Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

The construction industry is facing increased demand for adopting sustainable 'green' building materials to minimise the carbon footprint of the infrastructure sector to meet the United Nations 2030 Sustainability Goals. Natural bio-composite materials such as timber and bamboo have been widely used in construction for centuries. Hemp has also been used in different forms in the construction sector for decades for its thermal and acoustic insulation capability owing to its moisture buffering capacity and thermal conductivity.

- absorption

- carbon negative

- desorption

- hemp shive

- internal curing

1. Introduction

Sustainability is of prime importance in the construction industry since building materials are a significant source of greenhouse gas emissions [1][2]. Concrete, in particular, is responsible for significant greenhouse gas emissions as a result of using cement as a binding agent. As such, the use of ‘green’ building materials can significantly reduce adverse impacts on the environment. Significant research has been reported highlighting numerous examples of using recycled products to replace typical materials in the construction industry [3]. The use of plant-based materials has also been reported to be an effective substitute for chemicals in concrete construction. For example, the application of abaca fibre [4], kenaf cellulose microfiber [4] and eucalyptus fibre [5][6] to improve cracking and shrinkage properties; use of rice husk ash as supplementary cementitious materials to achieve ultra-high performance [7] and use of green artificial aggregate for curing [8].

A recent study [9] provided a detailed review on the multifaced application of hemp toward the sustainable development of the world. The use of hemp in construction is one of them. The use of hemp in concrete (hempcrete) is gaining popularity [10][11]. Hempcrete is a mixture of lime and hemp shives, and is considered to have a low environmental impact [12]. Hempcrete, through the carbon sequestration process, stores carbon in it in a stable form and thus brings the net Green House Gas (GHG) emission to negative values during its manufacture and installation in building products [13]. Hemp tree stem has a highly porous anatomical structure allowing the absorption of large amounts of water with little change to the volume [14]. They are also considered hygroscopic, and, as such, hemp-based concrete products (hempcrete) are often used in buildings to control moisture [15][16][17]. Herein, researchers propose that the hygroscopic behaviour of hemp could also be used to act as an internal supplier of water within a concrete mass during curing/hydration, and thus could increase the early age strength of concrete.

In the process of internal curing, water stored in curing agents are utilized by the cementitious materials to expedite chemical reactions [18]. The technique of internal curing is beneficial to scenarios where conventional (external) curing methods are difficult due to accessibility or site constraints [19] or in dense concrete with low w/c ratio [20]. Internal curing can also be used to prevent issues with external curing due to evaporation of water from the cement paste, which, in turn, may promote shrinkage cracking of concrete [21]. Consequently, the overall strength and durability of the concrete structure could be adversely impacted [19]. Insufficient curing limits the hydration process resulting in lower early strength development. This issue is more critical in temporary support products such as shotcrete [22] where rapid strength gain is required, which is instigated by using chemical accelerators. Due to the rapid hardening, the development of early age cracks makes shotcrete more vulnerable to physical and chemical attacks affecting its durability. Providing an additional internal curing agent could reduce early age cracking and significantly improve the early age strength gain and durability [23].

Apart from the conventional internal curing agents that are manufactured such as lightweight aggregates (LWA) and Superabsorbent Polymers (SAP), the performance of plant-based agents has also been considered [24] in the forms of cellulose, eucalyptus, kenaf, and hardwood pulp fibers [4][25][26]. Previous studies on plant based internal curing materials showed some encouraging results. However, to achieve a sustainable solution, the potential of plant-based internal curing materials must not be limited by local geographical regions. Thus, additional research is required to find other plant-based alternatives that are available in abundance worldwide and are a hardy, tolerant and annual plant species such as hemp which is ubiquitously grown and distributed globally as a food, medicine, or fabric [27]. Hemp shives—the chipped pieces of porous hemp tree stem possess excellent water absorbing characteristics, about 2–3 times of its own weight [28]. This hygroscopic behaviour shows potential for its use as an ideal candidate for a sustainable plant-based internal curing agent. Current research examines the possibility of utilizing hemp shives as an internal curing agent through material and mechanical characterization of Australian grown hemp.

