Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Fermentation is a metabolic process of conversion of an organic substrate by the action of enzymes. It is a completely natural process that occurs unhindered in nature.

- spirit

- yeast

- fermentation

- aroma compounds

- volatiles

1. Introduction

Fermentation is a metabolic process of conversion of an organic substrate by the action of enzymes. It is a completely natural process that occurs unhindered in nature. It could be said that fermentation is older than the human race because the first fermented products were actually fermented wild fruits. People have been taking advantage of fermentation for thousands of years. Fermentation by selected microbes gives foods new, improved sensory properties, longer shelf life, better nutritional properties, and higher health value [1]. Therefore, people have learned to manage, control, and optimize the fermentation process to achieve better quality of the final product at optimal cost. The simplified definition of alcoholic fermentation (AF) states that it is the conversion of sugar by yeast into ethanol and carbon dioxide with the release of energy. The energy released is necessary for the vital activities of yeast. AF, however, is a very complex biochemical process in which low molecular weight sugars are converted by the action of yeast strains into alcohol and CO2 as the main product of alcoholic fermentation, as well as hundreds of other chemical compounds belonging to different chemical classes. Some of them are present in very low concentrations but may have effects on the final product. All of these major and minor chemical compounds of AF form the aroma profile of alcoholic beverages. The aroma profile is the most important characteristic for consumer acceptance and preferences of beverages. It seems that AF plays a crucial role in the production of alcoholic beverages: beer, wine, spirits, and all their derivatives.

Fruit spirits, such as grain and sugar spirits, are a very popular beverage made by fermenting various fruits, grains, and vegetables and distilling the resulting fermented mash. The production of spirits begins with the preparation of the raw material. For this purpose, ripe, high-quality fruits are selected, washed, and cut into small pieces. Fruits provide primary aroma substances that allow to distinguish one fruit spirit from another. It is known that the fruit variety gives a specific sensory note to fruit spirits [2][3][4][5][6][7][8][9][10]. The fruit is then mashed or crushed to release the juice. The production of grain spirits requires saccharification of the starch raw materials to fermentable sugars with enzymes or malt [11]. The next step is fermentation of the raw materials, where yeast consumes the sugars and produces alcohol and a series of volatile compounds. This aroma is called fermentation or secondary aroma. After fermentation, the fermented marc is distilled, and the alcohol and volatile compounds are separated from the fermented solution. Volatile compounds are also formed during the distillation process [12][13]. Some compounds are formed while others are degraded. By separating the fractions, it is also possible to control the amount and type of volatile aromatic compounds in the distillates. Distillation ultimately concentrates the volatile aromatic compounds and enhances their aromatic influence. The aroma produced during distillation is referred to as tertiary aroma. Different distillation processes, such as pot still distillation and column distillation, influence the final flavor and aroma of the spirit [14][15]. During the aging process, additional aroma compounds are formed [16]. The distilled spirit can be aged in wooden barrels or in inert casks, which significantly affects the overall sensory characteristics of the product. The aging process can last from several months to several years, depending on the desired final product. This aging aroma provides crucial opportunities for achieving a positive and distinct sensory characteristic of spirits aged in wooden barrels. The aroma formed during aging is referred to as quaternary aroma. Once the spirit has achieved the desired flavor and aroma profile, it is bottled and sold as a fruit spirit such as Šljivovica, William’s pear brandy or apple brandy, grain spirits such as whiskey or vodka, or sugar spirits such as rum or honey brandy.

2. Spirits Are More than Just Alcohol and Water—They Conclude the Essence of the Scent

Spirit is not consumed for its nutritional value, but primarily for the pleasure it gives. Pleasure is something very personal, and in the case of spirits, it is based mainly on the perception of their sensory qualities. The quality of spirits is evaluated by the consumer on the basis of the sensory perception of their properties. The sensory perception of spirits is the result of the action of a variety of chemical compounds contained in the alcohol–water mixture. Spirits can be sweet and sour in taste, rarely bitter, but they are never salty or umami. This is especially true for unaged distillates without the addition of other flavors or other ingredients.

In aged distillates, the taste of spirits can be more intense in terms of sweetness, bitterness, and acidity due to the action of wood, even in flavored spirits. In contrast to taste, spirits are characterized by their intense odor. The smell is the most important determinant of the sensory quality of spirits and reaches the brain via orthonasal (odor) and retronasal pathways (aroma). Since spirits contain compounds that can evoke trigeminal impressions such as pungent, acrid, and astringent, flavor is the best term to describe the overall sensory perception of spirits. According to ISO 5492, flavor is the complex combination of olfactory, gustatory and trigeminal sensations perceived during tasting.

