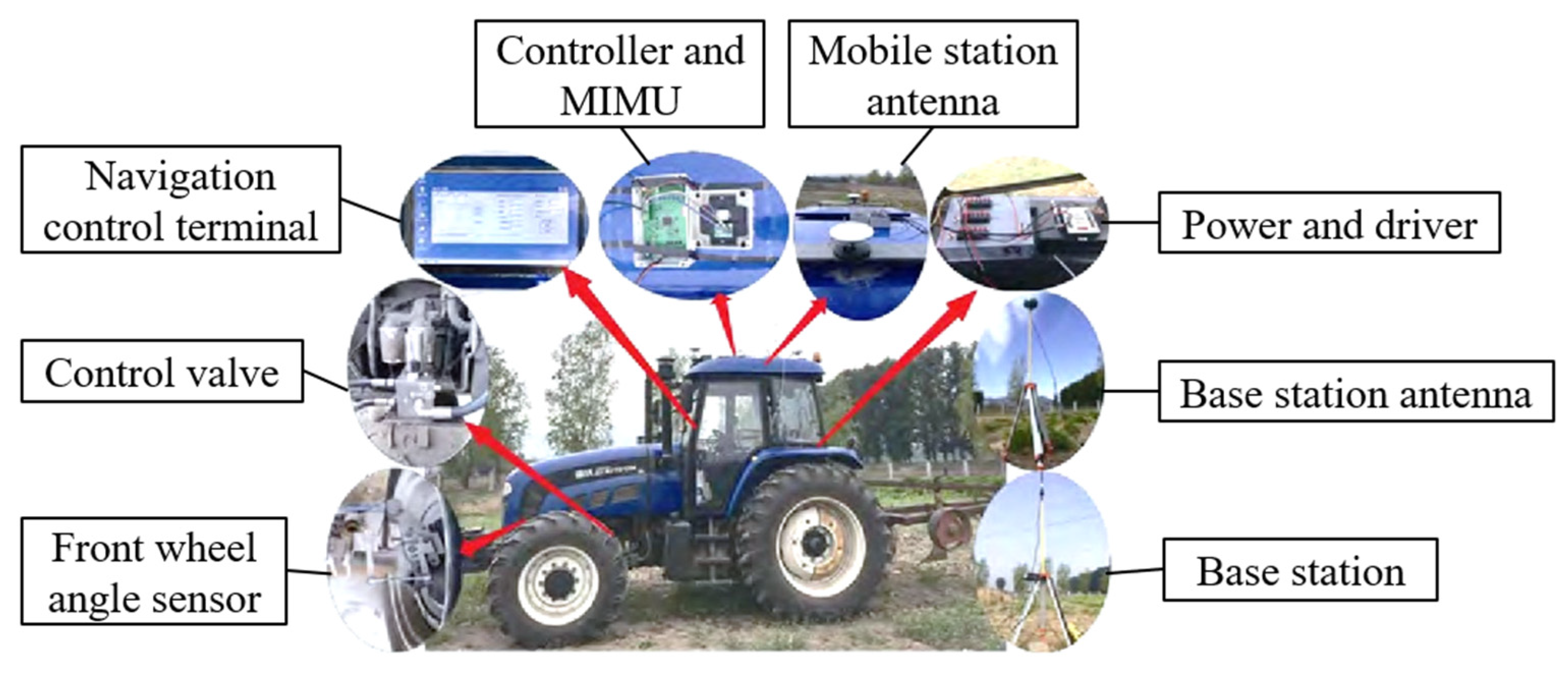

The agricultural land surface usually fluctuates greatly, and tractors will be affected by interference, such as the interaction between the supporting agricultural machinery and the uncertain ground. When wheel slip occurs, the tracking error of tractors will increase and even affect subsequent agricultural production activities. Taghia et al. [15] developed a sliding mode controller with a nonlinear perturbation observer, and the new controller performed better when slip occurred compared with backstepping controllers and model predictive controllers. Ding et al. [16] constructed a second-order sliding mode (SOSM) controller for a tractor path tracking system, fully considering longitudinal and lateral wheel slips. Ji et al. [17] proposed a novel adaptive second-order sliding mode controller (ASOSM), which alleviates the chattering problem in traditional sliding mode control and improves the convergence speed and anti-interference ability of the system. Ge et al. [18] proposed a novel adaptive sliding mode control (ASMC) method for path tracking of unmanned agricultural vehicles. This method is robust in the presence of parameter uncertainty, disturbances, and changing road conditions. During the straight-line operation of the tractor, stable high-speed driving will improve its work efficiency, but when turning on the ground, the driving speed should be reduced to improve the stability of the steering and reduce the turning distance. However, influenced by complex environments and uncertain external disturbances, when the tractor speed increases, the defects such as nonlinearity, hysteresis, and instability of the tractor-field path system become more prominent, which will affect system performance. Combined with optimal control theory, Han et al. [19] designed a dual-parameter optimal control algorithm based on speed and steering angle. Zhang et al. [20] designed a dual objective joint sliding mode control algorithm to solve the influence of tractor speed on the performance of the navigation control system. The field test platform of the tractor’s automatic navigation control system is shown in Figure 3. This algorithm achieves adaptive adjustment of speed while ensuring stable straight-line path tracking.

Figure 3. Tractor automatic navigation control system test platform.