2. Properties of an Internal Curing Agent

In general, when a concrete batch is prepared and placed, the relative humidity (RH) starts to drop, as the mixing water is used, and self-desiccation commences. When an internal curing agent is applied, stored water within the agent gets transferred to the cement paste with a reduction in the RH. With a small RH drop, water in larger pores will have less capillary tension and should serve the cement paste faster. Gradually, as hydration progresses, with the reduction in pore size, water stored in smaller sized pores will flow into the cement paste with a further decrease in RH.

Thus, to achieve the main objectives of internal curing, an agent should release its absorbed moisture at a high relative humidity at the required time. Previous research has shown that the ideal internal curing agent should release at least 85% of its absorbed water at 94% relative humidity [29][30]. On the other hand, a less efficient internal curing agent holds its absorbed water and releases it only gradually with the decrease in relative humidity. The characteristic factors to determine the efficiency of an internal curing agent were reported in [25] and include:

Water saturation status: it is essential to ensure that the internal curing agent is fully saturated by either soaking in water for 24 h prior to mixing (i.e., porous aggregate and luminous cellulose fibres) or by adding water during the mixing phase (i.e., superabsorbent polymer).

Water absorption and desorption properties: This agent response depends on the pore structure of the material and interaction with the cement paste. Water is required to be released at the onset of early self-desiccation of the cement paste. An earlier release may affect the rheological characteristics of the cement paste rather than aiding in internal curing [31]. Furthermore, water migration is only possible from the pores of the internal curing agent to the cement paste when its pore size is larger than the equivalent pore radius of the cement paste. Thus larger and open pores of the internal curing agent are better as it can hydrate cement paste with finer pores [32].

Particle size distribution: Cement paste located within the migration distance of the internal curing agent water when released is mitigated from self-desiccation. As such, the particle size distribution of the internal curing agent should be well distributed inside the cement paste to ensure greater surface area contact [33]. In the case of pumice aggregate, a particle size ranging between 1.18–2.36 mm was reported to perform better than 0.6–1.18 mm in reducing autogenous shrinkage [34]. A similar finding was observed in case of rice husk ash where a particle size of 5.6 µm and 9.0 µm performed better than 3.6 µm [35]. However, a different finding has been noted in case of Kenaf fibre [4] where small sized particles (400 µm) performed better in bridging micro-cracks and thus exhibited a better compressive strength compared to larger particle size (5 mm) when added at the same dosage.

3. Hemp Shives: An Internal Curing Agent

Although the infusion of plant fibres in concrete materials for increasing the tensile strength and toughness of concrete dates back to the end of the previous century [36][37], the idea of using plant fibers for internal curing is contemporary [25]. Plant fibers that have been previously considered as an internal curing agent include modified kenaf [4][26][38], hardwood pulp [39], luffa [6], eucalyptus [5], thermomechanical pulp [40], and cellulose [41]. Research has revealed that the natural plant fibres are able to contribute to the internal curing of concrete in a similar manner to SAP [42] and LWA [43]. The long-term durability of these lignocellulosic agents is a matter of concern, however, relevant research has shown that plant-based agents positively contribute to minimise self-desiccation and autogenous shrinkage during the early days of hydration before they degrade [7]. Herein, researchers propose using hemp shive for the internal curing of cementitious material based on its morphological characteristics such as pore size distribution, physical properties as absorption and desorption behaviour with varying particle sizes.

4. Pore Size Distribution

Hemp shives are porous in structure, consisting of interconnected voids with a very low density. As such, they are highly absorbent and capable of retaining significant amounts of water [10]. Pore sizes can be divided into gel nano pores (<0.01 µm), mesopores (0.01–0.05 µm), middle capillary pores (0.05–0.1 µm), large capillary pores (0.1–5 µm), and macro pores (>5 µm). [44][45].