The sensory impression of fruit spirits depends on hundreds of individual chemical compounds present in an ethanol–water matrix. This very complex mixture contains more than 500 compounds [17] belonging to very different chemical classes: alcohols, esters, aldehydes, ketones, acids, volatile phenols, sulfur compounds, and terpenes. It is essential for the sensory acceptance of the spirit that all the compounds present are in balance with each other and give a pleasant, harmonious impression of beverages. To achieve this, care must be taken at every stage of the spirit production process, from the selection of raw material, through crushing and introduction into fermentation, fermentation conditions, distillation, and finally, the ageing and care of the spirits. Recognizing that the consumer controls consumption, the distilling industry has transformed; producers have become more innovative, introducing new technologies and investing in research. Every effort is made to obtain a product that is safe for health and has the desired sensory characteristics.

3. The Research of Spirits Aroma Approach

Numerous studies have been conducted to investigate minor and major flavor compounds in spirits. The number of compounds detected has increased as instrumental methods for flavor investigation have improved, and the composition of spirits is now much clearer [10][17][18][19][20][21][22].

Volatiles are usually analyzed by gas chromatography (GC), which has been greatly improved over time. The GC method has evolved in all areas: column selection, carrier gas selection, temperature programming, injector selection, injector temperature, detector selection, and detector temperature [23]. Aromatic components are now determined using advanced and novel GC methods. Thus, solid-phase microextraction mass spectrometry (SPME-MS) and fast gas chromatography-based electronic nose (GC-E-Nose) have been used and compared in terms of their suitability for discriminating baijiu of different aromatic types and geographical origin [24]. The electronic nose-based on ultrafast gas chromatography was used for the rapid analysis of 24 samples of raw spirits from different cereals [19]. Paolini et al. [22] applied a rapid GC-FID method to identify volatile compounds in spirits. Comprehensive two-dimensional gas chromatography-mass spectrometry analysis (GCxGCxMS) combined with time-off-light mass spectrometry (GC-GC /TOFMS) or with gas chromatography-olfactometry (GC-O) is a powerful technique for the analysis of complex volatiles and allows the identification of minor compounds [25][26][27][28][29][30]. For the differentiation of volatile profiles of eight baijiu distillates, an advanced detection technology involving liquid–liquid microextraction (LLME) combined with gas chromatography-mass spectrometry (GC-MS) and head-space gas chromatography-ion mobility spectrometry (HS-GC-IMS) were used. The profiling of volatiles in soybean Korean brandy was obtained by a novel solid-phase microextraction technique (SPME Arrow technology GC-MS) [31]. Barnes et al. [32] developed a versatile analytical method for the analysis of aroma compounds in various types of distillates produced in micro-distilleries.

As Chambers and Koppel [33] noted, there are many different methods, but all are based on the separation, identification, and quantification of compounds either in headspace or in the actual product matrix.

With the development of instrumental methods, statistical and sensory analyses are also being developed, leading to a better understanding of the relationship between individual chemical compounds and sensory properties of spirits. Hanousek-Čiča et al. [34] used multivariate analysis to classify wine spirits based on their phenolic and volatile compounds. Ivanović et al. [35] performed GC-FID-MS metabolomics to identify 89 compounds in plum spirits and determined the correlation of plum spirit profiles with their sensory properties by dimensional orthogonal projections onto latent structures (OPLS) multivariate analysis. Bajer et al. [36] used OPLS to interpret the correlations between volatile profiles and fruit spirit type. Principal component analysis seems to be the most commonly used statistical analysis to investigate possible groupings of spirit samples based on the aroma compounds studied. Numerous studies with publication dates as recent as possible have been published using PCA as a method to distinguish different spirit samples based on their aroma composition [36][37][38][39][40][41][42][43][44][45][46][47]. Other common methods for clustering different spirits based on their aroma composition include hierarchical cluster analysis or heat map and partial least squares [48][49][50][51][52][53][54]. These techniques provide a clear visual representation of the relationships between aroma compounds and their sensory contributions to spirits or between aroma compounds and the origin and type of spirit.

4. Aroma Compounds in Spirts

As mentioned above, spirits contain a large number of aroma compounds, derived from raw materials and formed during the various stages of production. However, AF produces most of the compounds [3] that will be transferred to spirits by distillation.