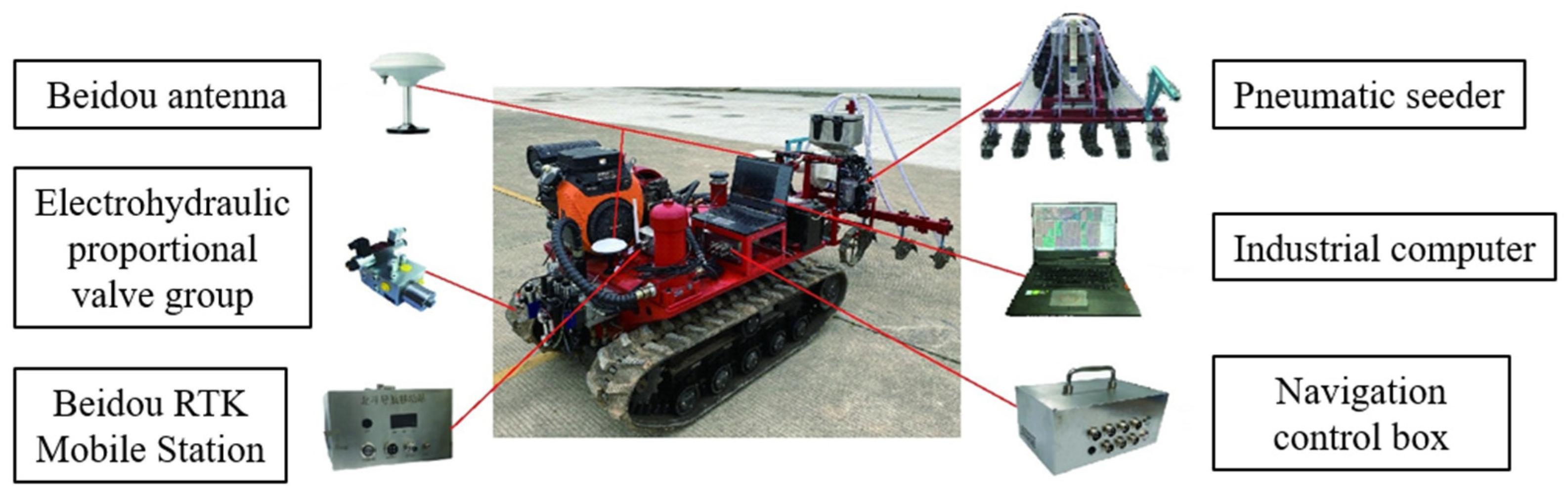

The pure pursuit control method has the characteristics of simulating human driving behavior with few control parameters, but in agricultural scenes, the robustness of preview point selection is poor and cannot be adjusted adaptively. In the study of pure pursuit model look-ahead distance, dynamic look-ahead distance performs better in path tracking than fixed look-ahead distance, although better tracking accuracy can be obtained when the look-ahead distance is equal to the wheel distance. To address the problem of poor adaptability of traditional pure pursuit algorithms to speed changes, Jia [21] proposed an improved pure pursuit algorithm on the basis of a seeker optimization algorithm (SOA), which can calculate the look-ahead distance online using the fitness function. The improved pure pursuit model algorithm can effectively resist the influence of speed changes. Zhang et al. [22] used the Dongfanghong 1104-C tractor as the test platform to determine the look-ahead distance in the pure pursuit model in real-time through particle swarm optimization (PSO). Li et al. [23] and Zhang et al. [24] developed a path-tracking method for agricultural machinery on the basis of the fuzzy adaptive pure pursuit model, which realized online real-time adjustment of look-ahead distance. The developed navigation controller has the advantages of short rise time and small overshot. Zhang et al. [24] developed the automatic navigation operation system of a crawler-type rape seeder, as shown in Figure 4. Zhang et al. [25] used deep reinforcement learning (DRL) to improve the pure pursuit model algorithm and derive correction commands to reduce tracking errors due to the improper selection of preview points. Yang et al. [26] designed a path-tracking algorithm based on the optimal target point, which searched for the optimal target point in a forward-looking area using an evaluation function.

Figure 4. Automatic navigation system for crawler-type rape seeder.

The quality and efficiency of manual harvesting operations largely depend on the driver’s driving skills. Applying automatic navigation technology to grain crop harvesting will help improve the quality, efficiency, and intelligence level of combined harvesters. To improve the quality of corn harvesting, Zhang et al. [27] developed an automatic tracking system for the corn harvester, which controlled the harvester by a pure pursuit model algorithm and dynamically adjusted the look-ahead distance by fuzzy logic. In response to the problem of missing cuts during the straight-line tracking harvesting operation of a combine harvester, Ding et al. [28] developed a single-neuron PID navigation controller for combine harvesters. Single-neuron PID can achieve rapid adjustment of control parameters through self-learning, which has the characteristics of small overshoot and fast entry into a steady state. The assisted driving system of a combined harvester with intermediate angle error can lead to path tracking deviation, which will limit the efficiency of the harvesting operation. Qiao et al. [29] proposed an improved path-tracking controller with mid-angle adaptive calibration. Hu et al. [30] developed a path-tracking PD controller for peanut harvesters. When the harvester operates automatically, the average absolute deviation and maximum deviation are 5.12 cm and 12.2 cm, respectively, which can ensure that the harvesting mechanism is aligned with the peanut row to realize digging and harvesting.