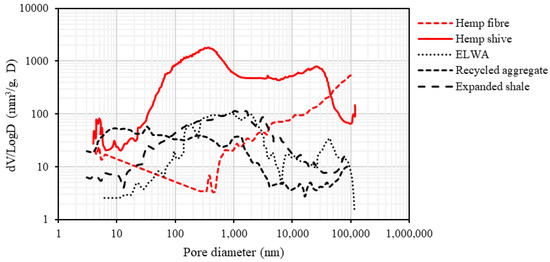

A detailed study suggests an average pore radius varies from 0.03 to 80 µm [14] and the total accessible porosity in hemp shive is in the order of 76.67 ± 2.03%. Presence of micro-pores (0.03 to 1 µm) in the pit membrane, cell walls and pit aperture were confirmed through SEM image analysis, whilst macro pores (20 to 80 µm) were present in the vessels. Voids in the parenchyma cell vary from 1 to 20 µm. Because of this unique microstructure, a multi-scale porosity is observed which is not subjected to change even after cutting and retting. It should be noted that retting is the process used to separate the hemp fibres from the stem, and is conducted with the help of microorganisms, acid/bases, and/or enzymes. A recent study [46] suggests that retting increases the water absorption property of hemp shives by 20%. As part of the current study, pore size distribution of hemp shives was compared against those reported for Expanded Lightweight Aggregate (ELWA), Recycled Aggregate, and Expanded shale as shown in Figure 1. Here, the x-axis represents the size of the pores, and the y-axis represents the volume of mercury required for filling the pore under different pressure for a specimen in Mercury Intrusion Porosimetry (MIP) method. It is observed that, with respect to pore size distribution, hemp shives have a greater number of pores with larger diameters when compared to other internal curing agents. It is worth noting that the proportion of inaccessible pores (<3 nm) present in hemp shives are lower than that of hemp fibre. Hemp shives possess a wide variation in pore size distribution compared to fibres [47] and, thus, should absorb significantly higher amount of water, which may be beneficial to curing.

Previous research showed that a curing agent loses its effectiveness in internal curing if the pore sizes are smaller than 100 nm, which makes it difficult in releasing the stored water [50]. Of the traditional internal curing agents, ELWA is the most efficient since 89.7% of its pores are greater than 100 nm. With slight variation, the micropores present in the pit membrane, cell wall, and pit aperture of hemp shives are predominantly above 100 nm in size [47]. Moreover, they have the added benefit of significantly larger pores than ELWA, and hence, there is a strong likelihood for application as an internal curing agent in concrete.

5. Absorption Behaviour

Being highly porous, hemp shive exhibits excellent water absorption behaviour [28][46][47][51][52]; test results showed that shives are capable of absorbing water equivalent to two-thirds of their own weight within 10 min of immersion reaching a saturation level of 95% [28]. This behaviour can be attributed to the presence of the macro pores due to the hemicellulose and lignin content. Presence of larger macro pores in hemp shive allows it to absorb water at a faster rate than a smaller pore size that slowly fills up with water [28][46][47][51][52]. Properties of other common internal curing agents such as LWA, which have smaller pore structure, suggest they will continue to absorb water for three days, but will likely reach their maximum after 48 h [29].

6. Desorption Behaviour

Although the water absorption property of hemp has been investigated by several researchers, very limited research has been reported on its water releasing behaviour, which is important for internal curing. A recent study analysed the moisture and heat sorption properties of hemp fibre and shive [47]. Both the hemp fibre and hemp shive were subjected to successive sorption and desorption over three consecutive cycles at a constant temperature and were plotted against relative humidity (RH). It was observed that in both cases for a single cycle, both the sorption and desorption curves from shives formed a hysteresis loop where the rate of water absorption (0.57–0.66) was higher than the desorption rate (0.27–0.35) at a RH range of 80–90%. This means, at high RH range hemp shives absorb water at a quicker rate compared to the rate of release during desorption.

The hemp shives’ hysteresis behaviour can be explained by the presence of micropores and the permanent uptake of water through pore molecules as interpreted by Collet, Bart [16]. In addition, capillary condensation hysteresis, contact angle hysteresis, and an ink-bottle effect may also contribute to such properties [16]. Research on eucalyptus pulp showed that within 25 h of hydration, water stored in the pulp lumen was released to the self-desiccating cement paste as a result of relative humidity gradient [25]. In the same way, water should be released from larger pores of hemp first and then gradually from smaller pores to promote internal curing of the cement paste. As hydration progresses, larger pores are divided into progressively smaller pores. This gradual water migration from the meso-pores to the smaller capillary pores should serve the hydrating cement paste. Research [32] shows that capillary pores in the range of 5–50 nm are more susceptible to cause capillary stress resulting in autogenous strain. Pore sizes in the pit membrane, aperture and cell walls of hemp shives are in the range of 0.03 µm to 1 µm and thus should help in mitigating autogenous shrinkage.