4.1. Aroma Compounds Treated during Alcohol Fermentation

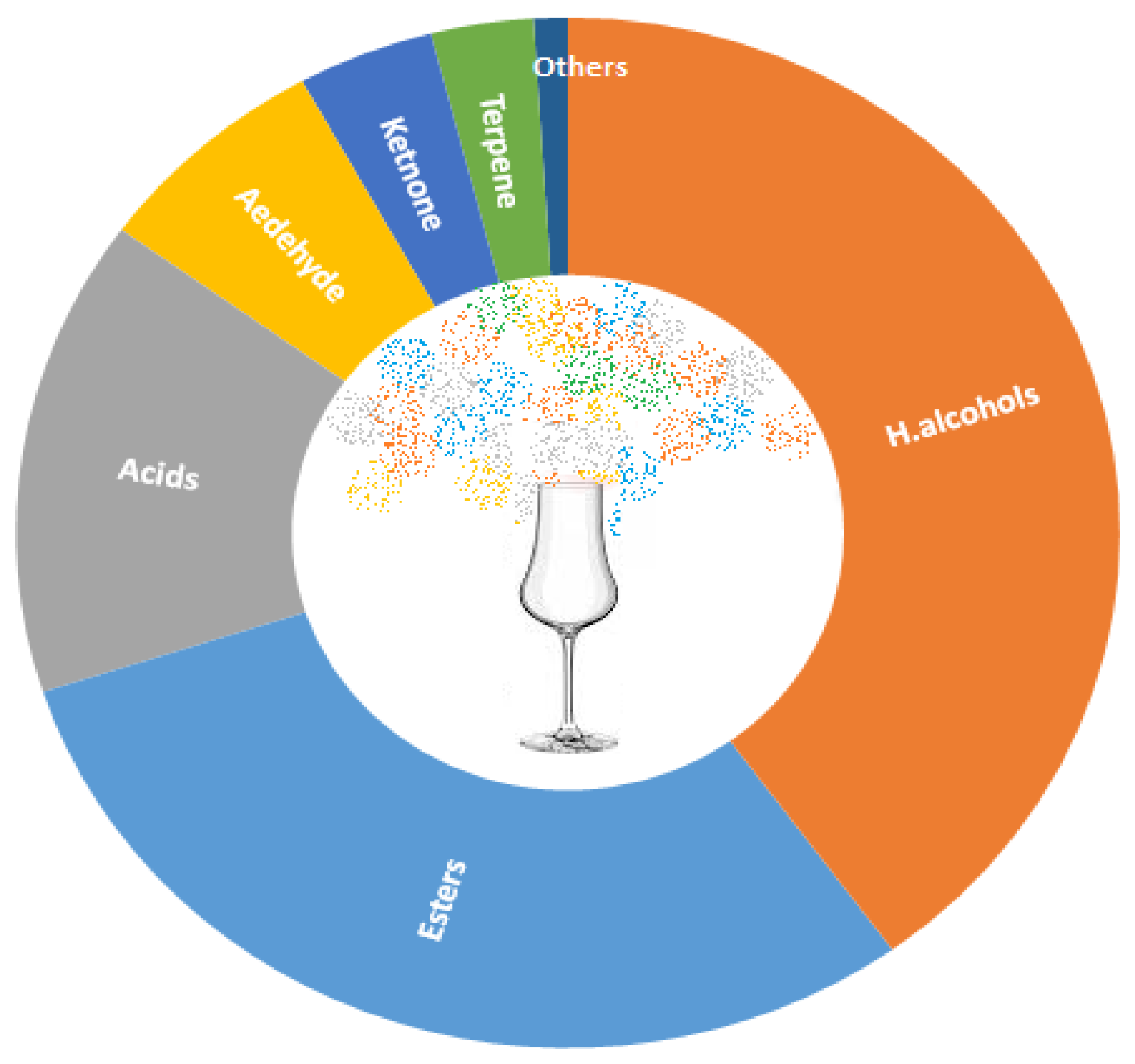

During the fermentation process, microorganisms convert sugars from raw materials into ethanol, carbon dioxide, and glycerol as the main product of AF and a variety of by-products or intermediates. This complex biochemical process produces hundreds of compounds belonging to different chemical classes, such as alcohols, esters, aldehydes, ketones, acids, and phenols. Although the principle of AF is the same for all alcoholic beverages, the amounts and types of secondary metabolites in beer, wine, and spirits differ significantly, which affects their different sensory properties. Since spirits contain only volatile compounds because they are a product of the distillation process, they are given more attention here. The most abundant compounds in spirits are higher alcohols, followed by esters, acids, and aldehydes (Figure 1). Most of these compounds are fermentative aroma compounds produced by yeast activity. They are mainly the most important flavoring substances in spirits.

Figure 1. Representation of chemical classes in spirits.