2.2. Paddy Field Agricultural Machinery

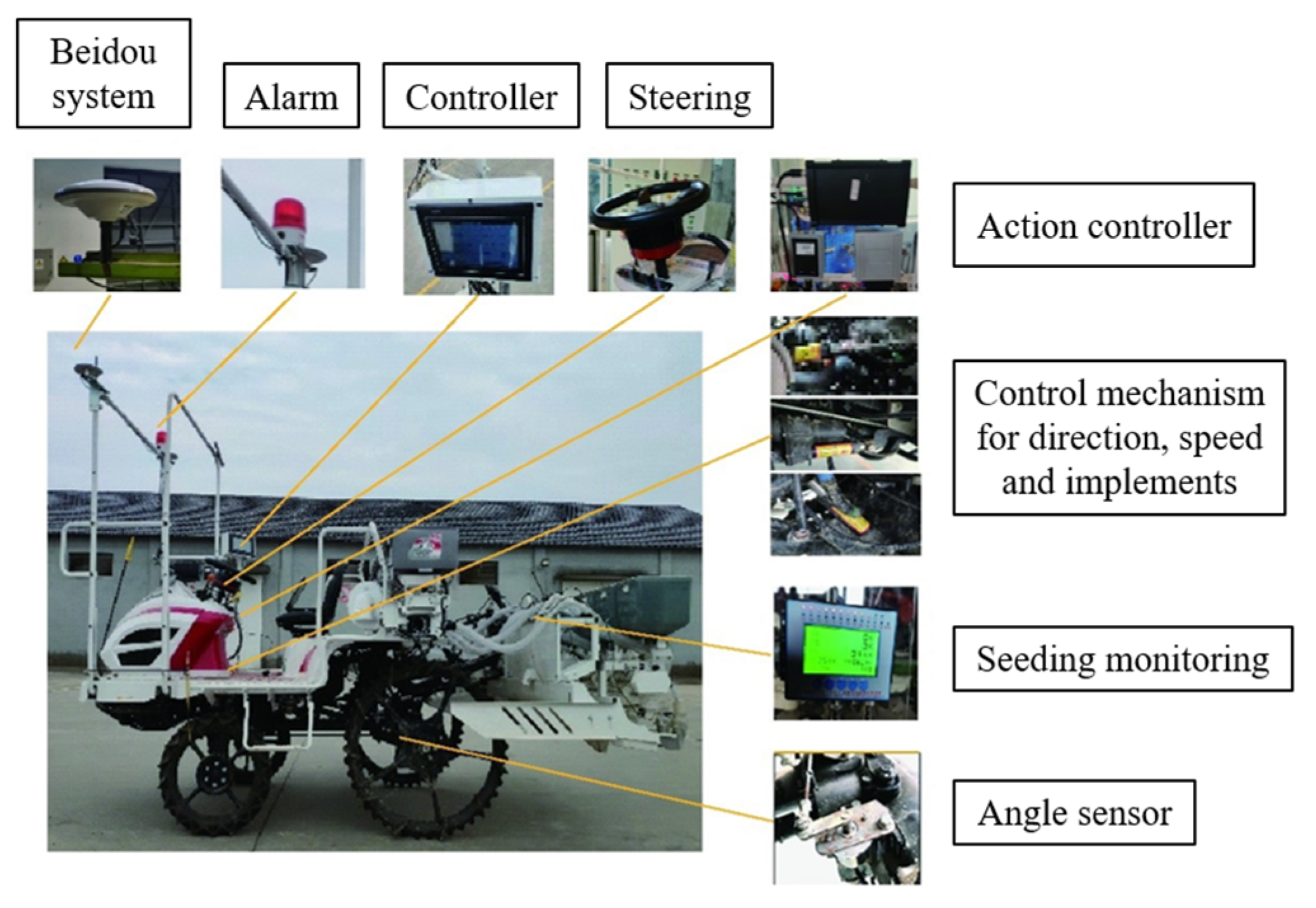

In the muddy and slippery rice field environment with uneven ground, compared with dry field agricultural machinery, paddy field machinery such as rice seeder and rice transplanter are more prone to sideslip, and even rolling and pitching, increasing the difficulty of automatic navigation of agricultural machinery. Most existing unmanned rice field agricultural machinery takes the front of the vehicle as the measurement and control object. There is a gap between the front machinery and rear implements, and the motion posture of the rear implements changes greatly relative to the front machinery, causing inconsistent travel trajectories between the front and the rear, leading to a decrease in straight-line operation accuracy and quality. In response to the above problems, He et al. [31] developed an unmanned path-tracking control method for agricultural rice machinery based on model predictive control based on the pose estimation of agricultural rice machinery. The experimental results indicate that this method can effectively suppress abrupt lateral position deviations caused by the relative position and attitude changes of the machine. Wei et al. [32] used GPS receivers and onboard sensors to gain the position and attitude information of rice transplanters and used the PID control method to construct a closed-loop steering control system, which achieved automatic navigation and headland steering of rice transplanters. In the research on the automatic driving of rice seeders, Zhang et al. [33] proposed a control strategy that uses fuzzy logic to adjust the PD controller parameter Kd adaptively. Compared with the PD controller with fixed parameters and the pure pursuit model control method, this method has a smaller overshoot, better robustness, and faster response speed. Tang et al. [34] and Shi et al. [35] established a fuzzy control model to adjust the look-ahead distance of the pure pursuit model in real-time. This method is adaptable to different vehicle speeds and can avoid oscillations when the rice transplanter operates at high speed, effectively improving the system’s robustness. Wu et al. [36][37] designed a fast terminal sliding mode controller with a nonlinear disturbance observer, which can improve the anti-interference ability of rice seeders in paddy fields. The automatic driving control system of the rice seeding machine is shown in Figure 5. Chi et al. [38] linearized the kinematic model of the rice transplanter in Taylor series form and developed a path-tracking controller using a model prediction algorithm, which can track linear and curve paths.

Figure 5. Automatic driving control system for rice seeding machine.

In the rice plant protection operation, the plant protection machinery needs to overcome the sliding interference caused by the muddy road surface of the paddy field and try to avoid rolling the rice seedlings, which increases the difficulty for the precise path tracking of rice field agricultural machinery. To solve the problems of driving wheel slipping and sinking in the paddy field, Wang et al. [39] constructed a layered path tracking strategy with model predictive control and fuzzy slip rate on the basis of the linear time-varying (LTV) kinematics model of the high clearance sprayer, which improves the tracking accuracy of the sprayer in muddy and slippery field. Liu et al. [40] developed a fuzzy adaptive predictive controller using model predictive theory, which can improve the robustness of the sprayer path-tracking. To improve the anti-interference ability and stability of the plant protection machinery, Lin et al. [41] proposed a path-tracking control method for rice field plant protection machines, which solved the chattering of the sliding mode control algorithm. Compared with wheeled tractors, tracked tractors have a large grounding area and are not easy to sink, making them widely suitable for paddy fields. However, the sliding phenomenon for tracked tractors in paddy fields is common. Most of the relevant research establishes control models under the assumption that tractors do not slip, which is difficult to achieve satisfactory accuracy. Jia et al. [42] studied the NF-752 tracked tractor mainly used for paddy field tillage, and comprehensively considered the effects of longitudinal speed and slip coefficient of both tracks. They proposed a path-tracking method based on a course control model, which to some extent, overcame the influence of slip-on control accuracy.