7. Particle Size Distribution

The particle size of the curing agent is particularly important to ensure better dispersion of the curing water into the matrix. This has previously been understood through previous research, such as the improvement of compressive strength and autogenous shrinkage properties of concrete though the addition of kenaf fibres [4]. This benefit is provided by the introduction of additional internal curing water through increased fibre dosage. In this regard, shorter fibres have been found to perform better in shrinkage mitigation at early ages which is largely due to their better dispersion into the matrix. To find out the effect of size variation of hemp shives in internal curing of concrete, a balance between the particle size distribution, water absorption and desorption capacity, and necessary dosage determination is required.

This entry is adapted from the peer-reviewed paper 10.3390/ma16113993

References

- Zabalza Bribián, I.; Valero Capilla, A.; Aranda Usón, A. Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Build. Environ. 2011, 46, 1133–1140.

- Van den Heede, P.; De Belie, N. Environmental impact and life cycle assessment (LCA) of traditional and ‘green’ concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431–442.

- Serati, M.; Jakson, N.; Asche, H.; Basireddy, S.; Malgotra, G. Sustainable shotcrete production with waste glass aggregates. SN Appl. Sci. 2022, 4, 82.

- Gwon, S.; Choi, Y.C.; Shin, M. Internal curing of cement composites using kenaf cellulose microfibers. J. Build. Eng. 2022, 47, 103867.

- Jongvisuttisun, P.; Negrello, C.; Kurtis, K.E. Effect of processing variables on efficiency of eucalyptus pulps for internal curing. Cem. Concr. Compos. 2013, 37, 126–135.

- Tong, Y.; Zhao, S.; Ma, J.; Wang, L.; Zhang, Y.; Gao, Y.; Xie, Y.M. Improving cracking and drying shrinkage properties of cement mortar by adding chemically treated luffa fibres. Constr. Build. Mater. 2014, 71, 327–333.

- Rößler, C.; Bui, D.-D.; Ludwig, H.-M. Rice husk ash as both pozzolanic admixture and internal curing agent in ultra-high performance concrete. Cem. Concr. Compos. 2014, 53, 270–278.

- Hamzah, N.; Saman, H.M.; Sam, A.R.M.; Sidek, M.N.M.; Loo, P.; Latif, S.A.A. Green artificial aggregates as self-curing agent in concrete. IOP Conf. Ser. Mater. Sci. Eng. 2020, 849, 012061.

- Ahmed, A.T.M.F.; Islam, M.Z.; Mahmud, M.S.; Sarker, M.E.; Islam, M.R. Hemp as a potential raw material toward a sustainable world: A review. Heliyon 2022, 8, e08753.

- Jami, T.; Karade, S.R.; Singh, L.P. A review of the properties of hemp concrete for green building applications. J. Clean. Prod. 2019, 239, 117852.

- Sáez-Pérez, M.P.; Brümmer, M.; Durán-Suárez, J.A. A review of the factors affecting the properties and performance of hemp aggregate concretes. J. Build. Eng. 2020, 31, 101323.

- Gourlay, E.; Glé, P.; Marceau, S.; Foy, C.; Moscardelli, S. Effect of water content on the acoustical and thermal properties of hemp concretes. Constr. Build. Mater. 2017, 139, 513–523.

- Arrigoni, A.; Pelosato, R.; Melià, P.; Ruggieri, G.; Sabbadini, S.; Dotelli, G. Life cycle assessment of natural building materials: The role of carbonation, mixture components and transport in the environmental impacts of hempcrete blocks. J. Clean. Prod. 2017, 149, 1051–1061.