4.2. Factors Influencing the Development of Aroma Compounds

Many factors affect the chemical composition of the volatile profile of the spirit, including the type and variety of fruit and its quality, AF, distillation, and storage conditions. As mentioned above, yeasts are the main producers of ethanol and volatile aroma compounds in the fermented substrate. Therefore, it can be said that yeast is the heart of AF. The selection of appropriate yeast strains is crucial for maximizing alcohol yield and achieving appropriate and attractive sensory characteristics of spirits. Walker [55] suggests and Pauley and Maskell [56] have additionally added to the concept of the ideal distillery yeast, reporting the following characteristics: high ethanol yield; tolerance to ethanol, heat, and high sugar stress; rapid fermentation of available sugars; production of the correct balance of flavor congeners; high viability during storage; and antibacterial and non-flocculating properties. A yeast with these diverse properties does not yet exist, the closest being the Saccharomyces cerevisiae species. Saccharomyces yeasts currently dominate the fermented beverage industry, but consumer demand for alternative products with different sensory profiles and actual or perceived health benefits is driving the diversification and use of non-Saccharomyces yeasts [57].

5. Aroma Active Compounds

As mentioned earlier, numerous studies have been conducted to investigate the composition of different types of spirits and to measure various influences on the amount of compounds present. However, there is surprisingly little work that determines the content of aroma-active compounds. The mere presence of an aromatic component does not mean that it has a sensory impact on the flavor profile of the spirit. The compound must be present in sufficient quantity to be perceived by humans. Sometimes, the amount must be high for the compound to be perceived; sometimes, the compound can be present in very low concentrations and the consumer can still perceive it. The concentrations of the compound at which it is perceived depend on its odor threshold. This is the lowest concentration of the compound that is detected by smelling (orthonasal) or testing (retronasal). The sensitivity of aroma compounds can be compared based on the threshold concentration [58].

Spirits are a highly complex mixture with hundreds of aroma compounds that provide a fingerprint for the raw material, origin, and method of production. The contributions of these compounds to the aroma profile are not equal. Some of them are more potent and contribute more to the aroma intensity, quality, or, sometimes, aroma character of spirits. The majority of potent aroma compounds have a low odor threshold. To quantify the contribution of each aroma substance to the aroma profile, the odor activity value (OAV) was introduced. The OAVs of the aroma compounds were calculated from the ratio of the concentrations detected in spirits compared to their threshold values, which are usually reported in the relevant literature [59]. This ratio is also referred to as odor value, odor unit, flavor unit, or aroma value.

OAV = C/T (1)

where C is the concentration of the compound, and OT is its detection odor threshold.

Compounds with high aroma values (greater than 1) may contribute to the aroma profile and actively participate in the overall aroma profile or aromagram of the product. He et al. [59] detected a total of 140 volatile compounds in baijiu samples during distillation by GC-MS, of which 50 contributed to the overall aroma profile. Among the aroma-active compounds, ethyl hexanoate had the highest OAV (7653–46,521), followed by ethyl butanoate, ethyl pentanoate, and ethyl octanoate. In the heart fractions of wine distillates, 45 odor-active compounds were identified by aroma extract dilution analysis (AEDA), but 22 of them had OAVs ≥ 1 [60]. Hong et al. [61] also investigated the contribution of individual aroma compounds to gain deeper insight into their involvement in the aroma diagram of Nongxiangxing baijiu samples. They found 18 aroma compounds with OAVs > 1, and they had strong correlation with flavor attributes and distinct aroma characteristics. The study by Spaho et al. [62] focused on the identification of some aroma active compounds in apple spirits. Among six aroma compounds, they found that ethyl benzoate and benzaldehyde had the largest OAVs. Among the 128 different types of aroma compounds found in litchi (Heiye) wine and distilled spirits, 22 aroma compounds had an OAV ≥ 1 [63]. Considering the OAVs, the authors evaluated the characteristic aromas for lychee distillate based on the elevated concentrations and OAVs of β-damascenone, linalool, ethyl butyrate, ethyl isovalerate, ethyl caproate, trans-rose oxide, and cis-rose oxide. Of the 62 aroma-impacting compounds identified in distilled peach spirit, 14 were considered important for aroma with OAVs ≥ 1 [64]. In traditional Japanese spirits, 14 compounds affect quality, of which β-damascenone has the highest OAV [65].

Although OAV is a good indicator of aroma constituents or key aroma components, it is not a definitive indicator of the actual importance of aroma components in products. As noted by Ferreira et al. [66], there are limitations to OAVs, such as that thresholds are relatively uncertain, OAVs are not strictly related to aroma intensity, and OAVs do not account for the presence of other aromatic compounds that may be enhanced or altered by synergistic or masking effects.

This entry is adapted from the peer-reviewed paper 10.3390/foods12101951

References

- Sharma, R.; Garg, P.; Kumar, P.; Bhatia, S.K.; Kulshrestha, S. Microbial Fermentation and Its Role in Quality Improvement of Fermented Foods. Fermentation 2020, 6, 106.

- Satora, P.; Tuszyński, T. Chemical characteristics of Śliwowica Łącka and other plum brandies. J. Sci. Food Agric. 2008, 88, 167–174.