2.3. Orchard Agricultural Machinery

In the case of labor shortage and rising labor costs, the development of autonomous orchard agricultural machinery is helpful in reducing the labor intensity of orchard farmers and improving the efficiency and quality of orchard operations. Bayar et al. [43] proposed a model-based control method for orchard autonomous agricultural vehicles, which calculates the velocity and wheel angle based on the vehicle kinematics model, thereby improving the path tracking accuracy. Thanpattranon et al. [44] developed a navigation system suitable for curve path tracking in orchards, and the average deviation of path tracking during the experiment was 0.275 m. Based on RTK-BDS positioning technology, Xiong et al. [45] developed a straight-line path-tracking controller for the orchard sprayer. When the sprayer speed is 2 km/h, the maximum linear tracking deviation is 0.13 m, and the average tracking deviation is less than 0.03 m, which can effectively achieve accurate straight-line path tracking of the orchard. To ensure the high robustness and speed adaptability of the navigation controller, Xue et al. [46] developed an orchard tractor path-tracking controller. Simulation test results showed that the controller can track the straight line, and when the tractor turns, the average lateral errors at 2.5 m/s and 5 m/s are 7 cm and 13 cm, respectively. Opiyo et al. [47] designed a machine vision navigation system based on the central axis for autonomous orchard robots, and the fuzzy controller with heading and error as input can well track the medial axis.

In the study on path tracking of orchard tractors, Wu et al. [48] used the look-ahead distance fuzzy adaptive pure pursuit model to calculate the expected wheel angle. In addition, to cope with the soft road surface of the orchard and the vibration of the tractor itself, the feedforward control is added to the pure pursuit model control to minimize the sideslip. To achieve automatic driving of agricultural machinery in orchards, Zhang et al. [49] developed an autonomous orchard vehicle system using a two-dimensional laser, which utilizes fuzzy control to adjust the look-ahead distance of pure pursuit model dynamically. The structure of the orchard vehicle automatic platform is shown in Figure 6. Orchards have a high planting density, and low and narrow working passages, and small tracked tractors have the advantages of small size and strong terrain adaptability, which are widely used in orchards [50]. Liu et al. [51] designed a path-tracking algorithm using a virtual radar model for small, tracked tractors. The algorithm describes the relative position between vehicles and paths with a virtual radar map and generates driving instructions through a deep neural network to control the tractor. Compared with the fuzzy control algorithm, this algorithm has higher accuracy and driving stability and has better adaptability to orchard working paths.

Figure 6. Orchard vehicle automatic test platform.

2.4. Agricultural Robots and Facility Agricultural Machinery

Autonomous agricultural robots are widely used in pesticide spraying, weeding, planting, and field biological and environmental information collection. The ground conditions constantly change during the steering process, making it difficult to establish accurate mathematical models for controlled vehicles. In the research of agricultural wheeled robot path tracking, Li et al. [52] introduced a radial basis function (RBF) neural network to estimate the uncertainty disturbance in real-time and then designed an adaptive sliding mode control method, which can improve the system robustness while reducing chattering. Gökçe et al. [53] used a PID control strategy to control the agricultural robot and optimized the controller parameters through the PSO algorithm. In order to adapt to changes in speed and road, Sun et al. [54] proposed an improved path-tracking control algorithm based on the fuzzy Stanley model (FSM) and PSO. Cui et al. [55] proposed an improved Stanley model path-tracking algorithm based on the fuzzy algorithm, which adjusts the gain coefficient in real-time. In the above research on the improvement of the Stanley model algorithm, the fuzzy algorithm improves the tracking accuracy of the automatic turning, and the particle swarm optimization algorithm can further optimize the front wheel steering angle and decision-making. The agricultural tracked robot is a multi-input and multi-output system, having the characteristics of time-varying, nonlinearity, and uncertainty, which is easily affected by parameter disturbance, thereby causing negative impacts on the system [56]. Song et al. [57] designed a path-tracking strategy based on heuristic dynamic programming (HDP) for tracked agricultural robots, which can accurately track multiple complex straight-line paths. The sliding mode control method can adjust the uncertainties and parameter disturbances in the system and track the path in an exponentially convergent manner [58]. Li et al. [59] designed a tracked robot path-tracking system on the basis of a sliding mode variable structure algorithm.

The autonomous mobile operating platform in agricultural facilities can undertake tasks such as autonomous working and autonomous transportation of agricultural materials, which plays an important role in the development of facility agriculture. The space in agricultural facilities is small, and the mobile operating platform needs to change the driving direction frequently. Wang et al. [60] designed an automatic tracking platform for greenhouse fruit and vegetable picking and transportation based on Kinect sensing technology. The system uses the pure pursuit model method to track the expected path and uses the fuzzy algorithm to determine the look-ahead distance dynamically. In order to adapt to the rectangular path tracking working conditions, Yao et al. [61] used ultra-wideband (UWB) wireless positioning technology to obtain high-precision positioning information of the mobile platform and proposed a dynamic look-ahead distance determination method based on the deviation. The improved pure pursuit model algorithm can meet the demand for automatic navigation of mobile platforms in agricultural facilities. Chai et al. [62] improved the pure pursuit model by PSO and selected the optimal look-ahead distance according to the platform’s real-time position. Based on the kinematic model of a 4WIS-4WID vehicle, as shown in Figure 7, Xu et al. [63] calculate the optimal look-ahead distance using a fuzzy algorithm.