- Jiang, Y.; Lawrence, M.; Ansell, M.; Hussain, A. Cell wall microstructure, pore size distribution and absolute density of hemp shiv. R. Soc. Open Sci. 2018, 5, 171945.

- Collet, F.; Prétot, S.; Chamoin, J.; Lanos, C. Hydric characterization of sprayed hempcrete. In Proceedings of the 4th International Building Physics Conference, Istanbul, Turkey, 15–18 June 2009.

- Collet, F.; Bart, M.; Serres, L.; Miriel, J. Porous structure and water vapour sorption of hemp-based materials. Constr. Build. Mater. 2008, 22, 1271–1280.

- Xie, Y.; Hill, C.A.; Jalaludin, Z.; Curling, S.F.; Anandjiwala, R.D.; Norton, A.J.; Newman, G. The dynamic water vapour sorption behaviour of natural fibres and kinetic analysis using the parallel exponential kinetics model. J. Mater. Sci. 2011, 46, 479–489.

- Bentz, D.P.; Weiss, W.J. Internal Curing: A 2010 State-of-the-Art Review; US Department of Commerce, National Institute of Standards and Technology: Gaithersburg, MD, USA, 2011.

- Galan, I.; Baldermann, A.; Kusterle, W.; Dietzel, M.; Mittermayr, F. Durability of shotcrete for underground support–Review and update. Constr. Build. Mater. 2019, 202, 465–493.

- Bentz, D.P.; Lura, P.; Roberts, J.W. Mixture Proportioning for Internal Curing; Concrete International: Farmington Hills, MI, USA, 2005; pp. 35–40.

- Weiss, J.; Bentz, D.; Schindler, A.; Lura, P. Internal curing. In Structure; NCSEA: Reedsburg, WI, USA, 2012; pp. 10–13. Available online: https://www.structuremag.org/?page_id=17956 (accessed on 30 April 2023).

- Wang, J.; Xie, Y.; Zhong, X.; Li, L. Test and simulation of cement hydration degree for shotcrete with alkaline and alkali-free accelerators. Cem. Concr. Compos. 2020, 112, 103684.

- Kim, J.H.; Choi, S.W.; Lee, K.M.; Choi, Y.C. Influence of internal curing on the pore size distribution of high strength concrete. Constr. Build. Mater. 2018, 192, 50–57.

- Onuaguluchi, O.; Banthia, N. Plant-based natural fibre reinforced cement composites: A review. Cem. Concr. Compos. 2016, 68, 96–108.

- Jongvisuttisun, P.; Leisen, J.; Kurtis, K.E. Key mechanisms controlling internal curing performance of natural fibers. Cem. Concr. Res. 2018, 107, 206–220.

- Guo, A.; Sun, Z.; Satyavolu, J. Impact of modified kenaf fibers on shrinkage and cracking of cement pastes. Constr. Build. Mater. 2020, 264, 120230.

- Manaia, J.P.; Manaia, A.T.; Rodriges, L. Industrial hemp fibers: An overview. Fibers 2019, 7, 106.

- Arnaud, L.; Gourlay, E. Experimental study of parameters influencing mechanical properties of hemp concretes. Constr. Build. Mater. 2012, 28, 50–56.

- Castro, J.; Keiser, L.; Golias, M.; Weiss, J. Absorption and desorption properties of fine lightweight aggregate for application to internally cured concrete mixtures. Cem. Concr. Compos. 2011, 33, 1001–1008.

- ASTM C1761/C1761M-17; Standard Specification for Lightweight Aggregate for Internal Curing of Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- Liu, J.; Khayat, K.H.; Shi, C. Effect of superabsorbent polymer characteristics on rheology of ultra-high performance concrete. Cem. Concr. Compos. 2020, 112, 103636.

- Yang, L.; Shi, C.; Liu, J.; Wu, Z. Factors affecting the effectiveness of internal curing: A review. Constr. Build. Mater. 2020, 267, 121017.

- Bentz, D.P.; Snyder, K.A. Protected paste volume in concrete: Extension to internal curing using saturated lightweight fine aggregate. Cem. Concr. Res. 1999, 29, 1863–1867.