- Lukić, I.; Tomas, S.; Milicević, B.; Radeka, S.; Peršuric, Ð. Behaviour of Volatile Compounds during Traditional Alembic Distillation of Fermented Muscat Blanc and Muškat Ruža Porecki Grape Marcs. J. Inst. Brew. 2011, 117, 440–450.

- Arrieta-Garay, Y.; García-Llobodanin, L.; Pérez-Correa, J.R.; López-Vázquez, C.; Orriols, I.; Lopez, F. Aromatically Enhanced Pear Distillates from Blanquilla and Conference Varieties Using a Packed Column. J. Agric. Food Chem. 2013, 61, 4936–4942.

- Spaho, N.; Dürr, P.; Grba, S.; Velagić-Habul, E.; Blesić, M. Effects of distillation cut on the distribution of higher alcohols and esters in brandy produced from three plum varieties. J. Inst. Brew. 2013, 119, 48–56.

- Rodriguez-Solana, R.; Galego, L.R.; Perez-Santin, E.; Romano, A. Production method and varietal source influence the volatile profiles of spirits prepared from fig fruits (Ficus carica L.). Eur. Food Res. Technol. 2018, 244, 2213–2229.

- Popović, B.; Mitrović, O.; Leposavić, A.; Paunović, S.; Jevremović, D.; Nikićević, N.; Tešević, V. Chemical and sensory characterization of plum spirits obtained from cultivar Čačanska Rodna and its parent cultivars. J. Serb. Chem. Soc. 2019, 84, 1381–1390.

- Januszek, M.; Satora, P.; Tarko, T. Oenological Characteristics of Fermented Apple Musts and Volatile Profile of Brandies Obtained from Different Apple Cultivars. Biomolecules 2020, 10, 853.

- Schwarz, M.; Rodríguez-Dodero, M.C.; Jurado, M.S.; Puertas, B.; Barroso, C.G.; Guillén, D.A. Analytical Characterization and Sensory Analysis of Distillates of Different Varieties of Grapes Aged by an Accelerated Method. Foods 2020, 9, 277.

- Magdas, D.A.; Cristea, G.; Pîrnau, A.; Feher, I.; Hategan, A.R.; Dehelean, A. Authentication of Transylvanian Spirits Based on Isotope and Elemental Signatures in Conjunction with Statistical Methods. Foods 2021, 10, 3000.

- Bathgate, G.N. A review of malting and malt processing for whisky distillation. J. Inst. Brew. 2016, 122, 197–211.

- Awad, P.; Athès, V.; Esteban Decloux, M.; Ferrari, G.; Snakkers, G.; Raguenaud, P.; Giampaoli, P. Evolution of Volatile Compounds during the Distillation of Cognac Spirit. J. Agric. Food Chem. 2017, 65, 7736–7748.

- Lourenço, S.; Anjos, O.; Caldeira, I.; Alves, S.O.; Santos, N.; Canas, S. Natural Blending as a Novel Technology for the Production Process of AgedWine Spirits: Potential Impact on Their Quality. Appl. Sci. 2022, 12, 10055.

- Spaho, N. Distillation techniques in the fruit spirits production. In Distillation—Innovative Applications and Modeling; Mendes Fernandes, M., Ed.; IntechOpen: London, UK, 2017; Chapter 6; pp. 129–152.

- Spaho, N.; Đukic-Ratković, D.; Nikićević, N.; Blesić, M.; Tešević, V.; Mijatović, B.; Smajić Murtić, M. Aroma compounds in barrel aged apple distillates from two different distillation techniques. J. Inst. Brew. 2019, 125, 389–397.

- Wang, L.; Chen, S.; Xu, Y. Distilled beverage aging: A review on aroma characteristics, maturation mechanisms, and artificial aging techniques. Compr. Rev. Food Sci. 2023, 22, 502–534.

- Tsakiris, A.; Kallithraka, S.; Kourkoutas, Y. Grape brandy production, composition and sensory evaluation. J. Sci. Food Agric. 2014, 94, 404–414.

- Coldea, T.E.; Socaciu, C.; Moldovan, Z.; Mudura, E. Minor Volatile Compounds in Traditional Homemade Fruit Brandies from Transylvania-Romania, As Determined by GC-MS Analysis. Not. Bot. Horti Agrobot. Cluj-Napoca 2014, 42, 530–537.

- Wiśniewska, P.; Śliwińska, M.; Namieśnik, J.; Wardencki, W.; Dymerski, T. The Verification of the Usefulness of Electronic Nose Based on Ultra-Fast Gas Chromatography and Four Different Chemometric Methods for Rapid Analysis of Spirit Beverages. J. Anal. Methods Chem. 2016, 2016, 8763436.

