The term “sea waste” generally refers to any solid, liquid, or gaseous material or substance that is discarded, disposed of, or abandoned in the ocean, sea, or any other body of salty water, such as a lagoon, etc. This includes waste generated by human activities on land that makes its way into the ocean, as well as waste generated by ships and other vessels at sea. Examples of sea waste include plastic debris, chemicals and toxic substances, oil spills, sewage, and other forms of pollution. These pollutants can harm marine ecosystems, endanger marine life, and impact human health and wellbeing. Sea waste can be recovered by its use into composite materials, as their reinforcement or as their matrix.

1. Reinforcements

1. Ceramic Fillers

The high purity of calcium carbonate content (95–97%) of mussel shells makes this filler, when powdered, a suitable component in cement, and in particular as the replacement for aggregate. In this sense, mussel shells represent one of the so-called “aquaculture modifiers”, together with, e.g., oyster shells or scallop shells, which are globally presented in [

25]. In the case of polymers, calcium carbonate is frequently used to reduce their cost, improve their properties (in particular hardness), and better control their rheology during molding. As a substitute for extracted limestone, mussel shells are lately in competition with eggshell powder (ESP), which also has around 95% calcium carbonate content [

26]. The two fillers have their origin as food industry waste in common. However, it can also be observed that calcium carbonate is prevalently formed by aragonite crystals, a high-density and -hardness material; thence it is very adapted as a bio-filler for polymer matrices [

27]. Some uncertainty remains about whether the few percentages of proteinaceous matter present in both of them would effectively link with the polymer or should be removed, possibly by thermal degradation, as they might harm the performance of the manufactured materials [

28].

The use of seashells in thermoplastic polymers requires more sophisticated methods, such as directly blending in polymer pellets before twin-screw extrusion, such as in [

29] where proportions of seashells (SS) of up to 18% were introduced in a nylon-6 matrix. Seashell content of up to 15% increases the composite crystallinity, leading to higher storage modulus, and at 18% content, SS leads to a more pronounced elastic behavior, as indicated by the lower loss modulus, though the temperature for degradation onset is lower for higher oxidative stability.

Another possibility regarding the use of calcium carbonate from seashells is its introduction in a bio-based polymer, as is the case for bio-epoxy. The work from Fombuena et al. evidenced as two main points the significant increase in flexural properties, up to 50%, achievable through the introduction of 30 wt.% seashell calcium carbonate, and, once again, the higher thermal stability subsequently reached, with an increase in glass transition temperature from 80.6 °C to 91 °C [

30]. A similar work, though focusing on bio-polyurethane with 25% castor oil resin content, was carried out in [

31] to improve the sound absorption characteristics of polyurethane foam, namely below 500 Hz, and at the same time to enhance its compression strength. To try to standardize test results, especially in regards to thermal characterization, it is essential to offer indications about the exact species from which the shells are obtained, as was the case for one of the first studies in the sector, concerning

Rapana Thomasiana, a type of sea-snail [

32]. To continue with the specific applications of seashell powder obtained from selected species encountered in sea waste, the use of cowrie shell powder in polypropylene-acrylonitrile injection-molded composites has also been reported [

33].

1.2. Cellulosic Fillers

The function of filler in polymer matrices of different origins and nature can also be exerted by fibers obtained from prevalently cellulosic sea-derived waste—namely algae and other plants such as

Posidonia oceanica—growing at sea, yet extirpated from particular areas, typically due to weather-related events or to specific activities, such as trawl fishing [

52]. These materials would become refuse unless economic opportunities for recycling are offered. In the case of Posidonia, an over-abundant waste in the Mediterranean context, and a refuse produced in quantities which can be only partially used for seashore protection, a proposal has been made for it to become a raw material for the wood chipboard industry [

53]. A further possibility, given the high amount and crystallinity of cellulose present, e.g., in algae cells, is the extraction of microcrystalline cellulose (MCC) from this waste [

54,

55]. This offers some interest, though it might be chemically intensive due to the substantial use of acids required, and is also strongly dependent on the algal species for MCC yield.

For the possible use of cellulosic marine waste in composites, the same issue reported above for ceramic fillers appears critical and requires attention. In practice, the limited knowledge of engineers about the botanical nature, properties, and origin of cellulosic biomass results in an equally incomplete development of possible biocomposites from their use, as reported in [

56]. This suggests that a multidisciplinary approach is increasingly needed in this respect, especially for the large and gradually growing number of species involved in experimentation with natural fiber composites. In a waste management approach, it is often the case that biomass from various species is available, so that it can be introduced in a polymer matrix. This occurred, e.g., with

Chlorella vulgaris, from algal oil extraction, when mixed biomass from two further species, such as

Enteromorpha and

Zostera marina, were introduced in a polyurethane elastomer matrix [

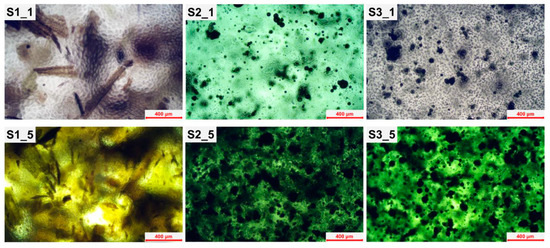

57]. The morphological differences between the species were not negligible, as shown in

Figure 1; however, they were not prevented from being applied as the reinforcement of the same matrix.

Figure 1. Optical micrograph of algae-thermoplastic polyurethane composites. S1 was filled with an

Enteromorpha–

Zostera marina blend, S2 with

Chlorella vulgaris after oil extraction, and S3 with

Chlorella vulgaris before oil extraction [

57]. (Figures marked with 1 do represent samples with 1 wt.% algae, while those marked with 5 do represent samples with 5 wt.% algae) Distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

2. Sea Waste Polymer Matrices

An additional possibility is linked to the extraction of polymers from sea waste in order to provide added functionalities as a matrix in composites for various uses. An example of this prospect is given by the mixing of chitosan, extracted from refuse shrimp shells, with

Ulva lactuca fibers in a biocomposite; this proved effective for the biosorption of cadmium ions (Cd II), most effectively at pH = 5.5 [

73]. The aforementioned work is capable of possible extension, since a similar mixture also worked for the removal of mercury from aqueous solutions at a more acidic pH = 4 [

74]. It is normally considered more straightforward to proceed to the deacetylation of waste sea shrimps’ chitin into chitosan to improve water retention properties; therefore, to provide possible interfaces for hydrophilic fillers, such as lignocellulosic fibers [

75]. Despite this, the reduction into powder of chitin from seashell waste for the prospective preparation of pellets for injection molding has been considered [

76].

Beyond the chitin/chitosan system of crustaceans, such as sea shrimps, products from excess algae biomass have also been considered in the production of biopolymers and, prospectively, bio-composite matrices: this is the case for alginates [

77], alginic acid [

78], and carrageenan, used more specifically for drug delivery purposes [

79]. The blending of the two biomasses of the wastes, chitosan, and

Cladophora algae also showed some promising properties for the removal of heavy metals ions, such as Cr(III), Cu(II), and Ni(II), from water solutions [

80].

This entry is adapted from the peer-reviewed paper 10.3390/jmse11040855