- Zhutovsky, S.; Kovler, K.; Bentur, A. Assessment of distance of water migration in internal curing of high-strength concrete. In ACI SP-220 ‘Autogenous Deformation Concrete’; American Concrete Institute: Farmington Hills, MI, USA, 2004; pp. 181–197.

- Rößler, C.; Bui, D.-D.; Ludwig, H.-M. Mesoporous structure and pozzolanic reactivity of rice husk ash in cementitious system. Constr. Build. Mater. 2013, 43, 208–216.

- Campbell, M.; Coutts, R. Wood fibre-reinforced cement composites. J. Mater. Sci. 1980, 15, 1962–1970.

- Lewis, G.; Premalal, M. Natural vegetable fibres as reinforcement in cement sheets. Mag. Concr. Res. 1979, 31, 104–108.

- Gwon, S.; Choi, Y.C.; Shin, M. Effect of plant cellulose microfibers on hydration of cement composites. Constr. Build. Mater. 2021, 267, 121734.

- Jongvisuttisun, P.; Kurtis, K.E. The role of hardwood pulp fibers in mitigation of early-age cracking. Cem. Concr. Compos. 2015, 57, 84–93.

- Mezencevova, A.; Garas, V.; Nanko, H.; Kurtis, K.E. Influence of thermomechanical pulp fiber compositions on internal curing of cementitious materials. J. Mater. Civ. Eng. 2012, 24, 970–975.

- Kawashima, S.; Shah, S.P. Early-age autogenous and drying shrinkage behavior of cellulose fiber-reinforced cementitious materials. Cem. Concr. Compos. 2011, 33, 201–208.

- Song, C.; Choi, Y.C.; Choi, S. Effect of internal curing by superabsorbent polymers–internal relative humidity and autogenous shrinkage of alkali-activated slag mortars. Constr. Build. Mater. 2016, 123, 198–206.

- Bentur, A.; Igarashi, S.-i.; Kovler, K. Prevention of autogenous shrinkage in high-strength concrete by internal curing using wet lightweight aggregates. Cem. Concr. Res. 2001, 31, 1587–1591.

- Zeng, Q.; Li, K.; Fen-chong, T.; Dangla, P. Pore structure characterization of cement pastes blended with high-volume fly-ash. Cem. Concr. Res. 2012, 42, 194–204.

- Mehta, P.K.; Monteiro, P.J. Concrete Microstructure, Properties and Materials; McGraw-Hill Education: New York, NY, USA, 2017.

- Delhomme, F.; Hajimohammadi, A.; Almeida, A.; Jiang, C.; Moreau, D.; Gan, Y.; Wang, X.; Castel, A. Physical properties of Australian hurd used as aggregate for hemp concrete. Mater. Today Commun. 2020, 24, 100986.

- Jiang, Y.; Lawrence, M.; Hussain, A.; Ansell, M.; Walker, P. Comparative moisture and heat sorption properties of fibre and shiv derived from hemp and flax. Cellulose 2019, 26, 823–843.

- Lee, N.K.; Abate, S.Y.; Kim, H.-K. Use of recycled aggregates as internal curing agent for alkali-activated slag system. Constr. Build. Mater. 2018, 159, 286–296.

- Li, Z.; Liu, J.; Xiao, J.; Zhong, P. Internal curing effect of saturated recycled fine aggregates in early-age mortar. Cem. Concr. Compos. 2020, 108, 103444.

- Jensen, O.M.; Pietro, L. Techniques for internal water curing of concrete. Adv. Cem. Concr. 2003, 1, 67–78.

- Niyigena, C.; Amziane, S.; Chateauneuf, A.; Arnaud, L.; Bessette, L.; Collet, F.; Lanos, C.; Escadeillas, G.; Lawrence, M.; Magniont, C. Variability of the mechanical properties of hemp concrete. Mater. Today Commun. 2016, 7, 122–133.

- Hussain, A.; Calabria-Holley, J.; Lawrence, M.; Jiang, Y. Resilient hemp shiv aggregates with engineered hygroscopic properties for the building industry. Constr. Build. Mater. 2019, 212, 247–253.

This entry is offline, you can click here to edit this entry!