- Matijašević, S.; Popović-Djordjević, J.; Ristić, R.; Ćirković, D.; Ćirković, B.; Popović, T. Volatile Aroma Compounds of Brandy ‘Lozovača’ Produced from Muscat Table Grapevine Cultivars (Vitis vinifera L.). Molecules 2019, 24, 2485.

- Pineda-Amaya, A.C.; Ocaña-Rios, I.; García-Aguilera, M.E.; Nolasco-Cancino, H.; Quiroz-García, B.; Esturau-Escofet, N.; Ruiz-Terán, F. 1H-NMR profile of mezcal and its distillation fractions using two sample preparation methods: Direct analysis and solid-phase extraction. Chem. Pap. 2021, 75, 4249–4259.

- Paolini, M.; Tonidandel, L.; Larcher, R. Development, validation and application of a fast GC-FID method for the analysis of volatile compounds in spirit drinks and wine. Food Control 2022, 136, 108873.

- Bhardwaj, K.S.; Dwivedi, K.; Agarwal, D.D. A Review: GC Method Development and validation. Int. Anal. Bioanal. Chem. 2016, 6, 1–7.

- He, X.; Yangming, H.; Górska-Horczyczak, E.; Wierzbicka, A.; Jeleń, H.H. Rapid analysis of Baijiu volatile compounds fingerprint for their aroma and regional origin authenticity assessment. Food Chem. 2021, 337, 128002.

- Zenilda, L.; Cardeal, P.; Marriott, J. Comprehensive two-dimensional gas chromatography–mass spectrometry analysis and comparison of volatile organic compounds in Brazilian cachaça and selected spirits. Food Chem. 2009, 112, 747–755.

- Vyviurska, O.; Pysarevska, S.; Jánošková, N.; Špánik, I. Comprehensive two-dimensional gas chromatographic analysis of volatile organic compounds in distillate of fermented Sorbus domestica fruit. Open Chem. 2015, 13, 96–104.

- Yao, F.; Yi, B.; Shen, C.; Tao, F.; Liu, Y.; Lin, Z.; Xu, P. Chemical Analysis of the Chinese Liquor Luzhoulaojiao by Comprehensive Two-Dimensional Gas Chromatography/Time-of-Flight Mass Spectrometry. Sci. Rep. 2015, 5, 9553.

- Wisniewska, P.; Sliwinska, M.; Dymerski, T.; Wardencki, W.; Namiesnik, J. Comparison of an Electronic Nose Based on Ultrafast Gas Chromatography, Comprehensive Two Dimensional Gas Chromatography, and Sensory Evaluation for an Analysis of Type of Whisky. J. Chem. 2017, 2017, 2710104.

- Mogollón, N.G.S.; Alexandrino, G.L.; de Almeida, J.R.; Niño-Ruiz, Z.; Peña-Delgado, J.G.; Torres-Gutiérrez, R.; Augusto, F. Comprehensive two-dimensional gas chromatography–mass spectrometry combined with multivariate data analysis for pattern recognition in Ecuadorian spirits. Chem. Cent. J. 2018, 12, 102.

- Ferracane, A.; Manousi, N.; Tranchida, P.Q.; Zachariadis, G.A.; Mondello, L.; Rosenberg, E. Exploring the volatile profile of whiskey samples using solid-phase microextraction Arrow and comprehensive two-dimensional gas chromatography-mass spectrometry. J. Chromatogr. A 2022, 1676, 463241.

- Cha, J.; Chin, Y.-W.; Lee, J.-Y.; Kim, T.-W.; Jang, H.W. Analysis of Volatile Compounds in Soju, a Korean Distilled Spirit, by SPME-Arrow-GC/MS. Foods 2020, 9, 1422.

- Barnes, Q.; Vial, J.; Thiébaut, D.; De Saint Jores, C.; Steyer, D.; Contamin, M.-A.; Papaiconomou, N.; Fernandez, X. Characterization of Flavor Compounds in Distilled Spirits: Developing a Versatile Analytical Method Suitable for Micro-Distilleries. Foods 2022, 11, 3358.

- Chambers, E.; Koppel, K. Associations of volatile compounds with sensory aroma and flavor: The complex nature of flavor. Molecules 2013, 18, 4887–4905.

- Hanousek Čiča, K.; Rupert, M.; Koczoń, P.; Derewiaka, D.; Gajdoš-Kljusurić, J.; Petravić-Tominac, V.; Mrvčić, J.; Stanzer, D. Characterisation of flavour compounds in Biska—A herbal spirit produced with mistletoe. J. Inst. Brew. 2019, 125, 143–154.

- Ivanović, S.; Simić, K.; Tešević, V.; Vujisić, L.; Ljekočević, M.; Gođevac, D. GC-FID-MS Based Metabolomics to Access Plum Brandy Quality. Molecules 2021, 26, 1391.