Figure 7. Test prototype and test environment.

The prominent problem faced by path-tracking technology based on the model predictive model is real-time performance. Linearization prediction models have better real-time performance than nonlinear prediction models, but linearization prediction models have the problem of weakening the controller’s ability to respond to path curvature and heading changes. Oyelere et al. [64] solved the path-tracking problem of autonomous ground vehicles (AGV) using nonlinear model predictive control (NMPC) and linear model predictive control (LMPC) and proved through experiments that LMPC has better real-time performance than NMPC. Zhang et al. [65] proposed a path-tracking method on the basis of linear time-varying model predictive control (LTVMPC). The reference path of agricultural robots usually consists of straight lines and arcs, with significant curvature changes, so linearized prediction models are not suitable for optimizing real-time performance. Liu et al. [66] proposed a path-tracking method based on nonlinear model predictive control. Test results showed that the developed controller has a smaller deviation than the linear model predictive controller when tracking linear and circular paths. Aiming at the poor real-time performance of nonlinear model predictive control, Bai et al. [67] proposed to optimize by reducing the number of control steps or lowering the control frequency. Experimental results show that reducing the number of control steps is more suitable for agricultural robots with high flexibility.

2.5. Agricultural Articulated Vehicle

Articulated vehicles mainly consist of two parts, the front, and the rear, connected by a rigid hinge body in the middle. The structural characteristics of the articulated vehicle not only reduce the turning radius, but also ensure the adhesion between the tire and the ground in rough terrain, making them suitable for transportation operations in non-structural rough terrain. Agricultural wheeled articulated vehicles experience severe vibrations when driving on rough terrain such as farmland. Compared with the traditional front-axle steering structure, the steering structure of the articulated vehicle allows both the front and the rear car body to move relative to the ground during the steering process, which increases the difficulty of path tracking. Zhao et al. [68] proposed a sliding mode variable structure path tracking controller for articulated agricultural vehicles. To suppress chattering, the symbolic function was replaced by a continuous function, and the Lyapunov function was used to prove its stability. Shao et al. [69] proposed an adaptive PID controller, which used the reinforcement learning algorithm to tune PID parameters adaptively. Reinforcement learning adaptive PID controllers have smaller overshot and vibrations than traditional ones so that the articulated vehicle can track the predetermined path more accurately. To improve the response speed of articulated agricultural vehicles, Meng et al. [70] proposed a linear quadratic regulator-genetic algorithm (LQR-GA) path-tracking method based on preview information. Preview information can improve the system response speed, and the genetic algorithm can optimize the control effect.