- Bajer, T.; Hill, M.; Ventura, K.; Bajerová, P. Authentification of fruit spirits using HS-SPME/GC-FID and OPLS methods. Sci. Rep. 2020, 10, 18965.

- Hanousek Čiča, K.; Lukin, P.; Derewiaka, D.; Mrvčić, J.; Stanzer, D. Chemical Composition, Physical Properties, and Aroma Profile of Ethanol Macerates of Mistletoe (Viscum album). Beverages 2022, 8, 46.

- Ding, X.; Wu, C.; Huang, J.; Zhou, R. Changes in Volatile Compounds of Chinese Luzhou-Flavor Liquor during the Fermentation and Distillation Process. J. Food Sci. 2015, 80, 2373–2381.

- Hanousek-Čiča, K.; Pezer, M.; Mrvčić, J.; Stanzer, D.; Čačić, J.; Jurak, V.; Krajnović, M.; Gajdoš-Kljusurić, J. Identification of phenolic and alcoholic compounds in wine spirits and their classification by use of multivariate analysis. J. Serb. Chem. Soc. 2019, 84, 663–677.

- Mrvčić, J.; Trontel, A.; Hanousek Čiča, K.; Vahčić, N.; Nikićević, N.; Spaho, N.; Mihaljević Žulj, M.; Brodski, A.; Jurak, V.; Krajnović, M.; et al. Chemical and sensorial characteristics of traditional fruit spirits from Southeast Europe. Glas. Zašt. Bilja 2021, 44, 80–89.

- Anjos, O.; Caldeira, I.; Roque, R.; Pedro, S.I.; Lourenço, S.; Canas, S. Screening of Different Ageing Technologies of Wine Spirit by Application of Near-Infrared (NIR) Spectroscopy and Volatile Quantification. Processes 2020, 8, 736.

- García-Moreno, M.V.; Sánchez-Guillén, M.M.; Mier, M.R.; Delgado-González, M.J.; Rodríguez-Dodero, M.C.; García-Barroso, C.; Guillén-Sánchez, D.A. Use of Alternative Wood for the Ageing of Brandy de Jerez. Foods 2020, 9, 250.

- Xia, Y.; Liu, Y.; Wang, J.; Shuang, Q. Assessment of key aroma compounds in fresh jujube brandy by GC-O-MS and odor activity value. J. Food Process. Preserv. 2020, 44, 14494.

- Raičević, D.; Popović, T.; Jančić, D.; Šuković, D.; Pajović-Šćepanović, R. The Impact of Type of Brandy on the Volatile Aroma Compounds and Sensory Properties of Grape Brandy in Montenegro. Molecules 2022, 27, 2974.

- Perestrelo, R.; Caldeira, M.; Rodrigues, F.; Pereira, J.A.M.; Câmara, J.S. DLLμE/GC-MS as a Powerful Analytical Approach to Establish the Volatilomic Composition of Different Whiskeys. Beverages 2022, 8, 53.

- Canas, S.; Anjos, O.; Caldeira, I.; Fernandes, T.A.; Santos, N.; Lourenço, S.; Granja-Soares, J.; Fargeton, L.; Boissier, B.; Catarino, S. Micro-oxygenation level as a key to explain the variation in the colour and chemical composition of wine spirits aged with chestnut wood staves. LWT 2022, 154, 112658.

- Oliveira-Alves, S.; Lourenço, S.; Anjos, O.; Fernandes, T.A.; Caldeira, I.; Catarino, S.; Canas, S. Influence of the Storage in Bottle on the Antioxidant Activities and Related Chemical Characteristics of Wine Spirits Aged with Chestnut Staves and Micro-Oxygenation. Molecules 2022, 27, 106.

- Valcárcel-Muñoz, M.J.; Butrón-Benítez, D.; Guerrero-Chanivet, M.; García-Moreno, M.V.; Rodríguez-Dodero, M.C.; Guillén-Sánchez, D.A. Influence of alcoholic strength on the characteristics of Brandy de Jerez aged in Sherry Casks®. J. Food Compos. Anal. 2022, 111, 104618.

- Johnson, A.J.; Hopfer, H.; Heymann, H.; Ebeler, S.E. Aroma Perception and Chemistry of Bitters in Whiskey Matrices: Modeling the Old-Fashioned. Chem. Percept. 2017, 10, 135–148.

- Mihajilov-Krstev, T.M.; Denić, M.S.; Zlatković, B.K.; Stankov-Jovanović, V.P.; Mitić, V.D.; Stojanović, G.S.; Radulović, N.S. Inferring the origin of rare fruit distillates from compositional data using multivariate statistical analyses and the identification of new flavour constituents. J. Sci. Food Agric. 2015, 95, 1217–1235.