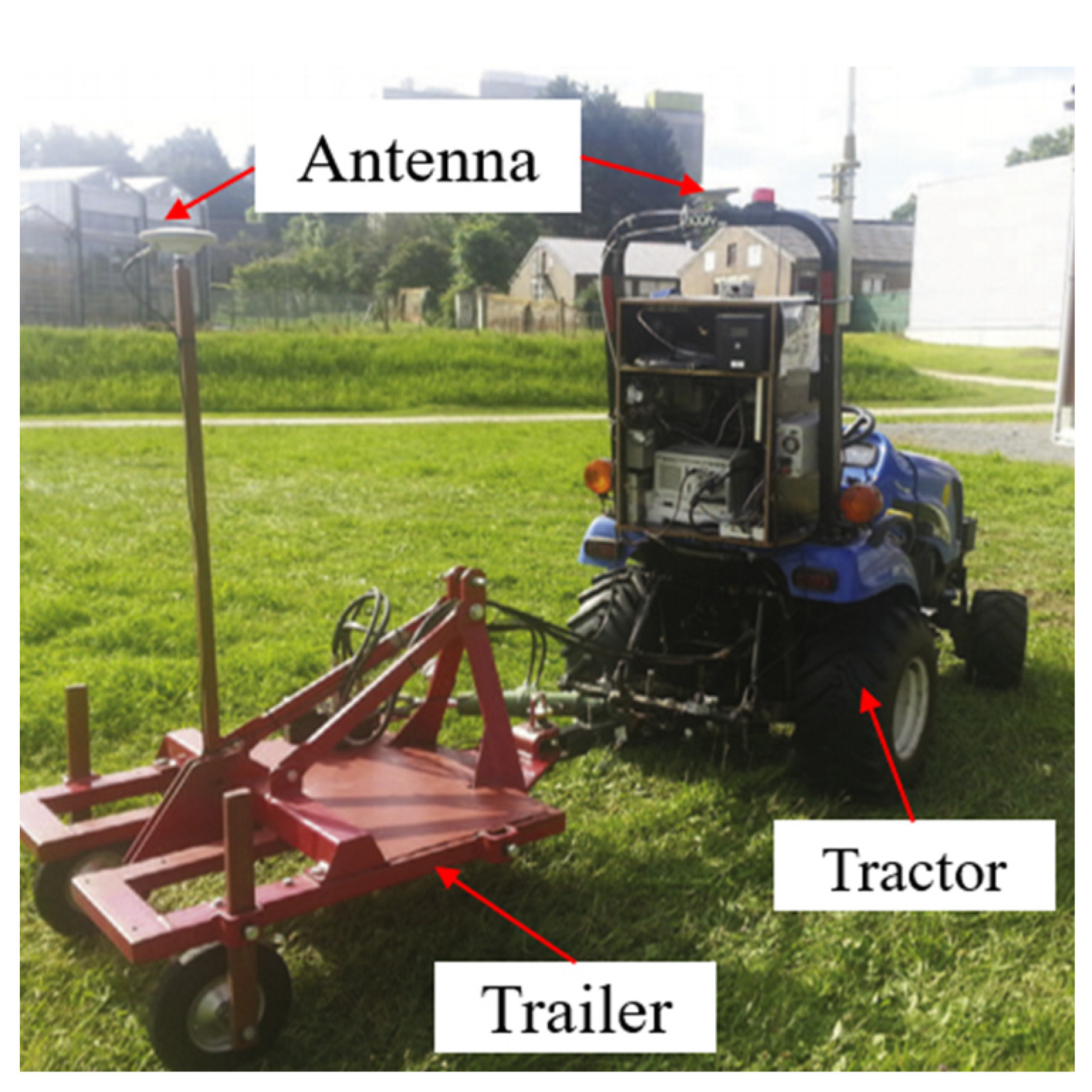

In order to keep the tractor and trailer on the same working trajectory, Backman et al. [14] designed a nonlinear model predictive path-tracking controller for the tractor-trailer system. During the straight-line path tracking, the lateral error of the trailer is much less than 10 cm. To improve the trajectory tracking performance of autonomous tractor-trailer systems, Kayacan et al. [71] combined fast-distributed nonlinear model predictive control with nonlinear movement level estimation for state and parameter estimation. The small agricultural tractor–trailer system is shown in Figure 8. The proposed method can improve the path-tracking accuracy of tractor-trailer systems and robustness to environmental disturbances. Apart from the development and improvement of control methods by the researchers mentioned above, commercial companies have proposed commercial solutions for autonomous tractor-trailer systems, such as John Deere’s iGuide and iSteer and Trimble’s TrueGuide. The difference between iGuide and iSteer, which is primarily used for straight-line path tracking, is that iGuide is a passive guidance solution where the implement does not have a steering system, while iSteer is an active guidance solution where both the tractor and the implement have a steering system.

Figure 8. The tractor-trailer system.

This entry is adapted from the peer-reviewed paper 10.3390/app13127155

References

- World Population Prospect. 2019. Available online: https://www.un.org/development/desa/pd/news/world-population-prospect-2019 (accessed on 15 July 2021).

- Van Der Ploeg, J.D. Revitalizing agriculture: Farming economically as starting ground for rural development. Sociol. Rural. 2000, 40, 497–511.

- Alberto-Rodriguez, A.; Neri-Muñoz, M.; Fernández, J.C.R.; Márquez-Vera, M.A.; Velasco, L.E.R.; Díaz-Parra, O.; Hernández-Huerta, E. Review of control on agricultural robot tractors. Int. J. Comb. Optim. Probl. Inform. 2020, 11, 9–20.

- Han, J.-H.; Park, C.-H.; Jang, Y.Y.; Gu, J.D.; Kim, C.Y. Performance evaluation of an autonomously driven agricultural vehicle in an orchard environment. Sensors 2021, 22, 114.

- Bochtis, D.D.; Sørensen, C.G.C.; Busato, P. Advances in agricultural machinery management: A review. Biosyst. Eng. 2014, 126, 69–81.

- Auat Cheein, F.A.; Carelli, R. Agricultural robotics: Unmanned robotic service units in agricultural tasks. IEEE Ind. Electron. Mag. 2013, 7, 48–58.

- Li, H.; Gao, F.; Zuo, G. Research on the agricultural machinery path tracking method based on deep reinforcement learning. Sci. Program. 2022, 2022, 6385972.

- Zhang, M.; Ji, Y.; Li, S.; Cao, R.; Xu, H.; Zhang, Z. Research progress of agricultural machinery navigation technology. Trans. CSAM 2020, 51, 1–18.

- Alonso-García, S.; Gómez-Gil, J.; Arribas, J.I. Evaluation of the use of low-cost GPS receivers in the autonomous guidance of agricultural tractors. Span. J. Agric. Res. 2011, 9, 377–388.

- Li, Q.; Ding, X.; Deng, X. Intra-row path extraction and navigation for orchards based on LiDAR. Trans. CSAM 2020, 51, 344–350.

- Yin, X.; Du, J.; Geng, D.; Jin, C. Development of an automatically guided rice transplanter using RTK-GNSS and IMU. IFAC-PapersOnLine 2018, 51, 374–378.

- Wu, C.; Wu, J.; Wen, L.; Chen, Z.; Yang, W.; Zhai, W. Variable curvature path tracking control for the automatic navigation of tractors. Trans. CSAE 2022, 38, 1–7.

- Luo, X.; Zhang, Z.; Zhao, Z.; Chen, B.; Hu, L.; Wu, X. Design of DGPS navigation control system for Dongfanghong X-804 tractor. Trans. CSAE 2009, 25, 139–145.

- Backman, J.; Oksanen, T.; Visala, A. Navigation system for agricultural machines: Nonlinear Model Predictive path tracking. Comput. Electron. Agr. 2012, 82, 32–43.

- Taghia, J.; Wang, X.; Lam, S.; Katupitiya, J. A sliding mode controller with a nonlinear disturbance observer for a farm vehicle operating in the presence of wheel slip. Auton. Robot. 2017, 41, 71–88.

- Ding, C.; Ding, S.; Wei, X.; Mei, K. Composite SOSM controller for path tracking control of agricultural tractors subject to wheel slip. ISA Trans. 2022, 130, 389–398.

- Ji, X.; Ding, S.; Wei, X.; Cui, B. Path tracking of unmanned agricultural tractors based on a novel adaptive second-order sliding mode control. J. Frankl. Inst. 2023, 360, 5811–5831.

- Ge, Z.; Man, Z.; Wang, Z.; Bai, X.; Wang, X.; Xiong, F.; Li, D. Robust adaptive sliding mode control for path tracking of unmanned agricultural vehicles. Comput. Electron. Agr. 2023, 108, 108693.

- Han, K.; Zhu, Z.; Mao, E.; Song, Z.; Xie, B.; Li, M. Joint control method of speed and heading of navigation tractor based on optimal control. Trans. CSAM 2013, 44, 165–170.