- Vivas, N.; Picard, M.; Bourden-Nonier, M.F.; Vivas de Gaulejac, N.; Mouche, C.; Rossy, C. Heartwood dry extract: A key fraction for the quality and the diversity of rums and spirits. J. Inst. Brew. 2021, 127, 59–69.

- Malfondet, N.; Brunerie, P.; Le Quéré, J.L. Discrimination of French wine brandy origin by PTR-MS headspace analysis using ethanol ionization and sensory assessment. Anal. Bioanal. Chem. 2021, 413, 3349–3368.

- Zhang, B.; Sun, Z.; Lin, L.; Zhang, C.; Wei, C. Analysis of the Effect of Mixed Fermentation on the Quality of Distilled Jujube Liquor by Gas Chromatography-Ion Mobility Spectrometry and Flavor Sensory Description. Foods 2023, 12, 795.

- Guerrero-Chanivet, M.; Ortega-Gavilán, F.; Bagur-González, M.G.; Valcarecl-Munoz, M.J.; Garcia-Moreno, M.V.; Guillen-Sanchez, D.A. Pattern Recognition of GC-FID Profiles of Volatile Compounds in Brandy de Jerez Using a Chemometric Approach Based on Their Instrumental Fingerprints. Food Bioprocess Technol. 2023, 16, 1–13.

- Walker, G.; Bringhurst, T.; Brosnan, J. The ideal distillers yeast. Brew. Distill. Int. 2011, 7, 30–32.

- Pauley, M.; Maskell, D. Mini-Review: The Role of Saccharomyces cerevisiae in the Production of Gin and Vodka. Beverages 2017, 3, 13.

- Ellis, D.J.; Kerr, E.D.; Schenk, G.; Schulz, B.L. Metabolomics of non-Saccharomyces Yeasts in Fermented Beverages. Beverages 2022, 8, 41.

- Belitz, H.D.; Grosch, W.; Schieberle, P. Food Chemistry, 3rd ed.; Springer: Berlin, Germany, 2004; p. 344.

- He, F.; Yang, S.; Zhang, G.; Xu, L.; Li, H.; Sun, J.; Huang, M.; Zheng, F.; Sun, B. Exploration of key aroma active compounds in strong flavor Baijiu during the distillation by modern instrument detection technology combined with multivariate statistical analysis methods. J. Food Compos. Anal. 2022, 110, 104577.

- Xiang, X.F.; Lan, Y.B.; Gao, X.T.; Xie, H.; An, Z.Y.; Lv, Z.H.; Duan, C.Q.; Wu, G.F. Characterization of odor-active compounds in the head, heart, and tail fractions of freshly distilled spirit from Spine grape (Vitis davidii Foex) wine by gas chromatography-olfactometry and gas chromatography-mass spectrometry. Food Res. Int. 2020, 137, 109388.

- Hong, J.; Wang, J.; Zhang, C.; Zhao, Z.; Tian, W.; Wu, Y.; Chen, H.; Zhao, D.; Sun, J. Correction: Unraveling variation on the profile aroma compounds of strong aroma type of Baijiu in different regions by molecular matrix analysis and olfactory analysis. RSC Adv. 2021, 11, 34262.

- Spaho, N.; Đukic-Ratković, D.; Nikićević, N.; Blesić, M.; Tešević, V.; Smajić Murtić, M. Some Important Aroma Active Compounds in Apple Distillates. In Proceedings of 10th Central European Congress on Food; Springer: Sarajevo, Bosnia and Herzegovina, 2022; pp. 420–429.

- Zhao, L.; Ruan, S.; Yang, X.; Chen, Q.; Shi, K.; Lu, K.; He, L.; Liu, S.; Song, Y. Characterization of volatile aroma compounds in litchi (Heiye) wine and distilled spirit. Food Sci. Nutr. 2021, 9, 5914–5927.

- Belda, I.; Ruiz, J.; Esteban-Fernández, A.; Navascués, E.; Marquina, D.; Santos, A.; Moreno-Arribas, M.V. Microbial Contribution to Wine Aroma and Its Intended Use for Wine Quality Improvement. Molecules 2017, 22, 189.

- Osafune, Y.; Toshida, K.; Han, J.; Isogai, A.; Mukai, N. Characterisation and threshold measurement of aroma compounds contributing to the quality of Honkaku shochu and Awamori. J. Inst. Brew. 2020, 126, 131–135.

- Ferreira, V.; de la Fuente, A.; Sáenz-Navajas, M.P. Wine aroma vectors and sensory attributes. In Woodhead Publishing Series in Food Science, Technology and Nutrition, Managing Wine Quality, 2nd ed.; Reynolds, A.G., Ed.; Woodhead Publishing: Cambridge, UK, 2022; pp. 3–39.

This entry is offline, you can click here to edit this entry!