- Zhang, S.; Liu, J.; Du, Y.; Zhu, Z.; Mao, E.; Song, Z. Method on automatic navigation control of tractor based on speed adaptation. Trans. CSAE 2017, 33, 48–55.

- Jia, Q. Adaptive Control Method for Tractor Auto-Guidance System. Ph.D. Thesis, Chinese Academy of Agricultural Mechanization Sciences Group Co., Ltd., Beijing, China, 2018.

- Zhang, H.; Wang, G.; Lü, Y.; Qin, C.; Liu, L.; Gong, J. Agricultural machinery automatic navigation control system based on improved pure tracking model. Trans. CSAM 2020, 51, 18–25.

- Li, T.; Hu, J.; Gao, L.; Liu, X.; Bai, X. Agricultural machine path tracking method based on fuzzy adaptive pure pursuit model. Trans. CSAM 2013, 44, 205–210.

- Zhang, C.; Dong, W.; Xiong, Z.; Hu, Z.; Wang, D.; Ding, Y. Design and experiment of fuzzy adaptive pure pursuit control of crawler-type rape seeder. Trans. CSAM 2021, 52, 105–114.

- Zhang, J. Path Planning and Control Method for Automatic Driving of Agricultural Machinery. Master’s Thesis, Harbin University of Science and Technology, Harbin, China, 2021.

- Yang, Y.; Li, Y.; Wen, X.; Zhang, G.; Ma, Q.; Cheng, S.; Qi, J.; Xu, L.; Chen, L. An optimal goal point determination algorithm for automatic navigation of agricultural machinery: Improving the tracking accuracy of the pure pursuit algorithm. Comput. Electron. Agr. 2022, 194, 106760.

- Zhang, K.; Hu, Y.; Yang, L.; Zhang, D.; Cui, T.; Fan, L. Design and experiment of auto-follow row system for corn harvester. Trans. CSAM 2020, 51, 103–114.

- Ding, Y.; Xia, Z.; Peng, J.; Hu, Z. Design and experiment of the single-neuron PID navigation controller for a combine harvester. Trans. CSAE 2020, 36, 34–42.

- Qiao, N.; Wang, L.; Zhu, W.; Tang, X.; Jin, C.; Li, Y.; Xu, L. An improved path-tracking controller with mid-angle adaptive calibration for combine harvester. J. Instrum. 2020, 15, P1025.

- Hu, L.; Guan, J.; He, J.; Man, Z.; Tian, L.; Luo, X. Design and experiment of automatic driving operation system of peanut harvester based on BDS. Trans. CSAM 2022, 53, 21–27.

- He, J.; Hu, L.; Wang, P.; Liu, Y.; Man, Z.; Tu, T.; Yang, L.; Li, Y.; Yi, Y.; Li, W.; et al. Path tracking control method and performance test based on agricultural machinery pose correction. Comput. Electron. Agr. 2022, 200, 107185.

- Wei, L.; Zhang, Q.; Yan, H.; Liu, Y. GPS Automatic navigation system design for XDNZ630 Rice transplanter. Trans. CSAM 2011, 42, 186–190.

- Zhang, Y.; Li, Y.; Liu, X.; Tao, J.; Liu, C.; Li, R. Fuzzy adaptive control method for autonomous rice seeder. Trans. CSAM 2018, 49, 30–37.

- Tang, X.; Tao, J.; Li, Z.; Li, Y.; Liu, C. Fuzzy control optimization method for stability of path tracking system of automatic transplanter. Trans. CSAM 2018, 49, 29–34.

- Shi, S. Design and Research on the Control System of Automatic Navigation Transplanter. Master’s Thesis, Shandong Agricultural University, Taian, China, 2020.

- Wu, T.; Li, Y.; Lin, H.; Gong, L.; Liu, C. Fast terminal sliding mode control for autonomous rice seeding machine based on disturbance observer. Trans. CSAM 2021, 52, 24–31.

- Li, Y.; Wu, T.; Xiao, Y.; Gong, L.; Liu, C. Path planning in continuous adjacent farmlands and robust path-tracking control of a rice-seeding robot in paddy field. Comput. Electron. Agr. 2023, 210, 107900.

- Chi, R.; Xiong, Z.; Jiang, L.; Ma, Y.; Huang, X.; Zhu, X. Path tracking control algorithm of transplanter based on model prediction. Trans. CSAM 2022, 53, 22–30, 99.

- Wang, Z.; Liu, G.; Zhang, D.; Shen, Y.; Yao, Z.; Zhang, H. Path following model predictive control of four wheel independent drive high ground clearance sprayer. Smart Agric. 2021, 3, 82–93.

- Liu, G.; Li, C.; Shen, Y.; Liu, H. Trajectory tracking and model predictive control of high clearance synchronous-steering sprayer. Trans. CSAM 2021, 52, 389–399.

- Lin, H.; Li, Y.; Yuan, Z.; Wu, T.; Liu, C. Sliding mode anti-interference path tracking method for autonomous operation of paddy field plant protection machine. Trans. CSAM 2021, 52, 383–388.

- Jia, Q.; Zhang, X.; Yuan, Y.; Wei, L.; Zhao, B.; Fu, T. Automatic driving system for NF-752 tracked tractor. Agric. Eng. 2018, 8, 24–29.

- Bayar, G.; Bergerman, M.; Koku, A.B.; Konukseven, E.I. Localization and control of an autonomous orchard vehicle. Comput. Electron. Agr. 2015, 115, 118–128.

- Thanpattranon, P.; Ahamed, T.; Takigawa, T. Navigation of autonomous tractor for orchards and plantations using a laser range finder: Automatic control of trailer position with tractor. Biosyst. Eng. 2016, 147, 90–103.

- Xiong, B.; Zhang, J.; Qu, F.; Fan, Z.; Wang, D.; Li, W. Navigation control system for orchard spraying machine based on Beidou navigation satellite system. Trans. CSAM 2017, 48, 45–50.

- Xue, P.; Wu, Y.; Yin, G.; Liu, S.; Shi, J. Path tracking of orchard tractor based on linear time-varying model predictive control. In Proceedings of the 2019 Chinese Control and Decision Conference (CCDC), Nanchang, China, 3–5 June 2019.

- Opiyo, S.; Okinda, C.; Zhou, J.; Mwangi, E.; Makange, N. Medial axis-based machine-vision system for orchard robot navigation. Comput. Electron. Agr. 2021, 185, 106153.

- Wu, C. Research of Autonomous Driving System of Tractor Based on Multi-Source Information Fusion in Orchard. Master’s Thesis, Southeast University, Nanjing, China, 2019.

- Zhang, S.; Guo, C.; Gao, Z.; Sugirbay, A.; Chen, J.; Chen, Y. Research on 2D laser automatic navigation control for standardized orchard. Appl. Sci. 2020, 10, 2763.

- Zheng, Y.; Jiang, S.; Chen, B.; Lü, H.; Wan, C.; Kang, F. Review on technology and equipment of mechanization in hilly orchard. Trans. CSAM 2020, 51, 1–20.

- Liu, Z.; Wang, X.; Ren, Z.; Mao, W.; Yang, F. Crawler tractor navigation path tracking control algorithm based on virtual radar model. Trans. CSAM 2021, 52, 376–385.

- Li, T. Adaptive sliding mode path tracking control of agricultural wheeled mobile robots. China Mech. Eng. 2018, 29, 579–584, 590.

- Gökçe, B.; Koca, Y.B.; Aslan, Y.; Gökçe, C.O. Particle swarm optimization-based optimal PID control of an agricultural mobile robot. Comptes Rendus De L’académie Bulg. Des Sci. 2021, 74, 568–575.

- Sun, Y.; Cui, B.; Ji, F.; Wei, X.; Zhu, Y. The full-field path tracking of agricultural machinery based on PSO-enhanced fuzzy Stanley model. Appl. Sci. 2022, 12, 7683.

- Cui, B.; Sun, Y.; Ji, F.; Wei, X.; Zhu, Y.; Zhang, S. Study on whole field path tracking of agricultural machinery based on fuzzy Stanley model. Trans. CSAM 2022, 53, 43–48, 88.

- Kayacan, E.; Young, S.N.; Peschel, J.M.; Chowdhary, G. High-precision control of tracked field robots in the presence of unknown traction coefficients. J. Field Robot. 2018, 35, 1050–1062.

- Song, Y.; Zhang, Y.; Yao, Q.; Yuan, S.; Liao, J.; Liu, L. Path following control method of tracked mobile robot based on heuristic dynamic programming. Trans. CSAM 2019, 50, 24–33.

- Ríos, H.; Falcón, R.; González, O.A.; Dzul, A. Continuous sliding-mode control strategies for quadrotor robust tracking: Real-time application. IEEE Trans. Ind. Electron. 2019, 66, 1264–1272.

- Li, Z.; Chen, L.; Zheng, Q.; Dou, X.; Yang, L. Control of a path following caterpillar robot based on a sliding mode variable structure algorithm. Biosyst. Eng. 2019, 186, 293–306.

- Wang, X.; Lu, W.; Chen, M.; Wang, T.; Zhang, Y.; Boukangou, M.P. Automatic following system for greenhouse harvesting transportation based on adaptive pure pursuit model. Trans. CSAM 2016, 47, 8–13.

- Yao, L.; Pitla, S.K.; Yang, Z.; Xia, P.; Zhao, C. Path tracking of mobile platform in agricultural facilities based on ultra wideband wireless positioning. Trans. CSAE 2019, 35, 17–24.

- Chai, S.; Yao, L.; Xu, L.; Chen, Q.; Xu, T.; Yang, Y. Research on greenhouse agricultural machinery path tracking based on dynamic look ahead distance pure pursuit model. J. Chin. Agric. Mech. 2021, 42, 58.

- Xu, L.; Yang, Y.; Chen, Q.; Fu, F.; Yang, B.; Yao, L. Path tracking of a 4WIS-4WID agricultural machinery based on variable look-ahead distance. Appl. Sci. 2022, 12, 8651.

- Oyelere, S.S. The application of model predictive control (MPC) to fast systems such as autonomous ground vehicles (AGV). IOSR-JCE 2014, 16, 27–37.

- Zhang, W.; Bai, W.; Lü, Z.; Liu, Z.; Huang, C. Linear time-varying model predictive controller improving precision of navigation path automatic tracking for agricultural vehicle. Trans. CSAE 2017, 33, 104–111.

- Liu, Z.; Zhang, W.; Lü, Z.; Zheng, W.; Mu, G. Design and test of path tracking controller based on nonlinear model prediction. Trans. CSAM 2018, 49, 23–30.

- Bai, G.; Liu, L.; Meng, Y.; Liu, S.; Liu, L.; Liu, W. Real-time path tracking of mobile robot based on nonlinear model predictive control. Trans. CSAM 2020, 51, 47–52, 60.

- Zhao, X.; Yang, J.; Zhang, W.; Zeng, J. Sliding mode control algorithm for path tracking of articulated dump truck. Trans. CSAE 2015, 31, 198–203.

- Shao, J.; Zhao, X.; Yang, J.; Zhang, W.; Kang, Y.; Zhao, X. Reinforcement learning algorithm for path following control of articulated vehicle. Trans. CSAM 2017, 48, 376–382.

- Meng, Y.; Wang, Y.; Gu, Q.; Bai, G. LQR-GA path tracking control of articulated vehicle based on predictive information. Trans. CSAM 2018, 49, 375–384.

- Kayacan, E.; Kayacan, E.; Ramon, H.; Saeys, W. Distributed nonlinear model predictive control of an autonomous tractor-trailer system. Mechatronics 2014, 24, 926–933.

This entry is offline, you can click here to edit this entry!